Patents

Literature

44results about How to "Stable working frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

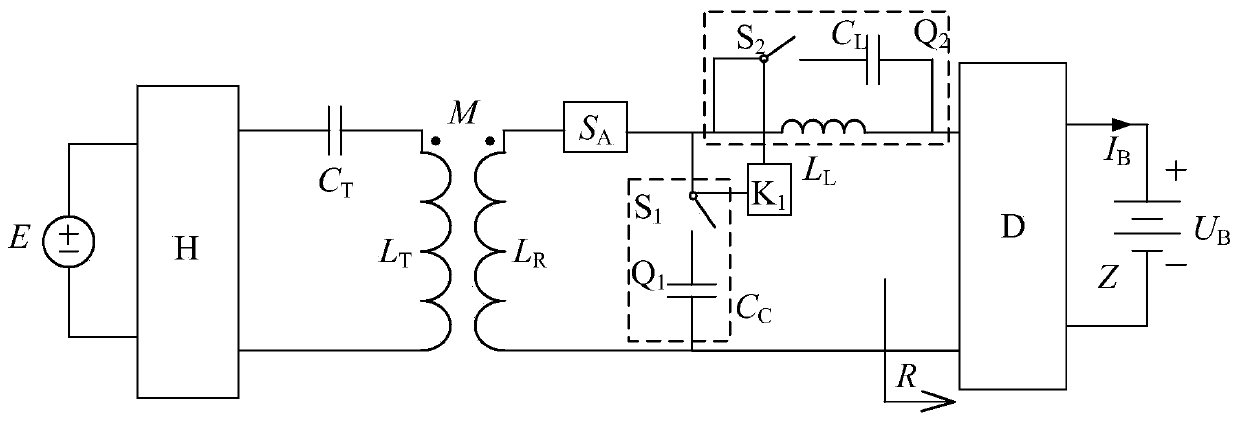

Induction type wireless electric energy transmission system capable of outputting constant current and constant voltage

ActiveCN106451800ANo frequency bifurcationStable jobBatteries circuit arrangementsElectric powerCapacitanceCapacitor

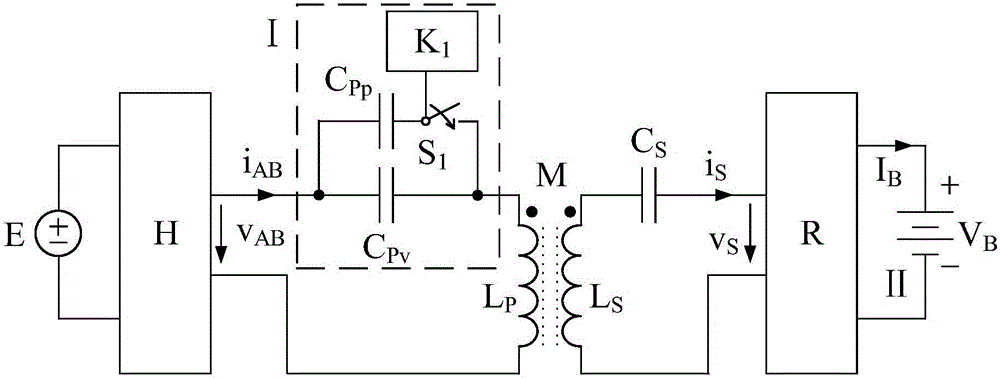

The invention discloses an induction type wireless electric energy transmission system capable of outputting constant current and constant voltage. The system is composed of a transmitting part and a receiving part. A constant-current and constant-voltage switching circuit (I) of the transmitting part is characterized in that a primary constant-voltage capacitor (CPv) is serially connected between a high-frequency inverter (H) and a primary coil (LP); after an additional parallel capacitor (CPp) is serially connected with a first switch (S1), an assembly which is composed of the additional parallel capacitor and the first switch is parallelly connected with a primary constant-voltage capacitor (CPv); the control end of the first switch (S1) is connected with a first controller (K1); or a primary constant-current capacitor (CPi) and an additional serial capacitor (CPs) are successively connected serially between the high-frequency inverter (H) and the primary coil (LP); a second switch (S2) is parallelly connected with the additional serial capacitor (CPs); and furthermore the control end of the second switch (S2) is connected with a second controller (K2). The induction type wireless electric energy transmission system can output constant current and constant voltage and furthermore has advantages of convenient control, high system operation stability, simple structure and low manufacture cost.

Owner:SOUTHWEST JIAOTONG UNIV

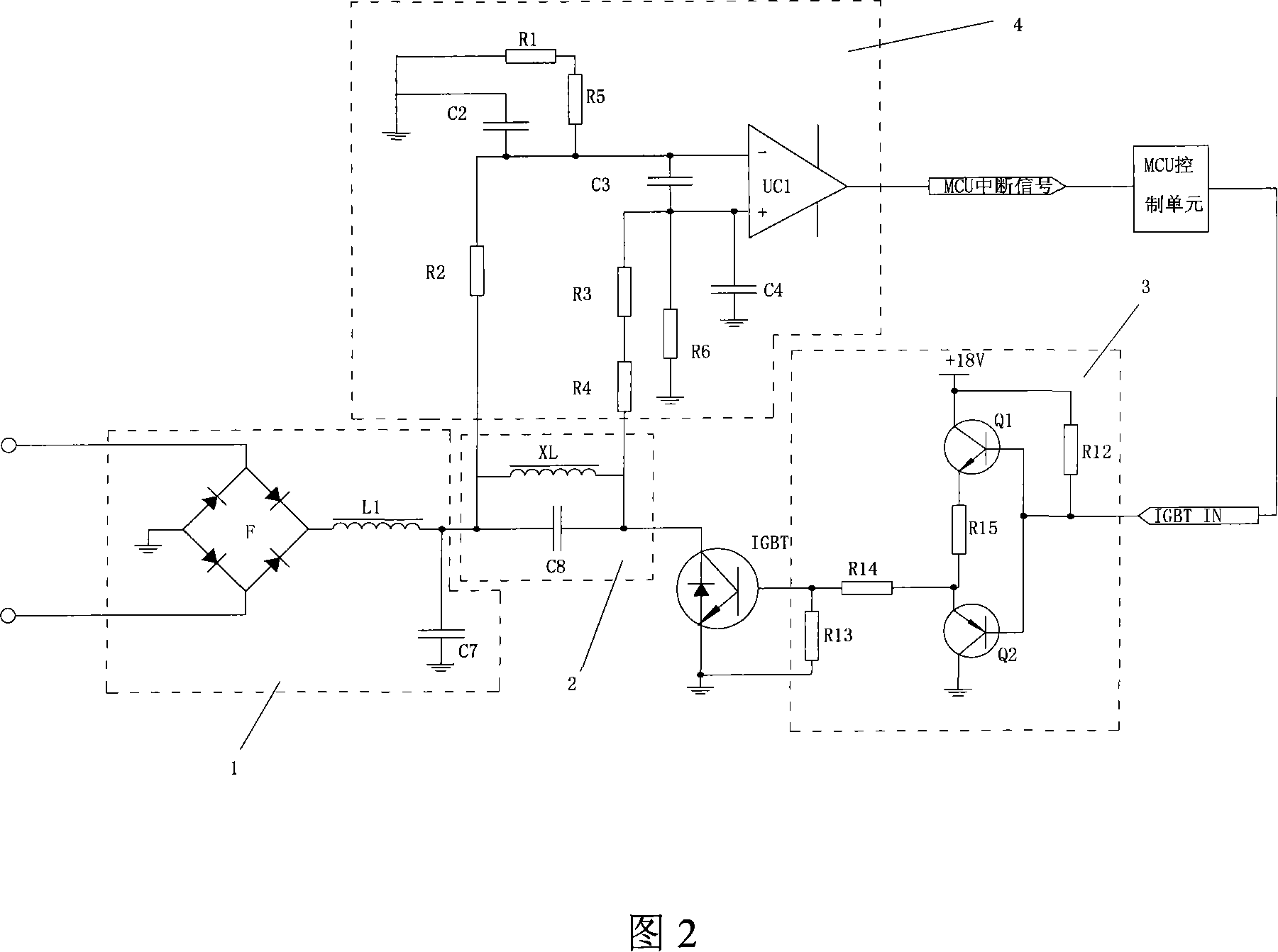

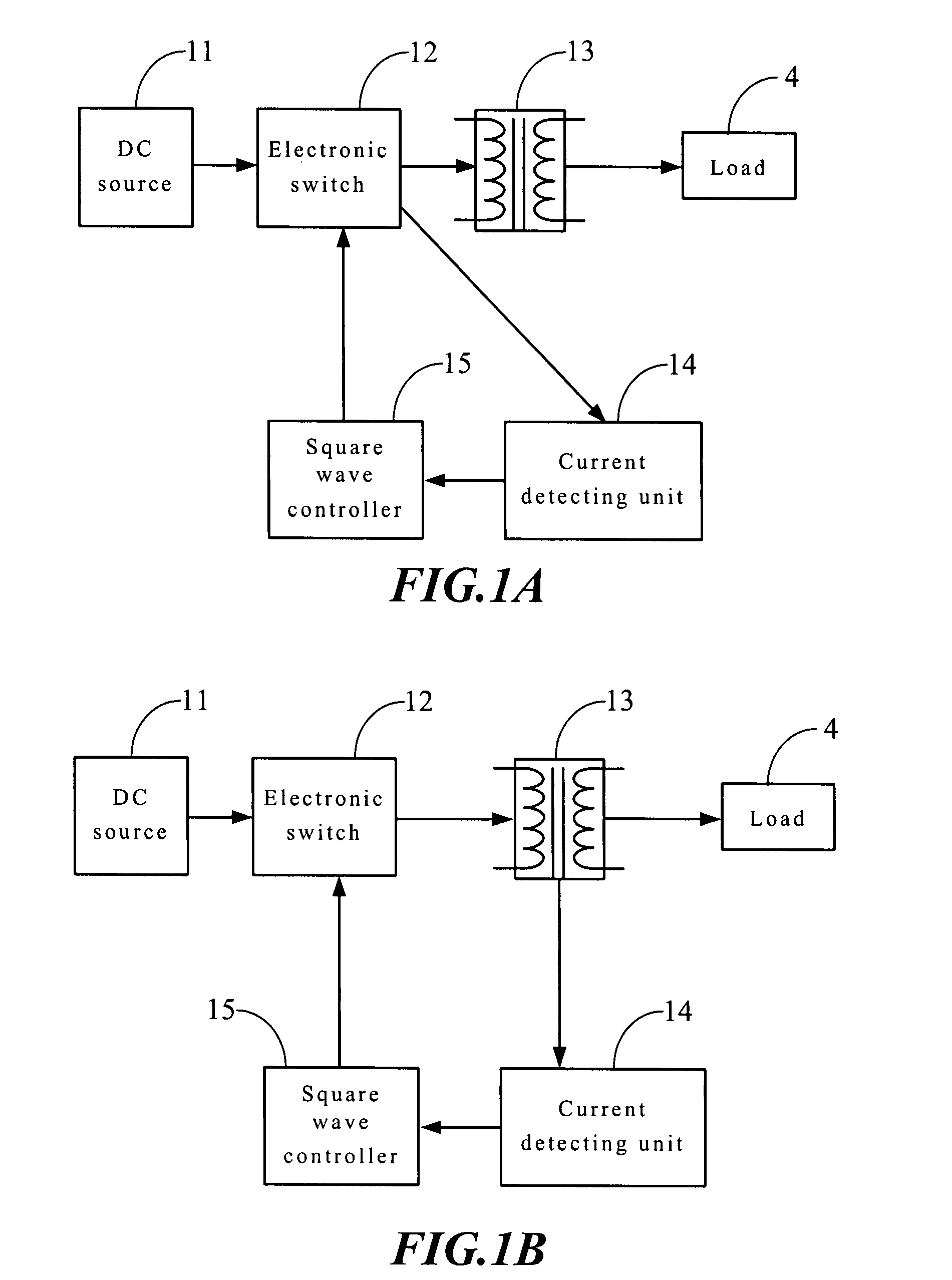

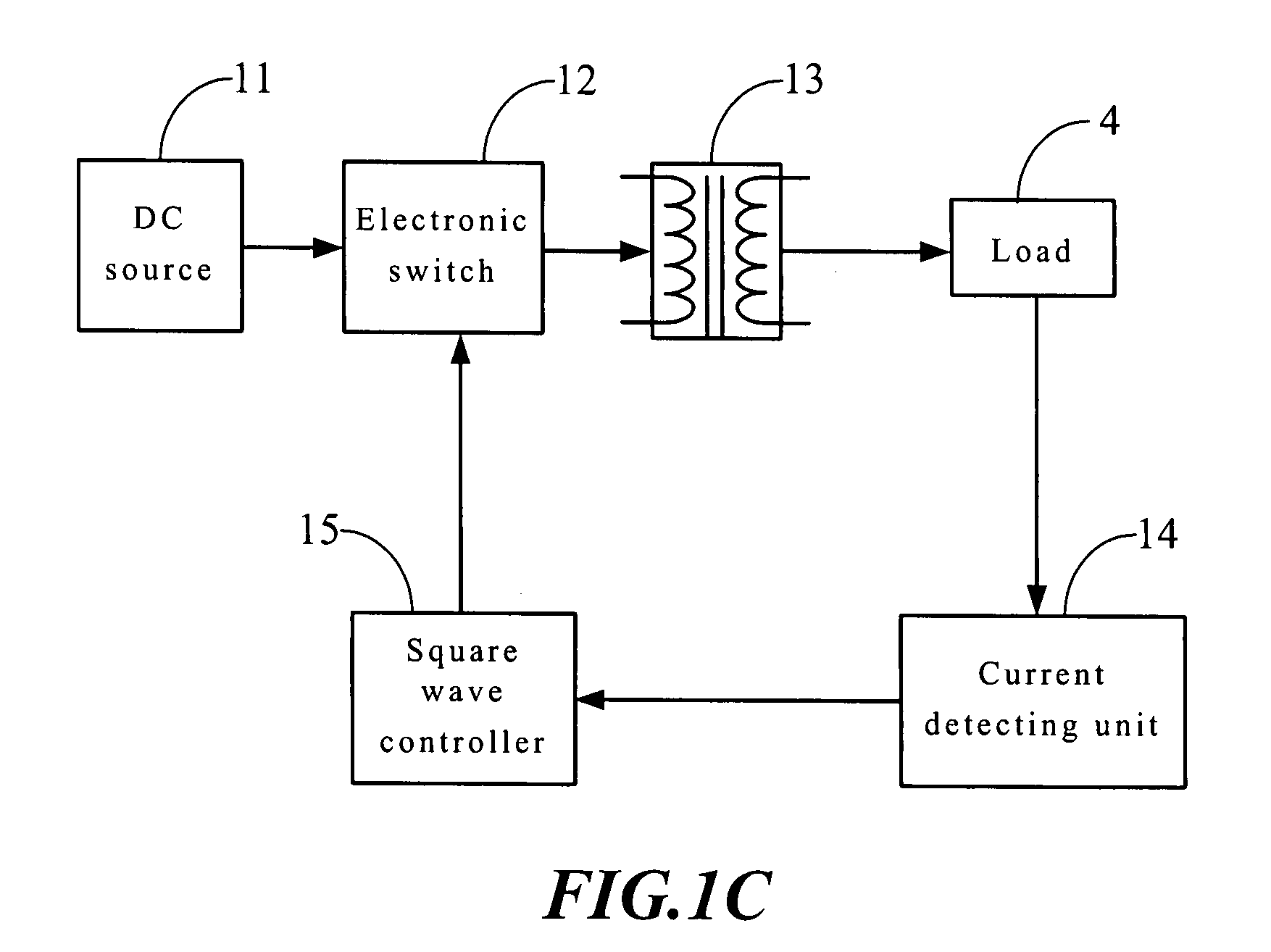

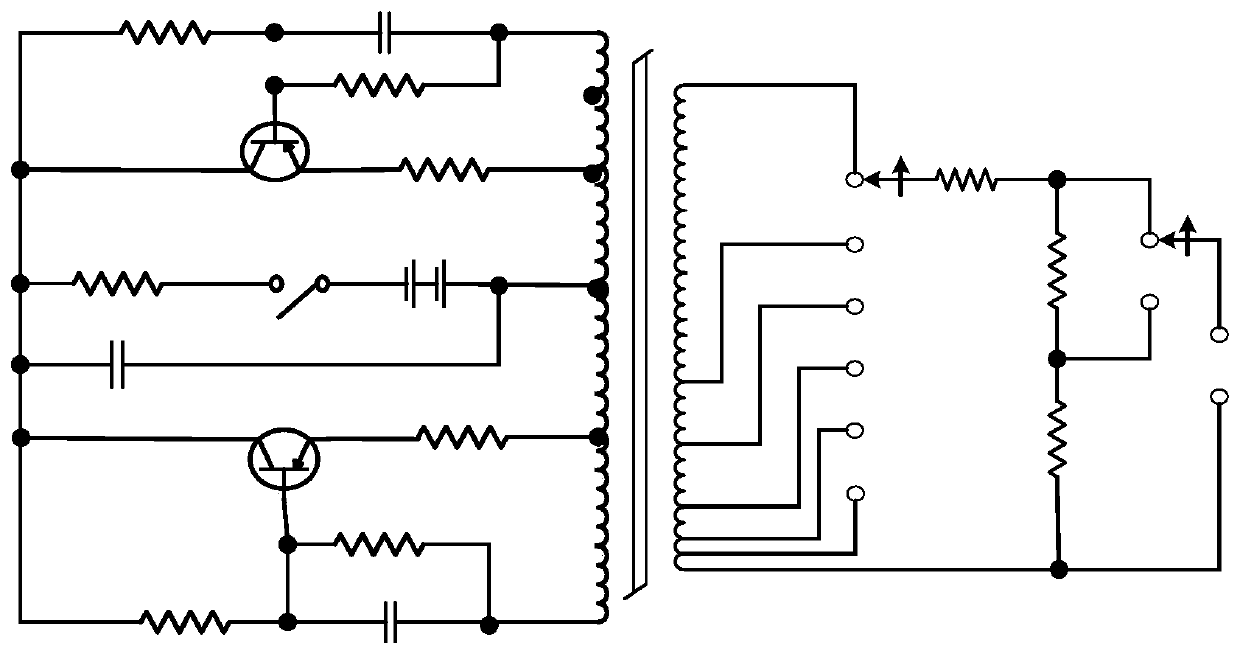

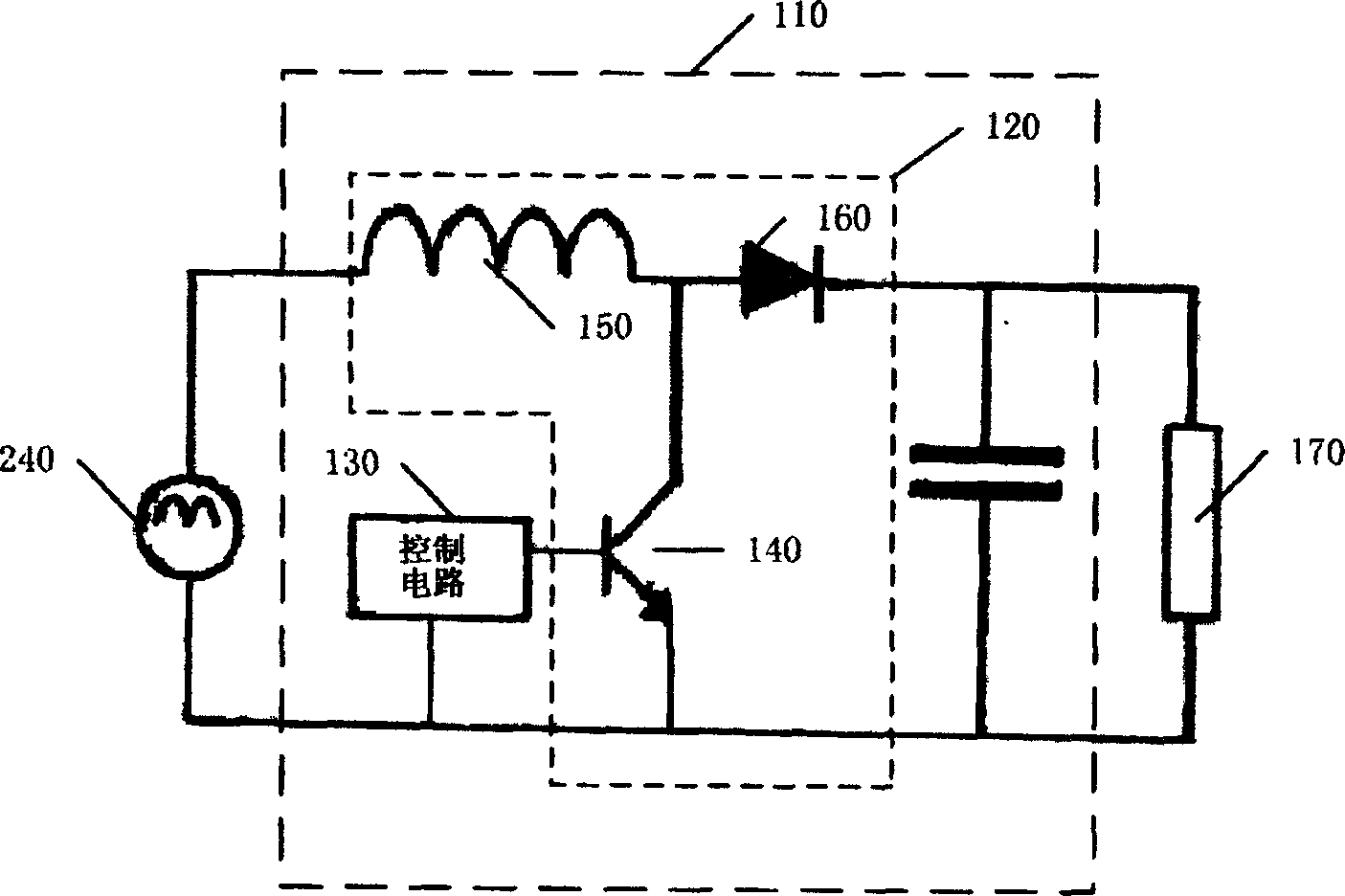

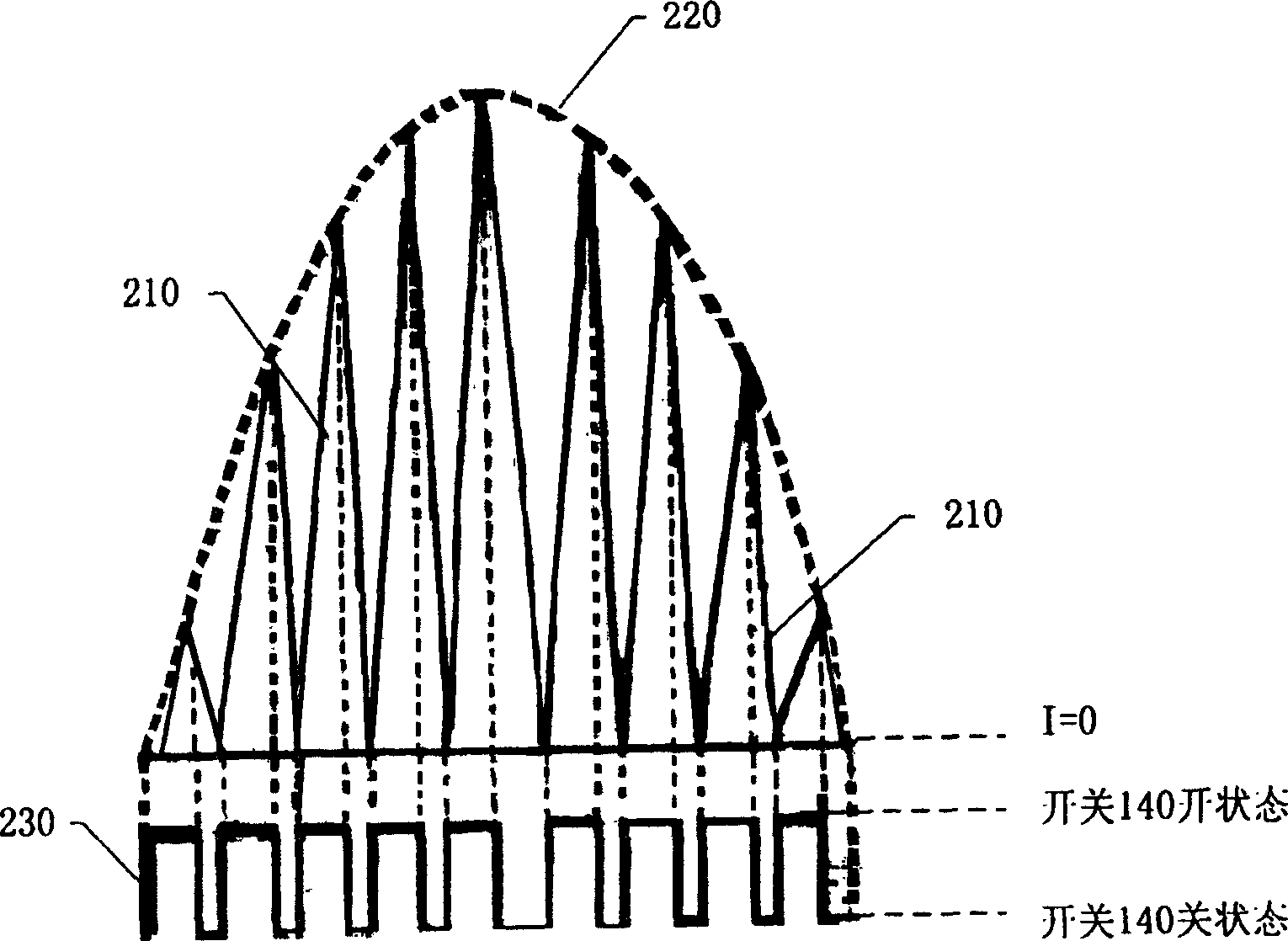

Synchronous control method and circuit of electromagnetic stove

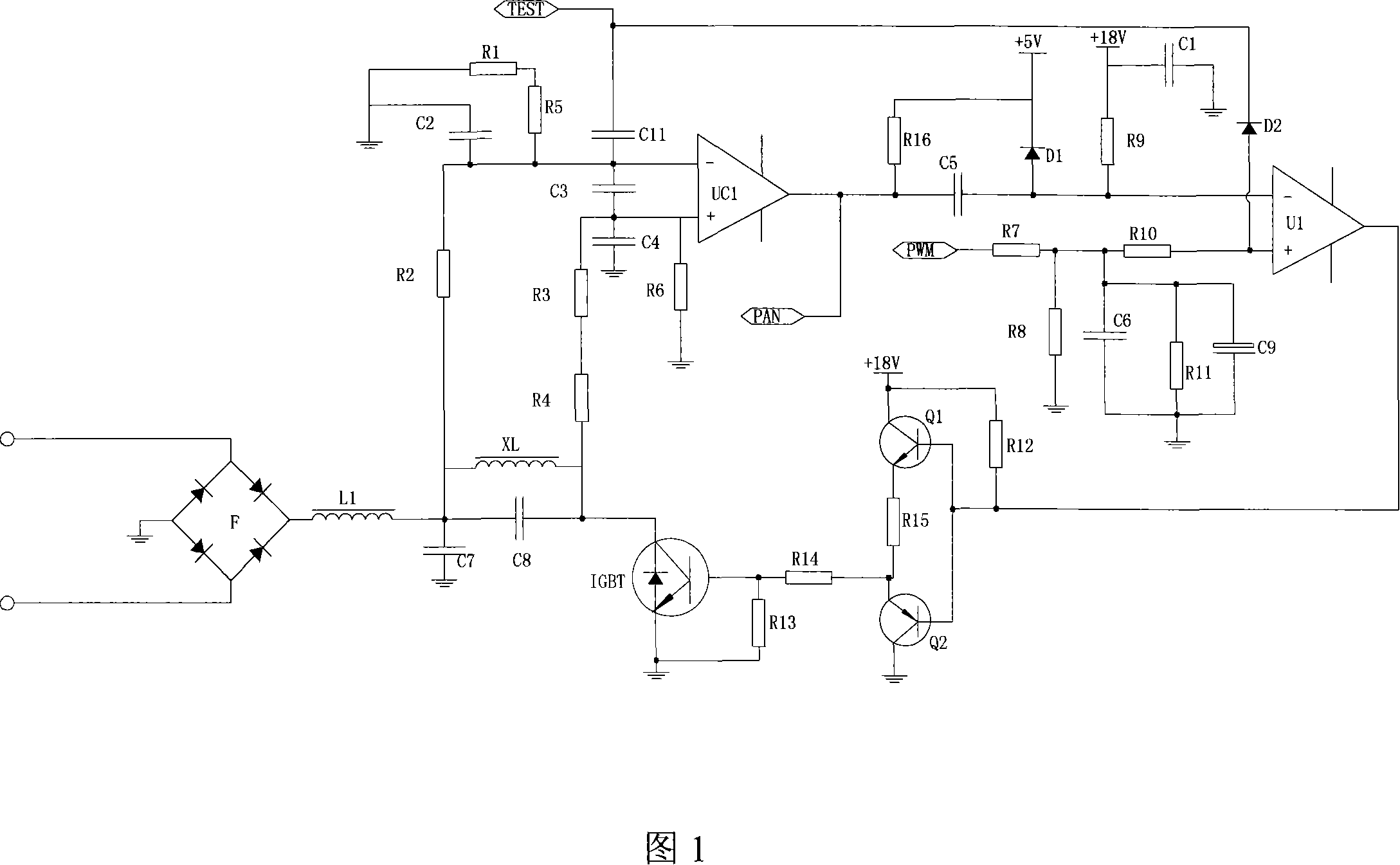

InactiveCN101159998AStable working frequencyHigh precisionInduction heating controlFrequency stabilizationResonance

The invention discloses a synchronization control method for an electromagnetic oven and a circuit thereof. The circuit includes a rectification filter circuit, a resonance circuit, a switch device, a drive circuit, a synchronizing signal circuit and a MCU control unit. The synchronization control method is: a synchronizing signal circuit detects the resonance voltage of a resonance circuit; when the resonance voltage decreases to a set value, the synchronizing signal circuit generates a synchronizing interrupt pulse signal; the MCU control unit detects the synchronizing interrupt pulse signal and outputs a high level continuity signal with specific width to a drive circuit, which controls the conduction of the switch device; after the high level continuity signal finishes, the switch device intercepts and the resonance circuit generates a resonance; and repeats the process. The invention adopts the MCU control unit to output the high level continuity signal to the drive circuit, in order to directly control the conduction and interception of the switch device, exerts the advantage of MCU stable working frequency and improves the synchronization course precision, with the advantages of simple circuit, convenient debugging and low cost.

