Gloves online release stacking machine

A stacking machine and glove technology, applied in the direction of coating, etc., can solve the problems of complex transmission structure, high maintenance cost, easy damage of motor, etc., achieve the effect of simple transmission structure, reduce manufacturing cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

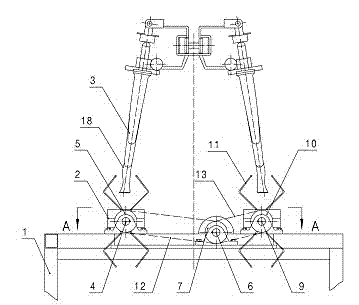

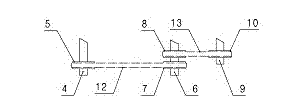

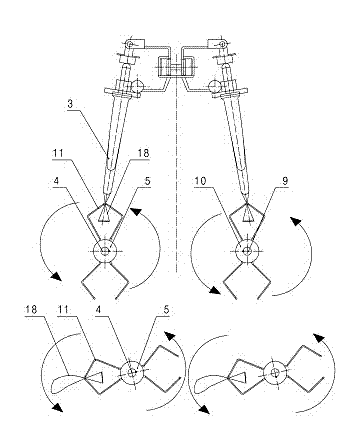

[0016] Such as figure 1 As shown, the online demoulding and piling machine for gloves according to the present invention includes: a frame 1 and a pair of rotating shafts arranged in parallel on the frame 1, that is, the first rotating shaft 4 and the second rotating shaft 9, the transmission shaft 6 and Rotary driving device, this rotating driving device includes: a driving motor, the output shaft of the driving motor is connected with the transmission shaft 6, this rotating driving device belongs to the conventional technology in the art, and is not shown in the figure; the first At least one swing seat 2 is fixed on the rotating shaft 4, and the swing seat 2 corresponding to the swing seat 2 on the first rotating shaft 4 is provided on the second rotating shaft 9, that is, two corresponding swing seats The positions of the seat 2 on the first rotating shaft 4 and the second rotating shaft 9 are corresponding, and the swing seat 2 is provided with a glove clamping device wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com