Injection molding part producing method

A technology of injection molding and injection molding machine, which is applied in the field of device of injection molding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

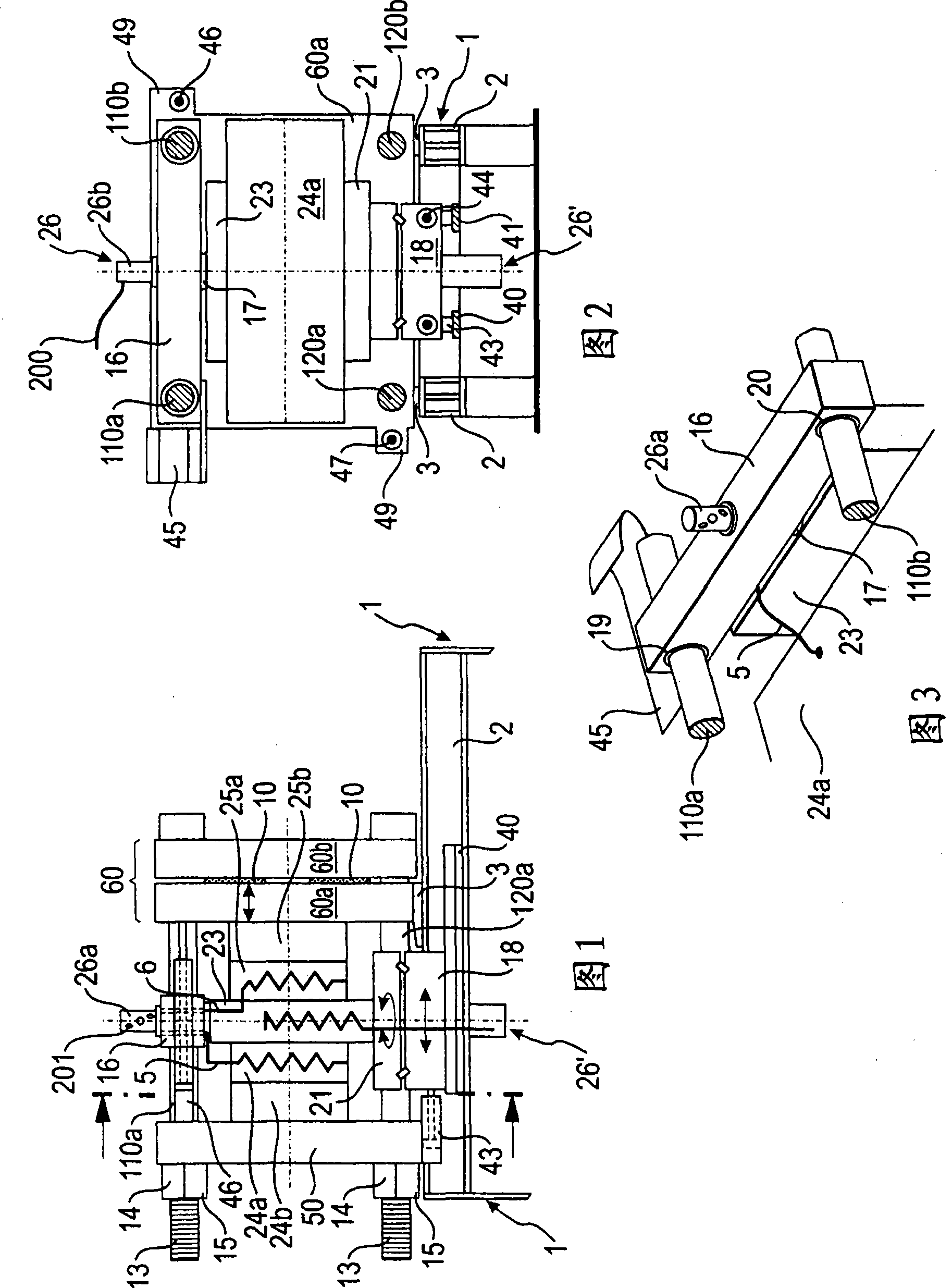

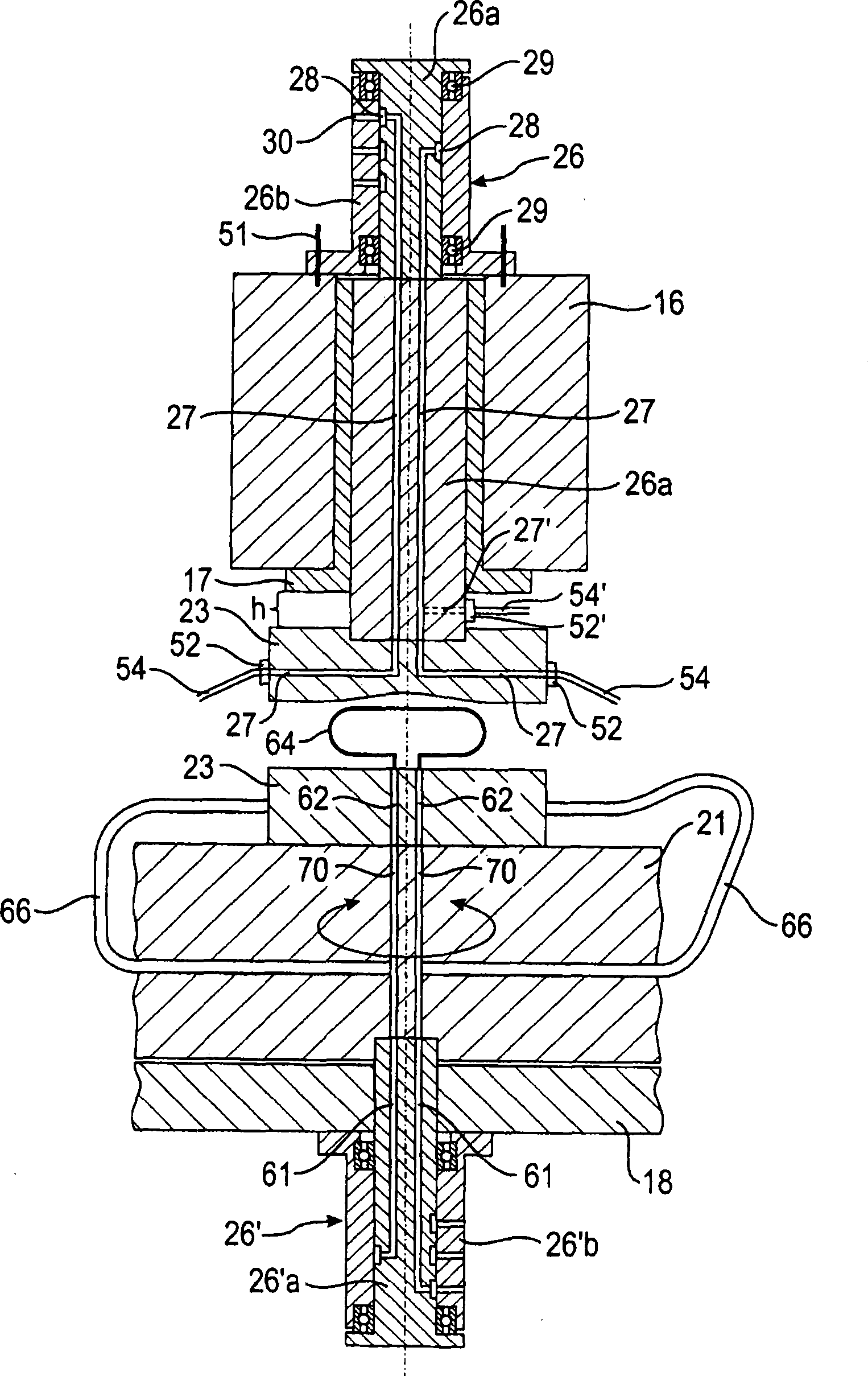

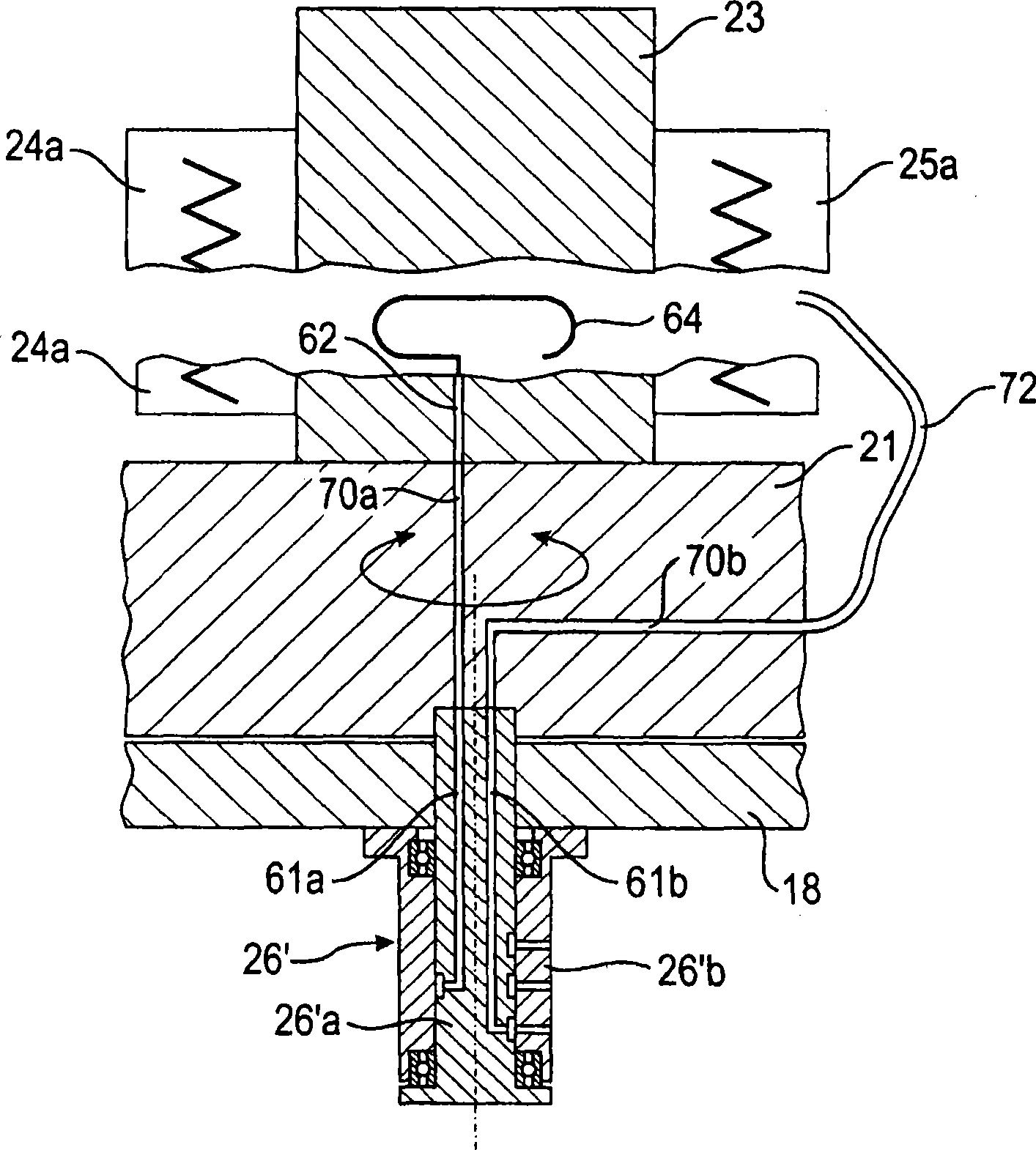

[0016] According to FIGS. 1 to 3, a frame 1 is provided with two longitudinal supports 2 spaced apart from one another, on which a fixed mold clamping plate 50 and a mold clamping plate 60 movable on a slide 3 are arranged. . The movable mold clamping plate 60 comprises an actual mold clamping plate 60a and a pressure plate 60b including a pressure cushion 10 in between which can be applied by means of a pressure medium source not shown here. to closing pressure. Between the mold clamping plates extend upper struts 110a and 110b and lower struts 120a and 120b. These struts are fixed at one end in the fixed mold clamping plate 50 and pass through the fixed mold clamping plate 50 with their other end. At the protruding end, each strut has a toothing 3 in which the interlocking jaws 14 and 15 can be moved in and out (the moved in position can be seen in the figure). For moving the movable mold clamping plate 60 relative to the fixed mold clamping plate 50 , hydraulic actuating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com