Owner:SHENZHEN H&T INTELLIGENT CONTROL

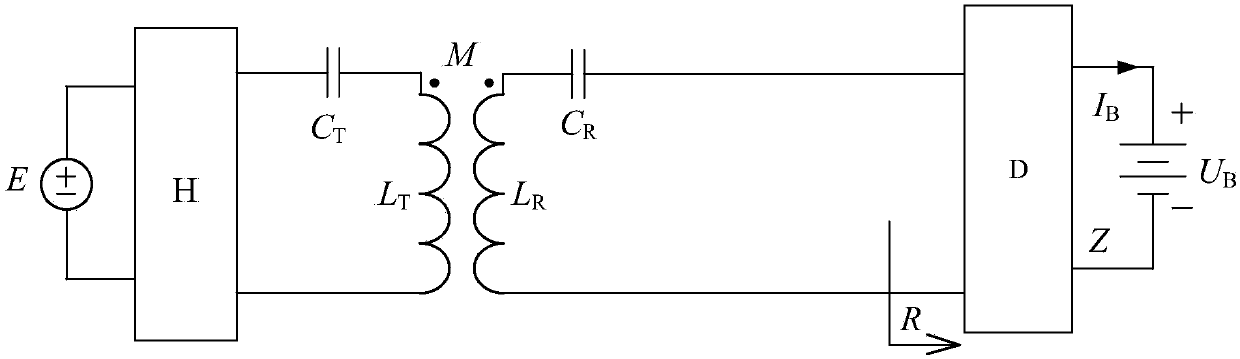

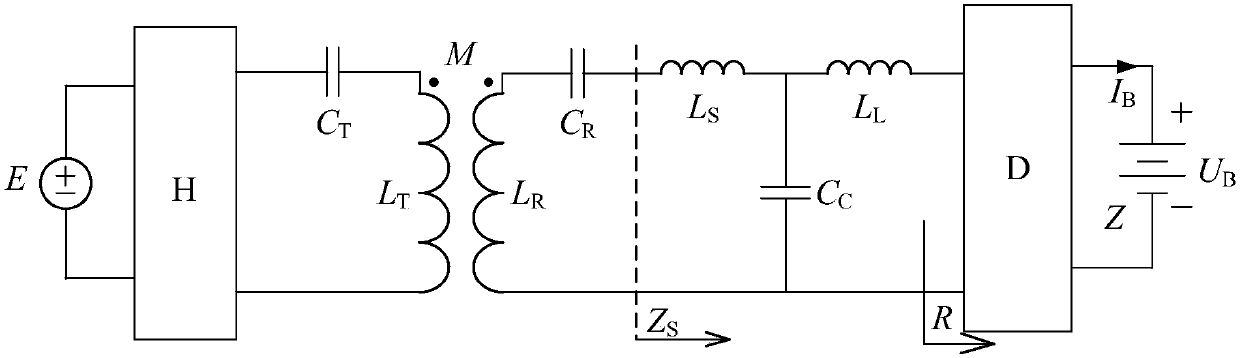

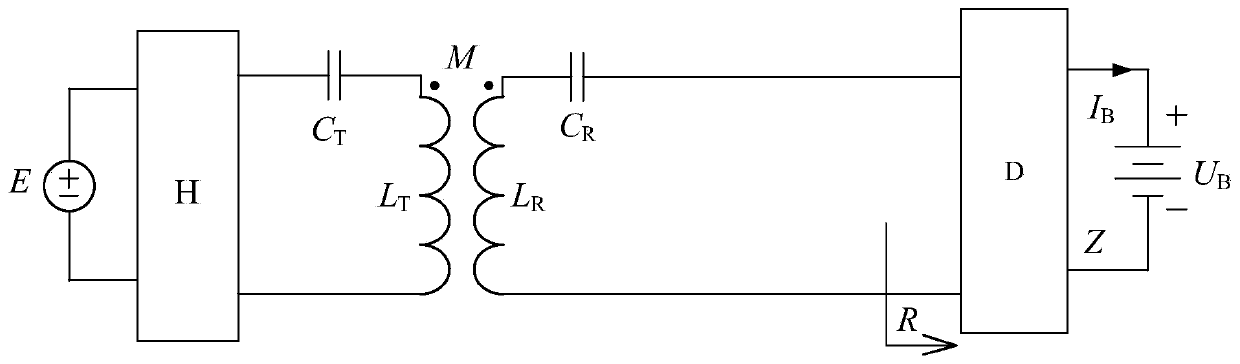

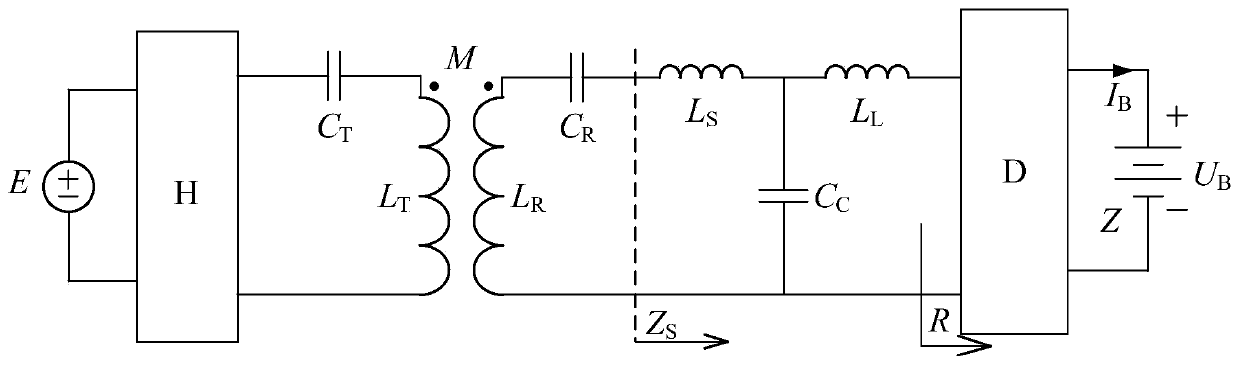

Inductive wireless charging system capable of changing secondary structure and parameters

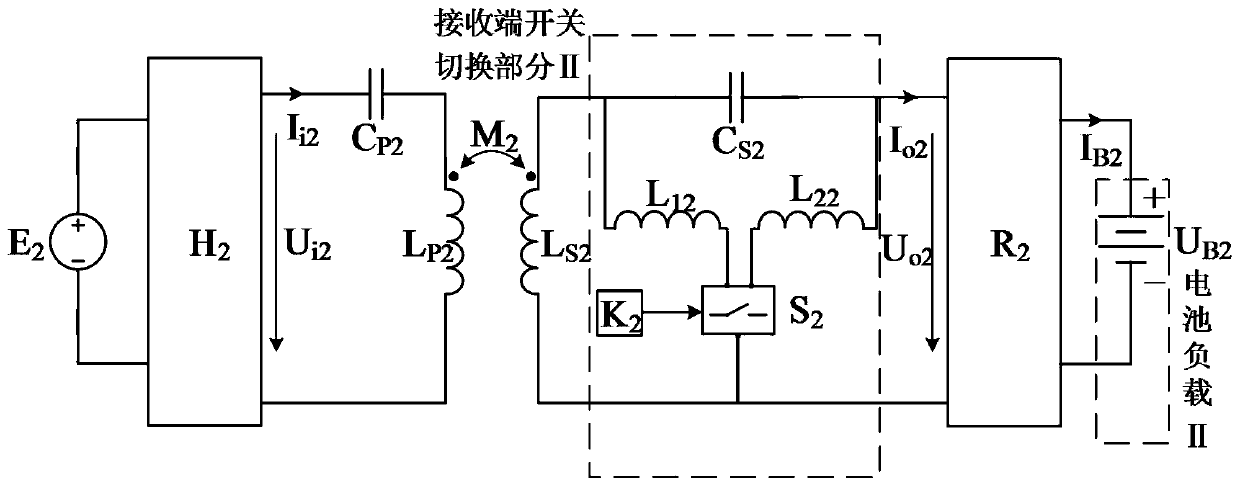

ActiveCN107069983ANo frequency bifurcationStable jobElectric powerArrangements for several simultaneous batteriesCapacitancePower inverter

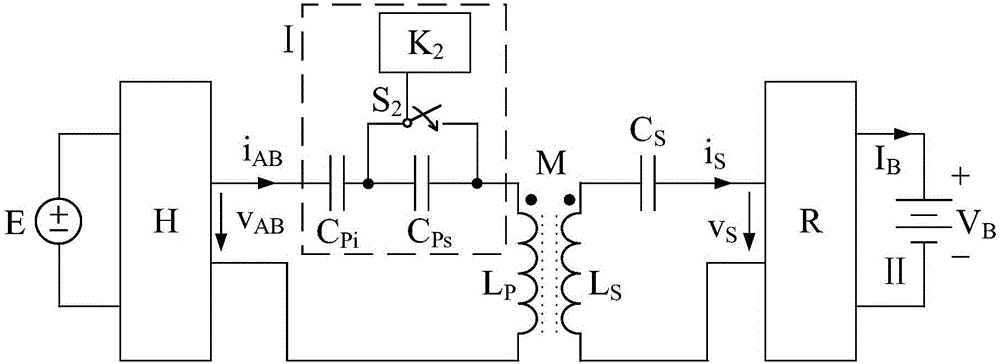

The invention discloses an inductive wireless charging system capable of changing the secondary structure and parameters. According to the invention, a constant-current constant-voltage switching circuit I and a constant-current constant-voltage switching circuit II are arranged in a receiving portion, a secondary constant-voltage compensation capacitor is connected with a change-over switch I in series, and a control end of the change-over switch I is connected with a controller I; the constant-current constant-voltage switching circuit II is formed by connecting a secondary constant-current compensation capacitor and a change-over switch II in series, and a control end of the change-over switch II is connected with the controller I. The invention further discloses a second implementation scheme which is slight different from the scheme at the control end. The inductive wireless charging system with the structure disclosed by the invention not only can output constant current, but also can output constant voltage, thereby being applicable to charging a battery, especially being applicable to charging multiple loads under a single power supply; The inductive wireless charging system is convenient to control, stable in operation, simple in structure, low in requirement for the capacity of an inverter and low in manufacturing cost, the input impedance is purely resistive in the whole process, input of reactive power can be avoided, and the system efficiency can be improved.

Owner:SOUTHWEST JIAOTONG UNIV

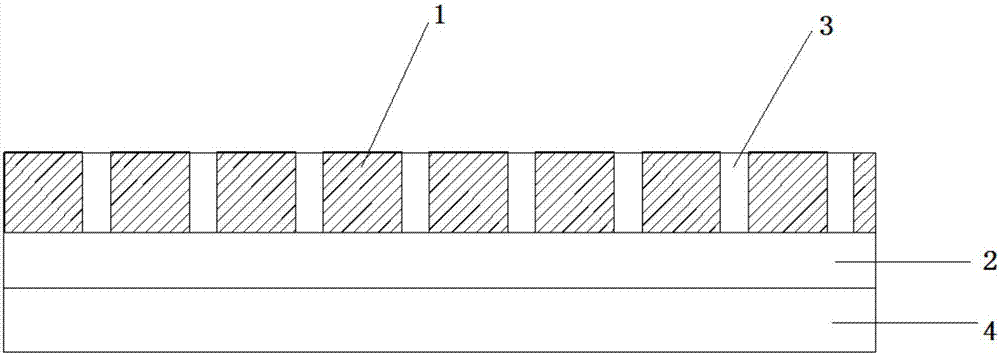

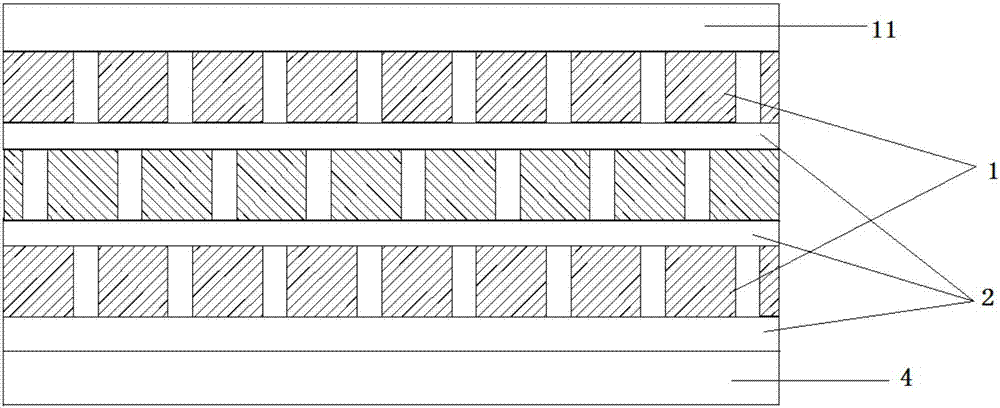

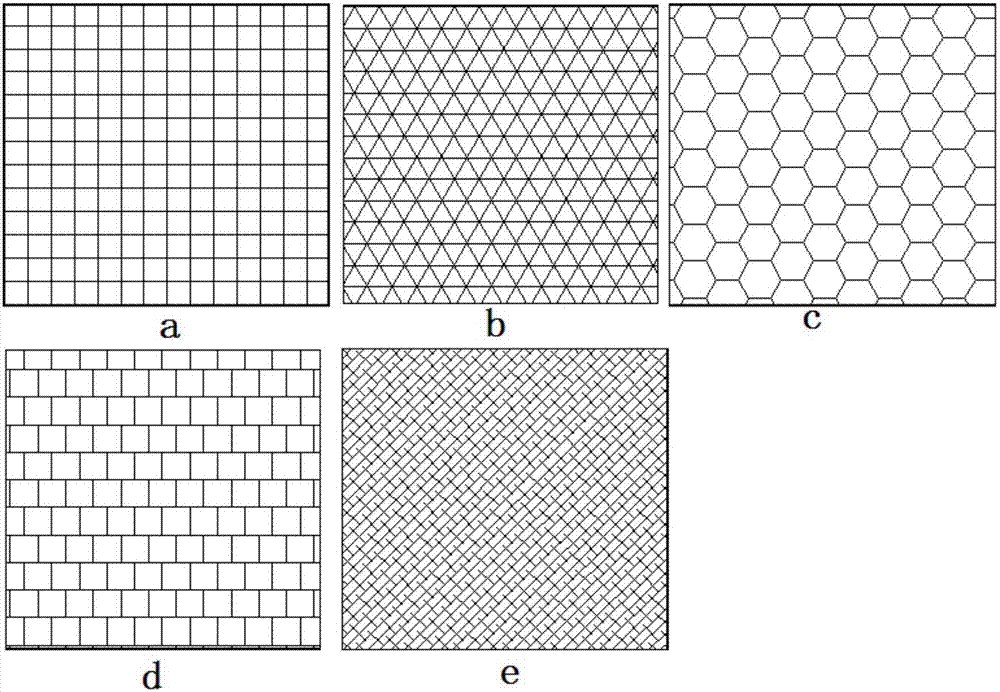

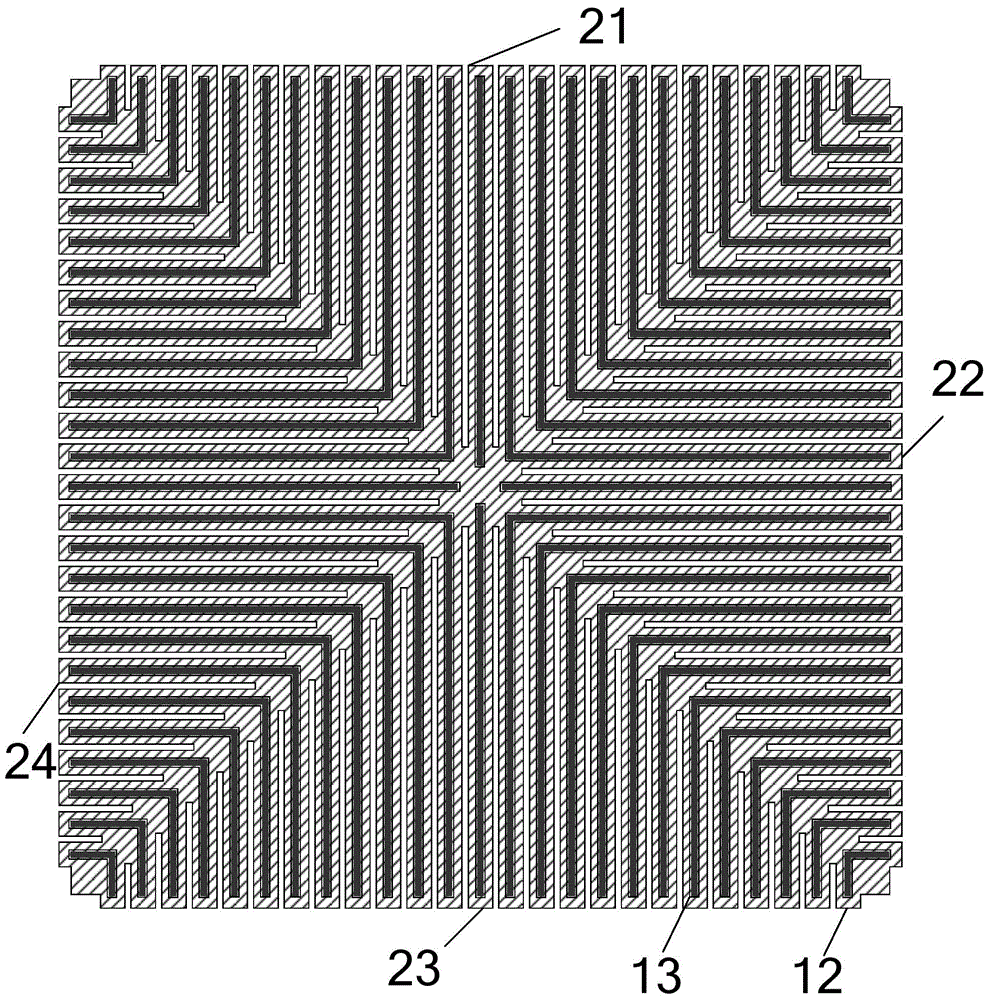

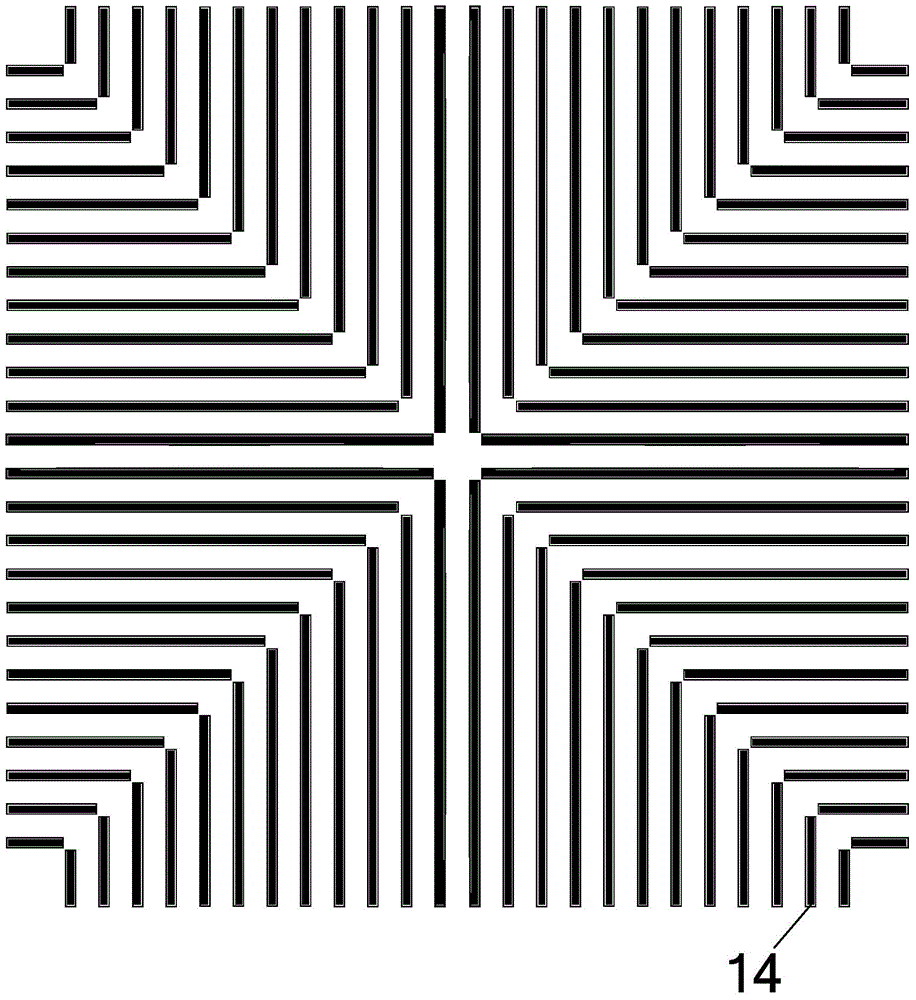

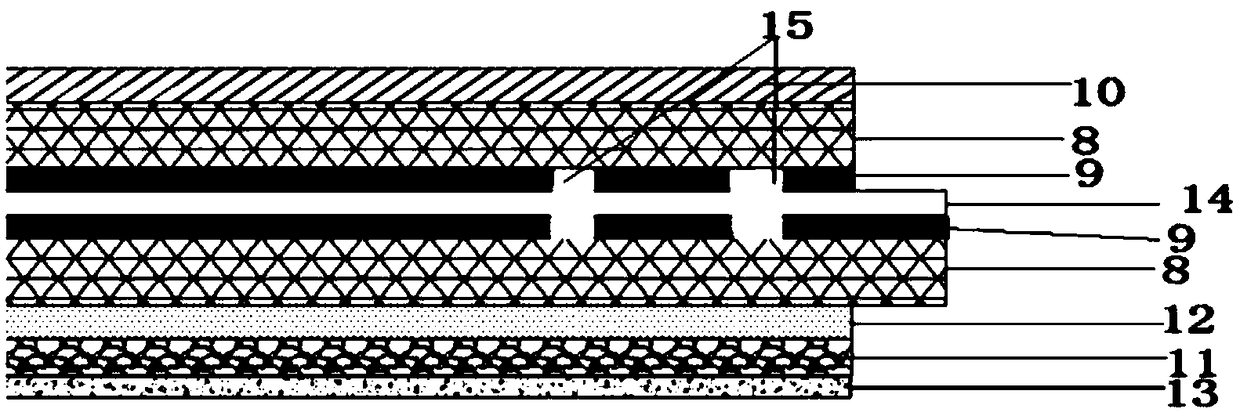

Magnetic isolation sheet applied to wireless charging and near field communication (NFC) and fabrication process of magnetic isolation sheet

InactiveCN107979966AStable working frequencyThe overall thickness is thinShielding materialsMagnetic tapeAdhesive

The invention discloses a magnetic isolation sheet applied to wireless charging and near field communication (NFC). The magnetic isolation sheet comprises at least one magnetic isolation unit, whereinthe magnetic isolation unit comprises a soft magnetic strip and a double-side adhesive tape, wherein the soft magnetic strip is of a sheet structure with two exposed surfaces, the double-side adhesive tape covers one of the exposed surfaces, and the other exposed surface of the soft magnetic strip is pressed to form a mesh-shaped line. The invention also discloses a fabrication process of the magnetic isolation sheet applied to wireless charging and NFC. The fabrication process comprises the steps of constructing a magnetic isolation unit, in which the double-side adhesive tape is pasted ontoone of the exposed surfaces of the soft magnetic strip by taking the soft magnetic strip of the sheet structure with the two exposed surfaces as an element, and the other exposed surface of the softmagnetic strip is pressed to form the mesh-shaped line; and constructing the magnetic isolation sheet. The magnetic isolation sheet applied to wireless charging and NFC, fabricated by the fabricationprocess has the advantages of thin thickness, good magnetic isolation capability, high charging efficiency, NFC working frequency stability and high product stability, and the process and the materialcost are greatly reduced.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Antenna using variable capacitance element and wireless communication apparatus using the same

InactiveCN1649205AChange electrical lengthChange the resonant frequencyResonant antennasCapacitanceEngineering

Owner:KYOCERA CORP

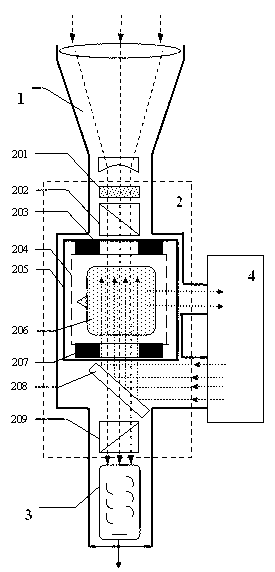

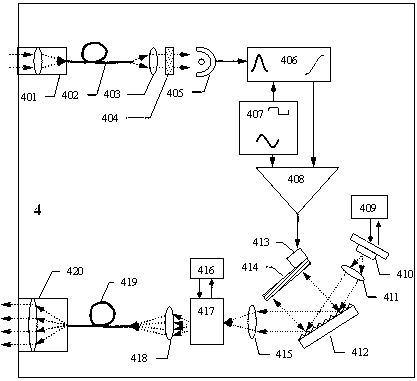

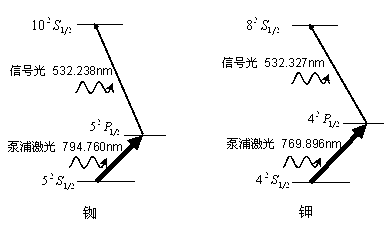

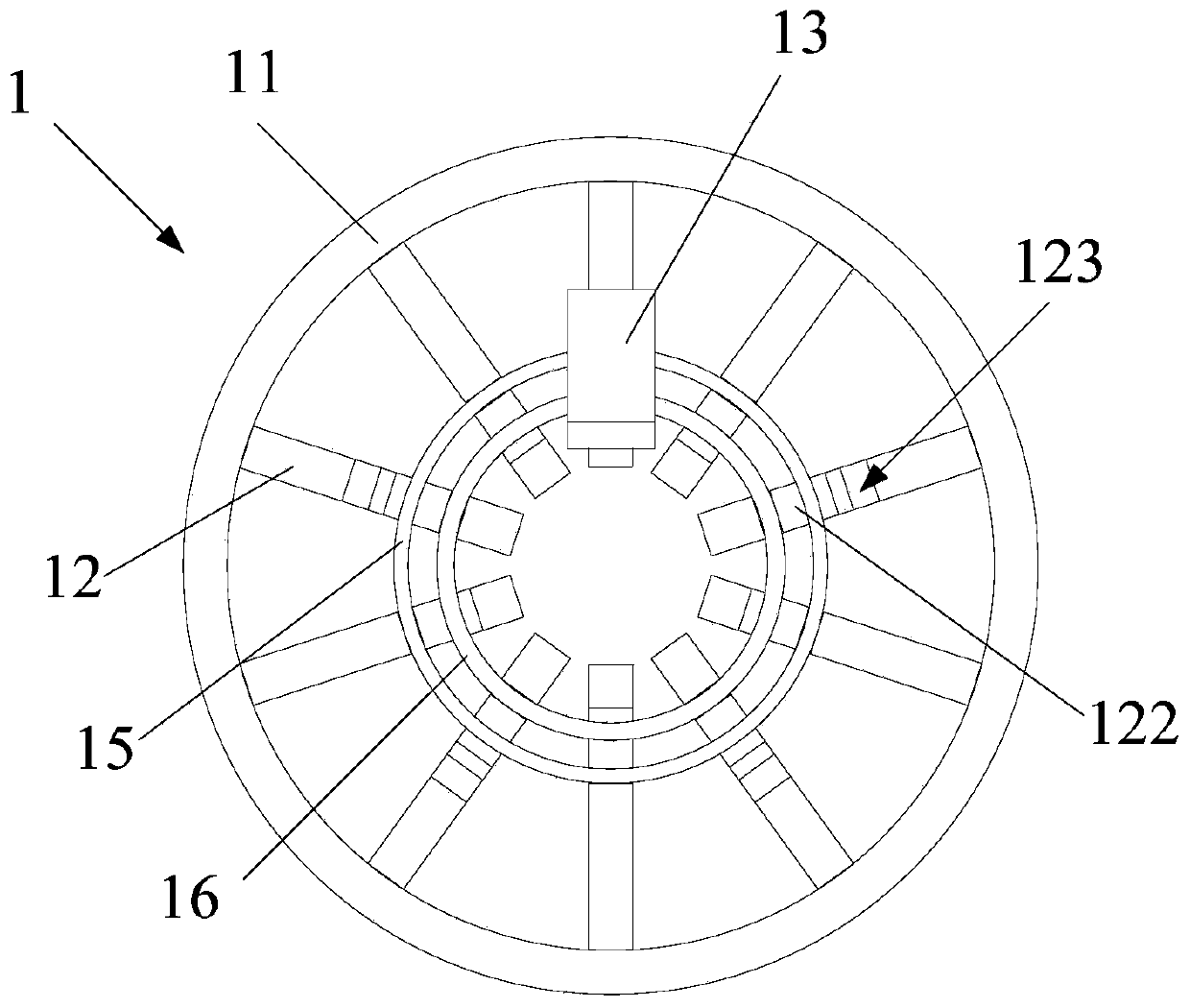

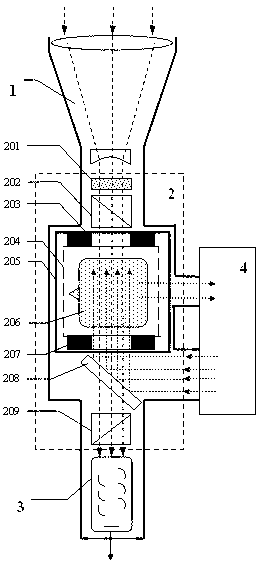

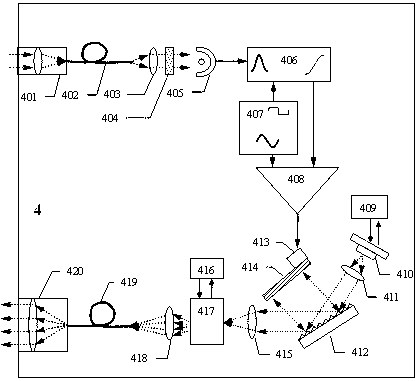

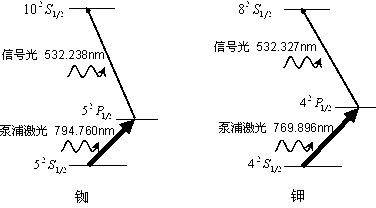

Excited state atom filter receiving device for pumping laser atom frequency stabilization

