Inner wall self-locking overall pipe high-temperature tension test clamp

A technology of tensile test and integral tube, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., to achieve the effect of convenient installation, uniform force, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

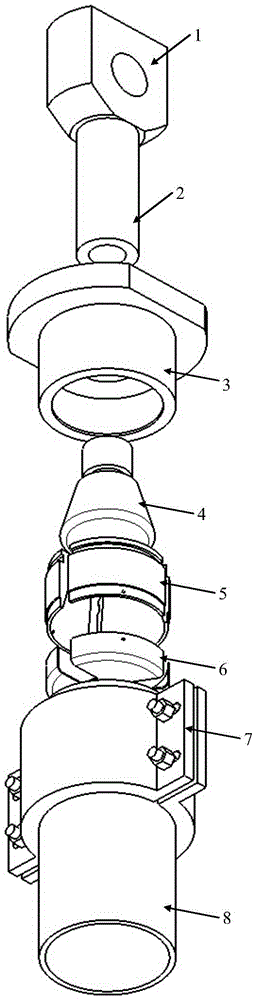

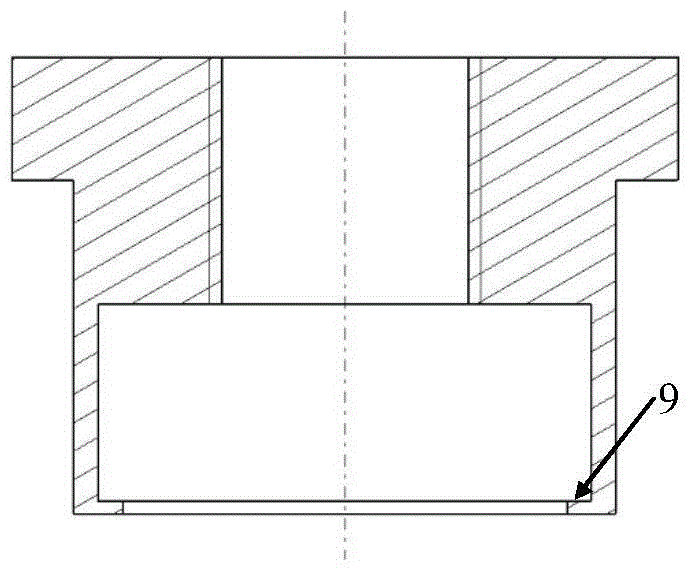

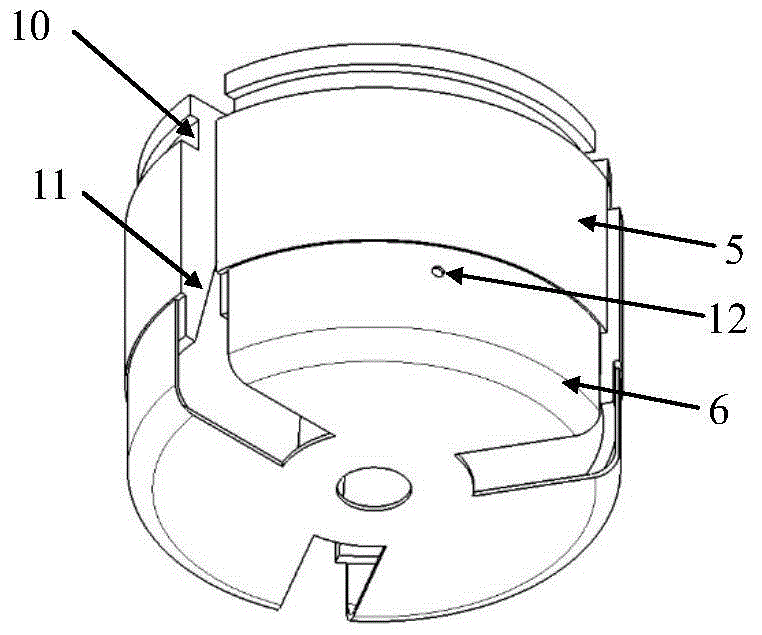

[0020] refer to Figure 1-Figure 3 . like figure 1The shown disclosure discloses a better scheme of the high-temperature tensile test jig for two parts with exactly the same structure size, which are respectively connected to the inner wall self-locking integral pipe high-temperature tensile test fixture of the upper and lower rods of the high-temperature tensile test equipment. The above fixture is mainly composed of connector 1, threaded rod 2, lock nut 3, cone linkage sliding core 4, slider 5, elastic lock ring 6 and slider snap ring 9, through its connector 1 and the testing machine The pull rod is pin-connected and fixedly connected to the pull rod of the testing machine. The beam of the testing machine drives the pull rod to drive the pipe tensile fixture and the overall pipe sample to realize the transmission of force value. In a preferred embodiment of the internal wall self-locking integral pipe high temperature tensile test fixture, the connector 1 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com