Support system for open-type full cross-section rock tunnel boring machine and support method

A roadheader, full-section technology, used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve problems such as untimely support, single support form, and time-consuming, reducing manufacturing and maintenance costs and simplifying machinery. structure, the effect of improving the driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

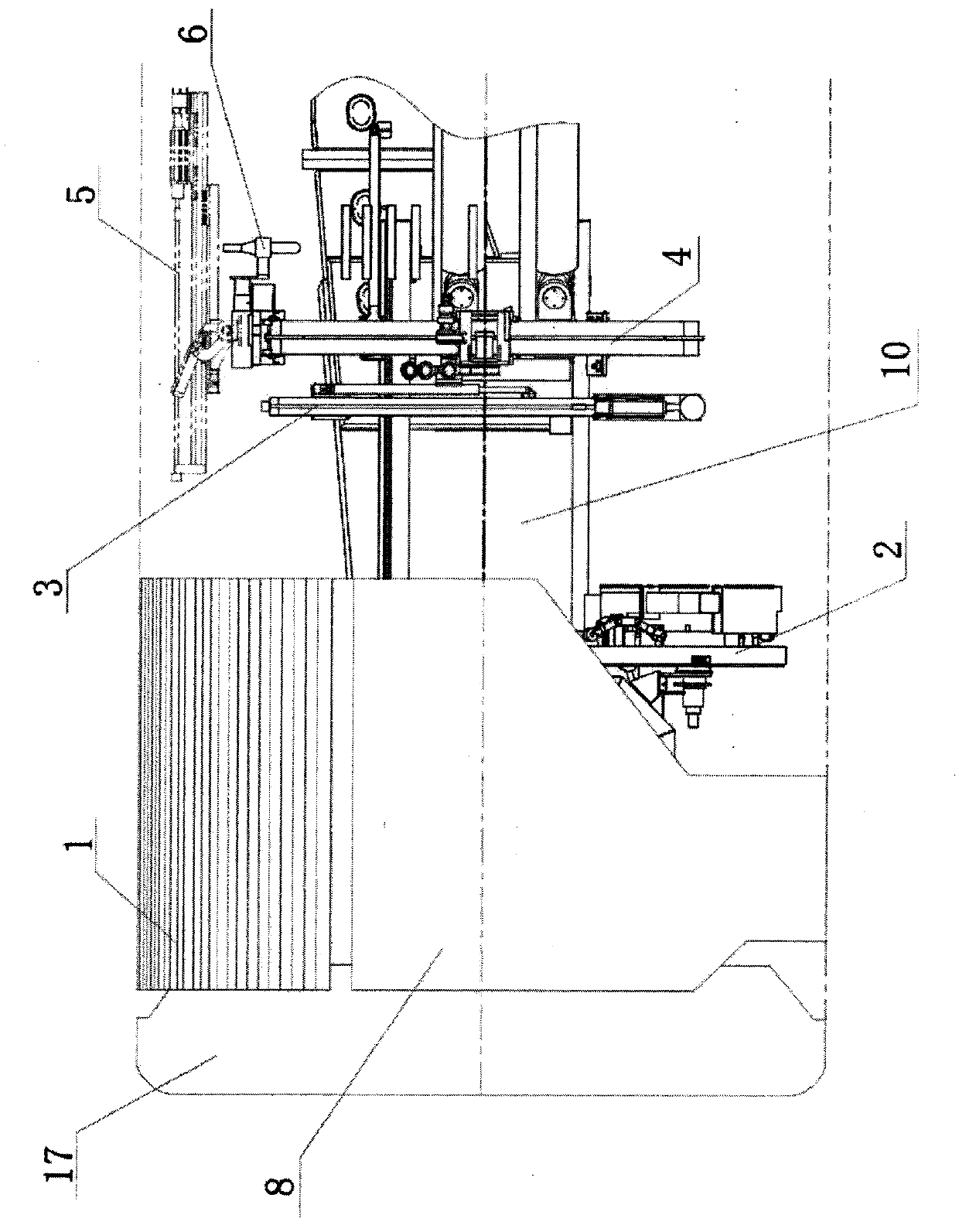

[0035] Embodiment 1: A support system for an open full-face rock boring machine, see figure 1 , including steel bar row storage and installation components, steel arch installer 2, bolter rig 3, advanced drill rig 5 and temporary shotcrete manipulator 6.