ActiveCN102709802AStable working frequencyImprove transmittanceLaser detailsFrequency stabilizationPhotovoltaic detectors

The invention discloses an excited state atom filter receiving device for pumping laser atom frequency stabilization. The device consists of a receiving telescope (1), an atom filter unit (2), a first photoelectric detector (3) and an atom frequency stabilization pumping laser unit (4). Resonance fluorescence generated by atoms is used for carrying out feedback frequency stabilization on a pumping laser, the work frequency of the pumping laser is stable without drifting, and further, low excited state atom number density and super-fine energy level distribution is stable, so the transmission spectrum type stability and the transmittance of an excited state atom filter are improved.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

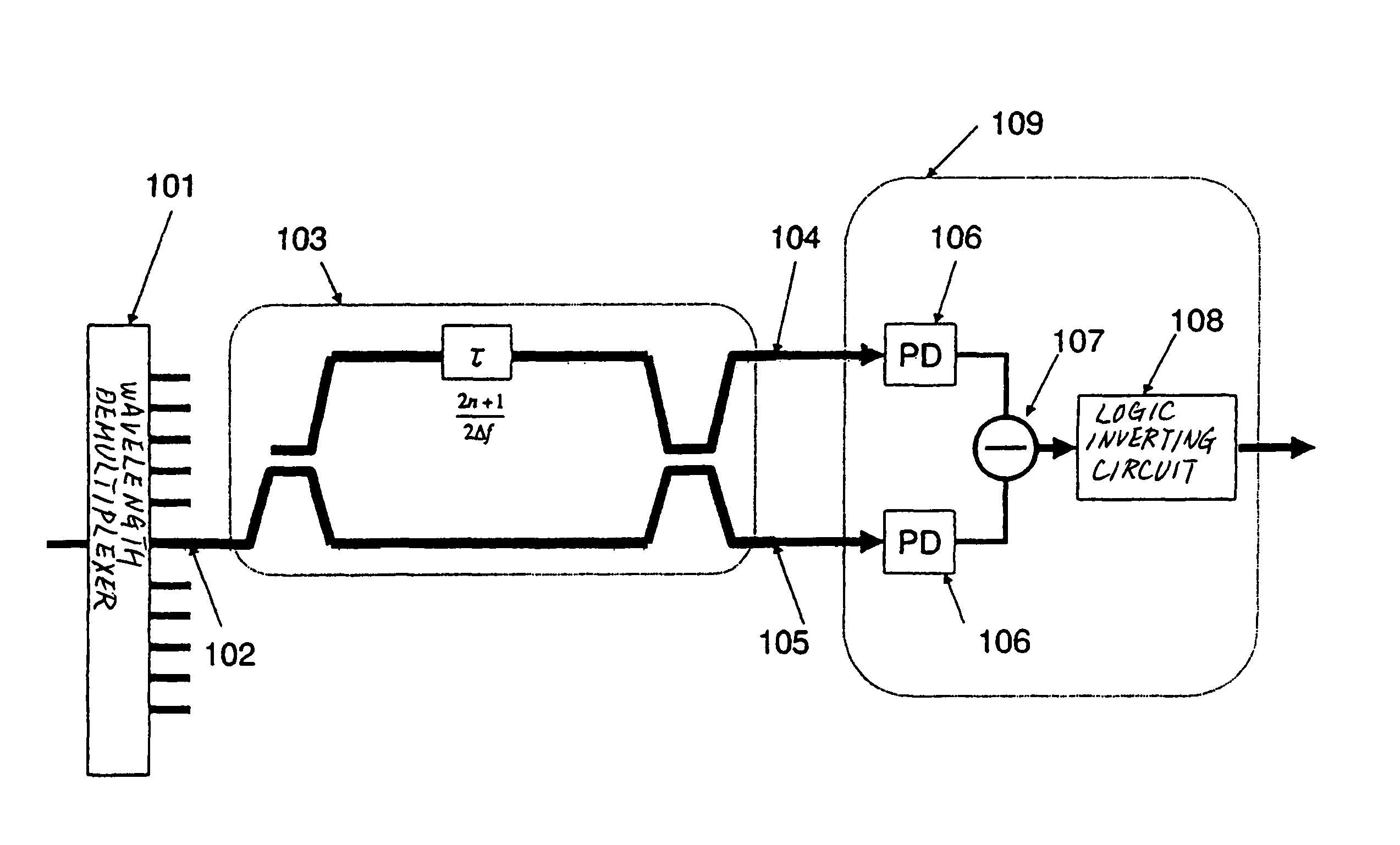

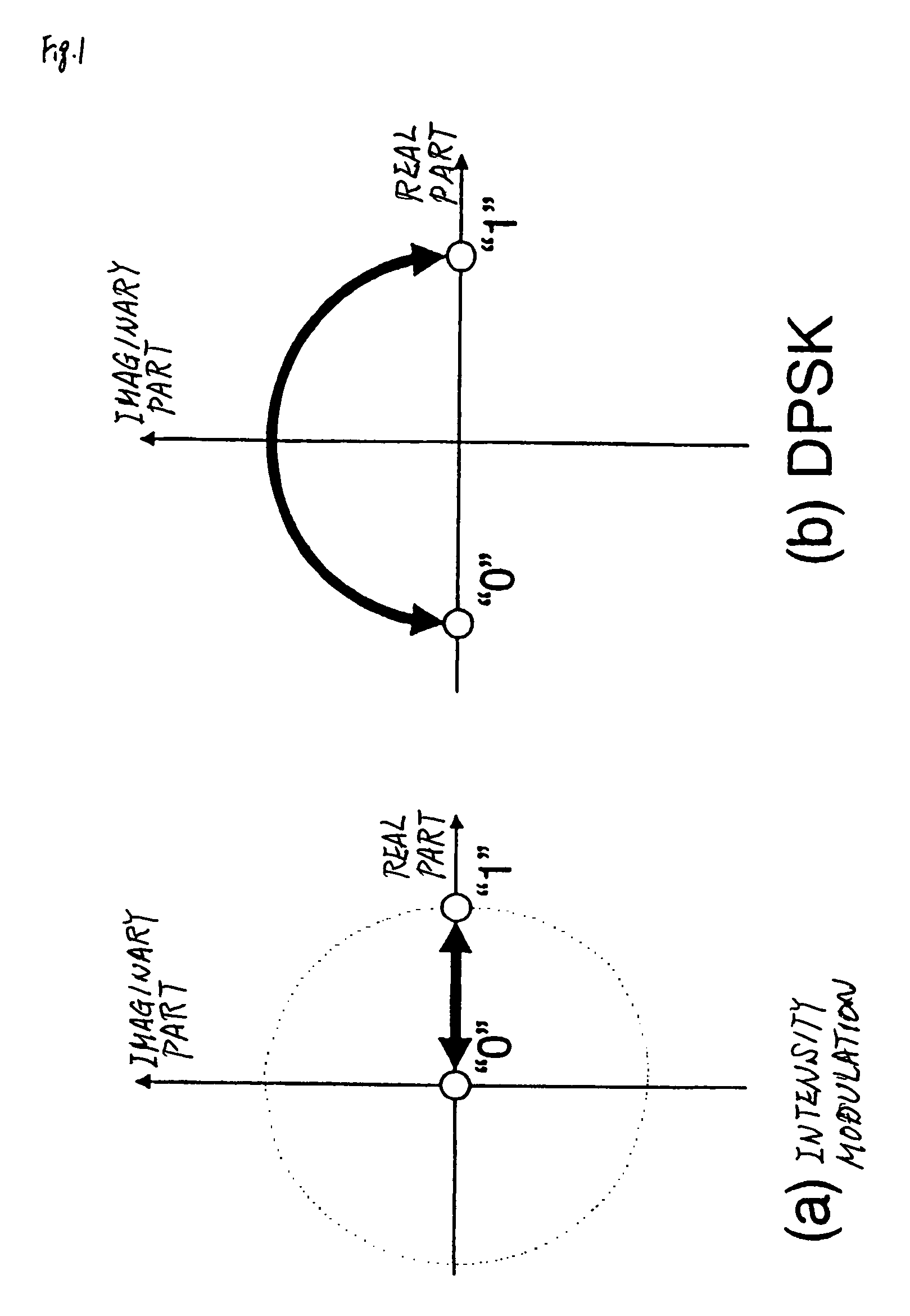

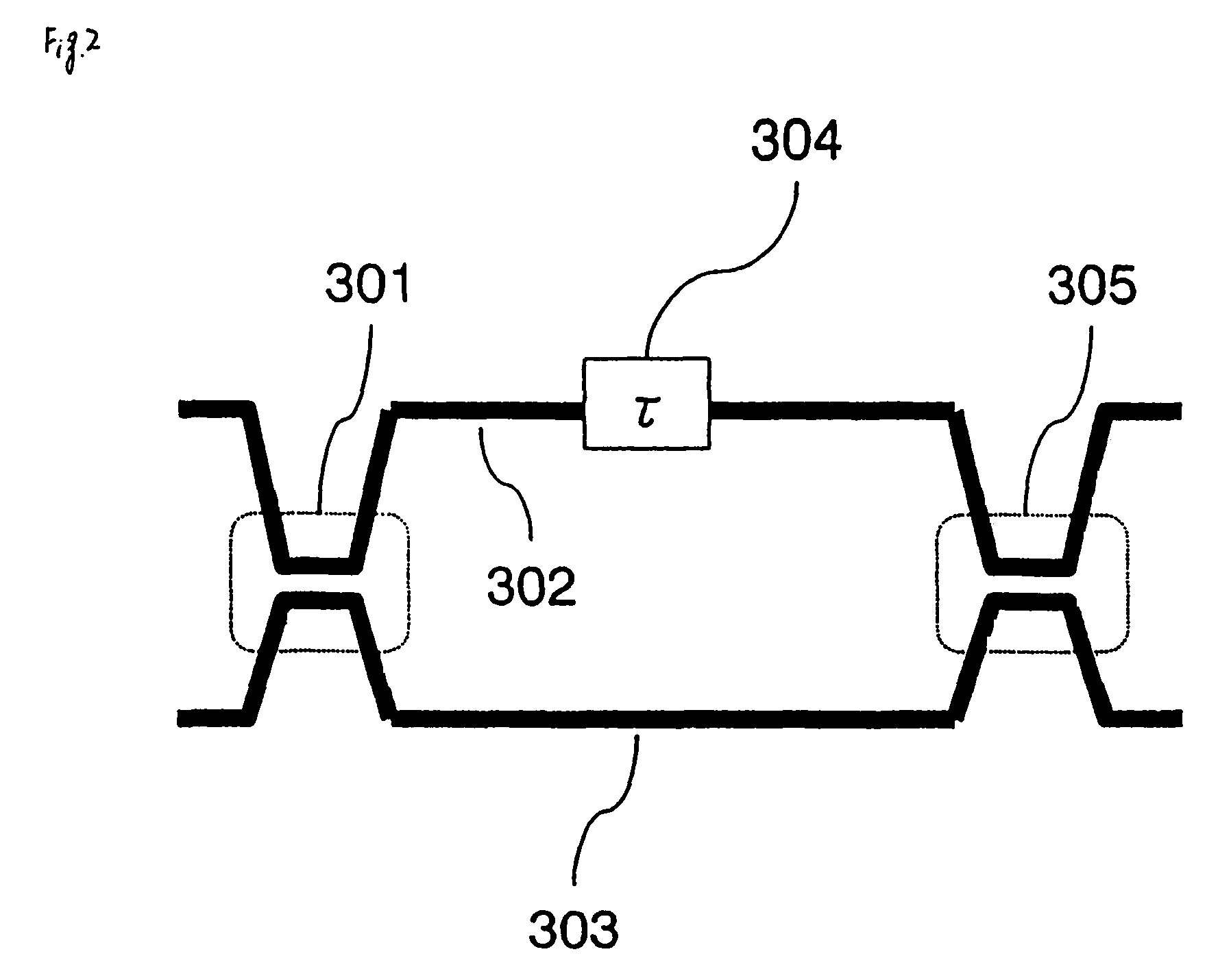

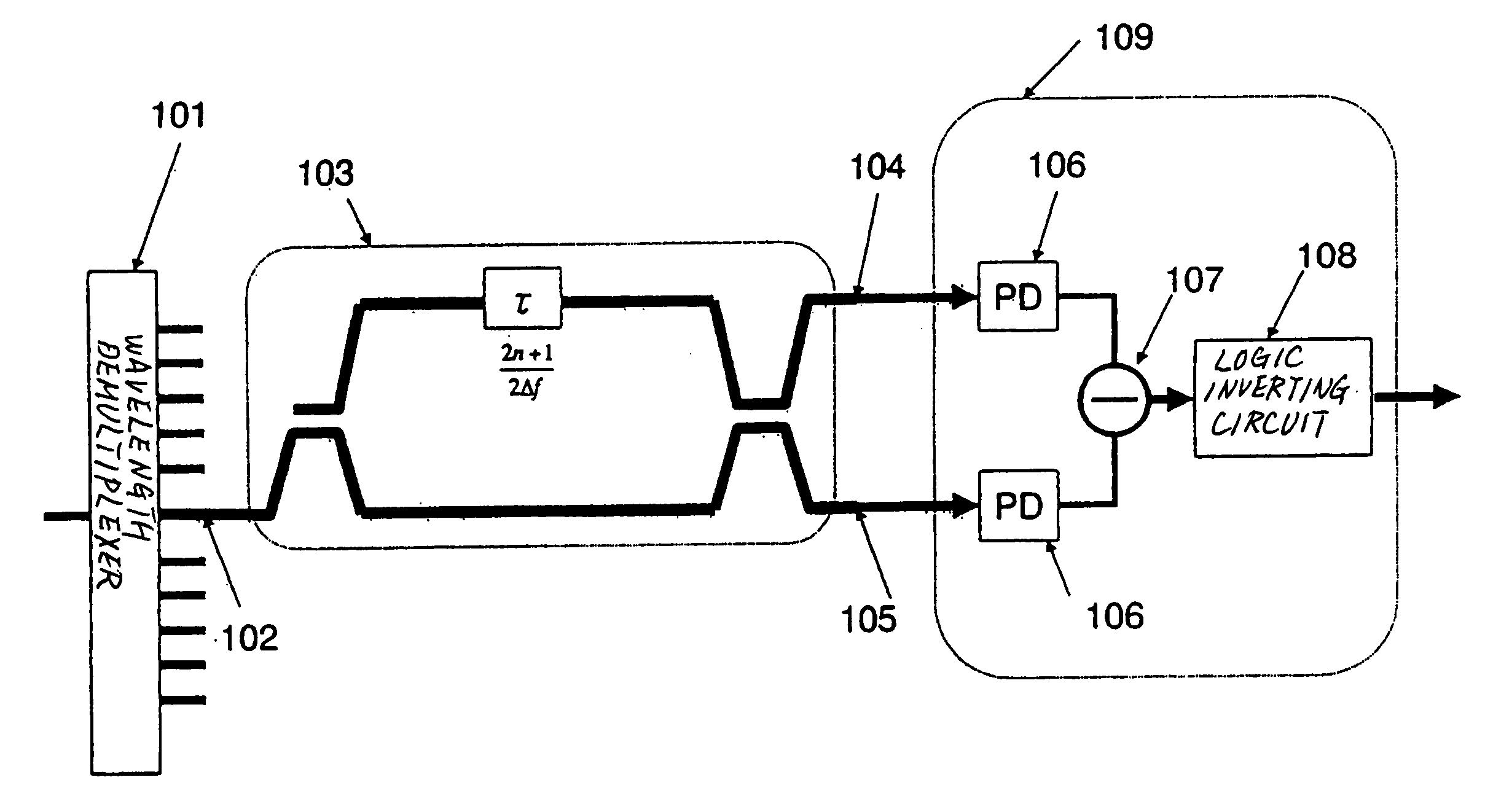

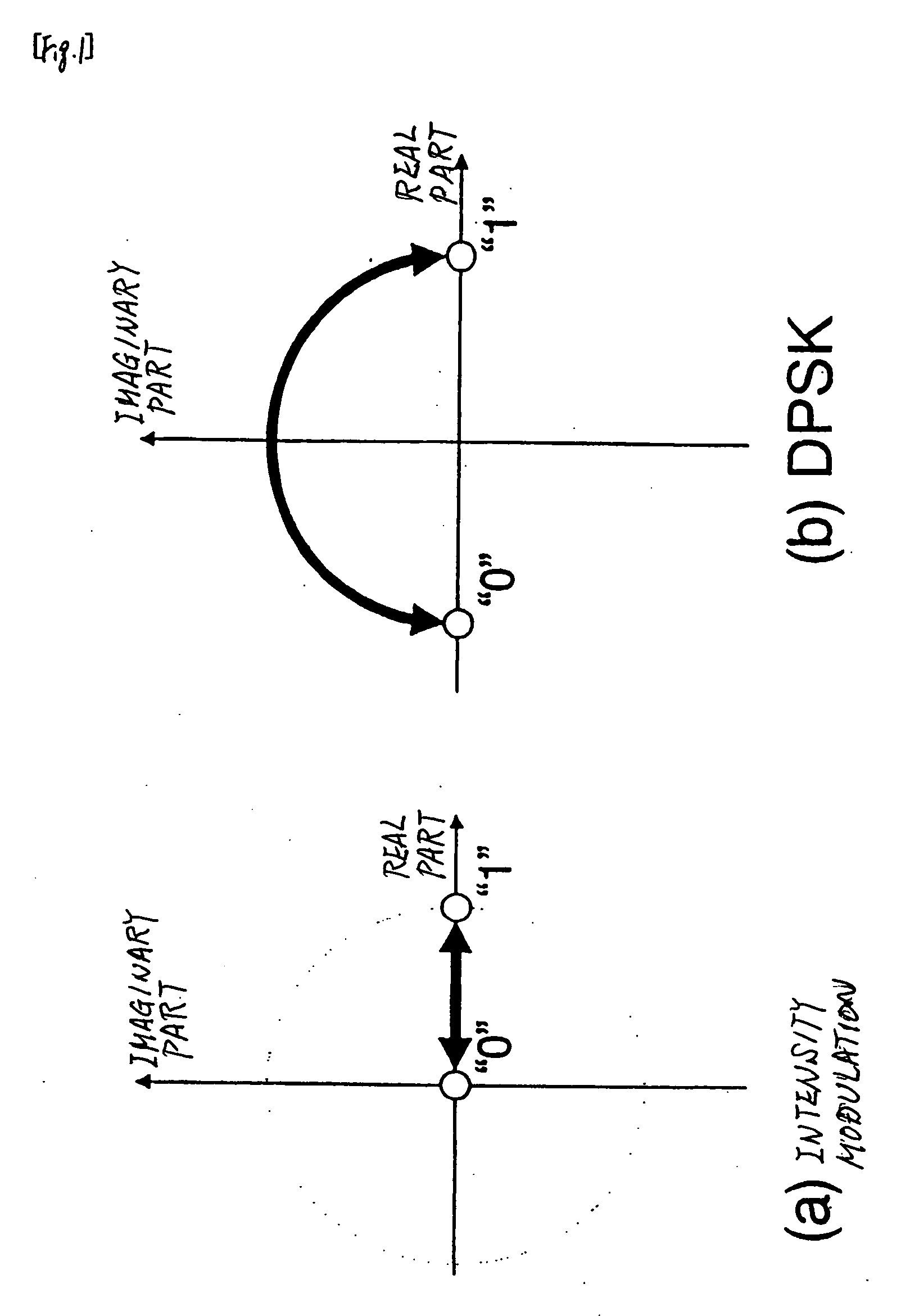

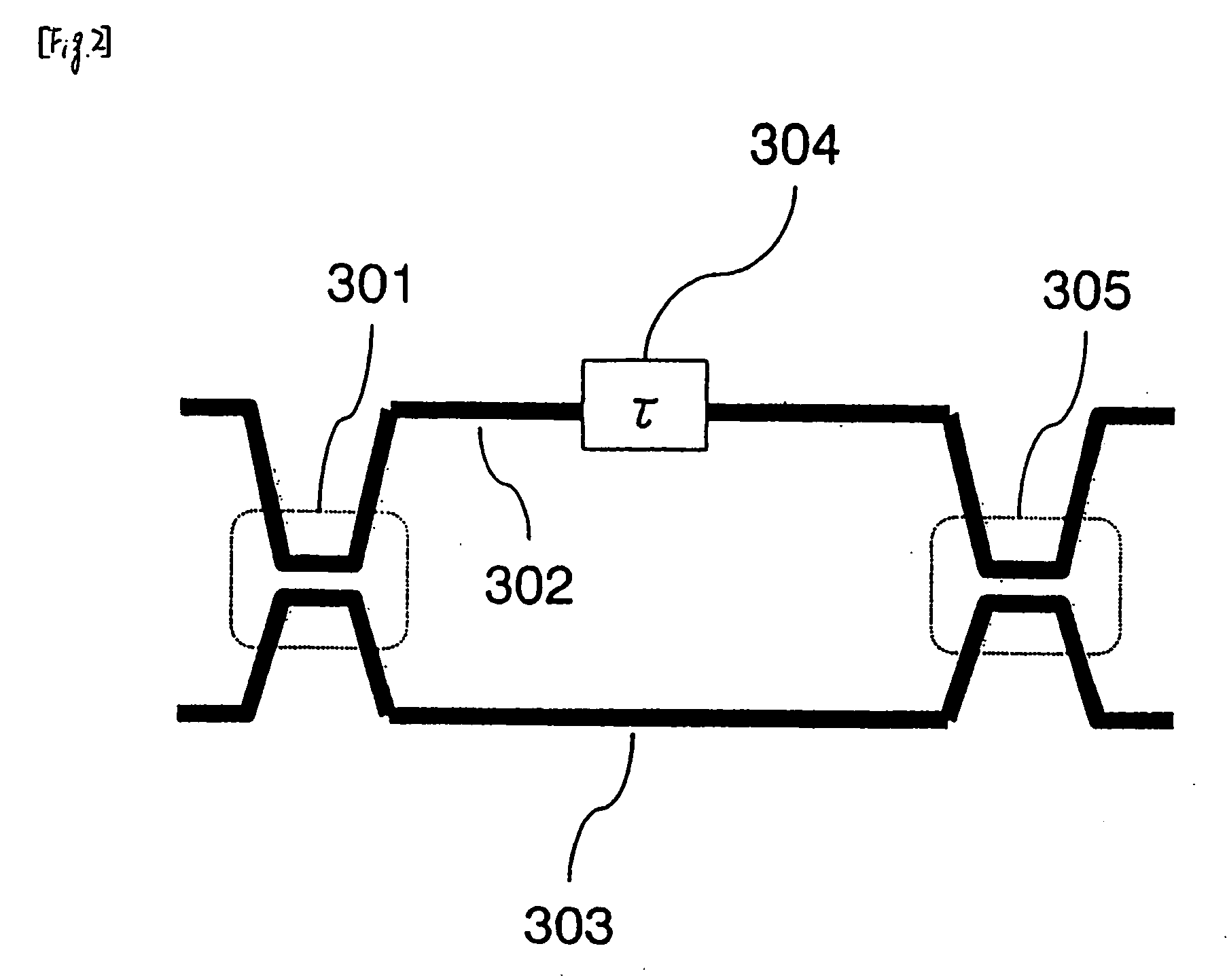

Light receiver, optical communication system and method

ActiveUS8320779B2Stable working frequencyDemodulate DPSK signalsWavelength-division multiplex systemsElectromagnetic transmittersCommunications systemLight signal

A receiver includes wavelength demultiplexer for demultiplexing a received WDM light into light signals at respective central frequencies thereof, delay interferometer for converting a light signal output from wavelength demultiplexer into an intensity signal, and light detector for converting an output signal from delay interferometer into an electric signal. The interval between interferential frequencies of delay interferometer is 2 / (2n+1) times the interval between the central frequencies of the WDM light. Logic inverting circuit outputs the output signal from the light detector while non-inverting or inverting the logic level thereof depending on the received central frequency.

Owner:NEC CORP

Light Receiver, Optical Communication System and Method

ActiveUS20090290876A1Small sizeStable working frequencyWavelength-division multiplex systemsElectromagnetic transmittersCommunications systemWavelength demultiplexer

A receiver includes wavelength demultiplexer for demultiplexing a received WDM light into light signals at respective central frequencies thereof, delay interferometer for converting a light signal output from wavelength demultiplexer into an intensity signal, and light detector for converting an output signal from delay interferometer into an electric signal. The interval between interferential frequencies of delay interferometer is 2 / (2n+1) times the interval between the central frequencies of the WDM light. Logic inverting circuit outputs the output signal from the light detector while non-inverting or inverting the logic level thereof depending on the received central frequency.

Owner:NEC CORP

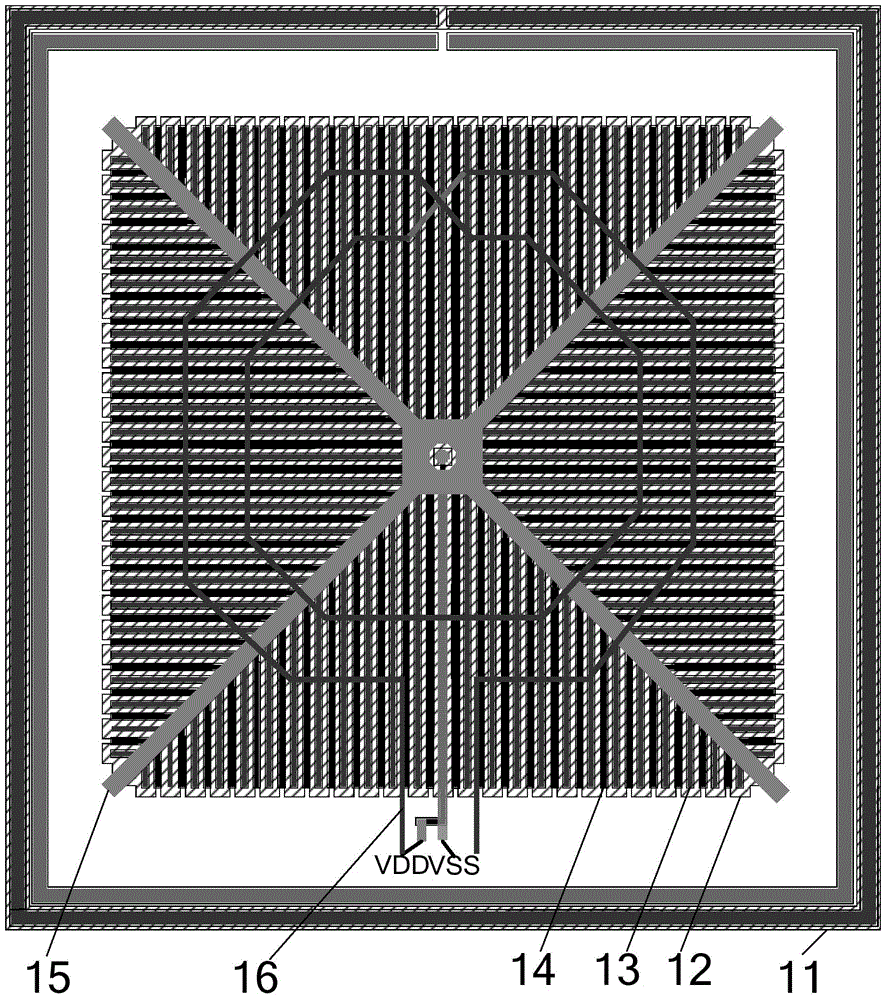

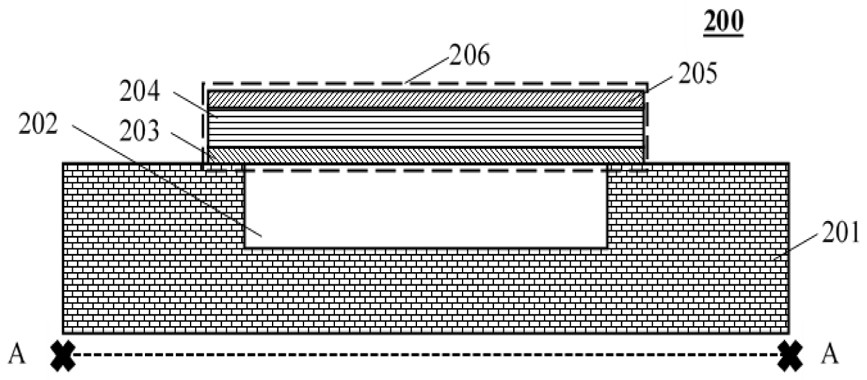

Inductor substrate isolation structure of integrated circuit

ActiveCN104064547AImprove performancePerformanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceInductor

The invention provides an inductor substrate isolation structure of an integrated circuit. The inductor substrate isolation structure comprises a p-type substrate, an n-type well region formed in the p-type substrate and including a plurality of n wells, a plurality of p-type active regions formed in the plurality of n wells through injection, a polycrystalline silicon shielding layer covering the n-type well region and including a plurality of strips of n-type polycrystalline silicon, a metal layer covering the polycrystalline silicon shielding layer, and an inductor covering the metal layer, wherein each strip of n-type polycrystalline silicon covers two adjacent n wells, the plurality of strips of n-type polycrystalline silicon are spaced from each other by the p-type active regions, the metal layer is of an X-shaped metal structure which is arranged in the diagonal position of the n-type well region, and the center point of the inductor coincides with the center point of the X-shaped metal structure. By adopting the inductor substrate isolation structure of the invention, the electromagnetic loss of the inductor to the substrate can be effectively reduced, the coupling capacitance between the inductor, the shielding layer and the substrate can be reduced, and the quality factor and working frequency of the inductor can be improved.

