Motor system started without reversing

A technology of electric motors and permanent magnet synchronous motors, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the service life of one-way couplings Short, one-way coupling inner key is easily damaged, not a solution, etc., to achieve the effect of increased magnetic field saturation, enhanced magnetic isolation capability, and reduced saturation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

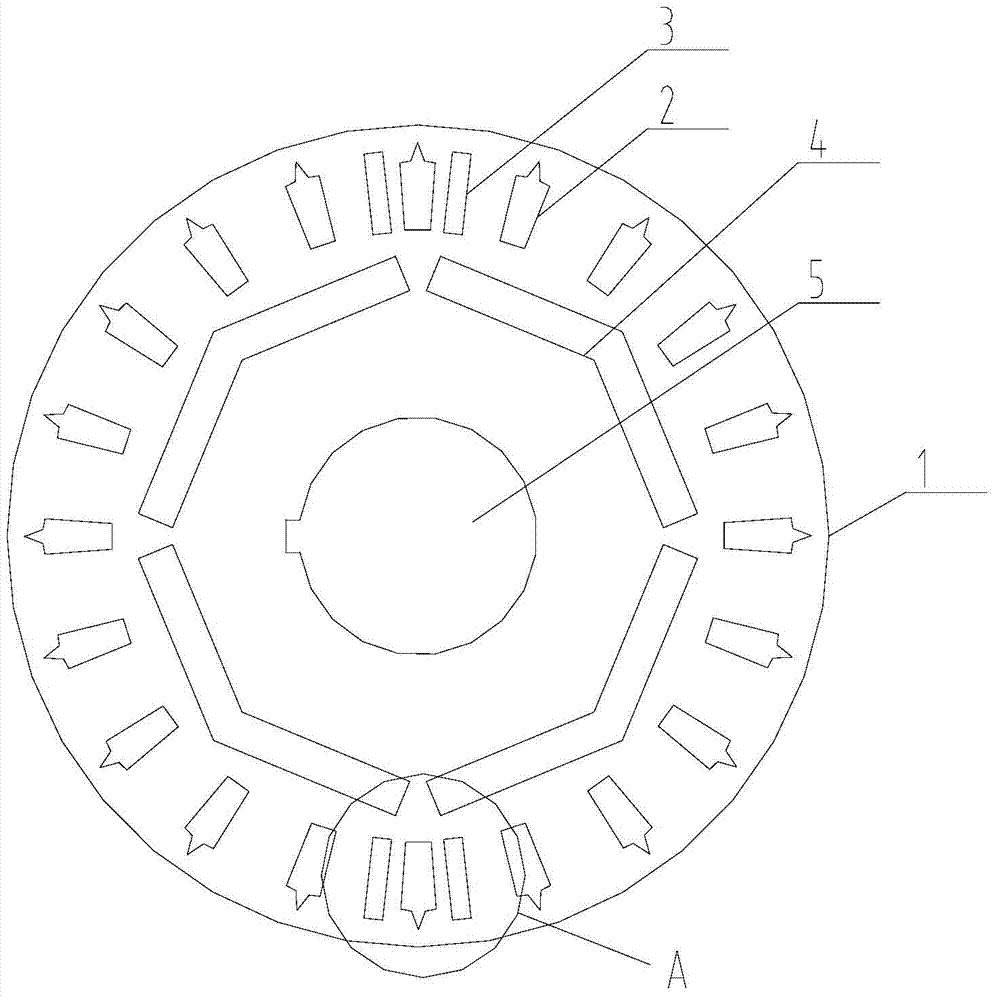

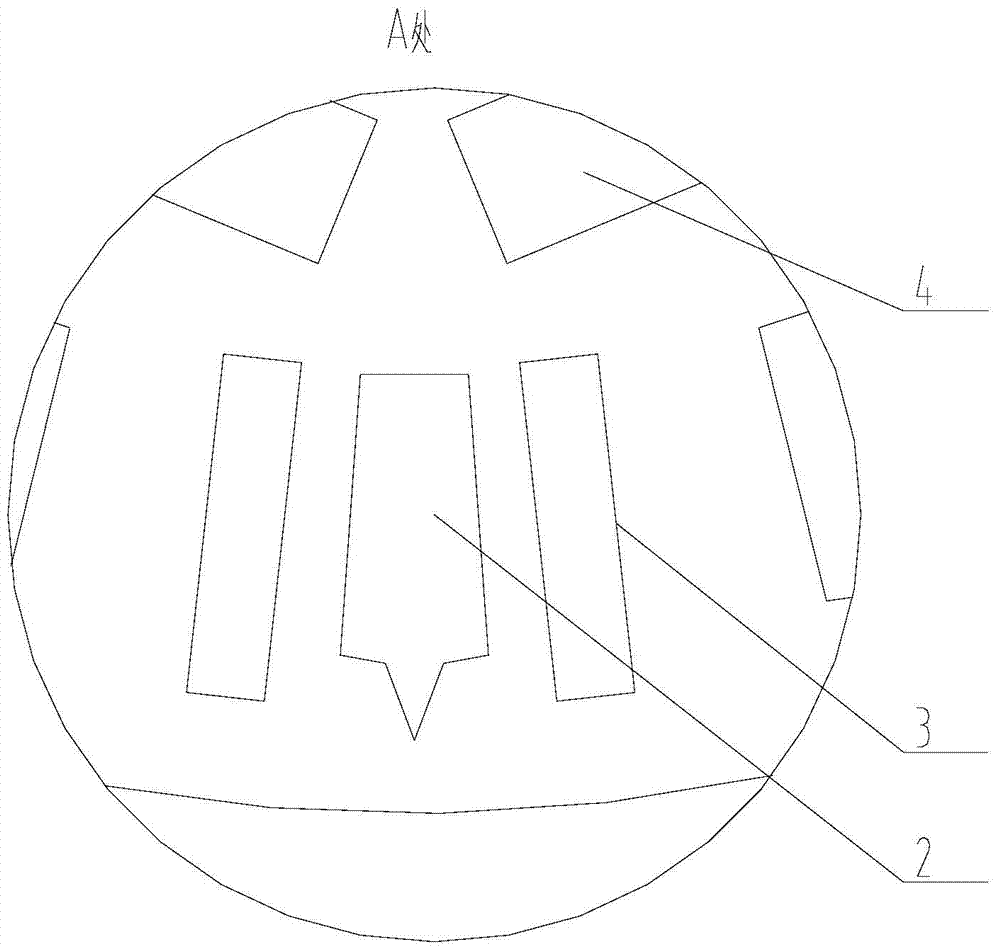

[0029] The present invention as Figure 1-2 As shown, including the frequency conversion speed controller and the three-phase variable frequency permanent magnet synchronous motor; the air gap flux of the three-phase variable frequency permanent magnet synchronous motor is reasonably controlled, that is, when the stator current of the variable frequency permanent magnet synchronous motor reaches the rated value, the air gap flux The communication should be in a saturated state. At this time, the estimated deviation of the frequency converter for the specific position of the rotor of the three-phase variable frequency permanent magnet synchronous motor can be contracted within ±30deg.

[0030] The above-mentioned variable frequency speed controller utilizes a control method in which the rotor position is estimated from magnetic flux saturation characteristics.

[0031] The frequency conversion speed controller is equipped with "initial angle compensation angle" technology, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com