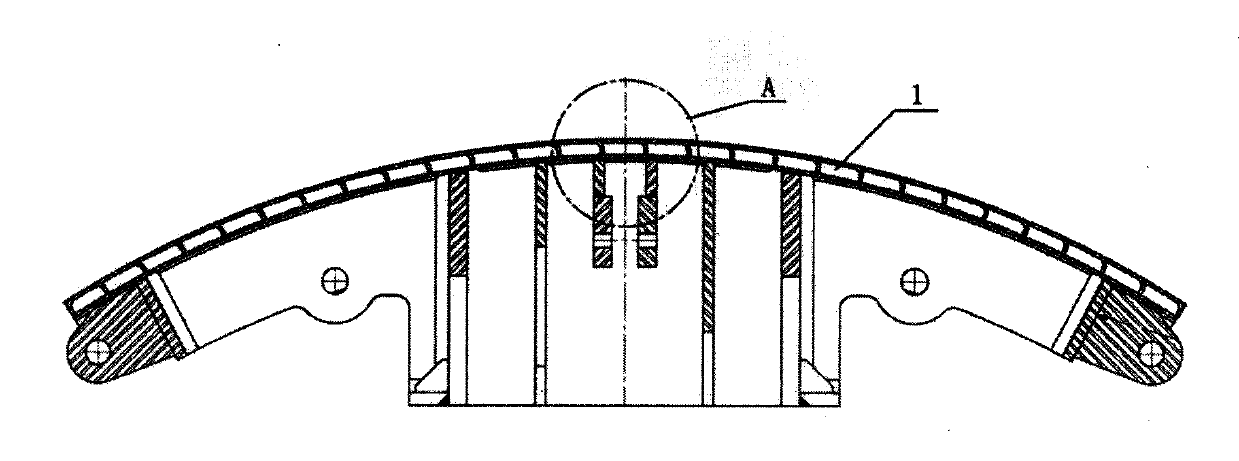

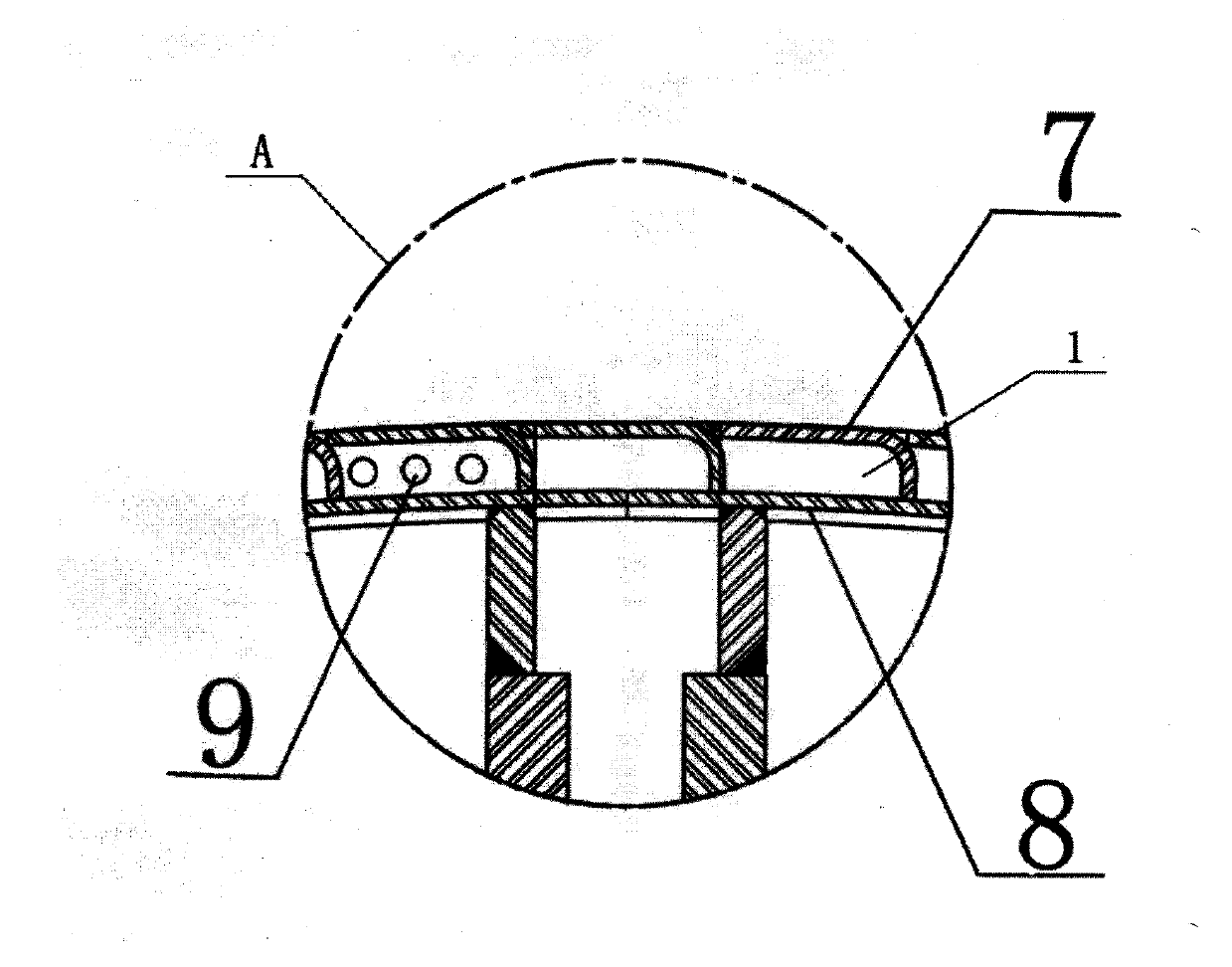

[0036] The steel bar row storage installation assembly is arranged on the top shield 8 of the tunneling machine, see figure 2 , image 3 , including the cross-sections arranged and fixed on the top of the top shield 8 of the tunneling machine are shaped partitions 7, the cavity formed between two adjacent partitions is the steel bar row storage chamber 1, and the shield steel bar row 9 is pre-installed in the storage chamber, the partition 7 is a wear-resistant steel plate, and its lower end surface It is welded and fixed on the top shield 8 of the boring machine, and the adjacent partitions are welded and fixed together.

[0037] Steel arch installer 2 comprises support frame 14 and steel arch grab manipulator, see F...

Embodiment 2

[0039] Embodiment 2: An open full-face rock boring machine support method, implemented using the support system in Embodiment 1, includes the following steps:

[0040] (1) The advanced drilling rig finds the broken strata ahead of the excavation through advanced drilling, and uses the advanced drilling rig to drill grouting holes on the top of the tunnel, and advances the surrounding rock reinforcement through grouting;

[0041](2) The anchor drilling rig selects an appropriate position to drive the anchor along the radial direction of the tunnel. The steel arch installer installs a circle of steel arches at the section where the anchors are driven in. The four steel arches are connected by bolts to form a ring, and weld the steel arch frame with each anchor rod to fix the steel arch frame;

[0042] (3) Weld the ends of the steel bars pre-installed in the shield steel bar storage cavity to the steel arch 16 sequentially. With the increase of the TBM excavation distance, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com