Owner:ZHUHAI JIELI TECH

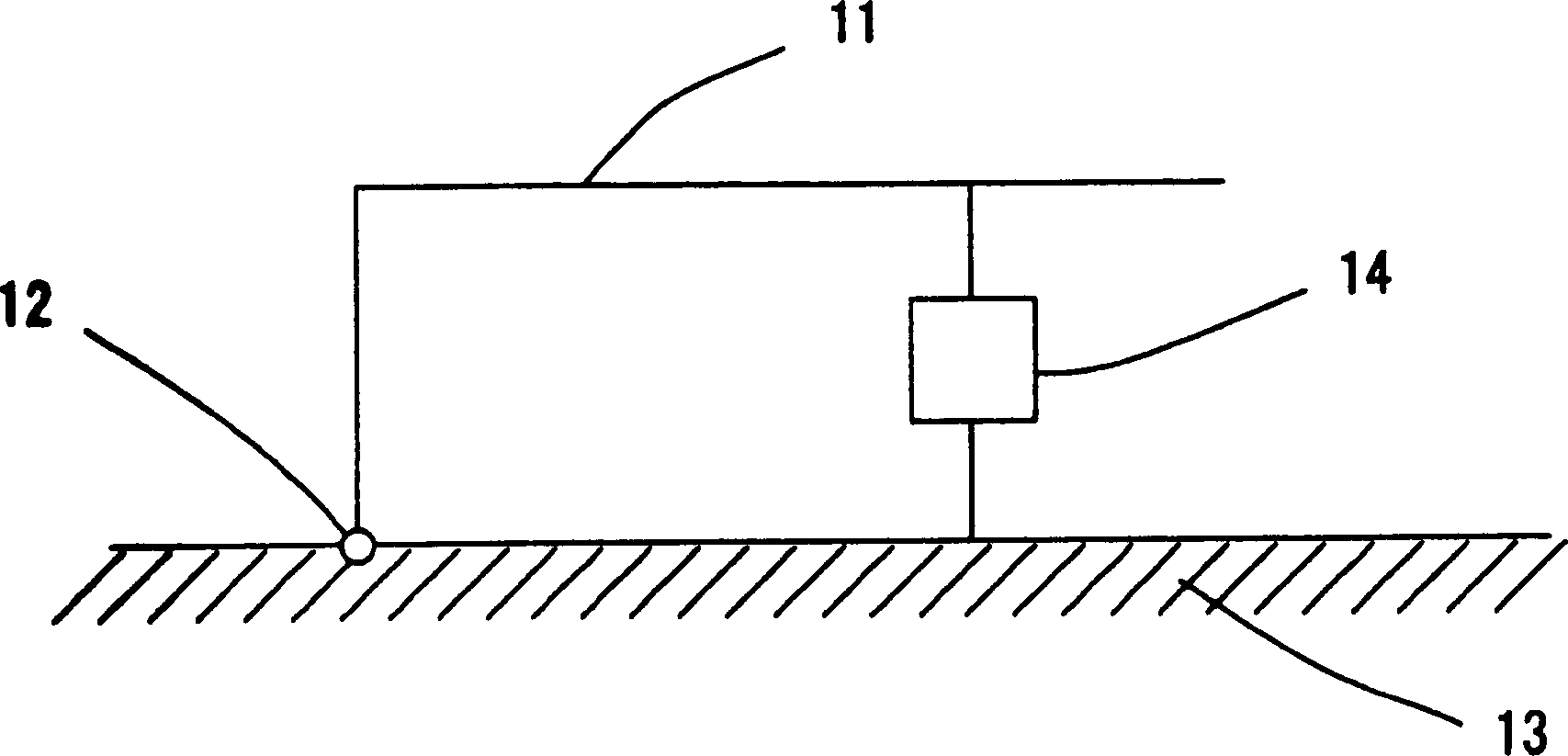

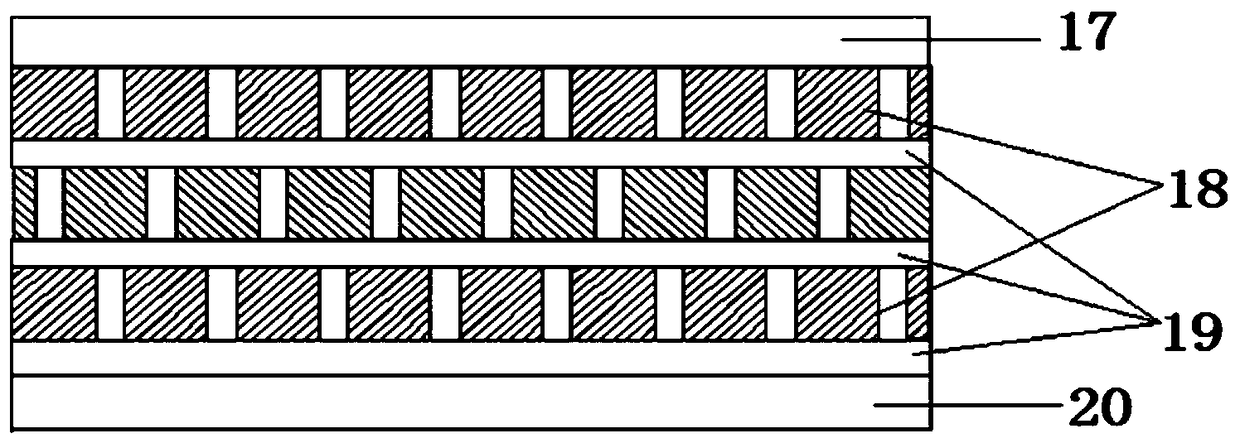

Composite application shield sheet of coil module and preparation process thereof

InactiveCN108922755AElectromagnetic Properties Permeability AverageReduce magnetic lossTransformers/inductances coolingTransformersMaterials scienceMono layer

The invention relates to a composite application shield sheet of a coil module and a preparation process thereof. The preparation process comprises, at least, the following process steps of heat treatment, composite lamination and soft magnetic material surface graphical processing. magnetic sheets formed by a resin bonding agent and a magnetic powder mixture are attached to the back of a first magnetic conductive layer formed by soft magnetic material strip laminations undergoing graphical processing or upper-single-layer graphical processing to form a second magnetic conductive layer; then cooling fins are attached to finally form the shield sheet, and finally the coil module is formed through shaped attachment. The process is simple and feasible, the integrated automation degree is high, the made shield sheet is small in thickness, good in shield capability, high in charging efficiency, small in temperature rise and more suitable for NFC composite functional module coils, the magnetic parameters of the materials are controllable, the surface processing shape of the shield sheet is uniform, the product stability is improved, and the processes and material costs are greatly saved.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

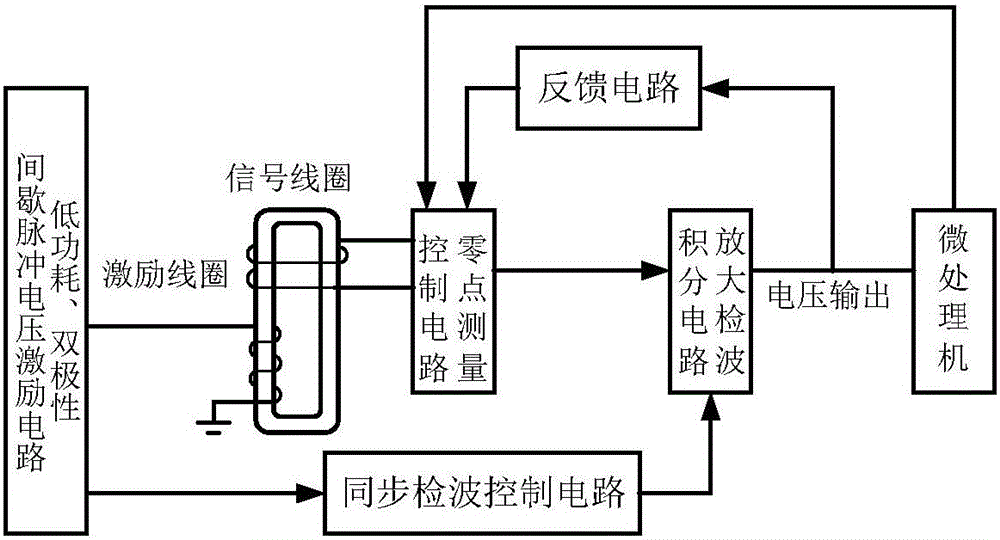

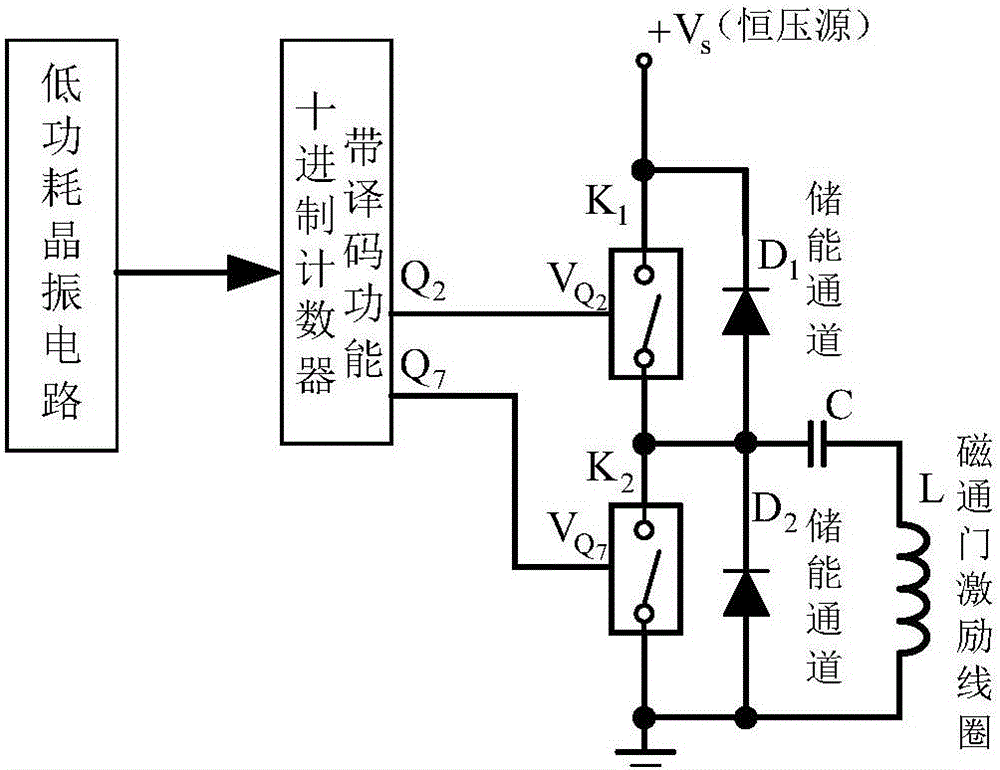

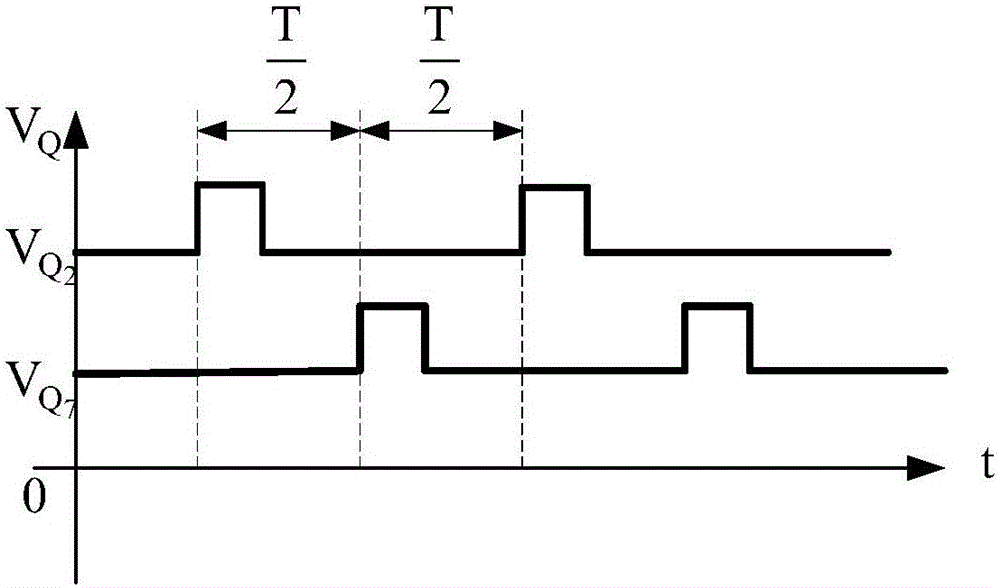

Triaxial decoupling self-zero-setting fluxgate magnetometer zero point measurement circuit

ActiveCN106324542AImprove energy efficiencyReduce incentive attack consumptionElectrical measurementsPhysicsConstant voltage

The invention discloses a triaxial decoupling self-zero-setting fluxgate magnetometer zero point measurement circuit, and the circuit employs a bipolar intermittent pulse excitation unit composed of low-power-consumption temperature control crystal oscillator to carry out the excitation of an iron core. The circuit employs the temperature control crystal oscillator to stabilize the work frequency, enables the iron core to be demagnetized in real time in a mode of bipolar excitation, and employs an intermittent pulse voltage excitation waveform to greatly reduce the power consumption. The circuit controls a constant voltage source to carry out the excitation of the iron core through a low-resistance switch, and greatly improves the energy utilization efficiency of the excitation unit. The circuit provided by the invention employs a weak coupling mode to install a triaxial magnetic probe, reduces the triaxial coupling error through the optimization of the relative position of the triaxial magnetic probe, employs a zero point automatic measurement circuit, can carry out the programming control to achieve the online detection of a circuit zero point, and can be used in the fields of magnetic field measurement and magnetic object detection.

Owner:NAVAL UNIV OF ENG PLA

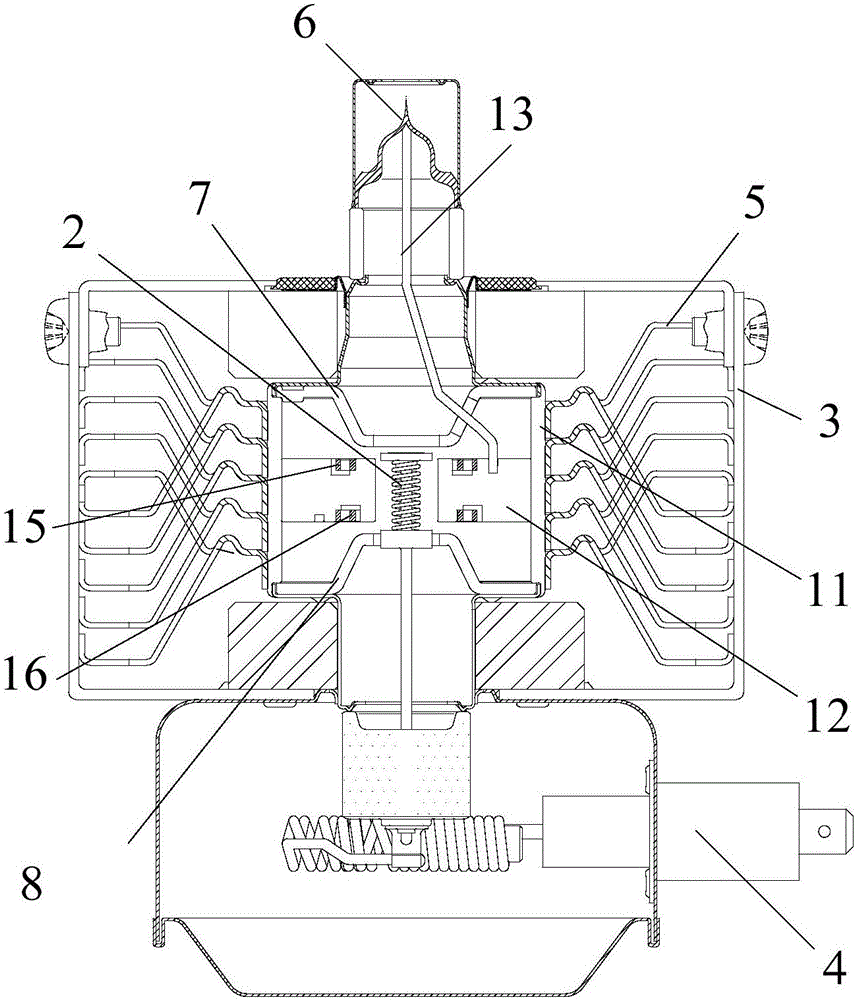

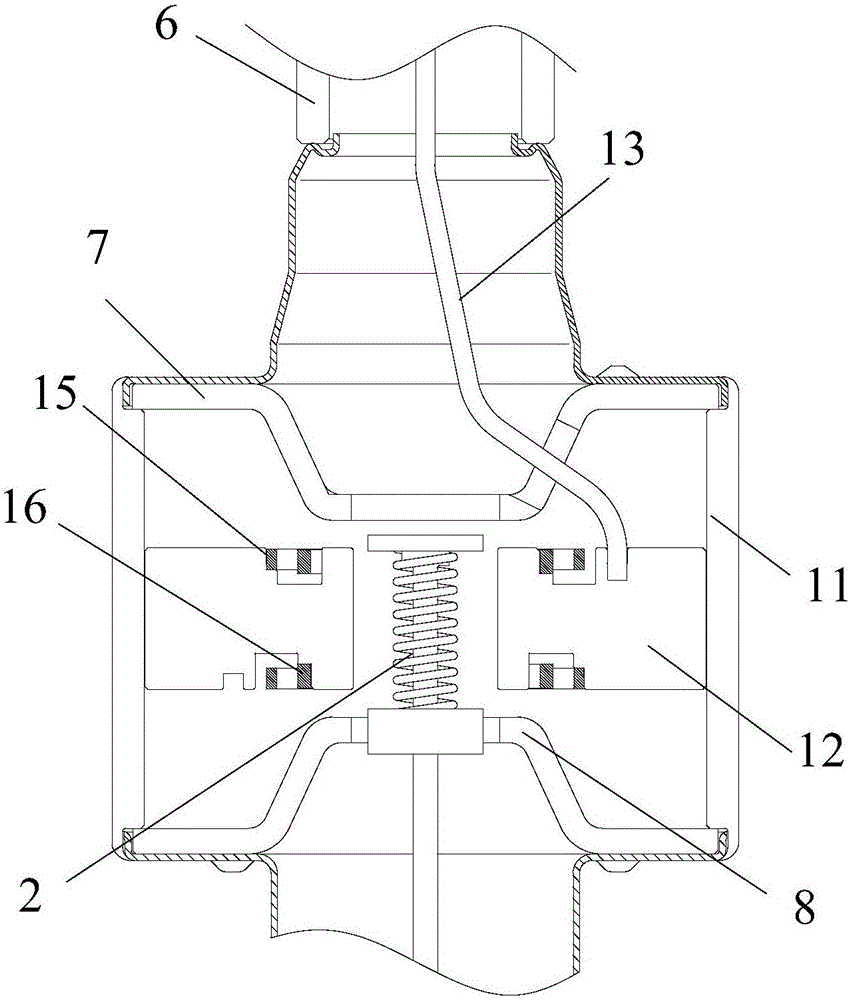

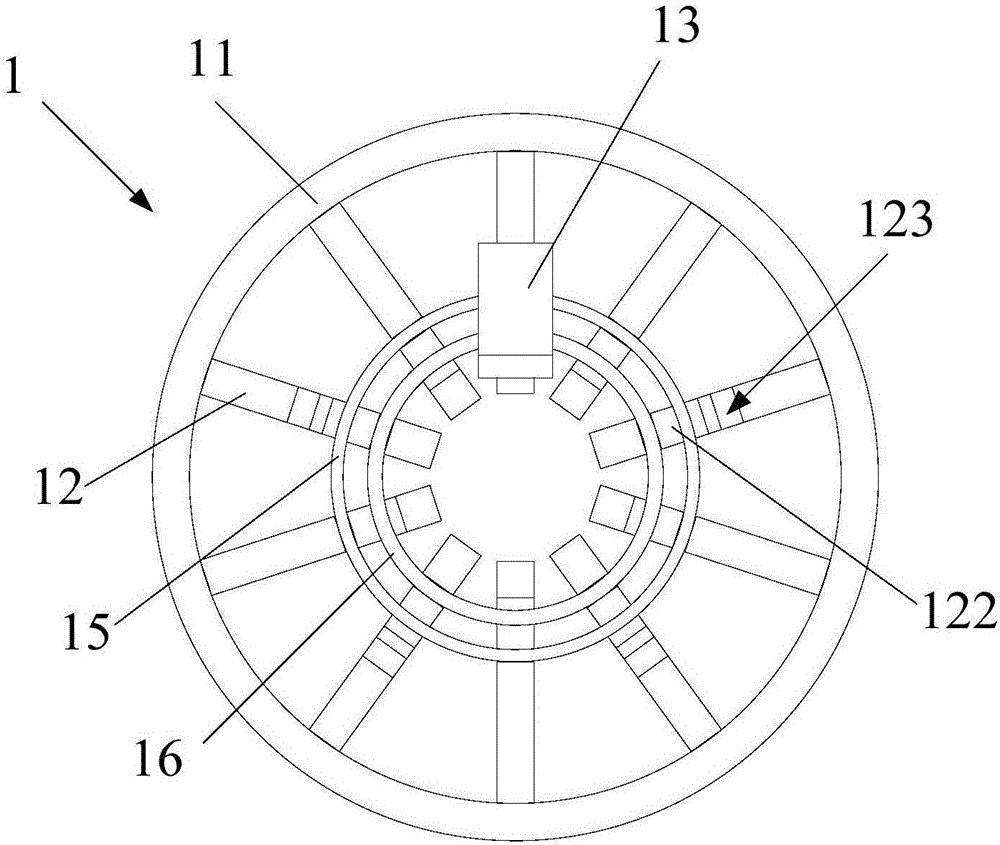

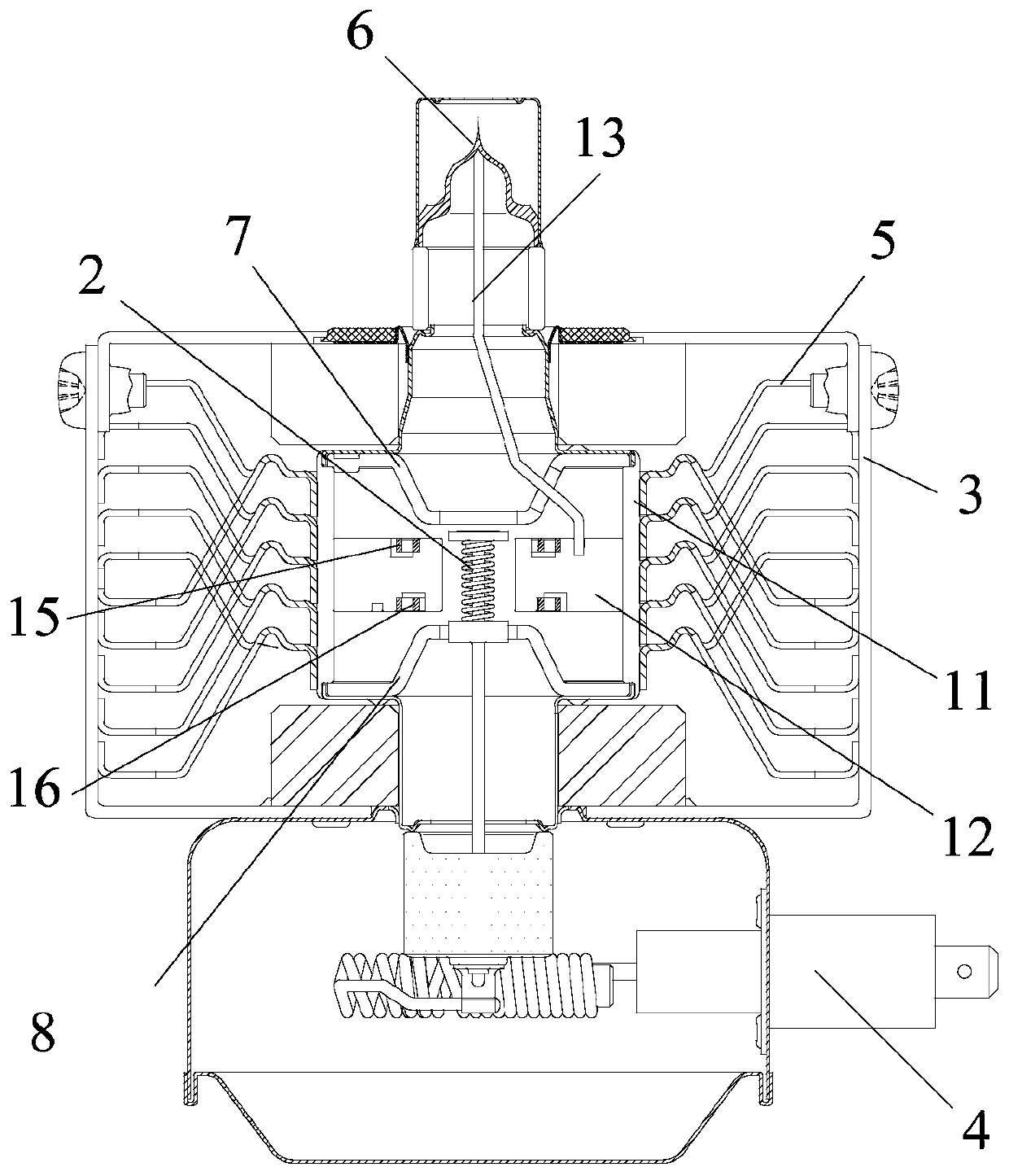

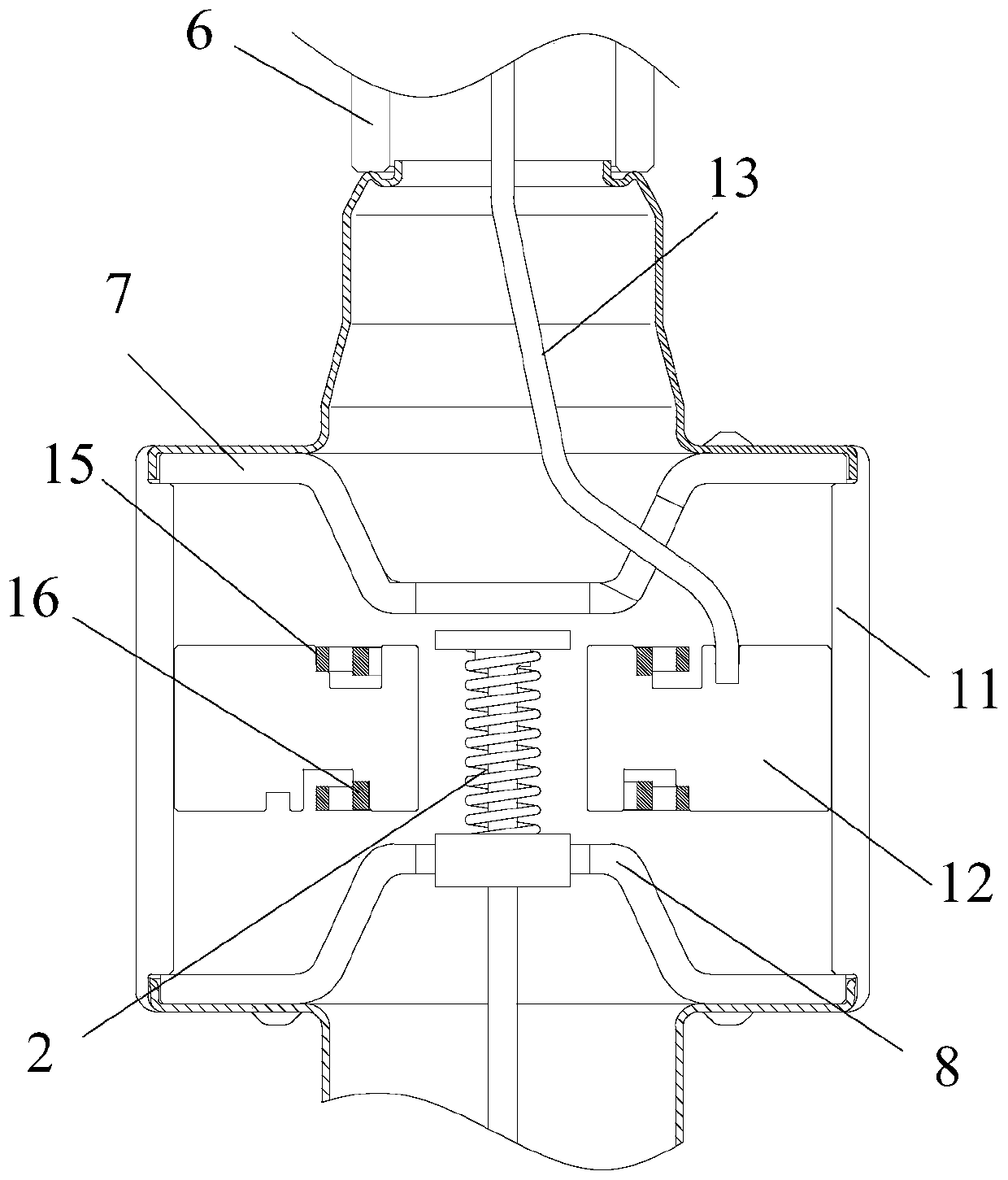

Magnetron anode assembly and magnetron provided with magnetron anode assembly

ActiveCN106710999AStable working frequencyImprove welding qualityMagnetronsTransit-tube collectorsManufacturing cost reductionOperating frequency

The invention relates to the technical field of a magnetron, in particular to a magnetron anode assembly and a magnetron provided with the magnetron anode assembly. A magnetron anode blade assembly provided by the invention comprises an anode tube and a plurality of anode blades arranged in the anode tube, wherein at least one flow guide groove is formed in each anode blade; the at least one flow guide groove is used for guiding molten welding materials positioned on the upper surface of the anode blades to one end, welded with the inner wall of the anode tube, of the anode blades, so that during the welding of the anode blades and the anode tube, the welding materials are molten on the upper surfaces of the anode blades; then, the molten welding materials flow to the welding position of the anode blades and the inner wall of the anode tube under the capillary effect and the gravity effect through the flow guide groove; the problem of welding failure of the anode blades and the anode tube due to the gathering of the welding materials on the upper surface of the anode blades can be avoided, so that the work frequency of the magnetron is more stable; the welding quality of the anode blades and the anode tube is higher; the welding success rate is improved; the manufacturing cost is reduced.

