Method for processing bearing seat cylinder surface on variable housing of plunger pump

A processing method and technology of bearing pad seat, applied in the field of cylindrical surface processing of bearing pad seat, can solve problems such as affecting product sealing, excessive tool wear, product failure, etc., so as to improve product reliability, tool durability, and avoid size effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

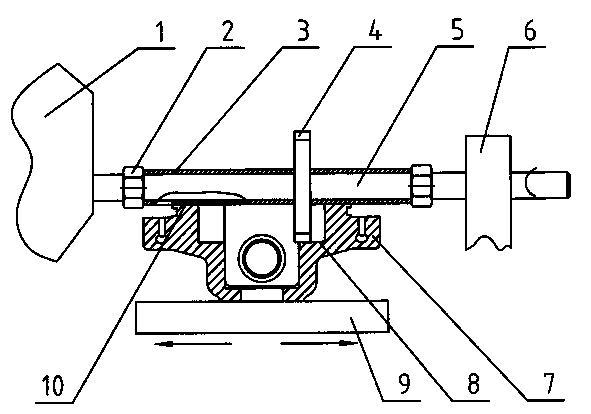

Image

Examples

Embodiment Construction

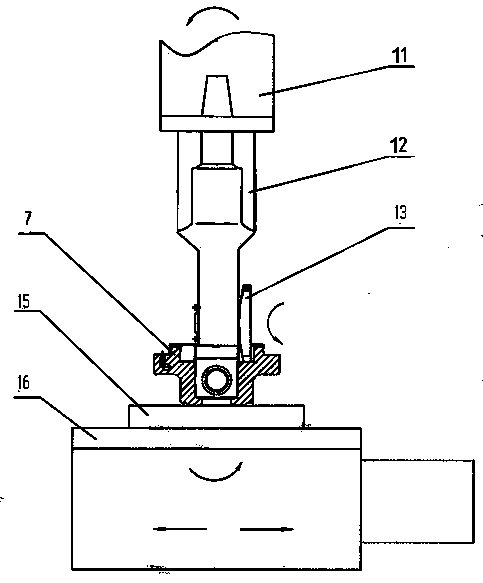

[0014] Attached below figure 2 The present invention is described in detail with embodiment. like figure 2 As shown, the machining method of the cylindrical surface of the bearing seat on the variable housing of the plunger pump is as follows:

[0015] 1. Tool and bearing seat installation

[0016] Install the angle head 12 on the machine tool spindle 11; the disc milling cutter 13 is installed on the transmission shaft of the angle head 12, and the transmission shaft of the angle head 12 forms an angle of 90° with the machine tool spindle 11, so the blade of the disc milling cutter 13 and the bearing bush The seat 7 (or worktable) is parallel; the bearing seat 7 is installed on the fixture 15, positioned by the mandrel on the fixture 15, and oriented by the process screw hole, the large plane of the bearing seat 7 is parallel to the machine table; the fixture 15 is installed on the horizontal On the four-axis 16, the horizontal four-axis can rotate within a horizontal ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com