Synchronous control method and circuit of electromagnetic stove

A synchronous control, induction cooker technology, applied in induction heating control, induction heating and other directions, can solve the problems of hardware synchronous circuit deviating from the resonant frequency of LC oscillation circuit, easily damaged switch tube IGBT, complicated circuit debugging, etc., to achieve stable working frequency and debugging. Convenient, simple circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

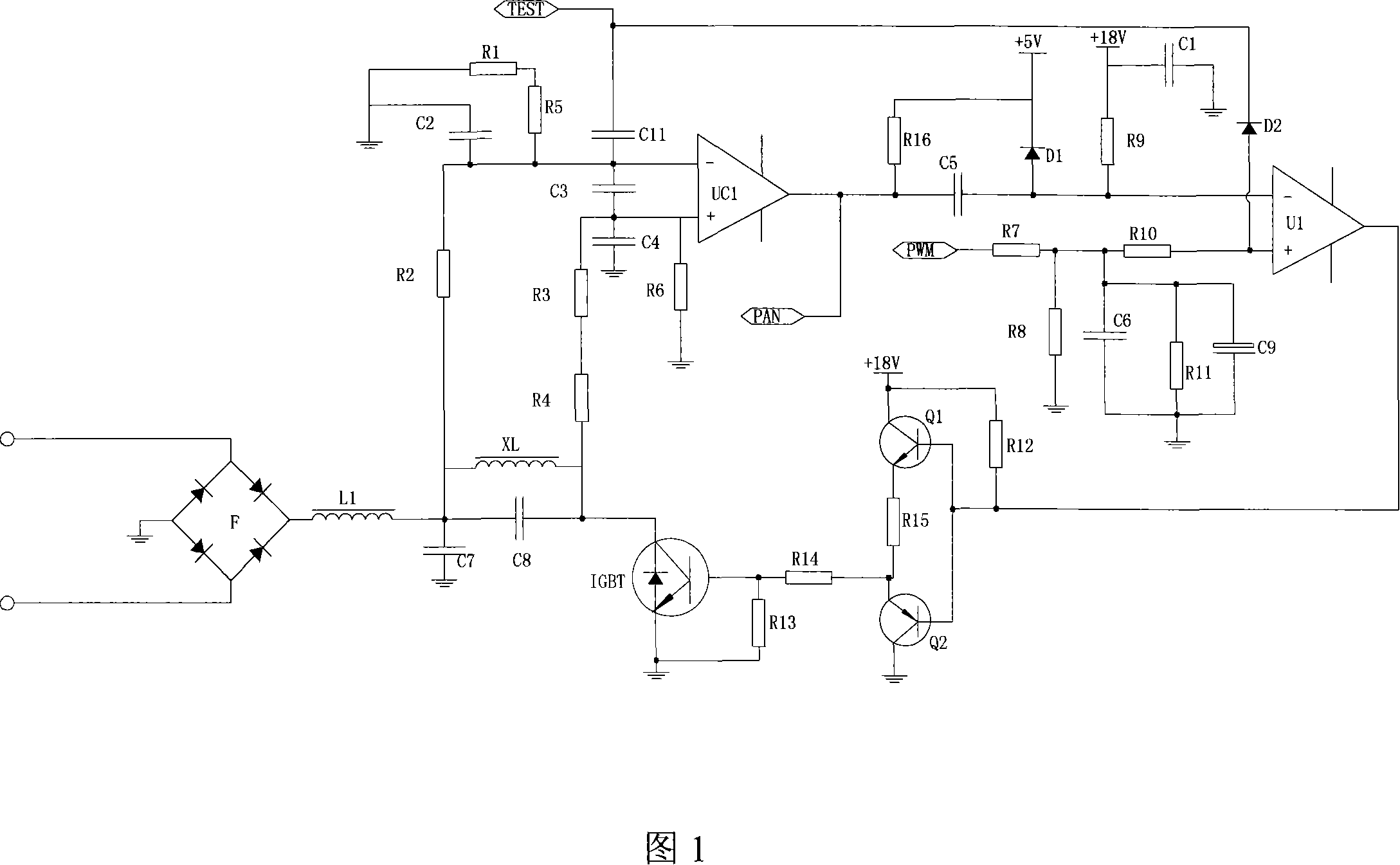

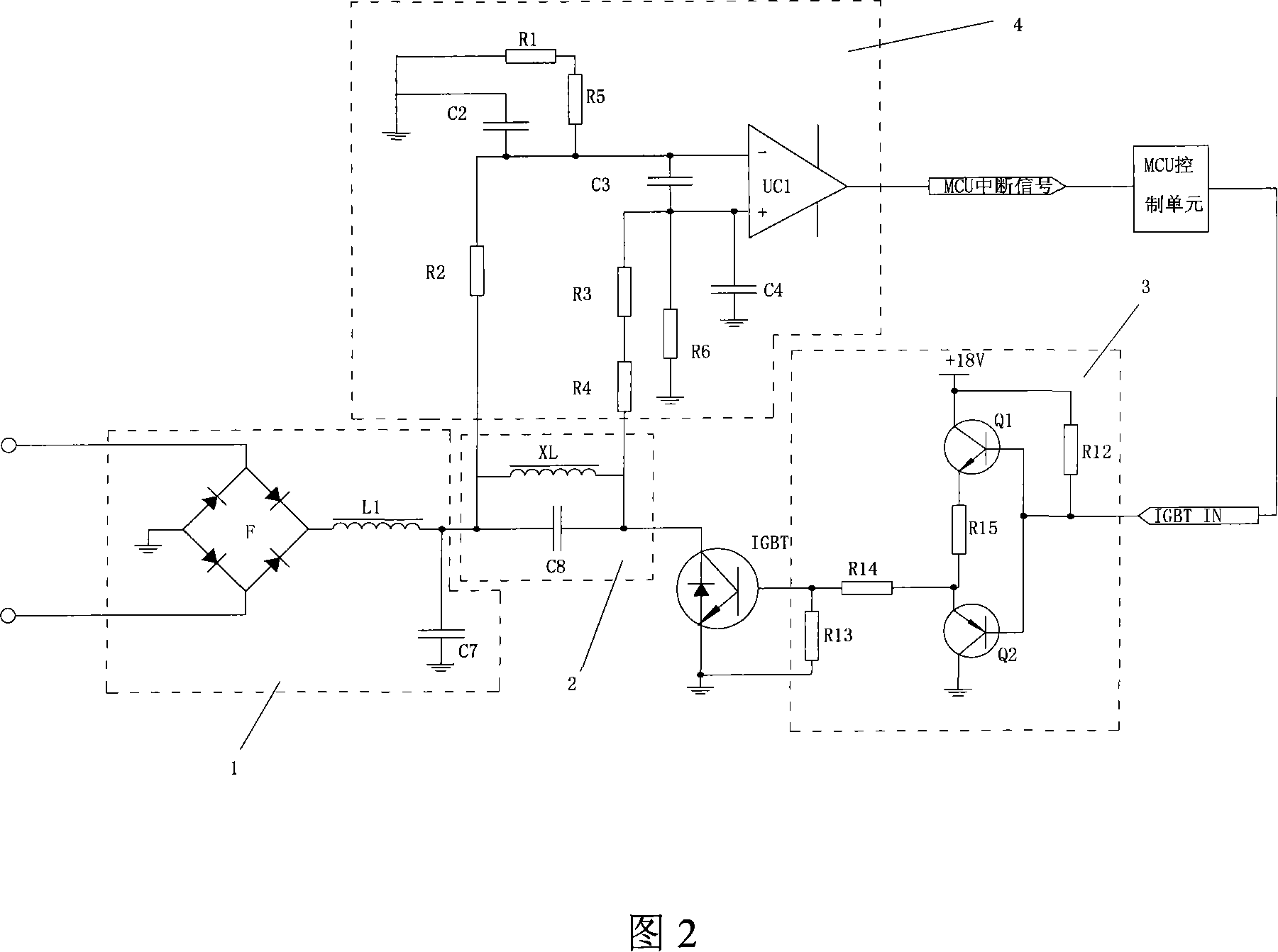

[0021] A synchronous control circuit for an induction cooker as shown in FIG. 2 includes a rectification filter circuit 1, a resonant circuit 2, a drive circuit 3, a synchronous signal circuit 4, an MCU control module and a switching device IGBT tube.

[0022] The rectifying and filtering circuit 1 includes a rectifying bridge stack F, an inductor L1 and a capacitor C7. The resonant circuit 2 includes a capacitor C8 and a reel inductance XL. The driving circuit 3 includes a transistor Q1, a transistor Q2, a resistor R12, a resistor R13 and a resistor R14. The synchronization circuit 4 includes a comparator UC1 , a capacitor C2 , a capacitor C3 , a capacitor C4 , a resistor R1 , a resistor R2 , a resistor R3 , a resistor R4 , a resistor R5 and a resistor R6 .

[0023] The working process of the above circuit is: the MCU controls the control unit to output an IGBT IN signal, which is a high-level signal with a set width. After the drive circuit 3 receives the signal, it drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com