Owner:GUANGDONG WITOL VACUUM ELECTRONICS MFR

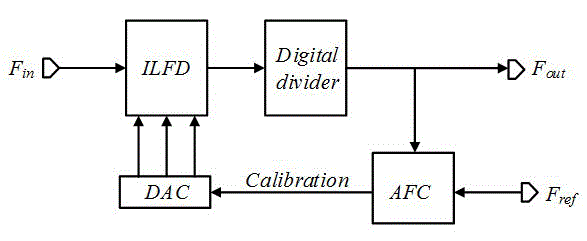

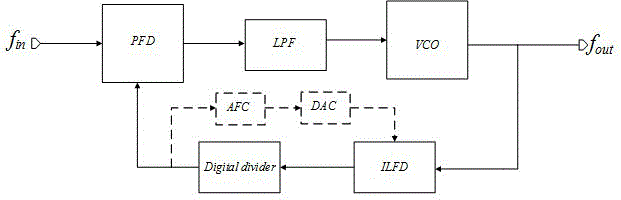

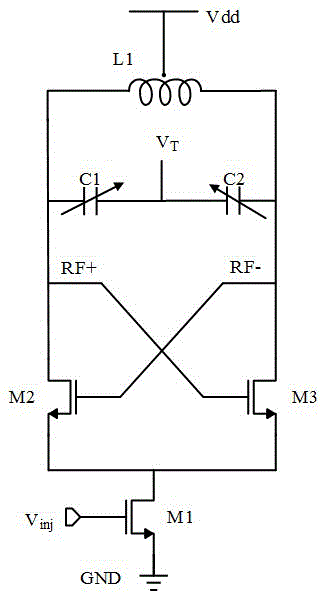

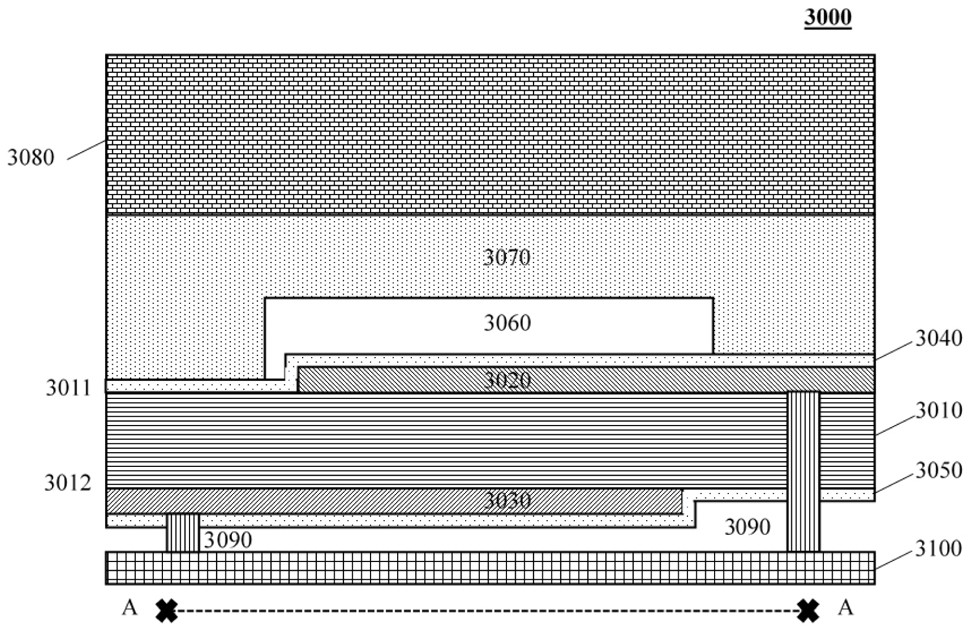

Injection locking frequency division structure with automatic frequency verification function

ActiveCN103916124AHigh stable working frequencyStable working frequencyPulse automatic controlInjection lockedProcess deviations

The invention discloses an injection locking frequency division structure with an automatic frequency verification function. The injection locking frequency division structure comprises an injection locking frequency divider, a digital frequency divider, an automatic frequency controller and a digital-to-analog converter. The injection locking frequency divider is used for receiving preset input signals and carrying out frequency division on the preset input signals according to resonant frequency to generate first frequency division signals. The digital frequency divider is used for receiving the first frequency division signals, carrying out second frequency division to generate second frequency division signals and outputting the second frequency division signals. The automatic frequency controller is used for comparing the frequency of the received second frequency division signals with the frequency of a reference signal to generate digital verification selecting signals. The digital-to-analog converter is used for receiving the digital verification selecting signals from the automatic frequency controller, converting the digital verification selecting signals into analog signals and feeding the analog signals to the injection locking frequency divider to carry out voltage control. The injection locking frequency division structure with the automatic frequency verification function can obtain a high-stability working frequency range, is low in power consumption and has the automatic frequency verification function; in the actual process, the control voltage in an injection locking frequency division circuit can be controlled better, and potential process deviation and other factors can be resisted better.

Owner:ZHEJIANG UNIV

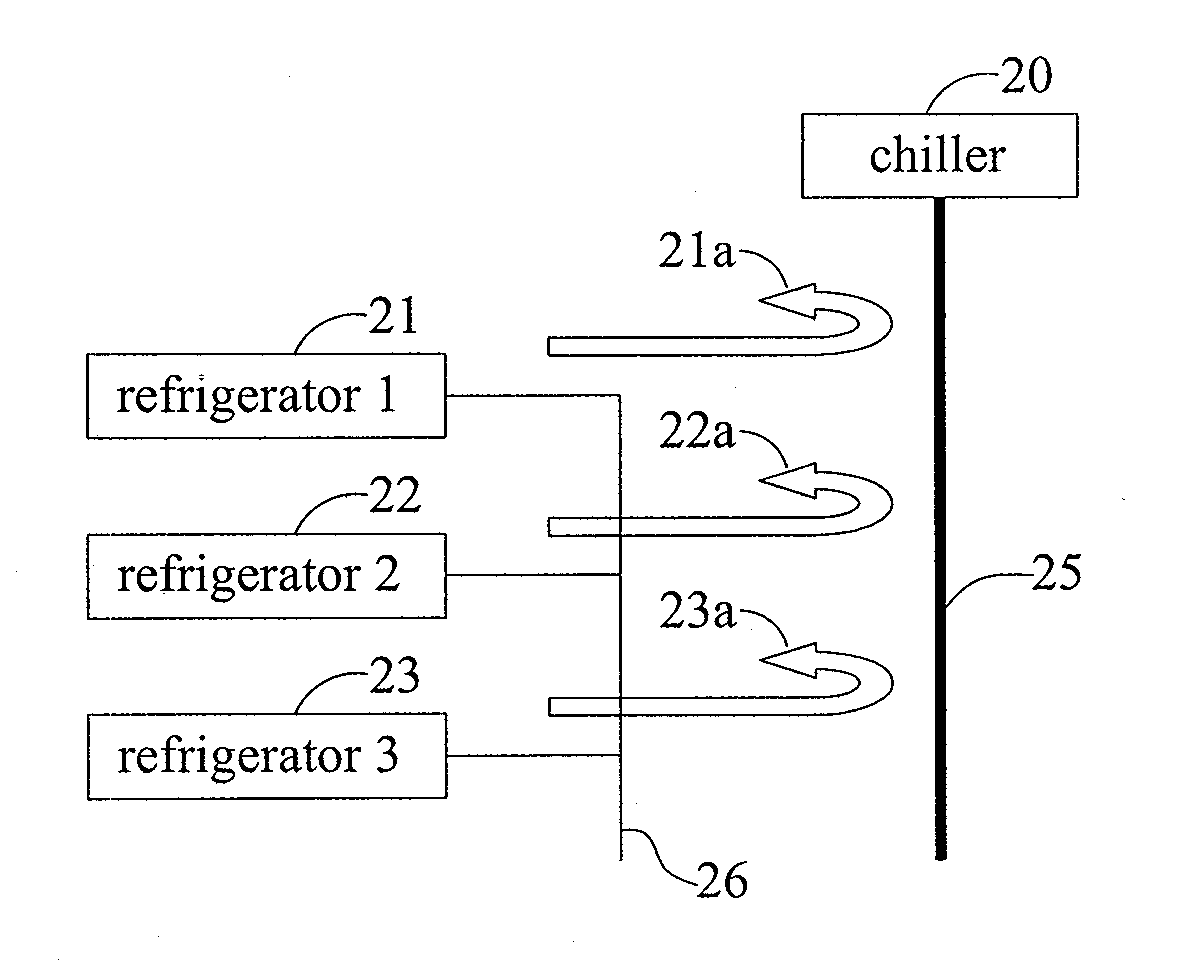

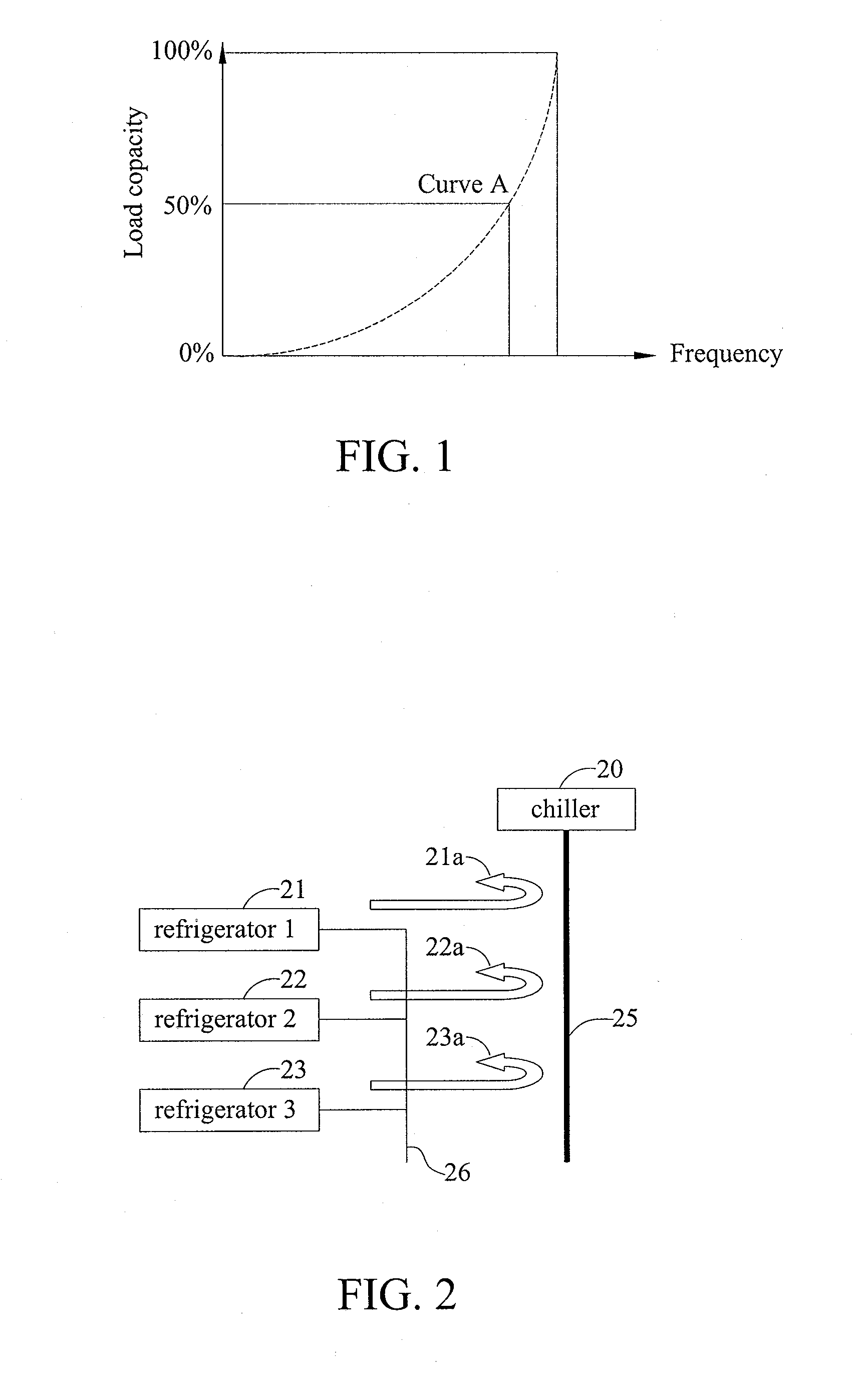

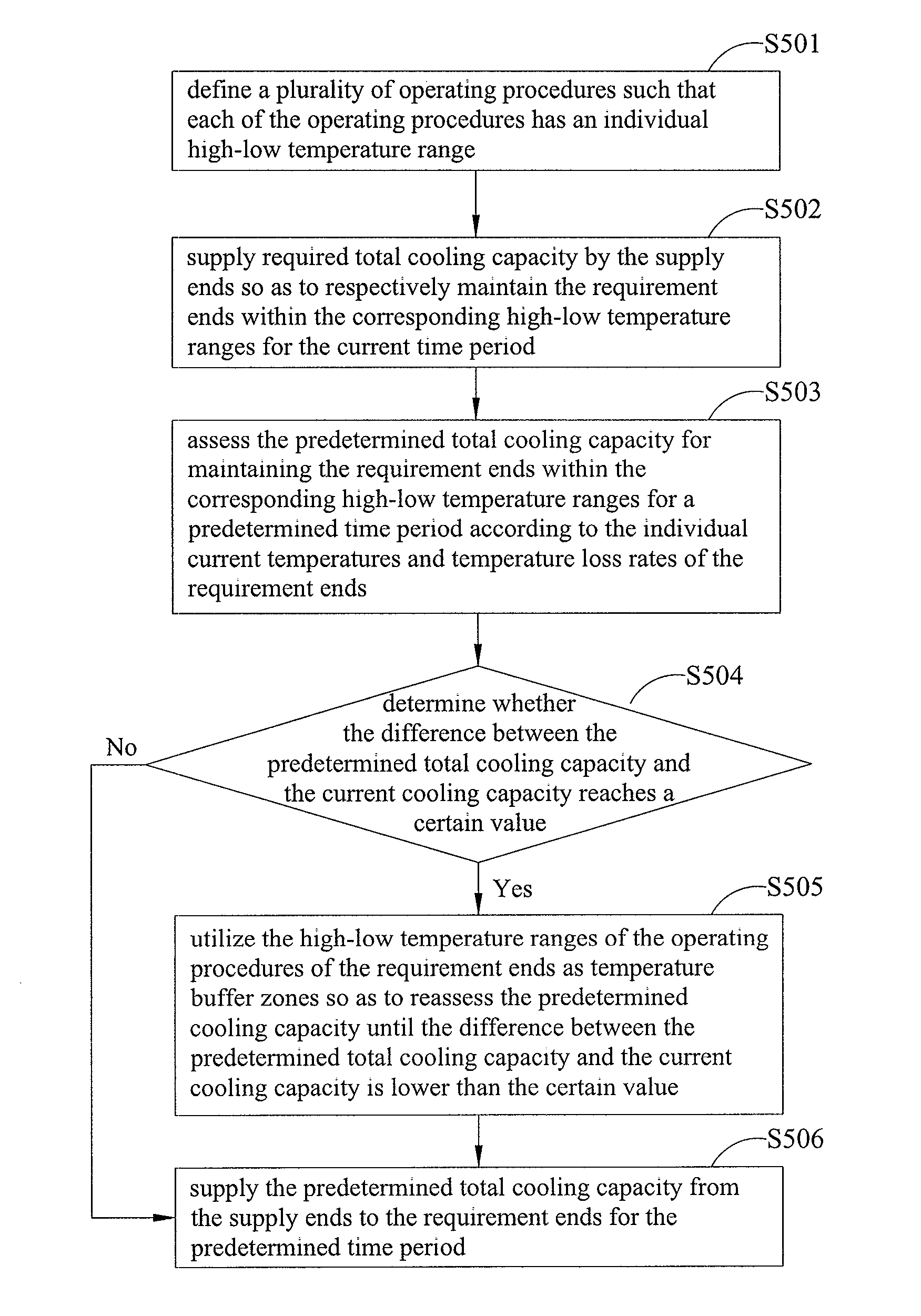

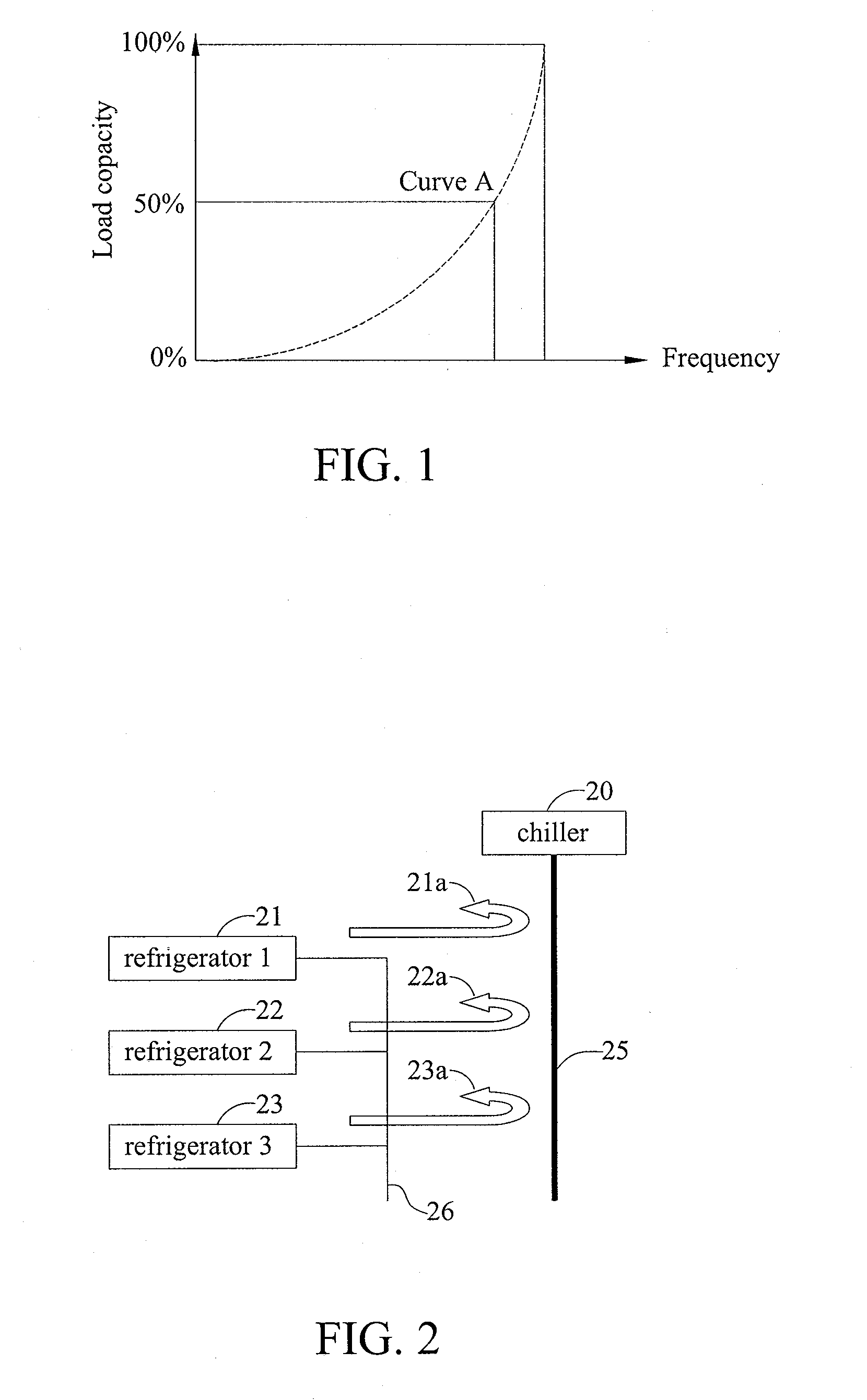

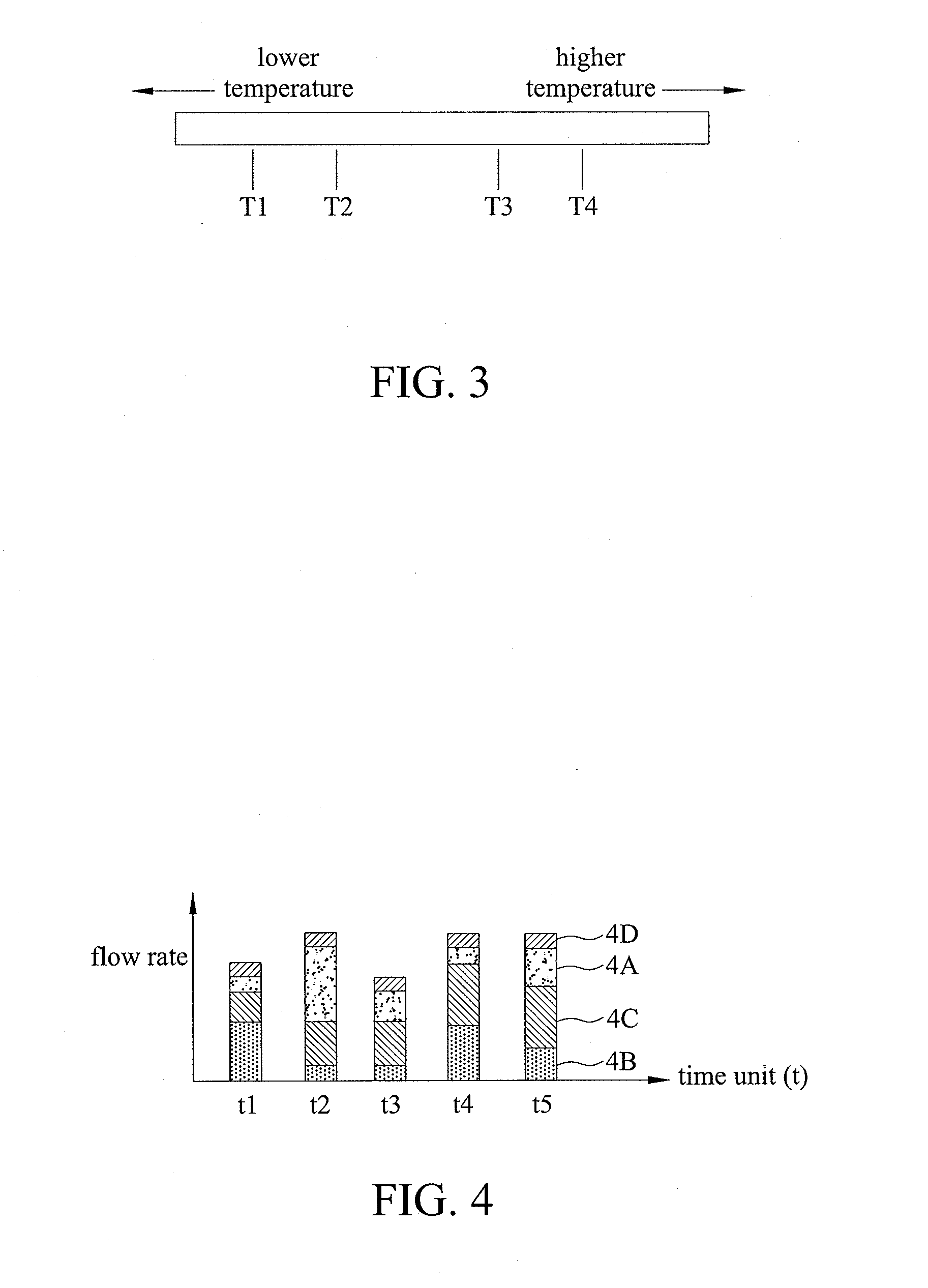

Method for controlling freezing capacity of a variable-frequency freezing ac ice-water system

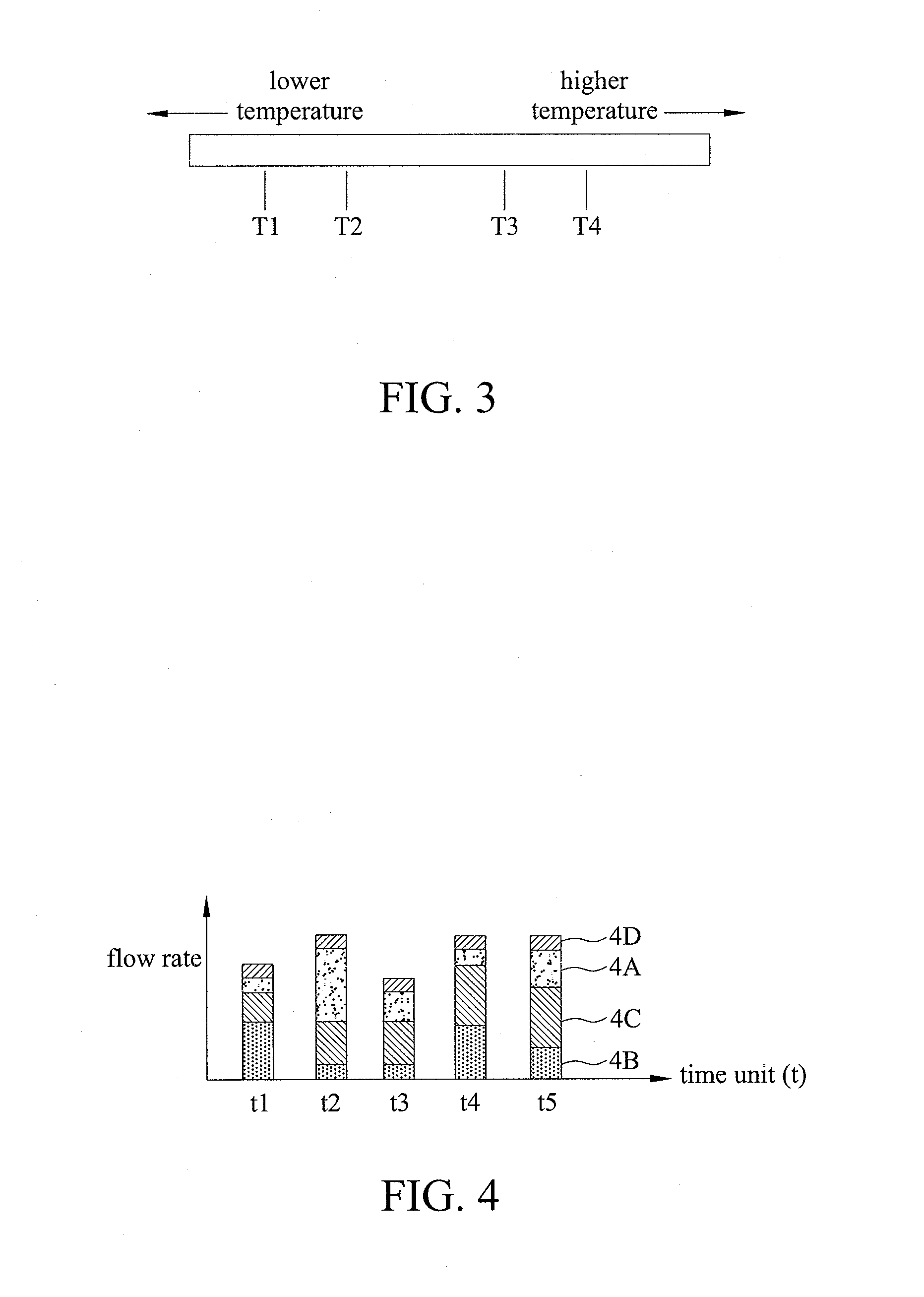

InactiveUS20120000215A1Reduce suddenReduce peak concentrating freezing demandMechanical apparatusLighting and heating apparatusIce waterEngineering

A method for controlling freezing capacity of a variable-frequency freezing AC ice-water system separates the freezing capacity of each individual requirement end so as to reduce sudden or peak concentrating freezing demand and relieve variable-frequency load demand, and defines operating procedures corresponding to different requirement ends, respectively, wherein each of the operating procedures has a corresponding high-low temperature range that can be used as a temperature buffer zone so as to redistribute supply of the freezing capacity to each requirement end, thereby allowing the compressors thereof to operate smoothly and thus achieve energy saving as a result. The drawbacks of damaged pipelines are overcome that cause deficiency in freezing capacity as encountered in prior techniques.

Owner:CHUNGHWA TELECOM CO LTD

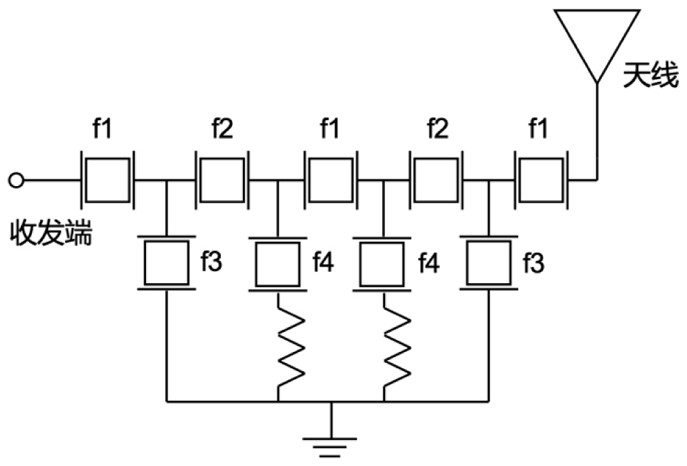

Bulk acoustic wave filtering device and forming method thereof, radio frequency front end and communication device

PendingCN114204913AStable working frequencyReduce packaging costsImpedence networksEngineeringRadio frequency front end

The invention discloses a bulk acoustic wave filtering device, a forming method thereof, a radio frequency front end and a communication device. The bulk acoustic wave filtering device comprises an unpackaged bulk acoustic wave resonance device, a connecting part and a circuit board, the first end of the connecting part is connected with the unpackaged bulk acoustic wave resonance device, and the second end of the connecting part is connected with the circuit board; the unpackaged bulk acoustic wave resonance device comprises a piezoelectric layer which comprises a first side and a second side opposite to the first side in the vertical direction; the first electrode layer is located on the first side; the second electrode layer is located on the second side; the first passivation layer is located on the first side and covers the first electrode layer, and the material of the first passivation layer comprises oxide or nitride; the second passivation layer is located on the second side and covers the second electrode layer; the cavity is located on the first side, and at least one end of the first electrode layer is located in the cavity or the first electrode layer covers the cavity; the connecting part is connected with the first electrode layer or the second electrode layer. The working frequency of the filtering device is stable, the resonator is not packaged, and the packaging cost is reduced.

