Beverage dispensing apparatus

a beverage and apparatus technology, applied in the direction of liquid transfer devices, packaging goods, transportation and packaging, etc., can solve the problems of excessive foam, unsatisfactory consumer and beverage vendor, and a tendency to form foam, etc., to achieve low manufacturing and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

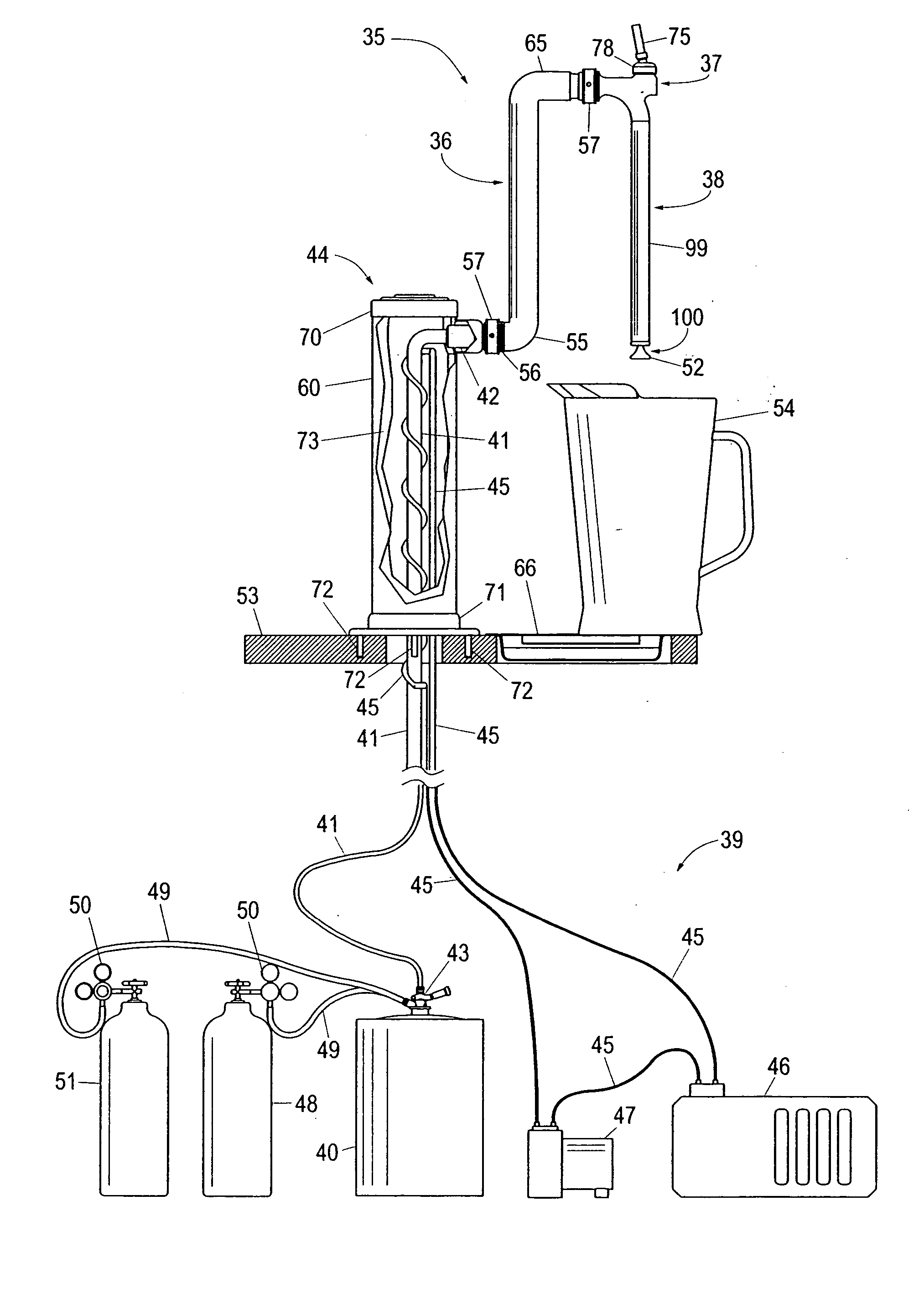

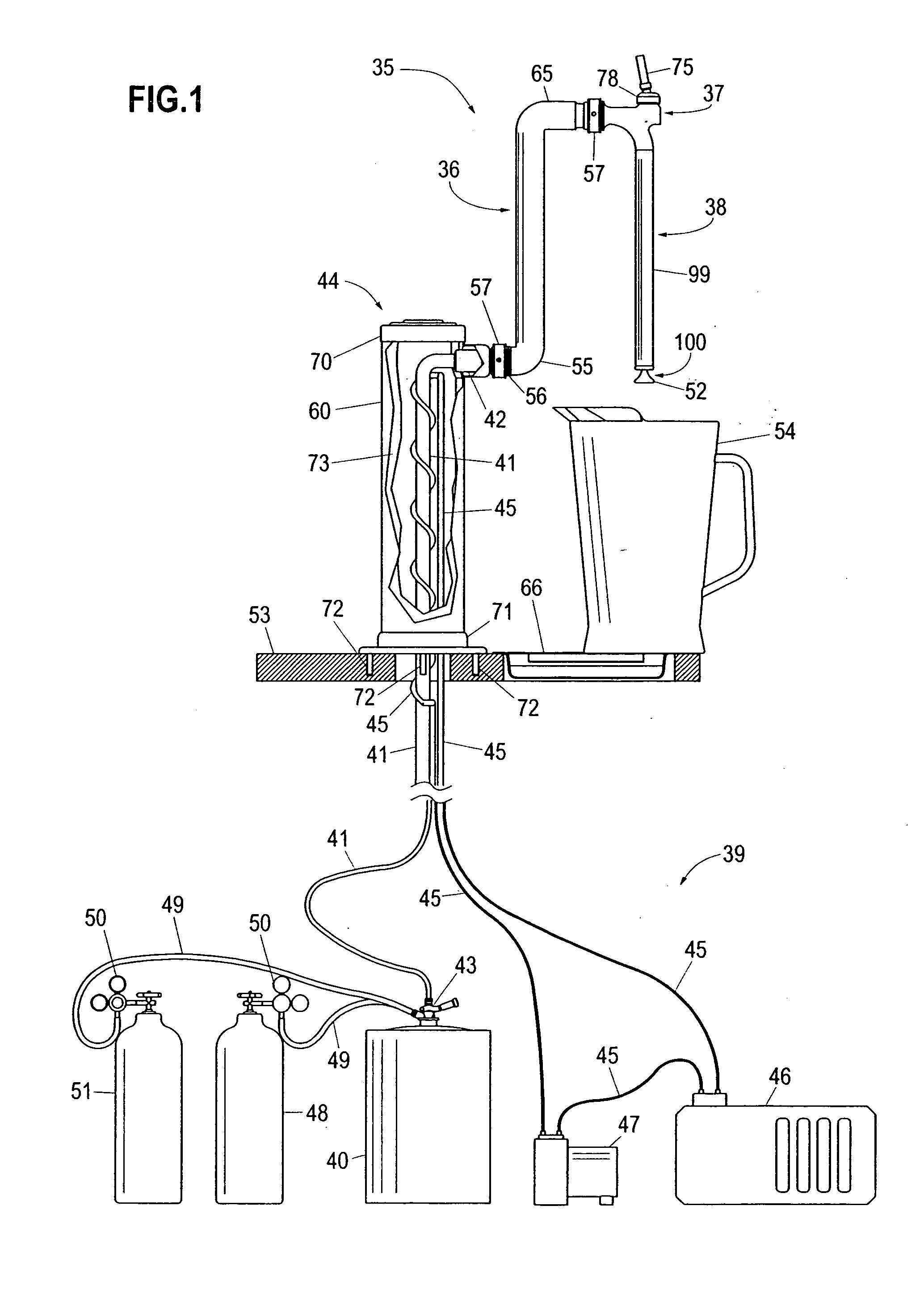

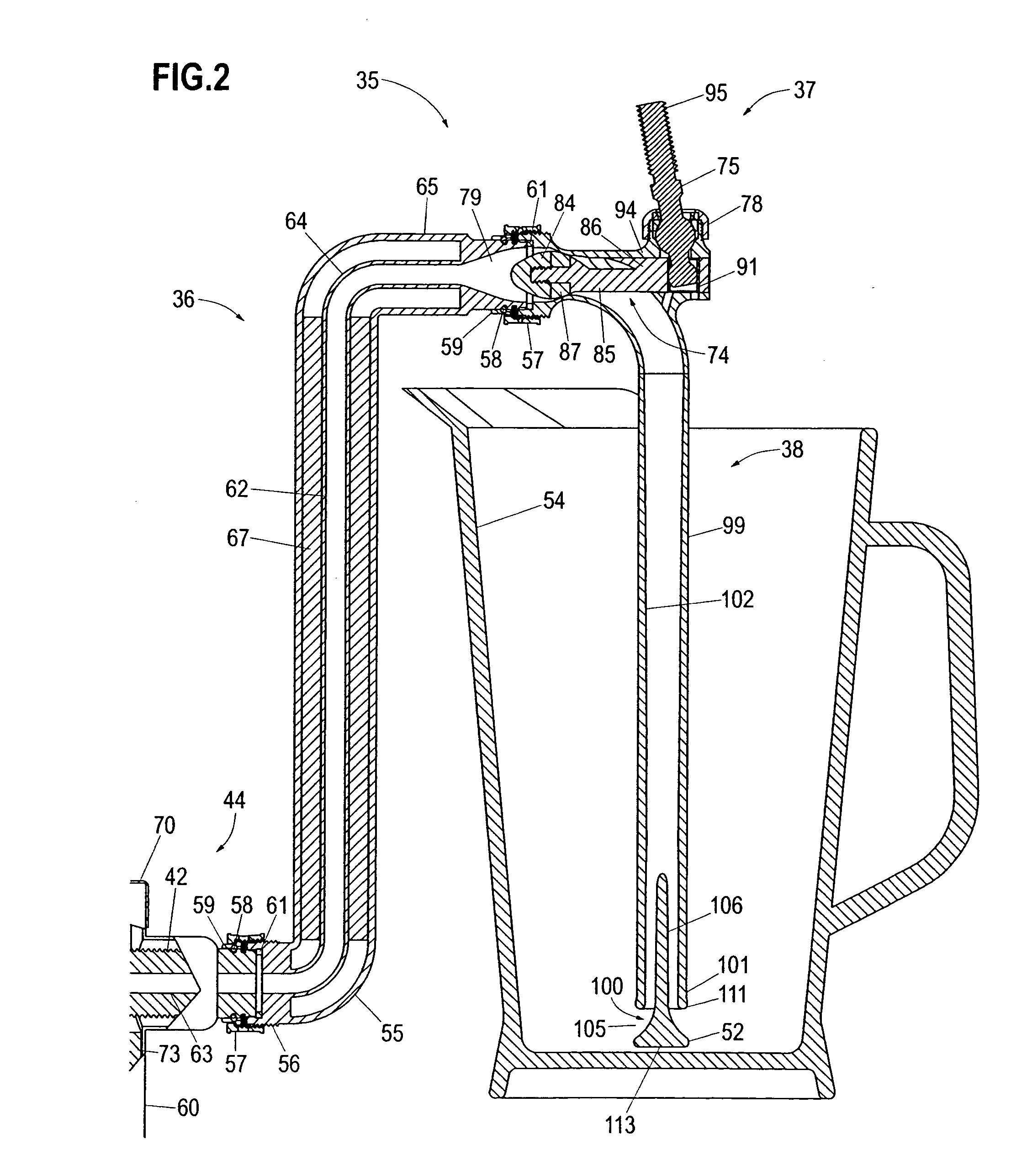

[0048] As shown in FIG. 1, the rapid beverage dispensing device 35 comprises a neck assembly 36, a valve assembly 37, and a downward-extending nozzle assembly 38. In a preferred embodiment, neck assembly 36 is substantially vertical. The rapid beverage dispensing device 35 is designed to attach to a conventional pressurized beverage dispensing system, such as a beer dispensing system 39 that includes a beer keg 40 or similar beverage-containing reservoir and beverage tubing 41 for conveying a beverage from a container or beer keg 40 to the rapid beverage dispensing device 35. A shank 42 connects the rapid beverage dispensing device 35 to beverage tubing 41. Keg tapping device 43 connects beverage tubing 41 to beer keg 40. Draft dispensing tower 44 supports shank 42.

[0049] Beer produced by most major manufacturers in the United States is formulated to be stored and served optimally at approximately 38 degrees Fahrenheit (3.3 degrees Celsius). If the beer is warmer than this optimal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com