Embedded type straight gear reversing Mecanum wheel

A built-in, straight-toothed technology, applied in the field of vehicle engineering, can solve problems such as the inability to use high-efficiency power sources of internal combustion engines, the inability to effectively utilize the workability of drive motors, the complexity of drive structures and control systems, and achieve compact structure and reduced manufacturing maintenance. The effect of cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

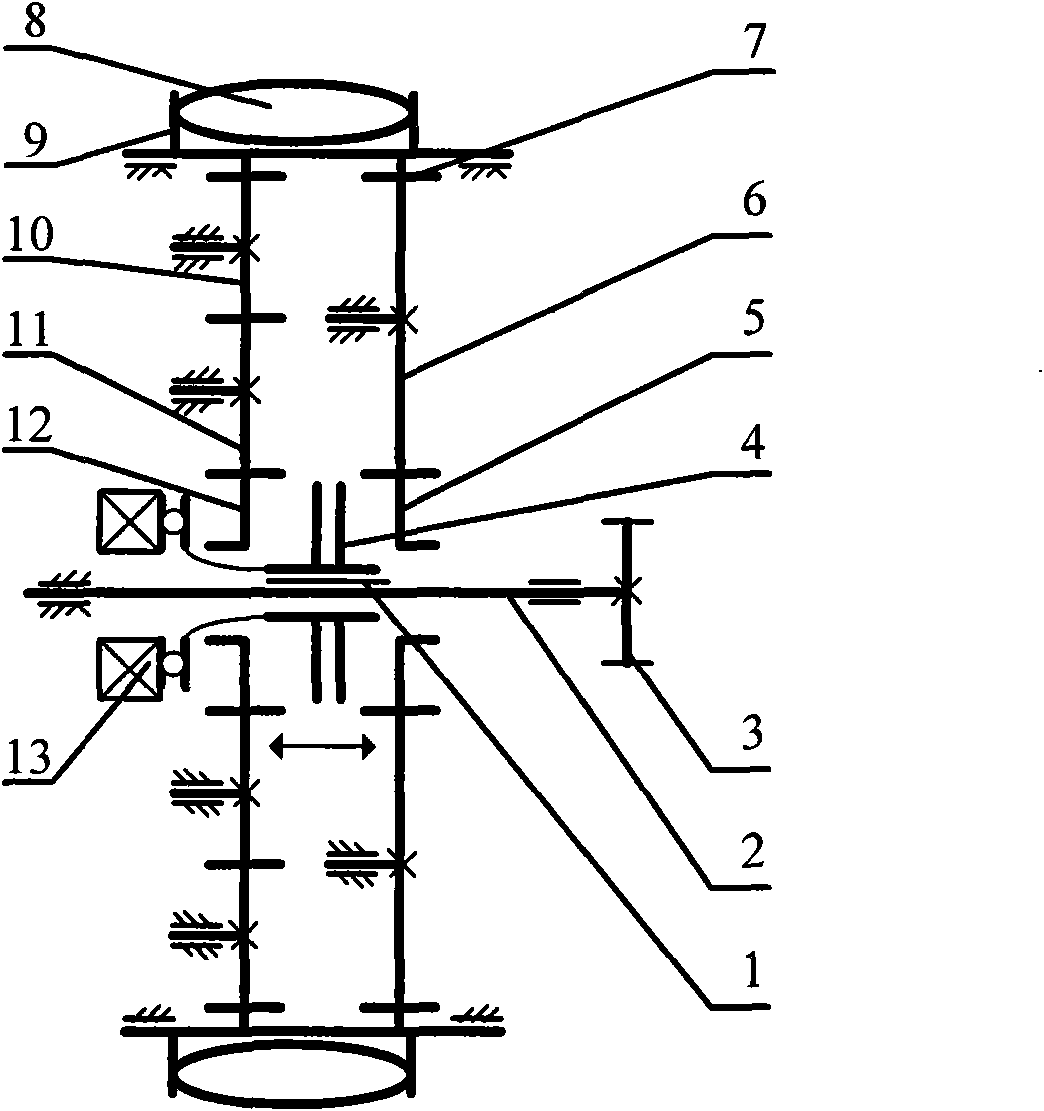

