Suspension type air spring middle-placed middle-low-speed magnetic suspension train running module

A technology of air springs and maglev trains, which is applied in the direction of electric vehicles, vehicle parts, devices for lateral relative movement between the underframe and the bogie, etc. Enhanced end effects and other issues, to achieve the effects of simplified structure and manufacturing assembly process, easy assembly and maintenance, convenient installation, assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

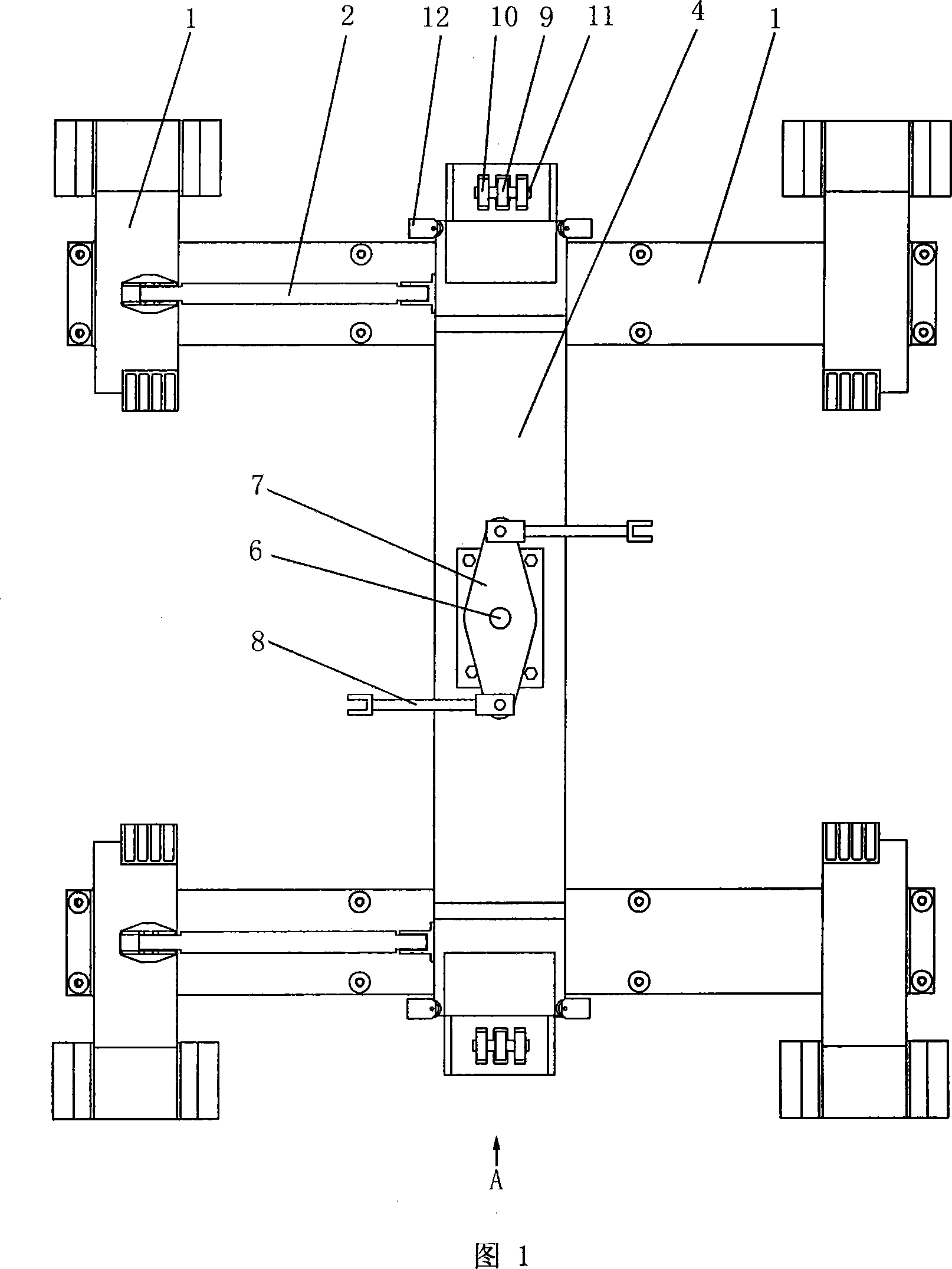

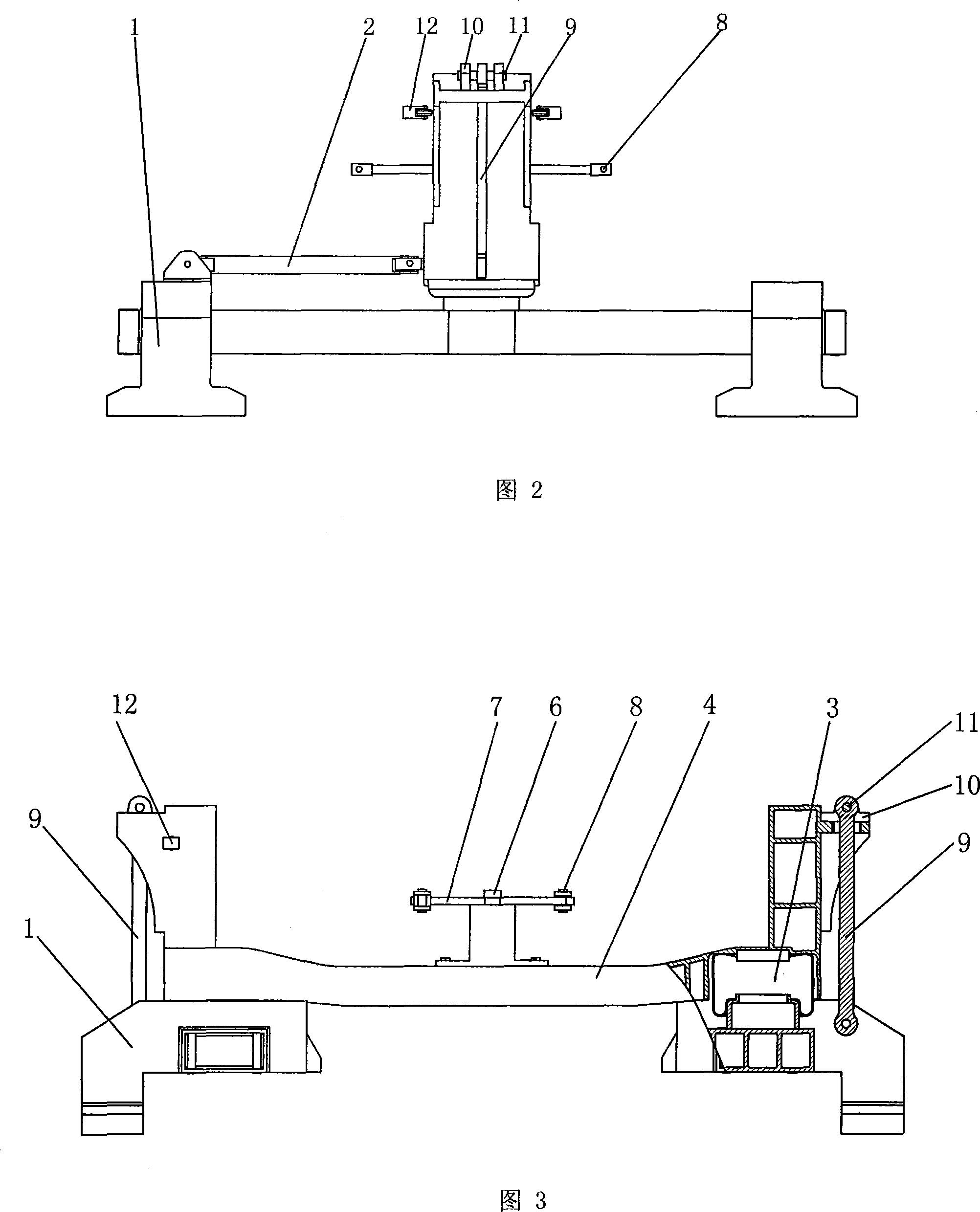

[0022] Figures 1, 2, and 3 show that a specific embodiment of the present invention is: a suspension-type, mid-air spring running module for low- and medium-speed maglev trains, including: a suspension frame 1, two poles on the suspension frame 1 Tow bar 2 and air spring 3. The middle position of the suspension frame 1 is horizontally provided with a bolster 4, and the two ends of the bolster 4 are supported on the suspension frame 1 by the air spring 3 below it; The other end of 9 is hinged with car body.

[0023] The specific structure that the two ends of the bolster 4 are suspended with suspenders 9 is as follows: the two ends of the bolster 4 are provided with a suspender 10 outside, and the suspender 9 is hinged on the longitudinal pin 11 of the suspender 10 .

[0024] When the present invention is implemented, longitudinal positioning wheels 12 are respectively arranged on the vehicle body corresponding to the front and rear positions of the two ends of the bolster 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com