Tilting-type roller polisher machine

A technology of finishing machine and drum, which is applied to surface polishing machine tools, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problem that the sealing performance of the drum body is easily damaged and the service life of the drum is affected. , long natural cooling time and other problems, to achieve the effect of saving materials, reducing manufacturing costs and maintenance costs, and using safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

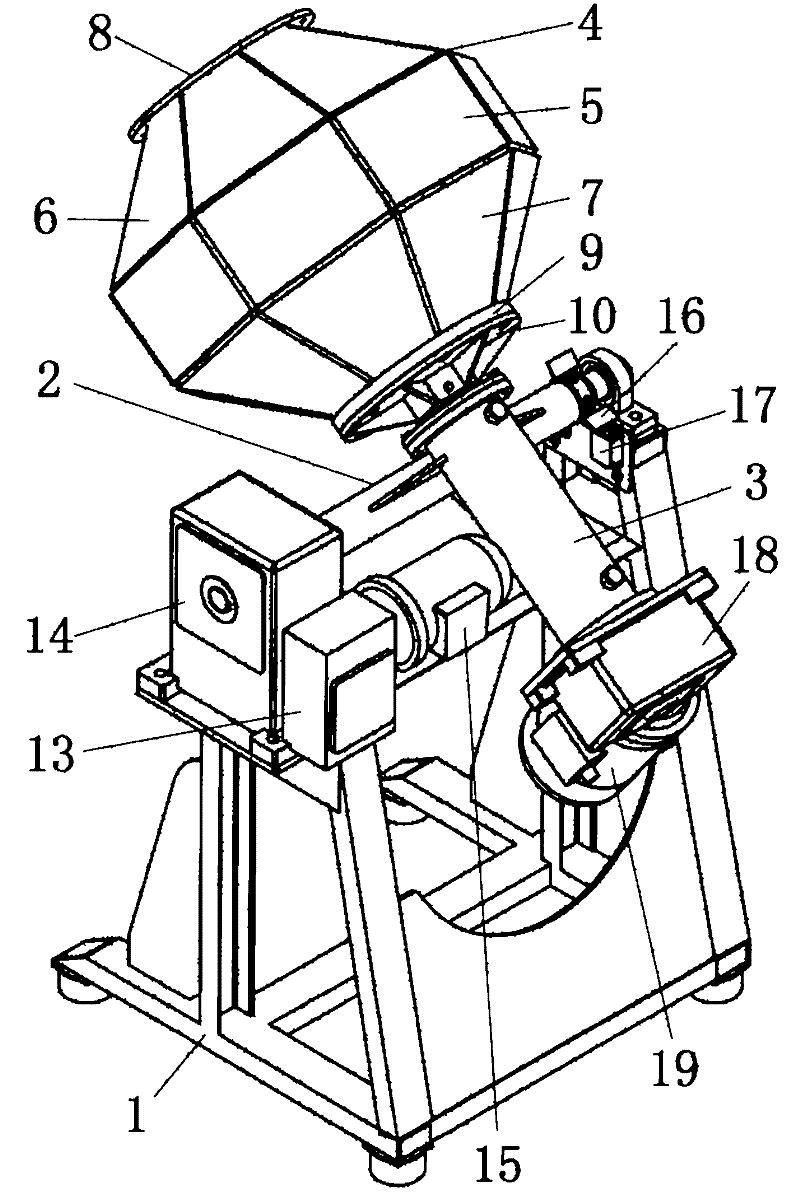

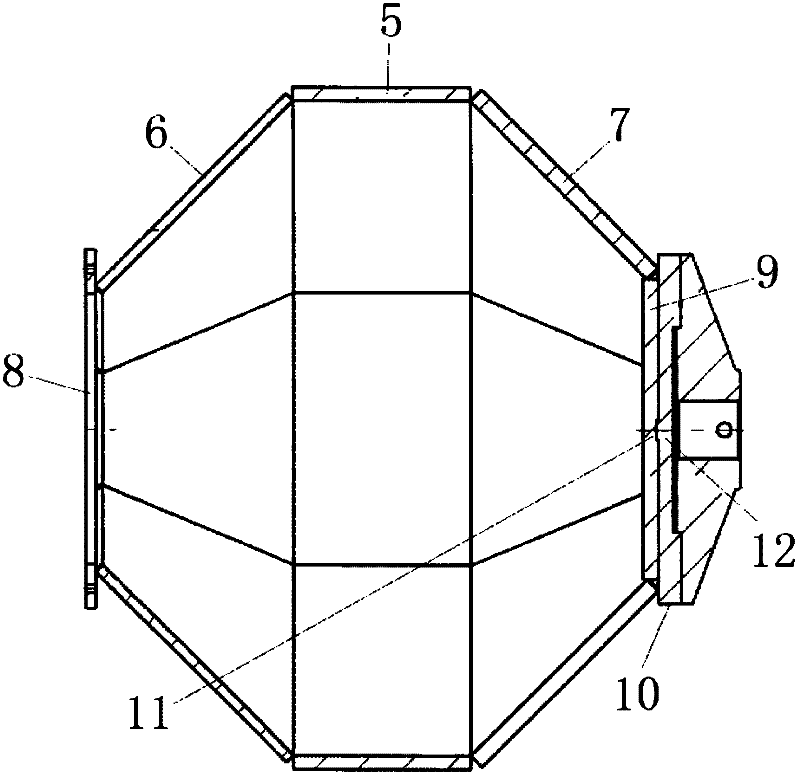

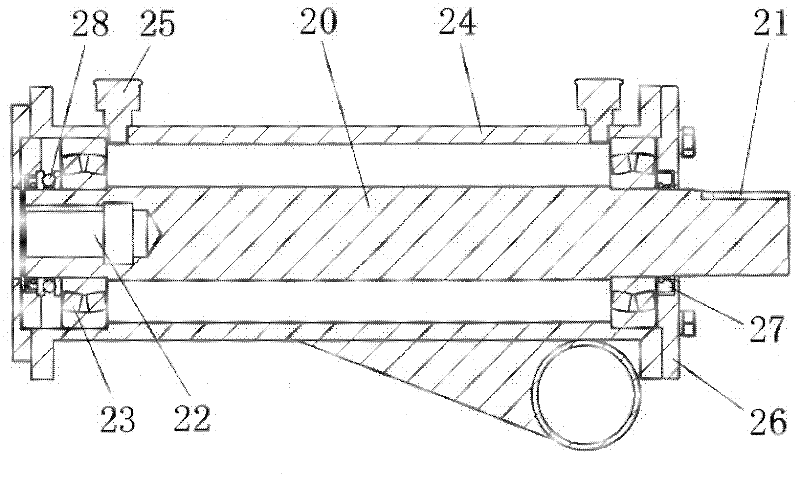

[0026] Example. A tilting drum finishing machine, such as figure 1 As shown, the drum 4 of the finishing machine is spliced by steel plates of different thicknesses. One end of the drum 4 is provided with a feed port 8, and the other end opposite to the feed port 8 rotates under the driving force of rotation. The drum 4 rotates under the turning force The pitch and elevation angles are adjusted under the drive. The drum 4 is spliced by steel plates of different thicknesses, and the drum 4 is divided into an outlet section 6, an intermediate section 5 and a driving section 7 along the axis; the thickness of the steel plates from the driving section 7 to the outlet section 6 decreases successively; 9 welding. The steel plate thicknesses of the driving section 7 , the middle section 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com