Owner:CHANGZHOU CHEMSEMI CO LTD

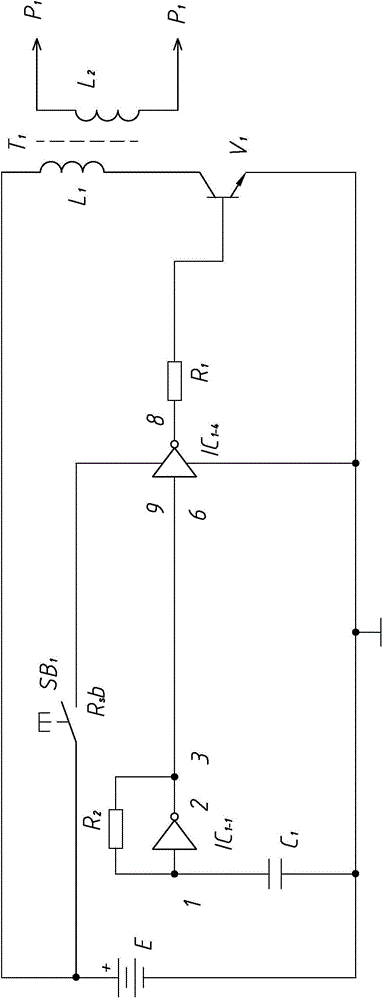

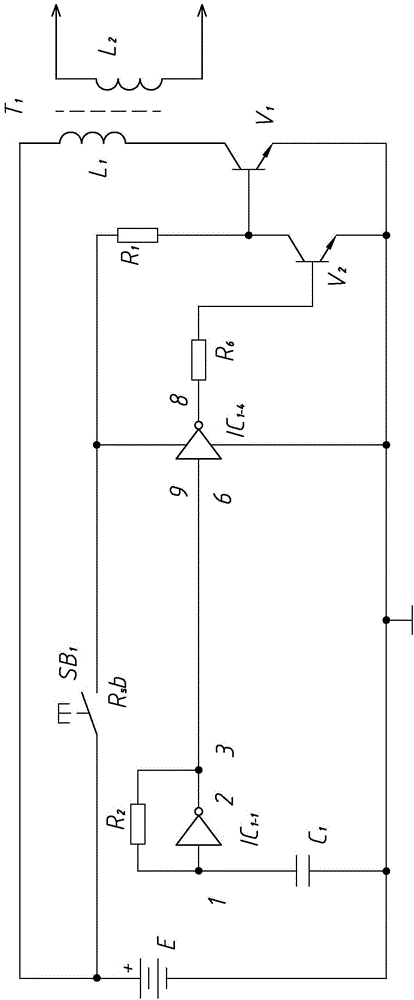

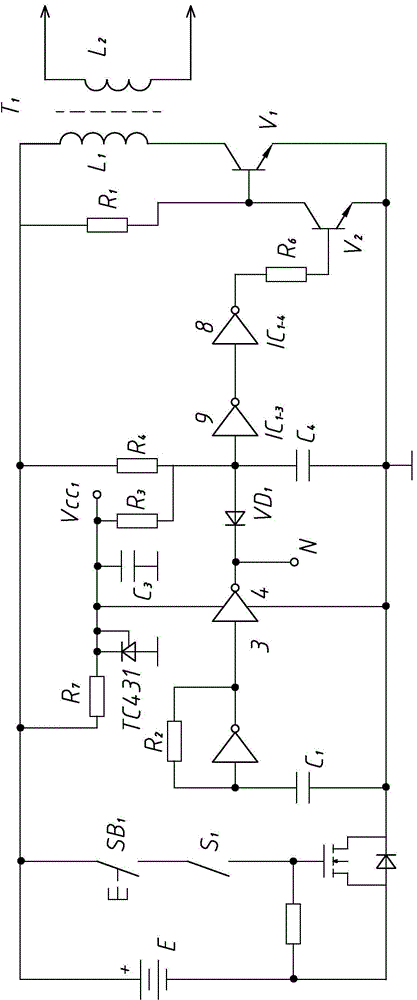

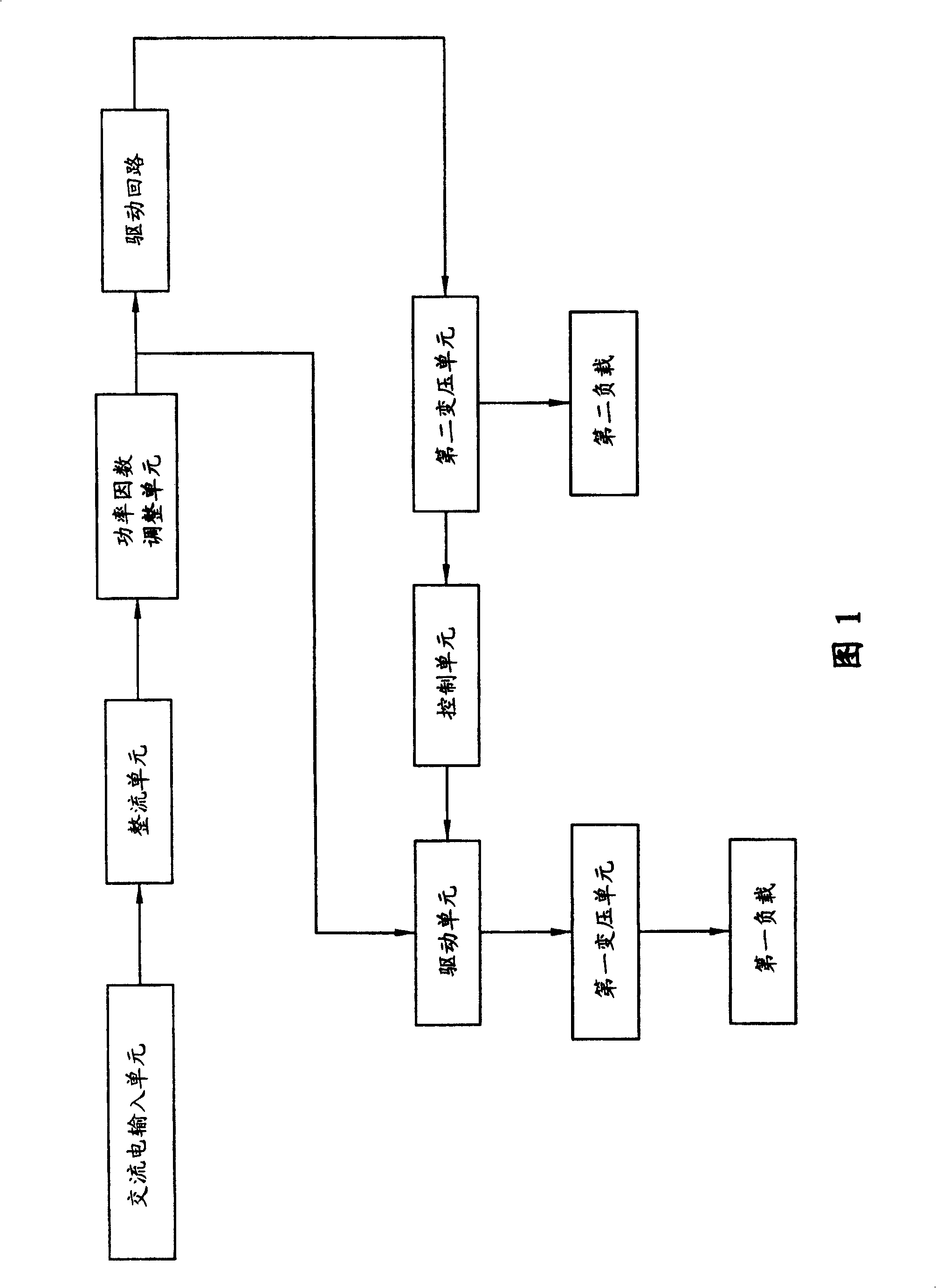

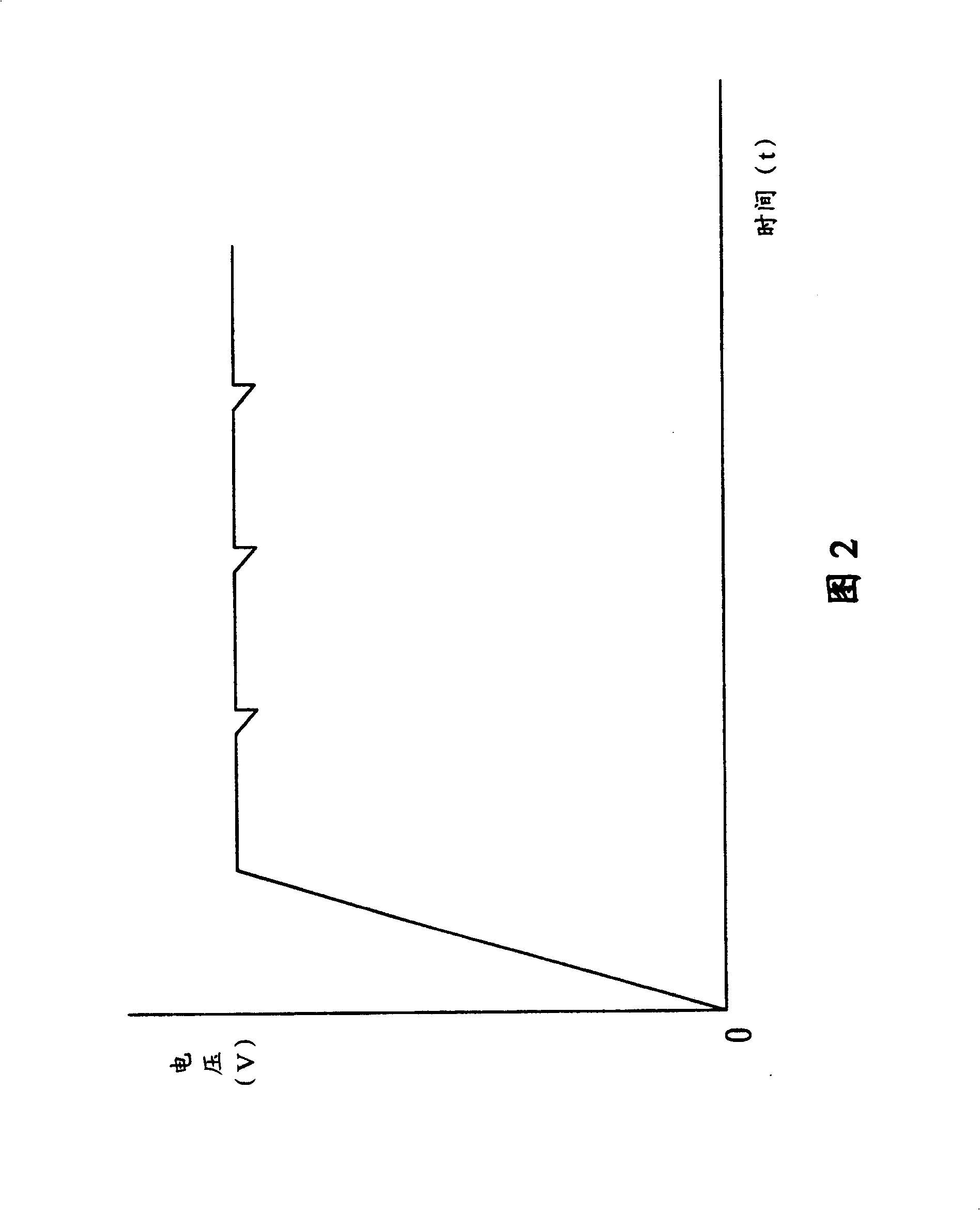

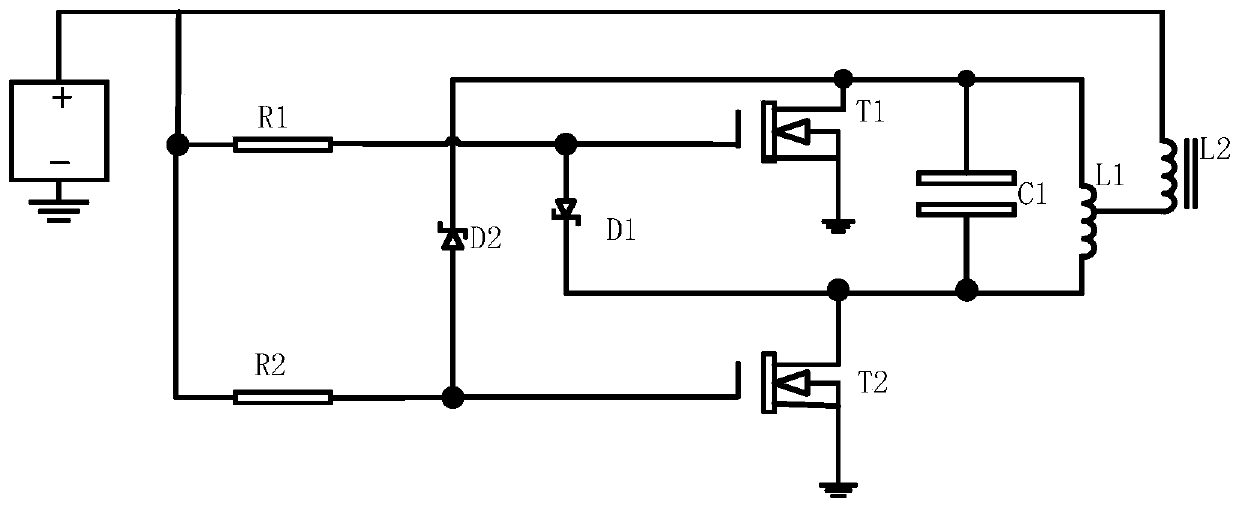

Locked phase active power current control circuit

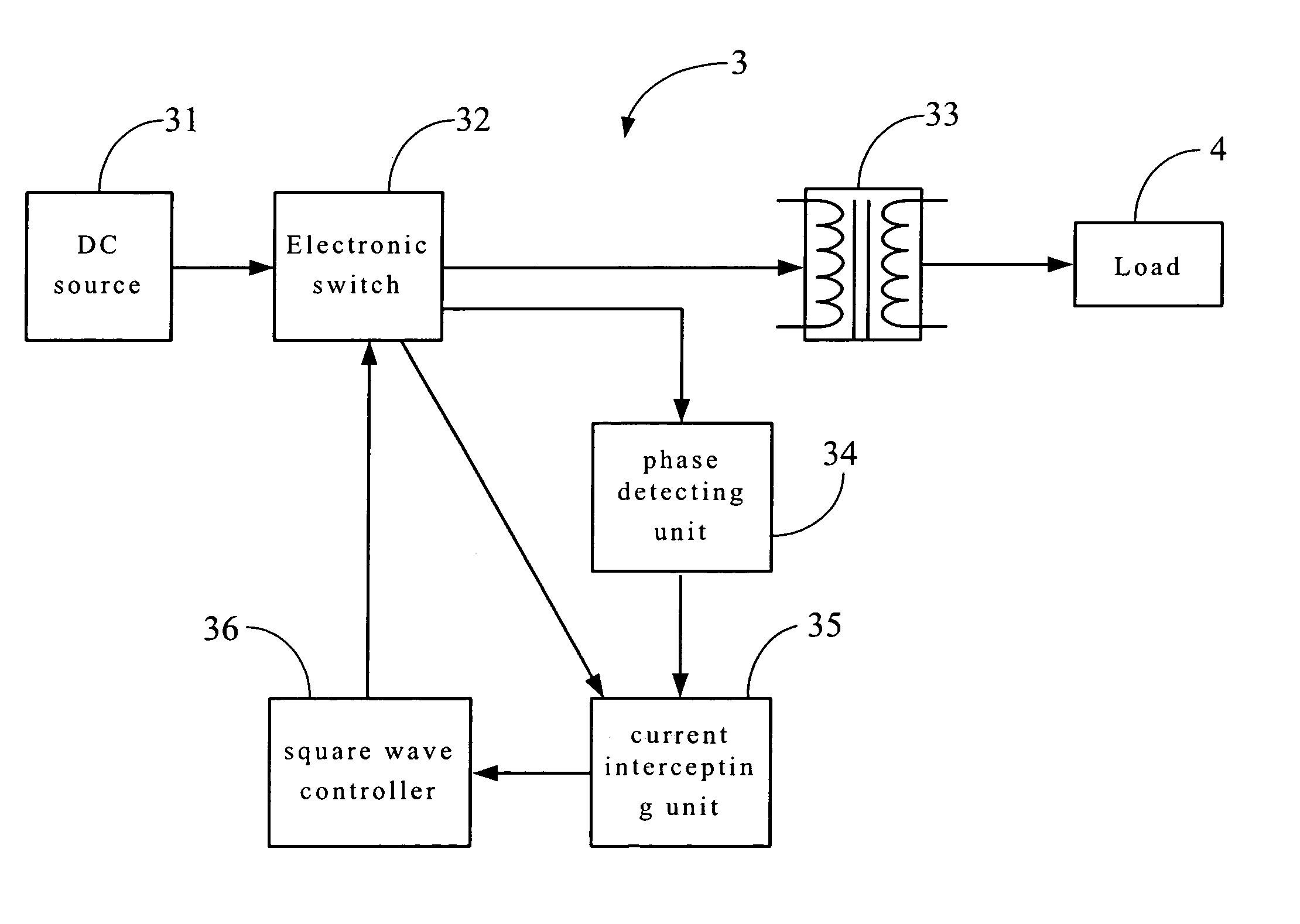

InactiveUS20090079478A1Stable working frequencyStrong loadPulse automatic controlStatic indicating devicesSquare waveformTransformer

The locked phase active power current control circuit is composed of a DC source, an electronic switch, a driving transformer, a phase detecting unit, a current intercepting unit and a square wave controller. A DC signal provided by the DC source is converted into a square wave signal by the electronic switch for the driving transformer to operate a load. The electronic switch outputs the square wave signal to the phase detecting unit whereat a phase signal of the square wave is detected and the detected signal is transmitted to the current intercepting unit whereat the detected signal is compared with the current intercepted at the electronic switch, the driving transformer, or the load, and the comparison result is fed back to the square wave controller so as to set the operation frequency of the electronic switch. The essential principle of the present invention is based on the fact that the square wave is in phase with the first harmonic wave.

Owner:LOGAH TECH CORP

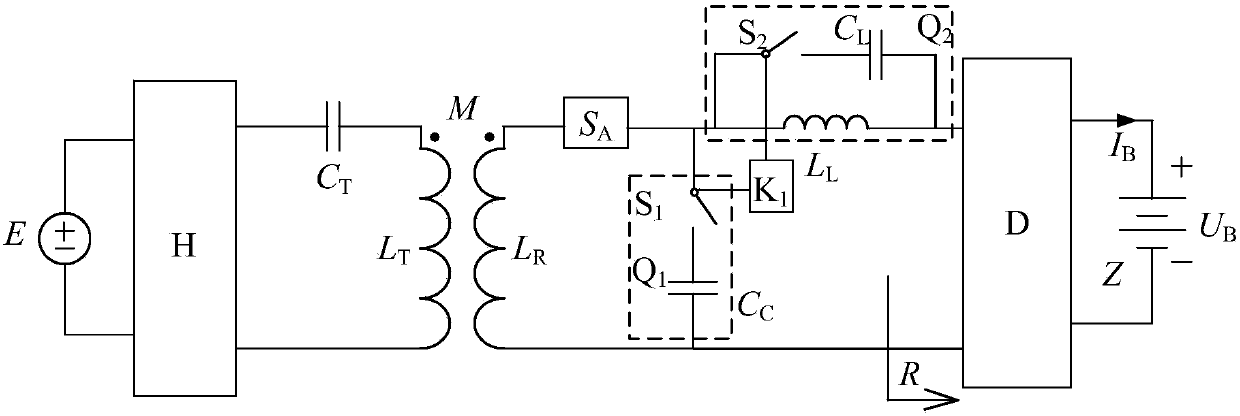

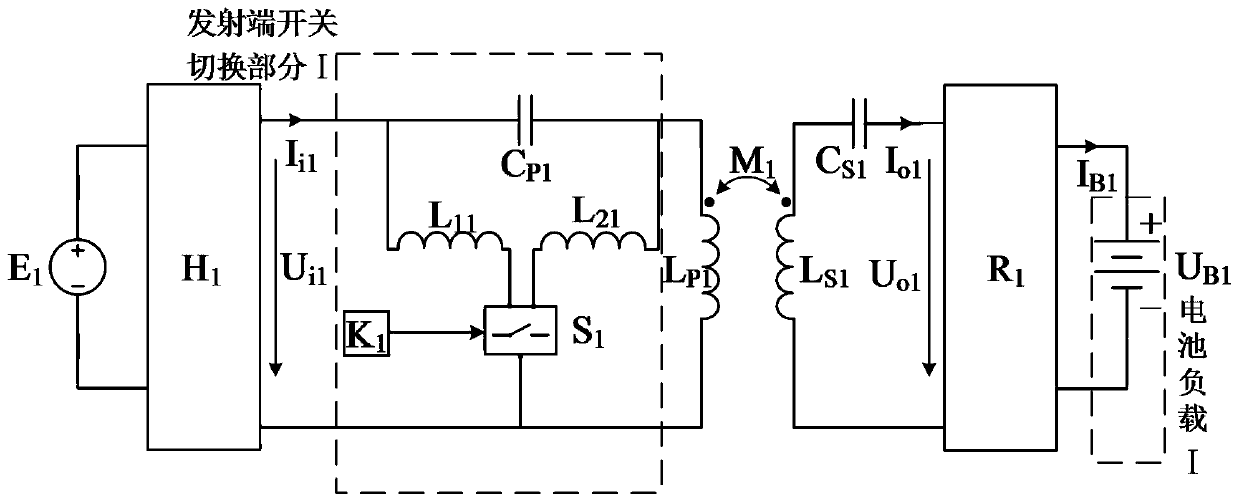

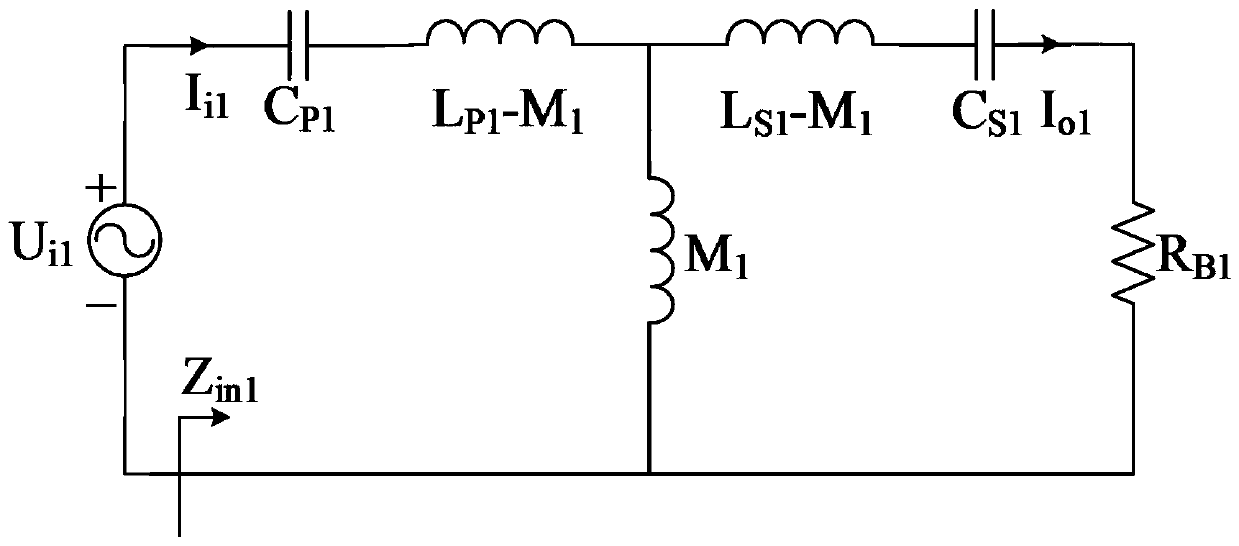

Constant-current constant-voltage wireless charging system based on topology switching

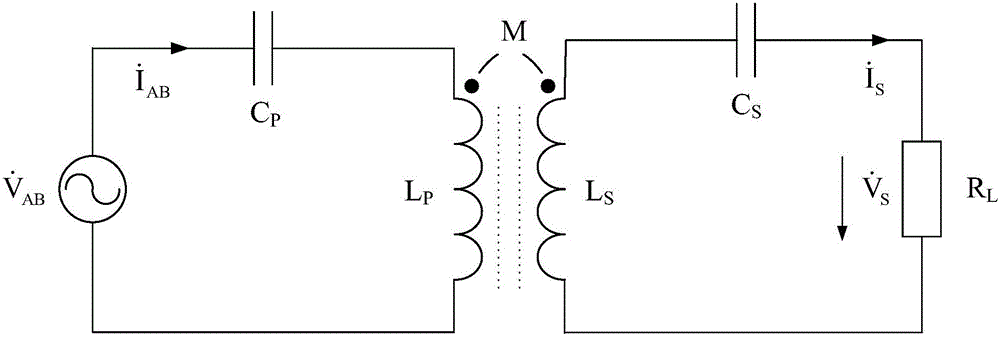

ActiveCN109980757ARealize switchingNo frequency bifurcationBatteries circuit arrangementsElectric powerZero phaseInductor

The invention discloses a constant-current constant-voltage wireless charging system based on topology switching, and belongs to the field of wireless charging. A switch switching part is disposed ina transmitting part or a receiving part, so that the system can switch between a constant-voltage characteristic and a constant-current characteristic, and is suitable for charging a battery. The switch switching part only has one AC switch and two additional inductors, thereby achieving a small number of components. The equivalent input impedance of the system is pure resistance in both constant-voltage and constant-current modes, namely, the switching device of a high-frequency inverter can work in a zero-phase switching mode in both constant-voltage and constant-current modes, which can effectively reduce the reactive power loss in the system.

Owner:SOUTHWEST JIAOTONG UNIV

A magnetron anode assembly and a magnetron provided with the magnetron anode assembly

ActiveCN106710999BStable working frequencyImprove welding qualityMagnetronsTransit-tube collectorsManufacturing cost reductionCapillary action

The invention relates to the technical field of magnetrons, in particular to a magnetron anode assembly and a magnetron provided with the magnetron anode assembly. The magnetron anode vane assembly provided by the present invention includes an anode cylinder and a plurality of anode vanes arranged in the anode cylinder, each anode vane is provided with at least one diversion groove, wherein at least one diversion groove is used to place the The melted solder on the upper surface of the vane is guided to the end where the anode vane is welded to the inner wall of the anode cylinder, so that when the anode vane and the anode cylinder are welded, the solder melts on the upper surface of the anode vane, and then passes through the capillary action and gravity of the melted solder Under the action of the guide groove, it flows to the welding place between the anode blade and the inner wall of the anode cylinder, avoiding the problem of welding failure between the anode blade and the anode cylinder caused by the accumulation of solder on the upper surface of the anode blade, and making the working frequency of the magnetron more stable. The welding quality of the anode vane and the anode cylinder is higher, the success rate of welding is improved, and the manufacturing cost is reduced.

Owner:GUANGDONG WITOL VACUUM ELECTRONICS MFR

Excited state atom filter receiving device for pumping laser atom frequency stabilization

ActiveCN102709802BStable working frequencyImprove transmittanceLaser detailsFrequency stabilizationPhotovoltaic detectors

The invention discloses an excited state atom filter receiving device for pumping laser atom frequency stabilization. The device consists of a receiving telescope (1), an atom filter unit (2), a first photoelectric detector (3) and an atom frequency stabilization pumping laser unit (4). Resonance fluorescence generated by atoms is used for carrying out feedback frequency stabilization on a pumping laser, the work frequency of the pumping laser is stable without drifting, and further, low excited state atom number density and super-fine energy level distribution is stable, so the transmission spectrum type stability and the transmittance of an excited state atom filter are improved.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

Method for controlling freezing capacity of a variable-frequency freezing AC ice-water system

InactiveUS8733115B2Save electricityReduce capacityMechanical apparatusSpace heating and ventilation safety systemsIce waterPeak value

A method for controlling freezing capacity of a variable-frequency freezing AC ice-water system separates the freezing capacity of each individual requirement end so as to reduce sudden or peak concentrating freezing demand and relieve variable-frequency load demand, and defines operating procedures corresponding to different requirement ends, respectively, wherein each of the operating procedures has a corresponding high-low temperature range that can be used as a temperature buffer zone so as to redistribute supply of the freezing capacity to each requirement end, thereby allowing the compressors thereof to operate smoothly and thus achieve energy saving as a result. The drawbacks of damaged pipelines are overcome that cause deficiency in freezing capacity as encountered in prior techniques.

Owner:CHUNGHWA TELECOM CO LTD

Ignition circuit of separately-excited arc lighter

The invention relates to an ignition circuit of a separately-excited arc lighter. The ignition circuit comprises a direct-current power supply, a square wave generating circuit, a first driving and voltage boosting circuit and a first discharging needle, wherein the first driving and voltage boosting circuit comprises a power switch tube and a high-voltage transformer, a winding of the high-voltage transformer consists of a low-voltage winding and a high-voltage winding, and the power switch tube and the low-voltage winding in the high-voltage transformer are connected in series and then are connected to the two ends of the direct-current power supply; the first discharging needle is connected with the output end of the high-voltage winding, and a first driving branch is connected between the output end of the square wave generating circuit and the control end of the power switch tube; the power switch tube is disconnected and connected under the control of the output of the square wave generating circuit through the first driving branch, so that the current on the low-voltage winding is controlled. Due to the adoption of the separately excited driving mode, the ignition circuit is stable in work frequency, low in noise, large in instant starting power, easy to realize arc striking and reliable in work. Besides, the winding of the high-voltage transformer only consists of the low-voltage winding and the high-voltage winding, so that the production cost and the defective rate of the high-voltage transformer are reduced, and massive production is facilitated.

