Liquid preparation for contact lens

A liquid preparation, contact lens technology, applied in the application, biocide, animal repellent and other directions, can solve the problems of easy adhesion of smudges to the lens, deterioration of the visual field of the lens, adverse effects on the optical characteristics of the lens, etc., and achieve excellent sterilization effect, Achieving sterilization effect and excellent safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

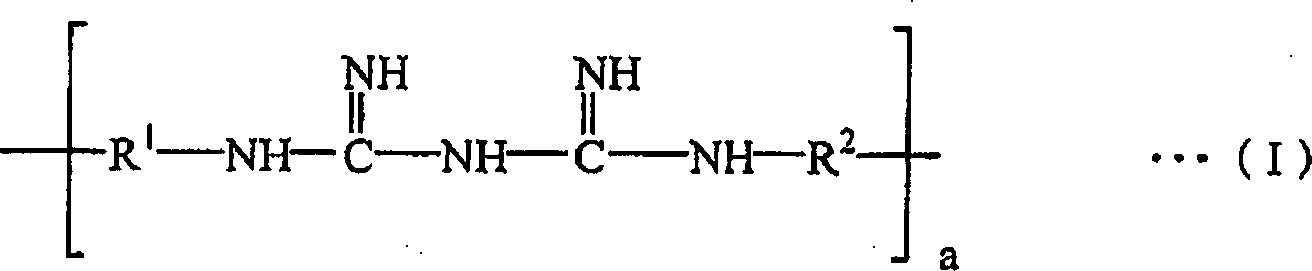

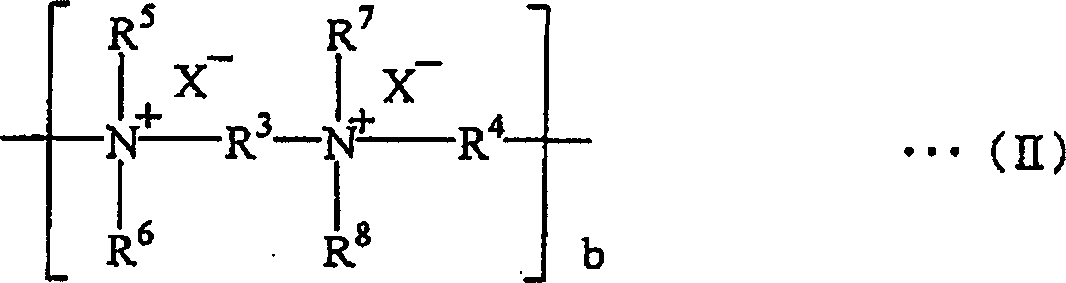

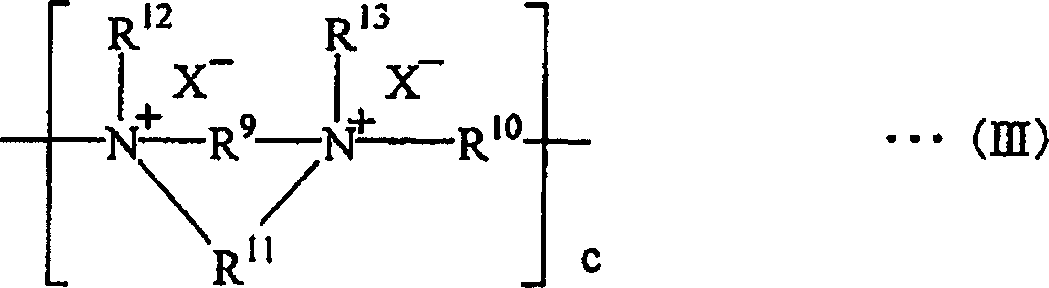

Method used

Image

Examples

Embodiment

[0085] Several experimental examples including the embodiments of the present invention are listed below to illustrate the present invention more specifically. Of course, the present invention is not subject to any restriction by the contents described in the above experimental examples. It should be understood that various changes, revisions, improvements, etc. based on the knowledge of those skilled in the art can be added to the present invention, as long as they do not depart from the gist of the present invention, in addition to the following examples and the above specific description.

[0086] First, in sterilized distilled water, add the specified additive components in various ratios as shown in the following Table 1, and then add an appropriate amount of pH adjuster (hydrochloric acid or sodium hydroxide) if necessary, thereby preparing the osmotic pressure The liquid formulations of Experimental Examples 1 to 19 were 290 mOsm / kg and pH about 7.3.

[0087] When prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com