Electronic component and method for manufacturing electronic component

A technology of electronic components and electrodes, which is applied in the field of electronic components and electronic component manufacturing, can solve problems such as inability to fully realize miniaturization, achieve the effects of avoiding dimensional changes, ensuring connection reliability, and improving electrical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

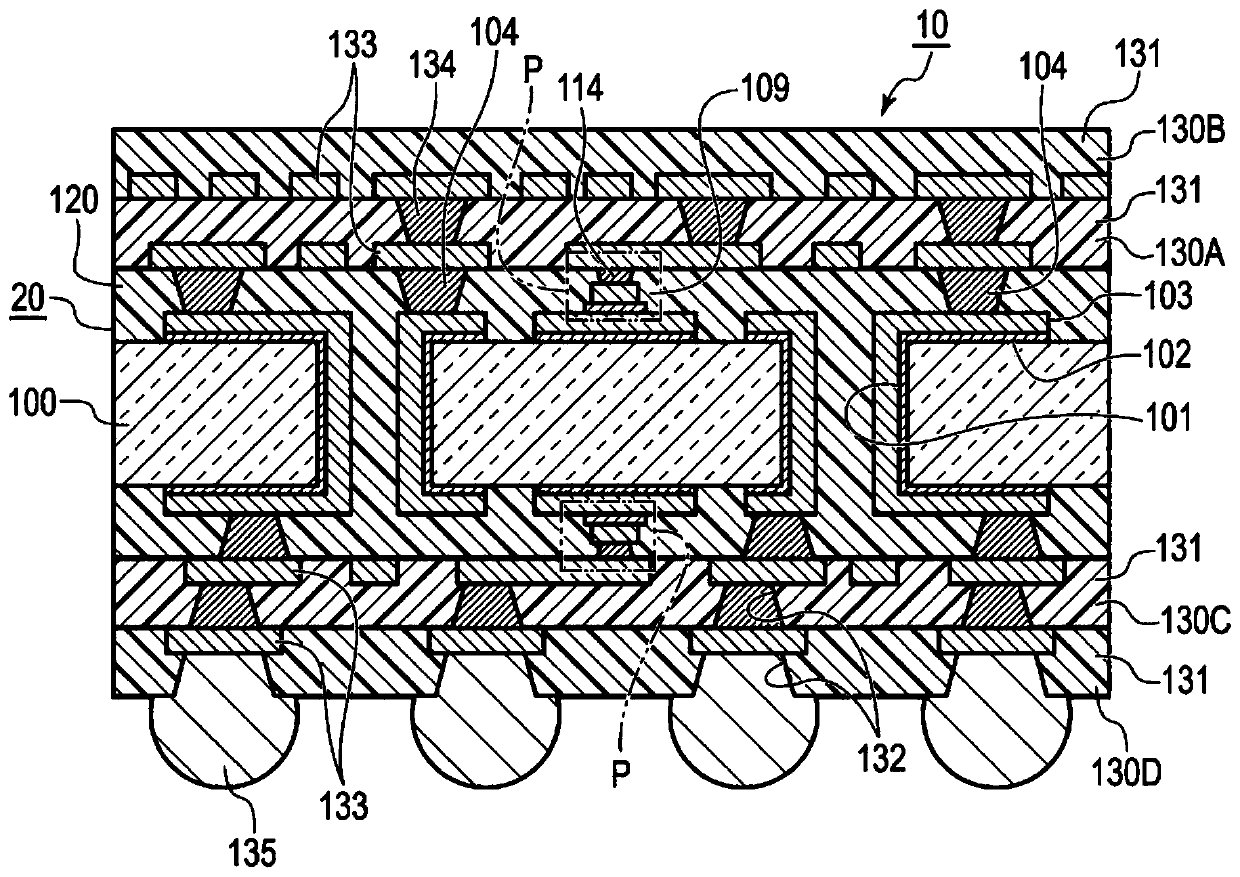

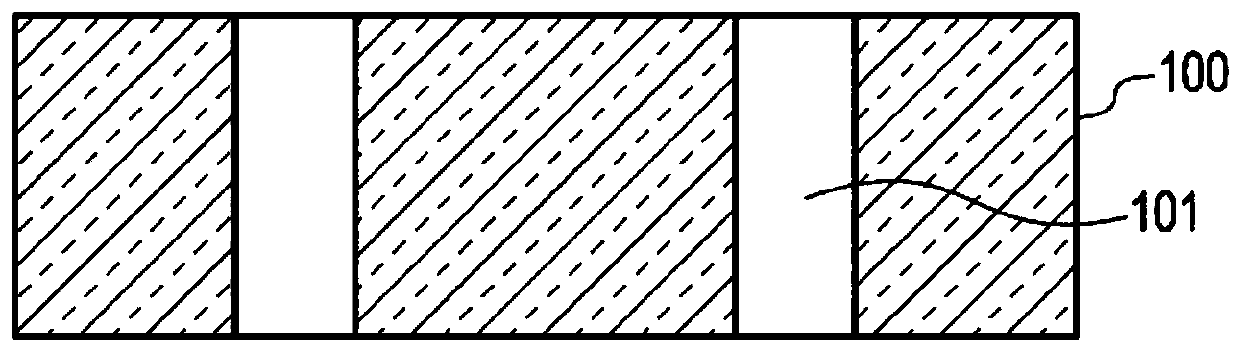

[0086] Such as figure 2 As shown, a glass substrate 100 (OA-10G manufactured by Nippon Denki Glass Co., Ltd., thickness: 0.5 mm, linear thermal expansion coefficient: 3 ppm / K) was prepared. Next, if image 3As shown, a through-hole 101 with a top diameter of 80 um and a bottom diameter of 60 um among the diameters of the through-hole 101 was formed by using a picosecond laser processing machine. and, if Figure 4 As shown, on the front and back of the glass substrate 100 , a 50 nm titanium film and a 300 nm copper film are formed by sputtering as the seed metal layer 102 . Furthermore, an electroless nickel plating layer with a thickness of 0.1 μm was formed for the purpose of increasing the size of the seed metal layer 102 in the through hole 101 . As above, the seed metal layer 102 made of titanium, copper, and nickel was formed.

[0087] Then, if Figure 5 As shown, a photosensitive dry film resist having a thickness of 25 μm was provided on the seed metal layer 102 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com