Owner:CITY COLLEGE WENZHOU UNIV

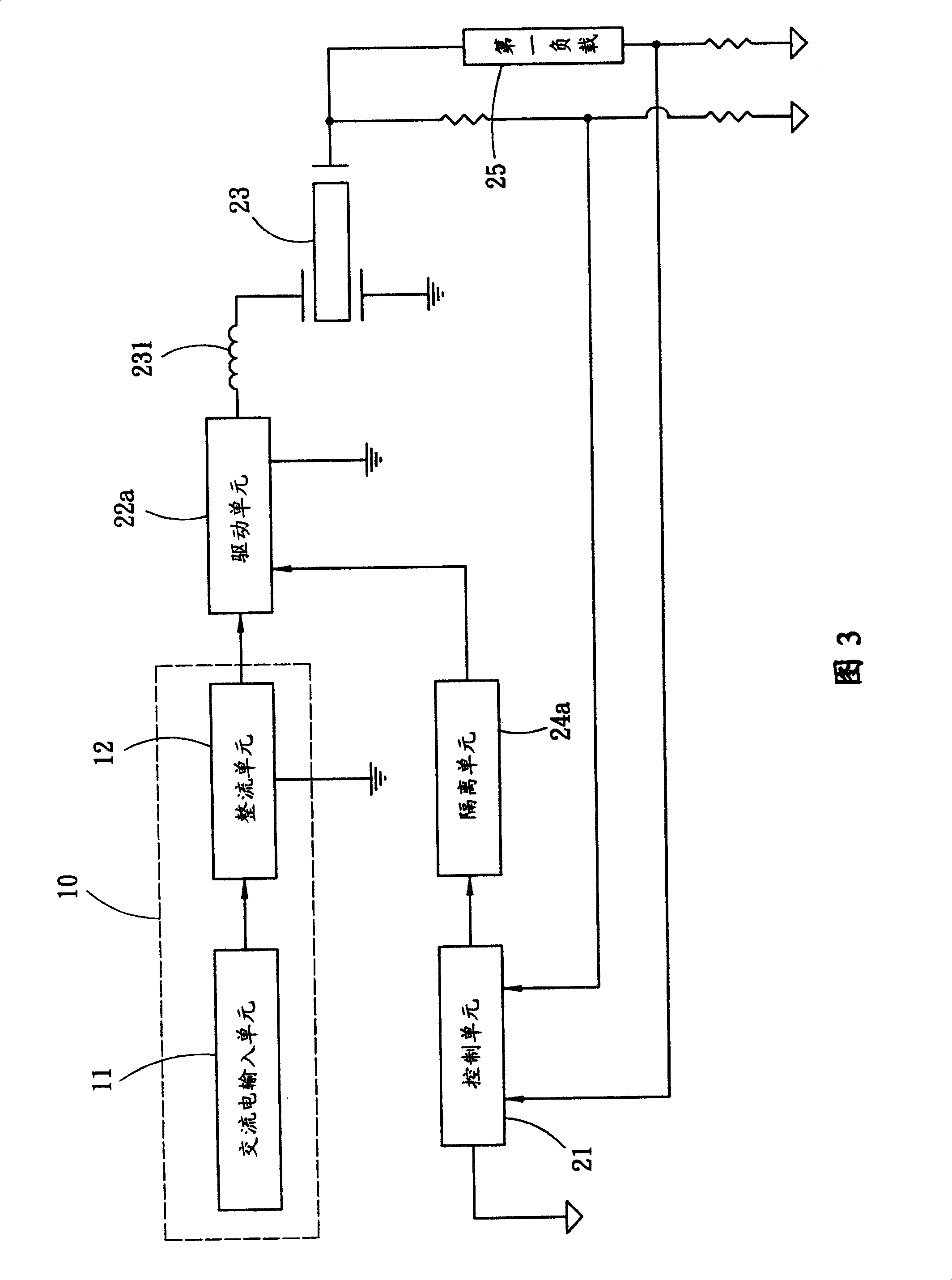

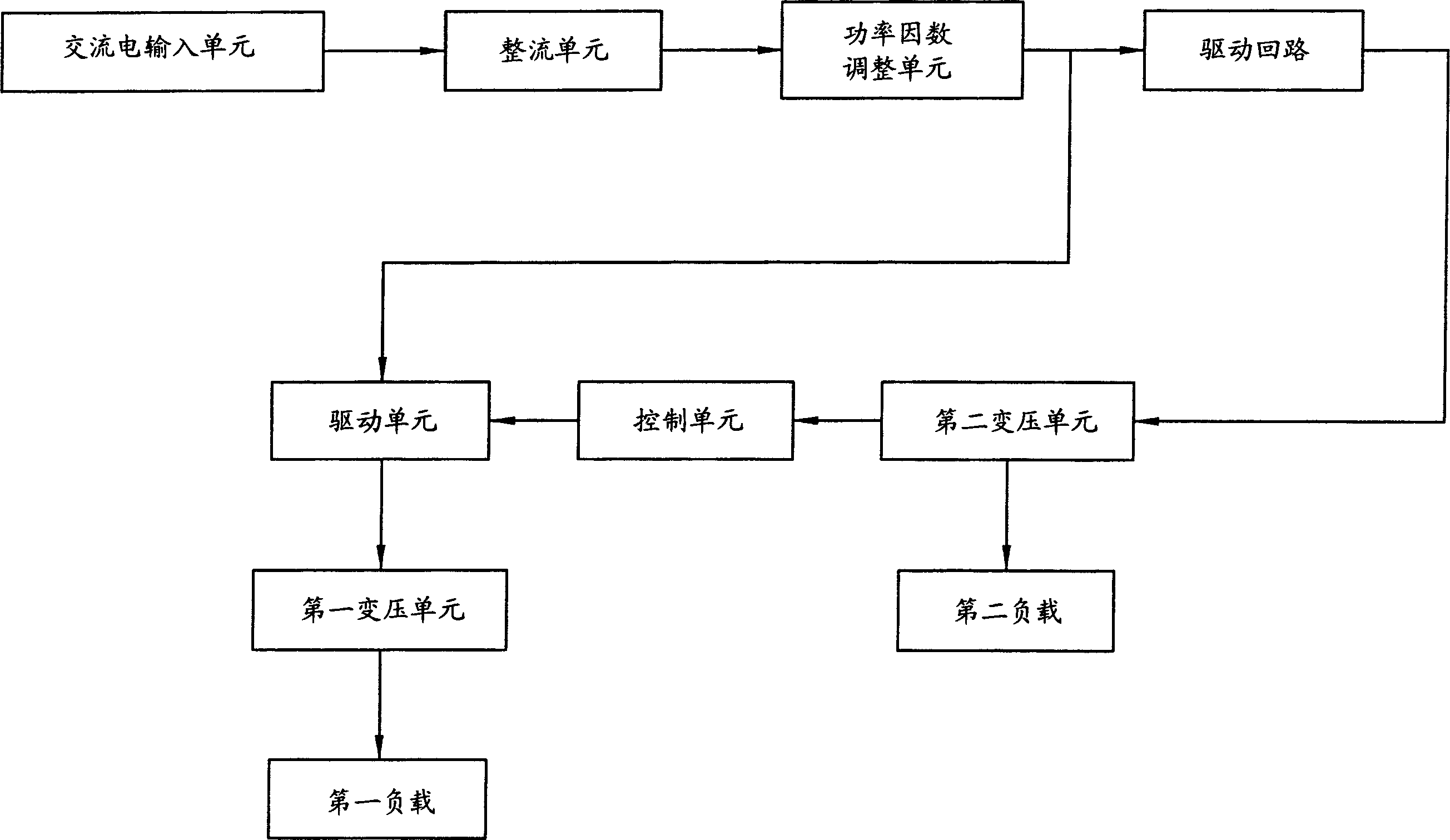

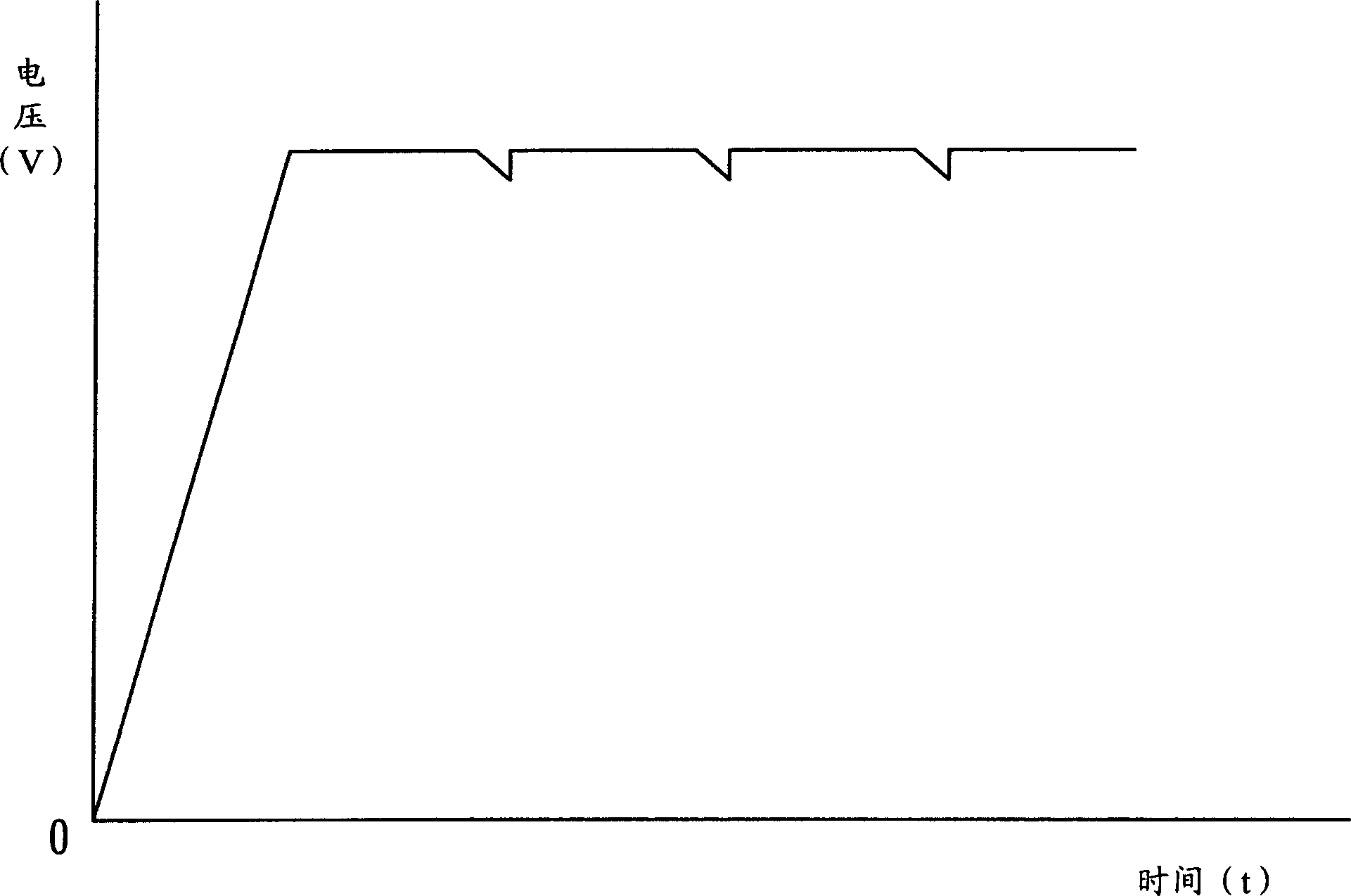

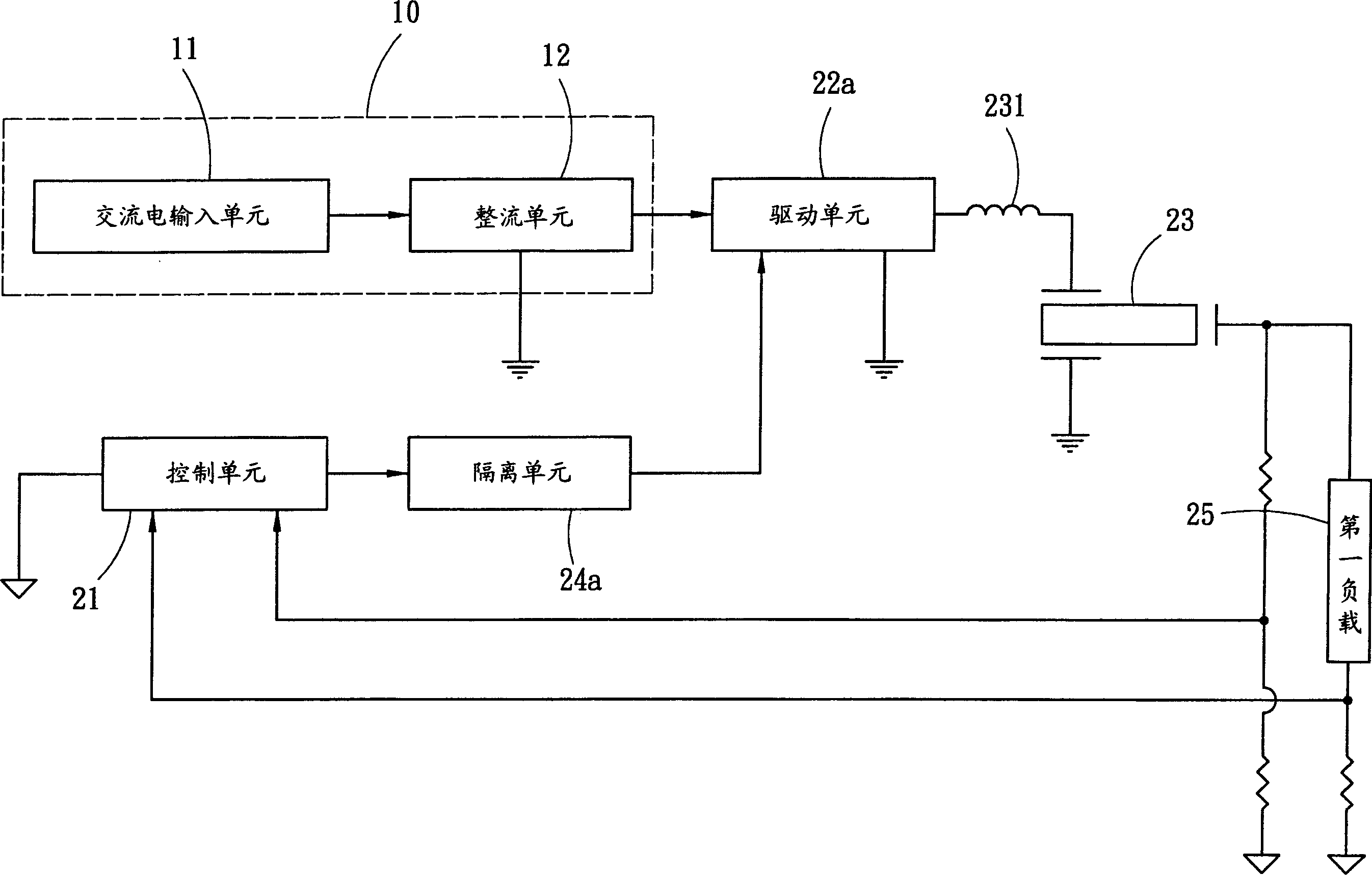

Inverter circuit for suppressing electric power conducted interference

InactiveCN100428322CStable working frequencyAvoid flickeringStatic indicating devicesElectric power systemReverse current

The invention discloses a reverse current device circuit to inhibit power conducted interference. Wherein, receiving output signal from power input circuit, outputting operating frequency; using a drive unit to receive said frequency and cut signal and output drive signal; using a transformation unit to receive said drive signal and take power conversion to drive first load action; arranging an isolation unit between drive and control units to divide grounding type of drive unit and control unit as non-share grounding with first and secondary sides of transformation unit. Thereby, the control unit outputs stable operating frequency and realize inhibiting effect.

Owner:ZIPPY TECH

An Inductive Wireless Charging System with Secondary Variable Parameters and Variable Structure

ActiveCN107069983BNo frequency bifurcationStable jobElectric powerArrangements for several simultaneous batteriesCapacitanceControl engineering

The invention discloses an inductive wireless charging system capable of changing the secondary structure and parameters. According to the invention, a constant-current constant-voltage switching circuit I and a constant-current constant-voltage switching circuit II are arranged in a receiving portion, a secondary constant-voltage compensation capacitor is connected with a change-over switch I in series, and a control end of the change-over switch I is connected with a controller I; the constant-current constant-voltage switching circuit II is formed by connecting a secondary constant-current compensation capacitor and a change-over switch II in series, and a control end of the change-over switch II is connected with the controller I. The invention further discloses a second implementation scheme which is slight different from the scheme at the control end. The inductive wireless charging system with the structure disclosed by the invention not only can output constant current, but also can output constant voltage, thereby being applicable to charging a battery, especially being applicable to charging multiple loads under a single power supply; The inductive wireless charging system is convenient to control, stable in operation, simple in structure, low in requirement for the capacity of an inverter and low in manufacturing cost, the input impedance is purely resistive in the whole process, input of reactive power can be avoided, and the system efficiency can be improved.

Owner:SOUTHWEST JIAOTONG UNIV

Inverter circuit for suppressing electric power conducted interference

InactiveCN1755784AStable working frequencyAvoid flickeringStatic indicating devicesReverse currentEngineering

The invention discloses a reverse current device circuit to inhibit power conducted interference. Wherein, receiving output signal from power input circuit, outputting operating frequency; using a drive unit to receive said frequency and cut signal and output drive signal; using a transformation unit to receive said drive signal and take power conversion to drive first load action; arranging an isolation unit between drive and control units to divide grounding type of drive unit and control unit as non-share grounding with first and secondary sides of transformation unit. Thereby, the control unit outputs stable operating frequency and realize inhibiting effect.

Owner:ZIPPY TECH

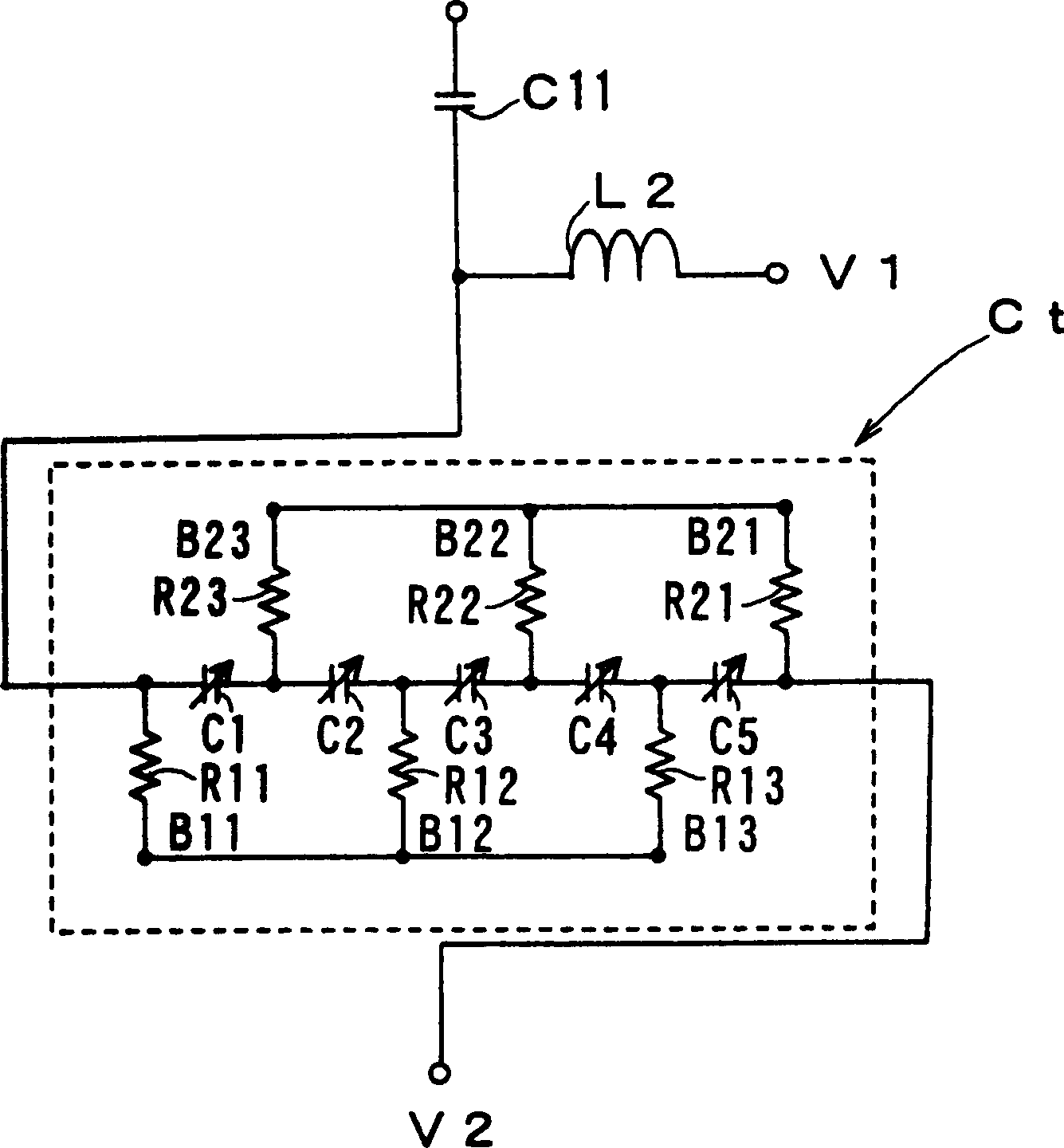

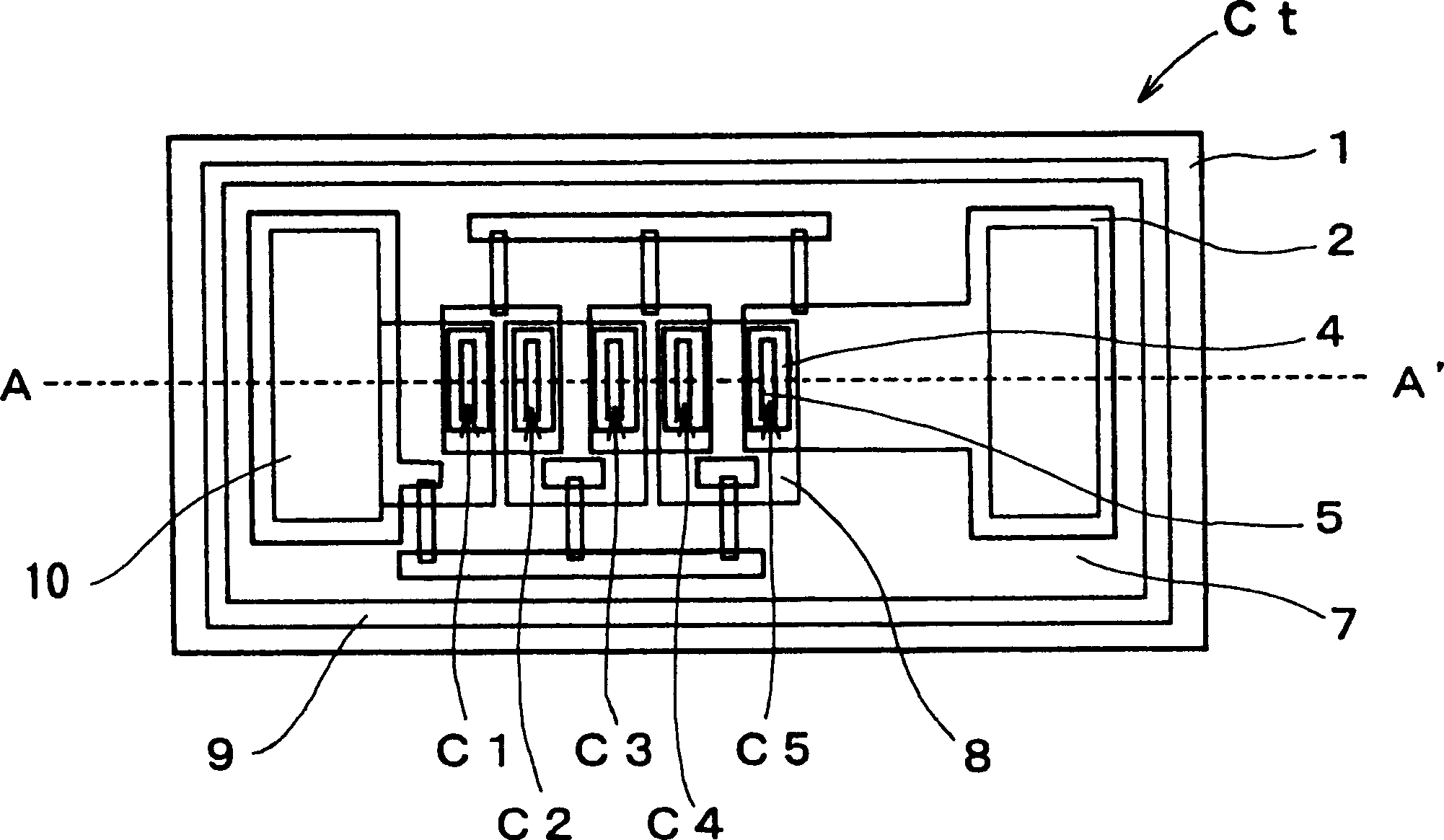

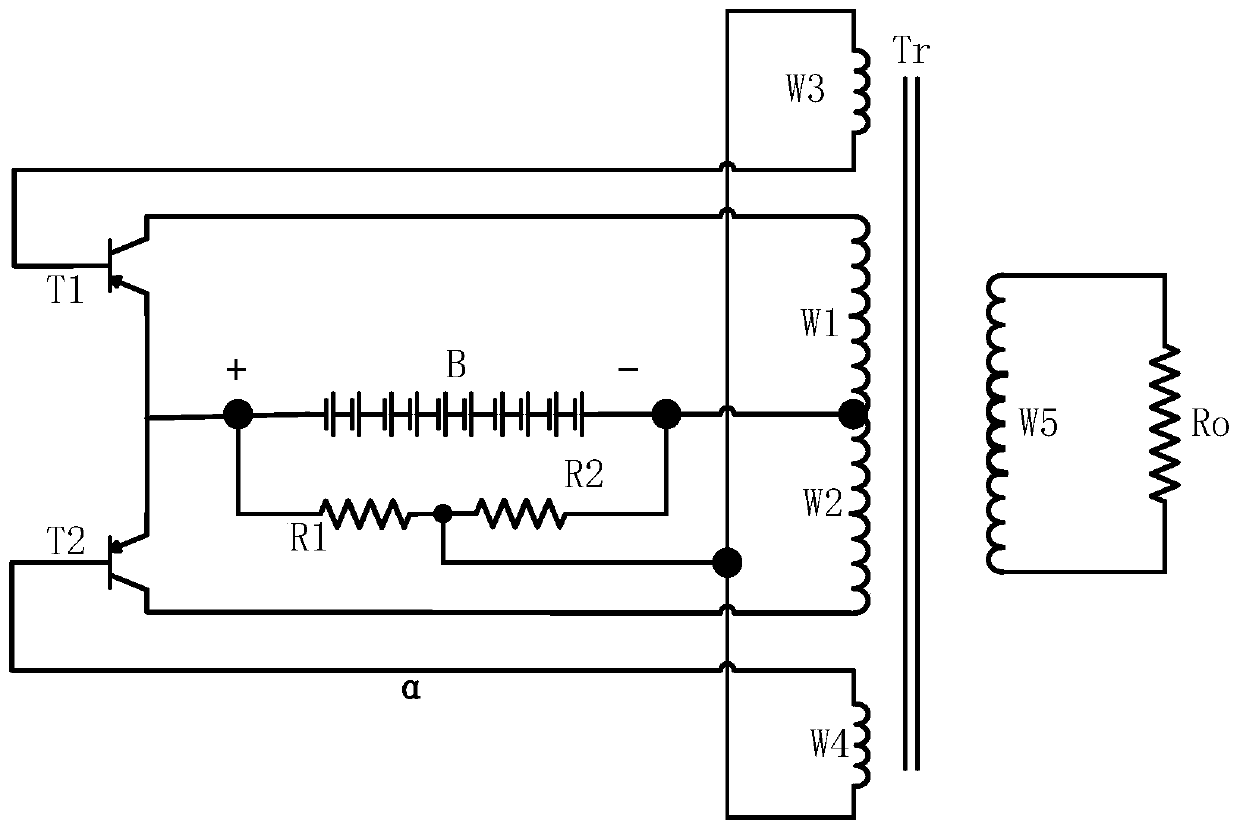

Complementary symmetrical self-excited push-pull converter

PendingCN110932581AImprove consistencySmall influence of high frequency inductanceAc-dc conversionCapacitanceTransformer

The invention relates to a complementary symmetrical self-excited push-pull converter. The converter comprises a direct-current power supply V1, a capacitor C1, a resistor R1, a resistor R2, an NPN transistor Q1, an NPN transistor Q2, a resistor R3, a resistor R4, a capacitor C2, a capacitor C3, an NPN transistor Q3, an NPN transistor Q4, a high-frequency transformer T and a filter inductor Lf. The complementary symmetrical self-excitation push-pull converter disclosed by the invention has the following beneficial effects: 1, the consistency of products produced in batches is good, and the influence of high-frequency inductance is small; 2, the working frequency of the switching tube is stable; 3, the self-oscillation frequency can be designed to be relatively high, and correspondingly, the size of the high-frequency transformer is reduced, so that the cost is reduced; and 4, due to the driving of the independent self-excited oscillation circuit, the working power of the switching tubecan be selected to be greater.