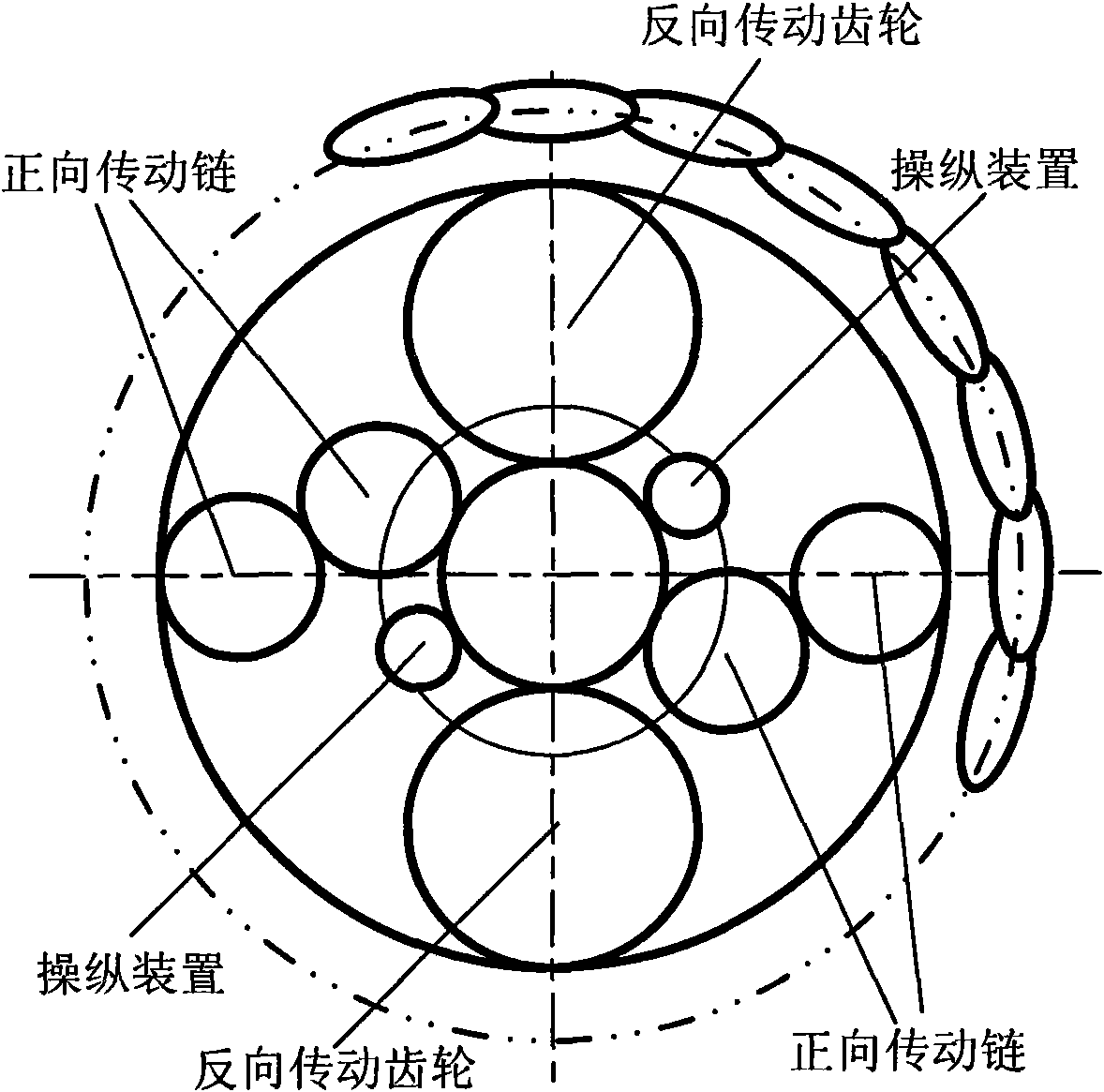

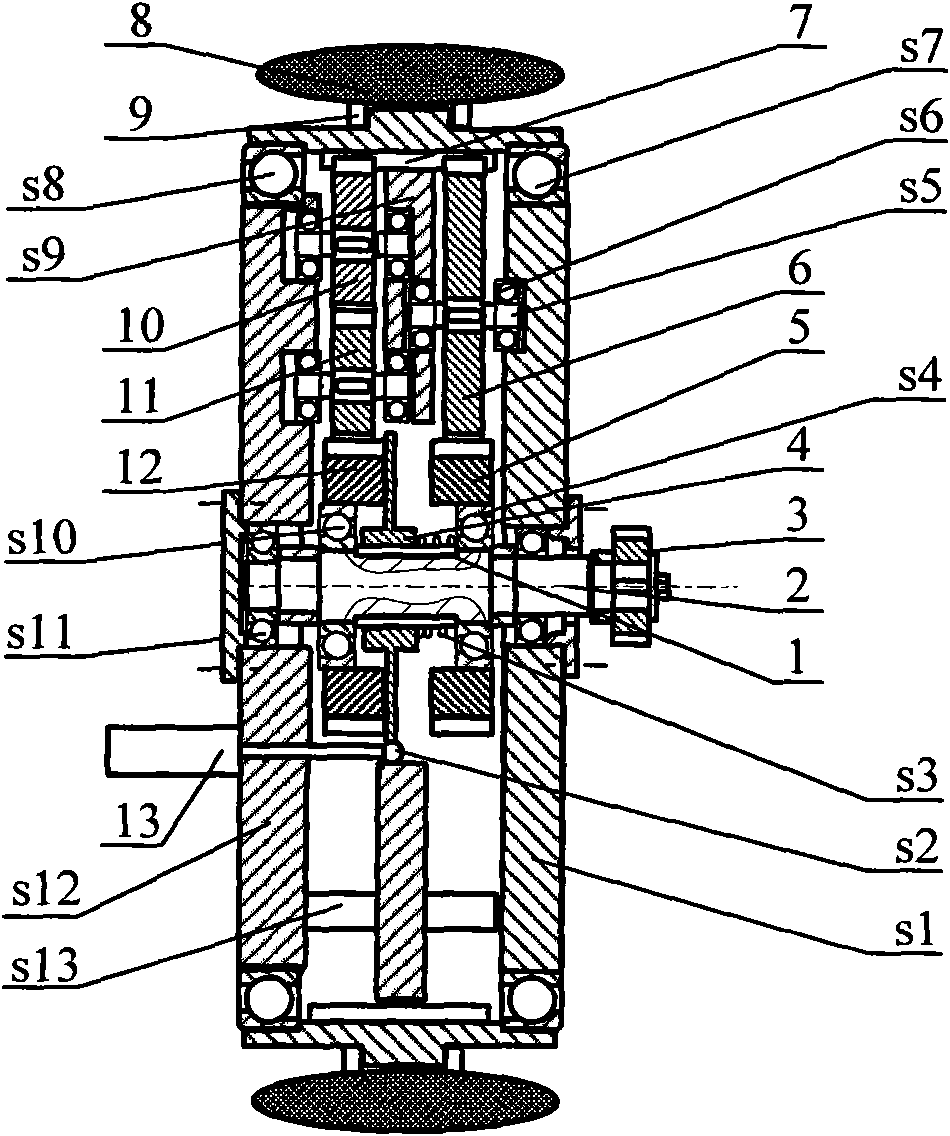

[0045] An embedded straight-tooth reversing mecanum wheel, including a mecanum wheel body, a support system is arranged inside the mecanum wheel body and the mecanum wheel body is rotatably connected to the support system, and the mecanum wheel body There is an inner ring gear rim 7 on the inner wall, and a power input shaft 2 is set on the support system and the power input shaft 2 is located at the center of rotation of the mecanum wheel body. The gear 5 and the same direction idler sun gear 12 are bonded on the power input shaft 2 with a reversing mechanism for transferring the power from the power input shaft 2 to the reverse idler sun gear 5 or the same direction idler sun gear 12 , the reverse transmission gear 6, the first co-direction transmission gear 11 and the second co-direction transmission gear 10 are rotatably connected to the support system, and the reverse transmission gear 6 is connected with the reverse idler sun gear respectively 5 and the ring gear rim 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com