Owner:雷博塔斯(广州)科技有限公司

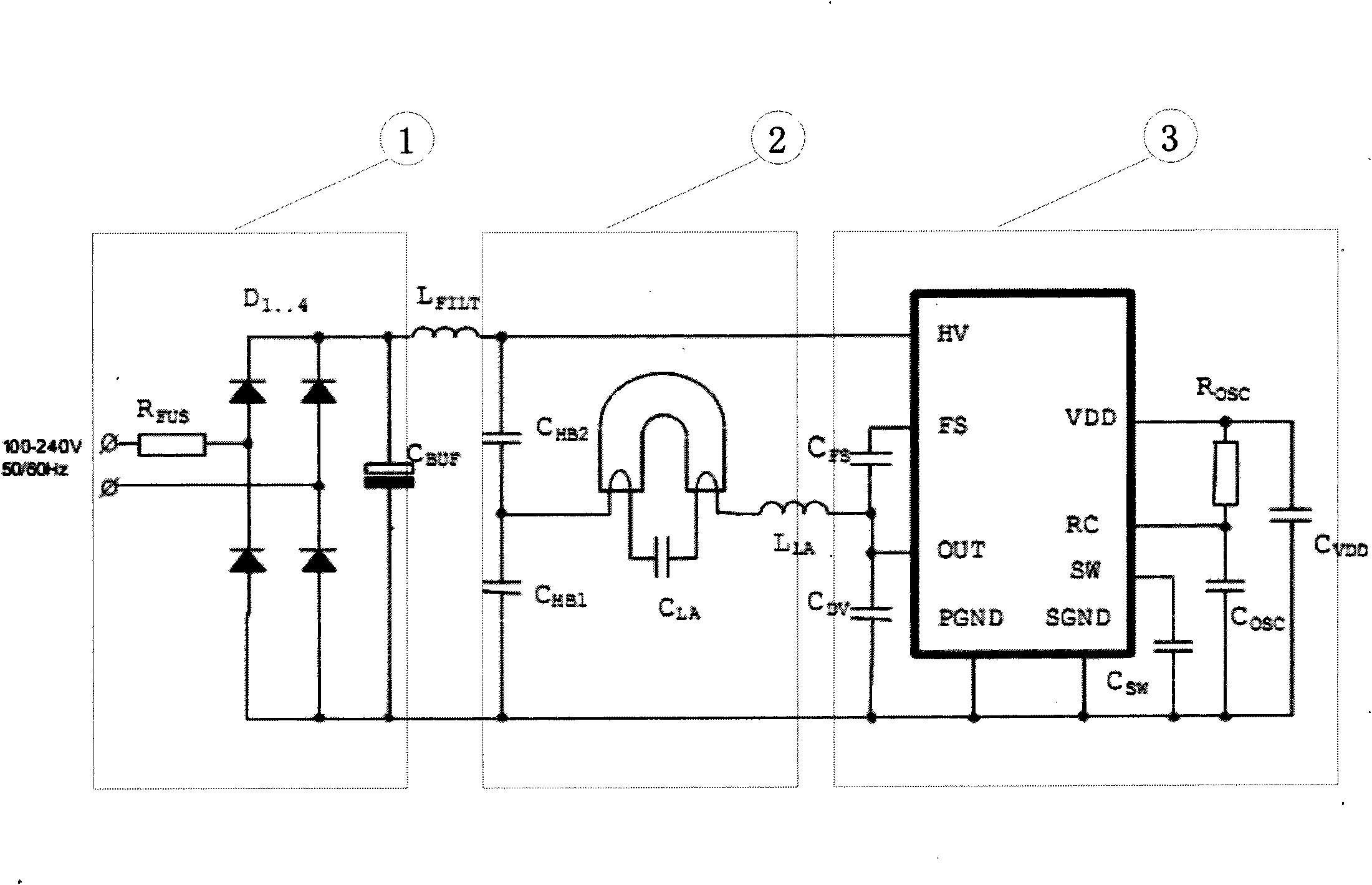

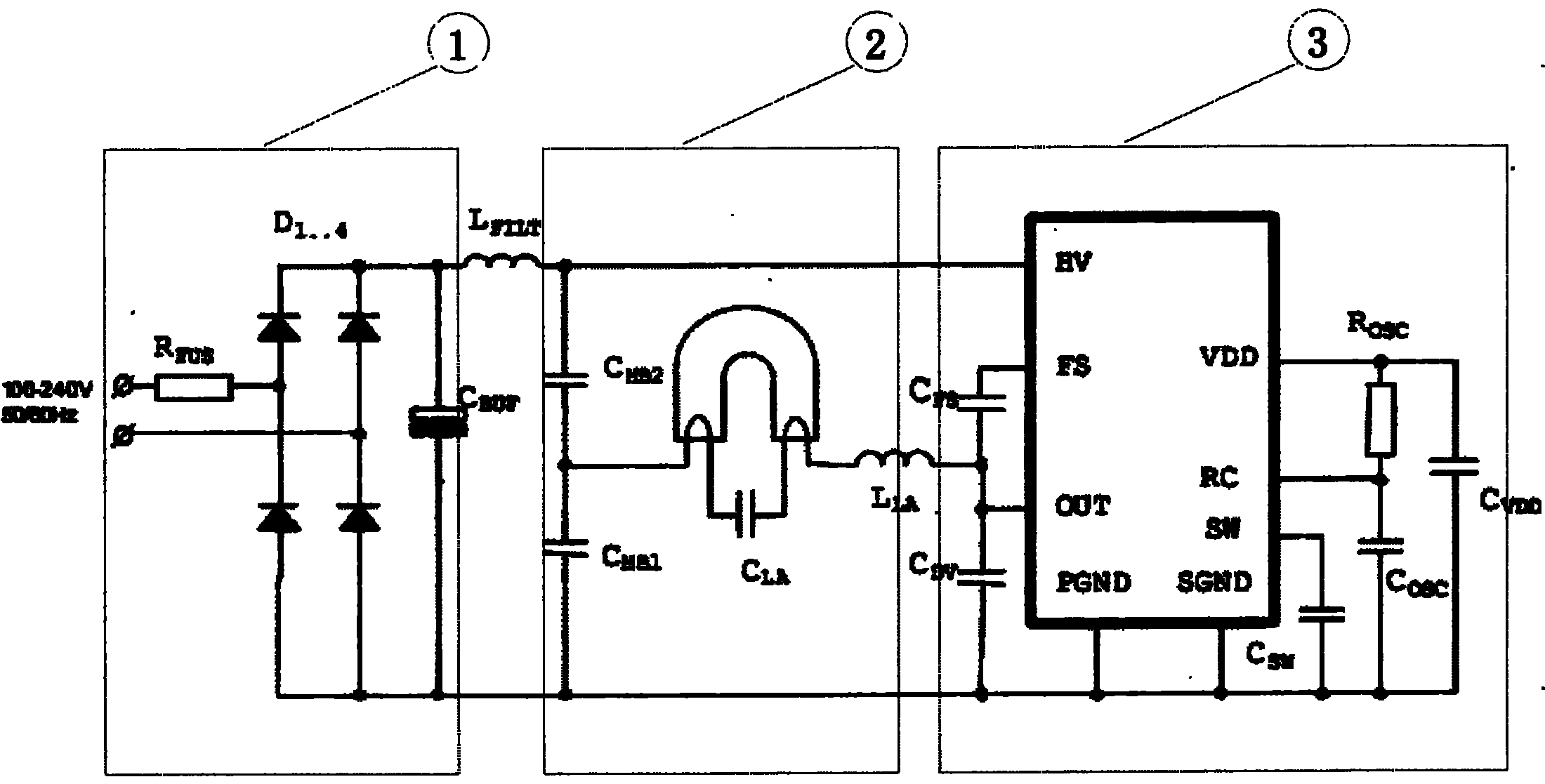

Digital energy-saving lamp circuit

InactiveCN101835323APromote healthy developmentStable working frequencyElectrical apparatusElectric lighting sourcesSelf excitedLow voltage

The invention relates to the technical field of energy-saving lamp circuits, in particular to a digital energy-saving lamp circuit. The circuit comprises a rectifier circuit used for converting an alternating current into a direct current and an inverting circuit used for converting the direct current into the alternating current for starting an energy-saving lamp tube, and is characterized by also comprising a control circuit, wherein the control circuit comprises two half-bridge power transistors, a level shifter, a power tube driver, a bootstrap circuit, an internal low-voltage power supply, a self-excited oscillator and starting and frequency-sweeping functions required by soft start and preheating; and the inverting circuit is connected with the power output end of a 2024 integrated circuit. As the integrated circuit generates a driving signal for the internal self-excited oscillator, the frequency is very stable. The power tube runs in an alternate mode, so that the power tube has longer relative service life.

Owner:石茂林

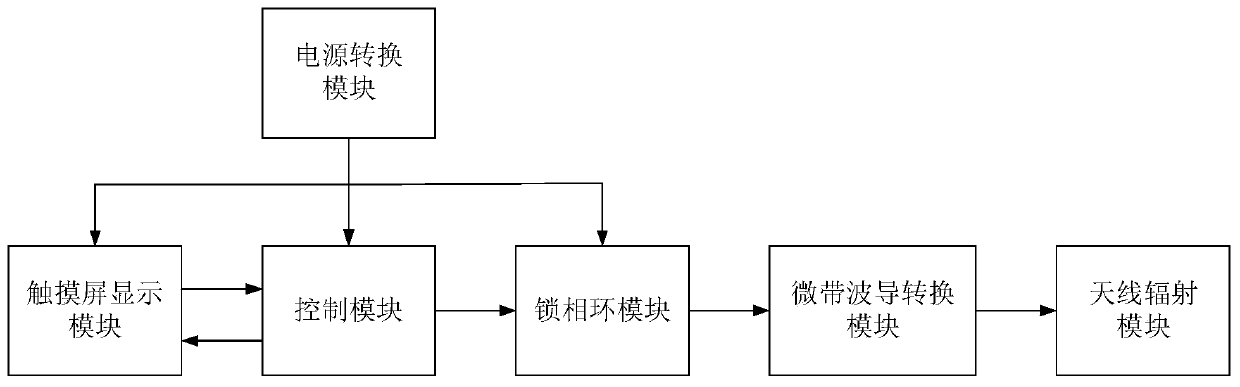

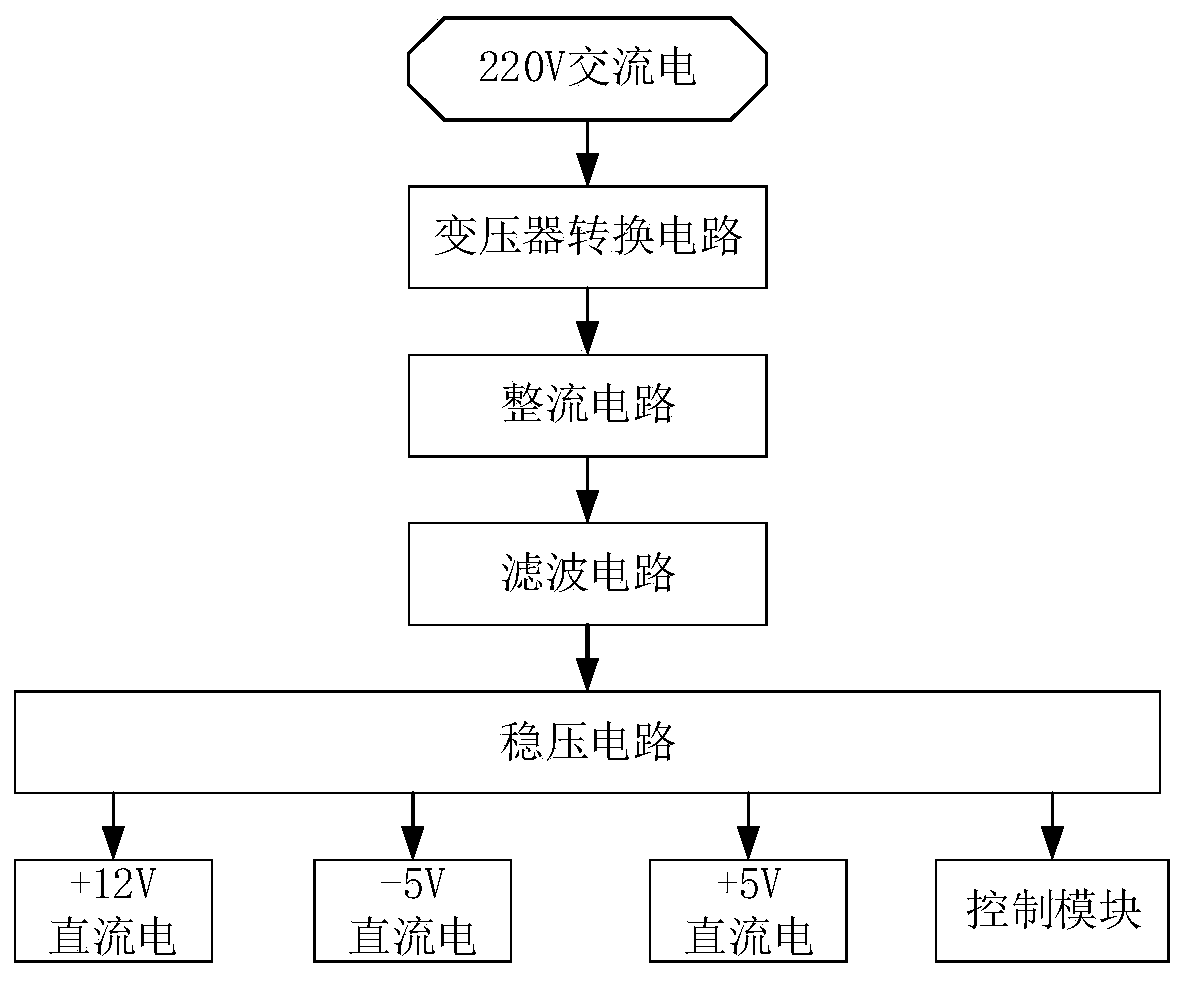

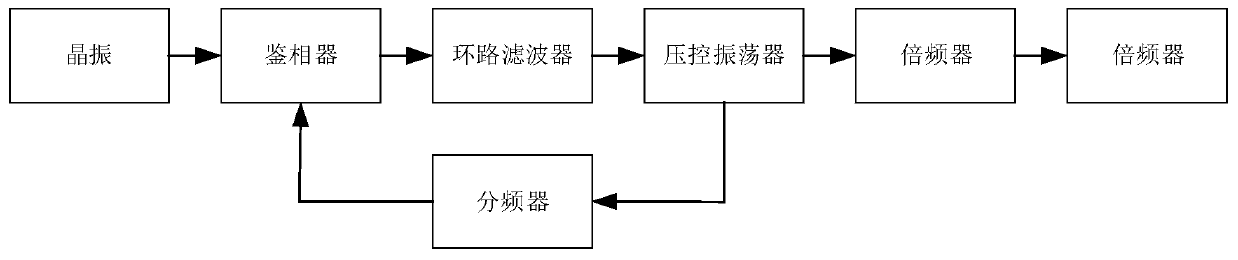

A millimeter wave therapy device

ActiveCN107485793BStable working frequencyEasy transferRadiation therapyTherapeutic effectEngineering

The invention relates to a medical device and particularly relates to a millimeter wave therapeutic instrument which comprises a power conversion module, a control module, a phase-locked loop module, a micro strip waveguide conversion module and an antenna radiation module. The power conversion module is connected to the control module and provides operating voltage for the control module. The control module is connected to the phase-locked loop module and controls the phase-locked loop module to generate a frequency signal. The phase-locked loop module is connected to the antenna radiation module through the micro strip waveguide conversion module. The frequency signal is transmitted to the antenna radiation module via the micro strip waveguide conversion module to form millimeter waves. The millimeter wave therapeutic instrument provided by the invention is provided with the phase-locked loop module, the stability of outputting the millimeter waves by the millimeter wave therapeutic instrument is improved, and a treatment effect of ensured. At the same time, the loss of a millimeter wave signal generated by the phase-locked loop module is reduced, a higher mode is restrained well, and the transmission of the millimeter wave signal generated by phase-locked loop module is facilitated.

Owner:XIDIAN UNIV

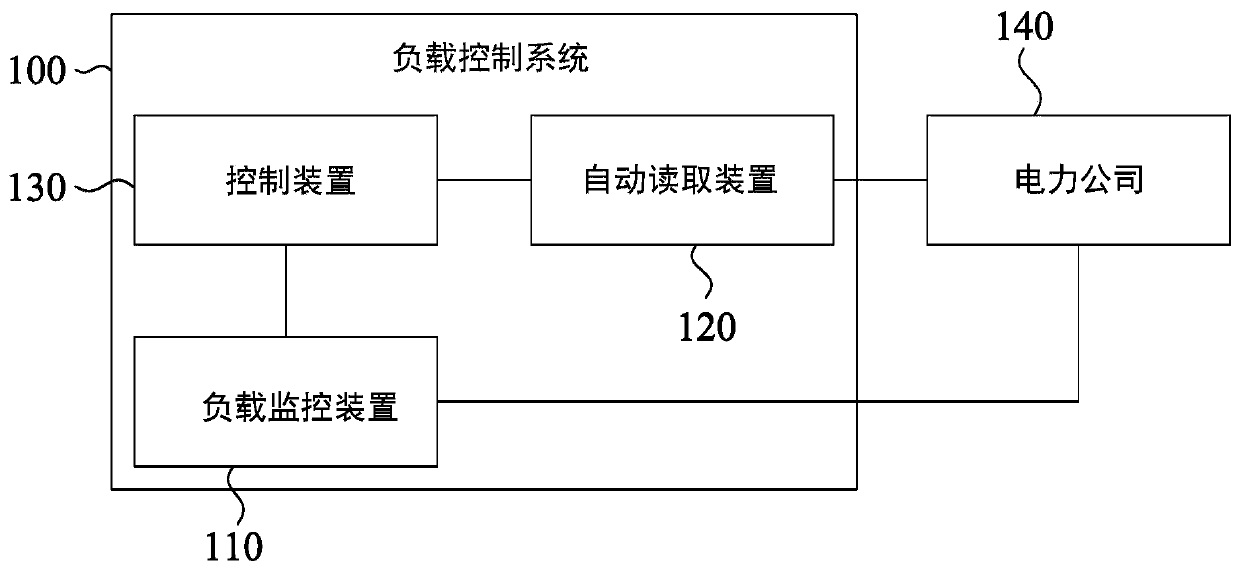

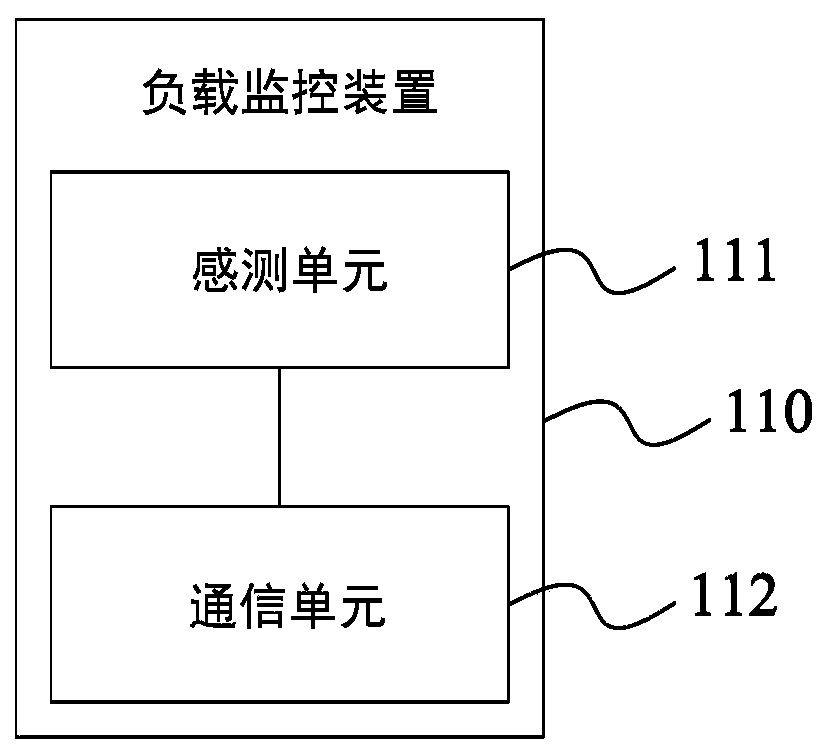

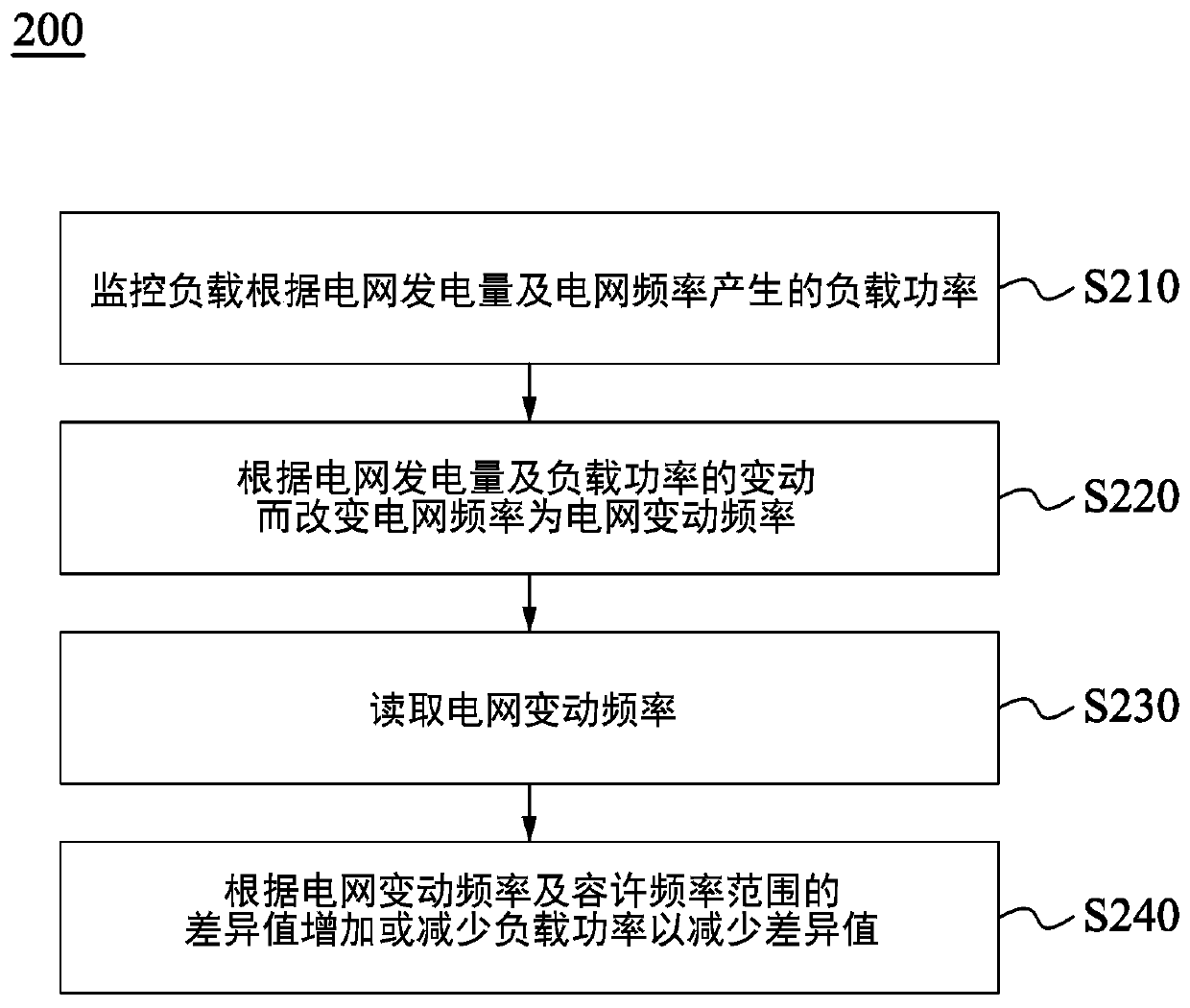

Load control system and load control method

ActiveCN111181173AVariance value reductionStable working frequencyEfficient power electronics conversionSingle network parallel feeding arrangementsControl systemPower grid

The present disclosure relates to a load control system and a load control method. The load control system includes a load monitoring device, an automatic reading device, and a control device. The load monitoring device is configured to monitor the load power generated by the load according to the power generation amount of a power grid and the grid frequency, and the grid frequency is changed tothe grid change frequency according to the change of the grid power generation amount and the load power. The automatic reading device is configured to read the grid change frequency. The control device is configured to increase or decrease the load power according to a difference between an allowable frequency range and the grid change frequency to reduce the difference.

Owner:AU OPTRONICS CORP

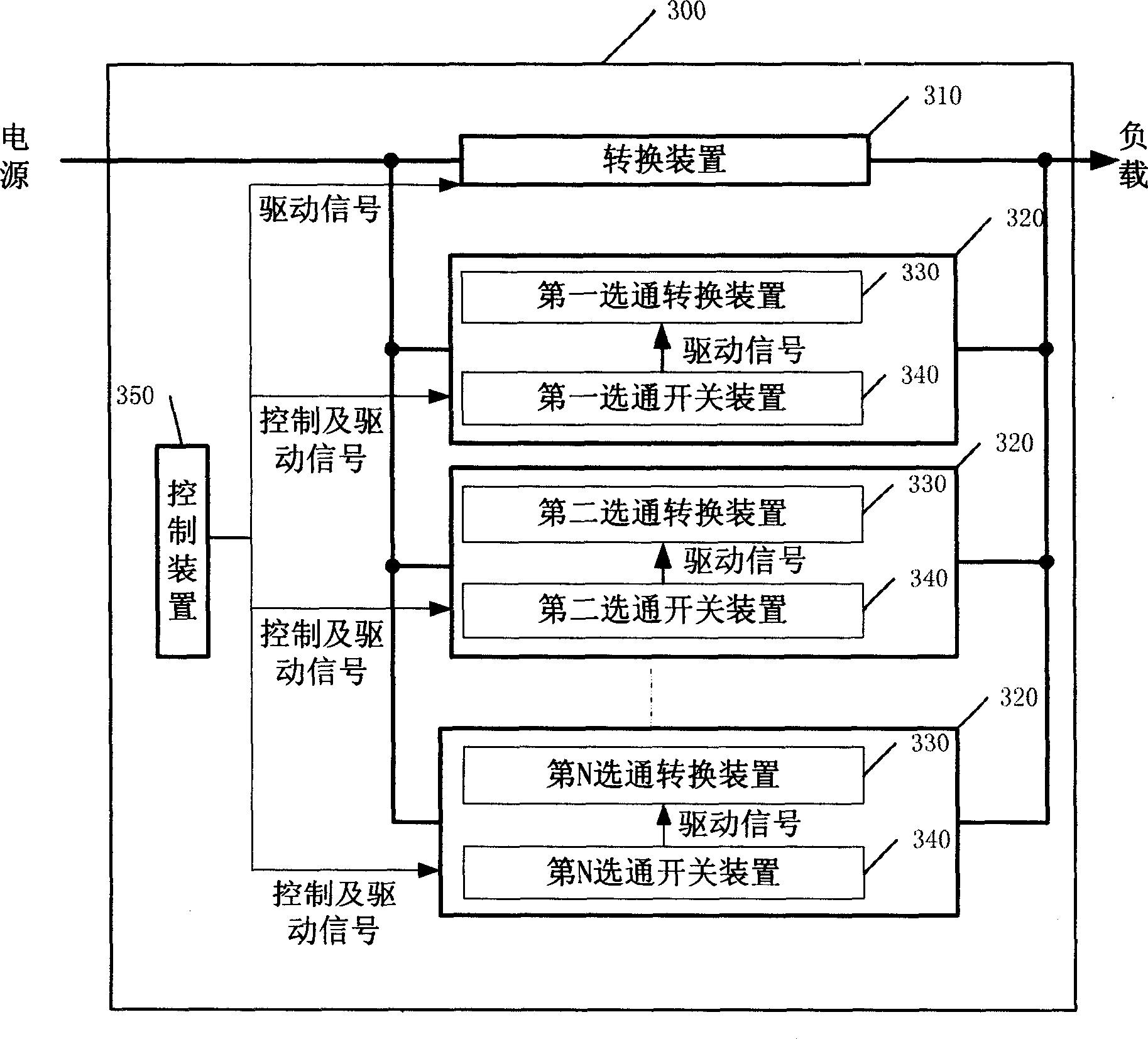

Power supply converting circuit system

InactiveCN1652444AStable working frequencyEasy to controlAc-dc conversion without reversalEngineeringOperating frequency

Operating together one or more strobe units turned on by stepping selection and conversion device, making operation of power supply change over undertaken by conversion device become stable relatively so as to make operation frequency of power supply change over system become stable. Thus, designing relevant circuits is easier than before.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

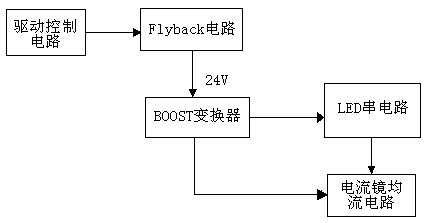

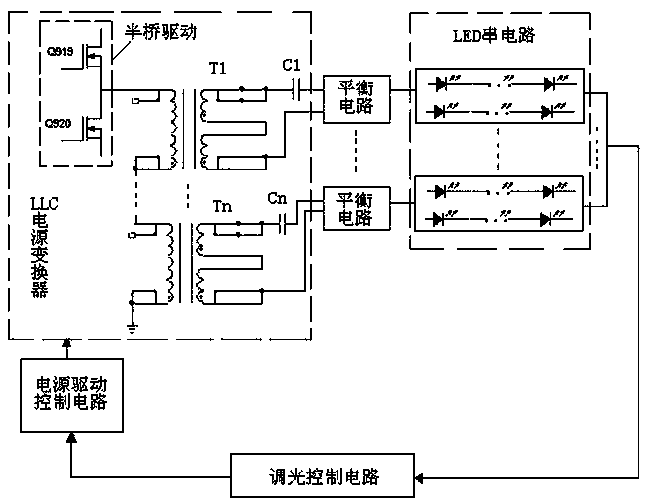

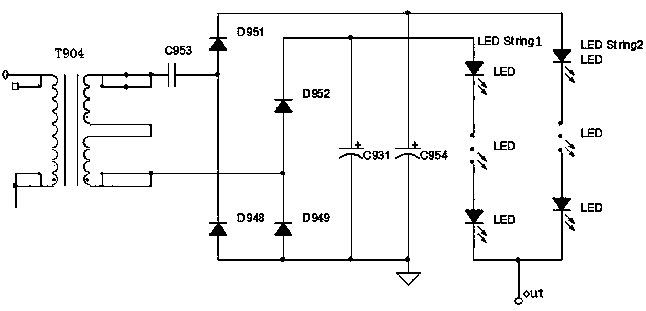

Highly-efficient drive circuit of light emitting diode (LED) Light Bars

InactiveCN102665347BStable working frequencyAvoid back and forthElectric light circuit arrangementCapacitanceTransformer

The invention relates to a highly-efficient drive circuit of light emitting diode (LED) Light Bars. The drive circuit is characterized by comprising a half-bridge driver of a logical link control (LLC) power converter, wherein the output end of the half-bridge driver is connected with a loop which consists of an integral number of primary serial transformers; and a first end of a secondary winding of each transformer is connected in series with a blocking capacitor and provides power for an LED light set through an LED voltage difference balance circuit, the LED light set is formed by parallelly connecting a first LED string and a second LED string, the output end of the LED light set is connected with a dimming control circuit, and the output end of the dimming control circuit is connected with the LLC power converter through a power drive control circuit. According to the highly-efficient drive circuit of the LED Light Bars, the output of a main power circuit is used for directly driving each LED Light Bar, and the phenomenon that the output of the main power circuit in the conventional framework is required to pass through one stage of direct current / direct current (DC / DC) booster converter at first and then drive each LED light string is avoided.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com