Multi-dimensional protective cutting treatment machine tool

A multi-dimensional, machine tool technology, applied in maintenance and safety accessories, improvement of process efficiency, metal processing machinery parts, etc., can solve problems such as rapid temperature changes of parts, substandard dimensions of processed parts, waste of materials, etc., to reduce The time wasted in handling workpieces, ensuring the accuracy of dimensions, and making up for the lack of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

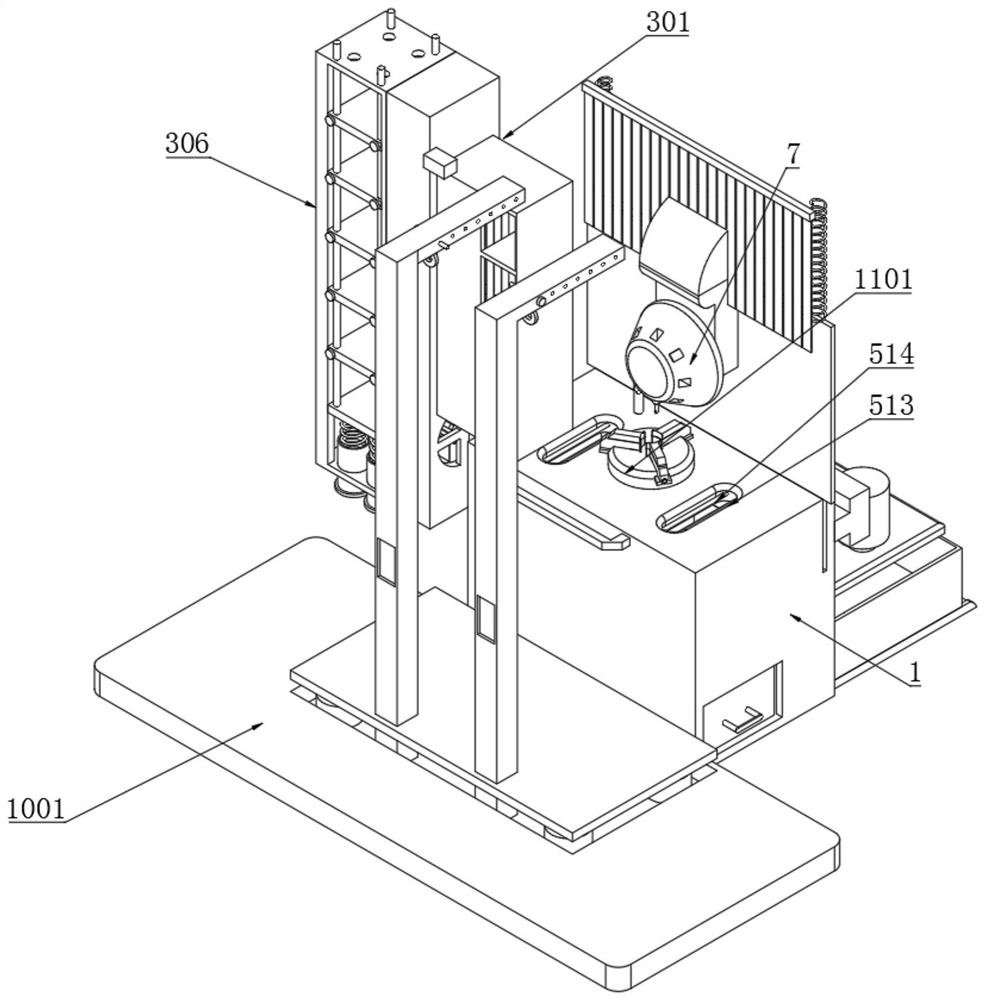

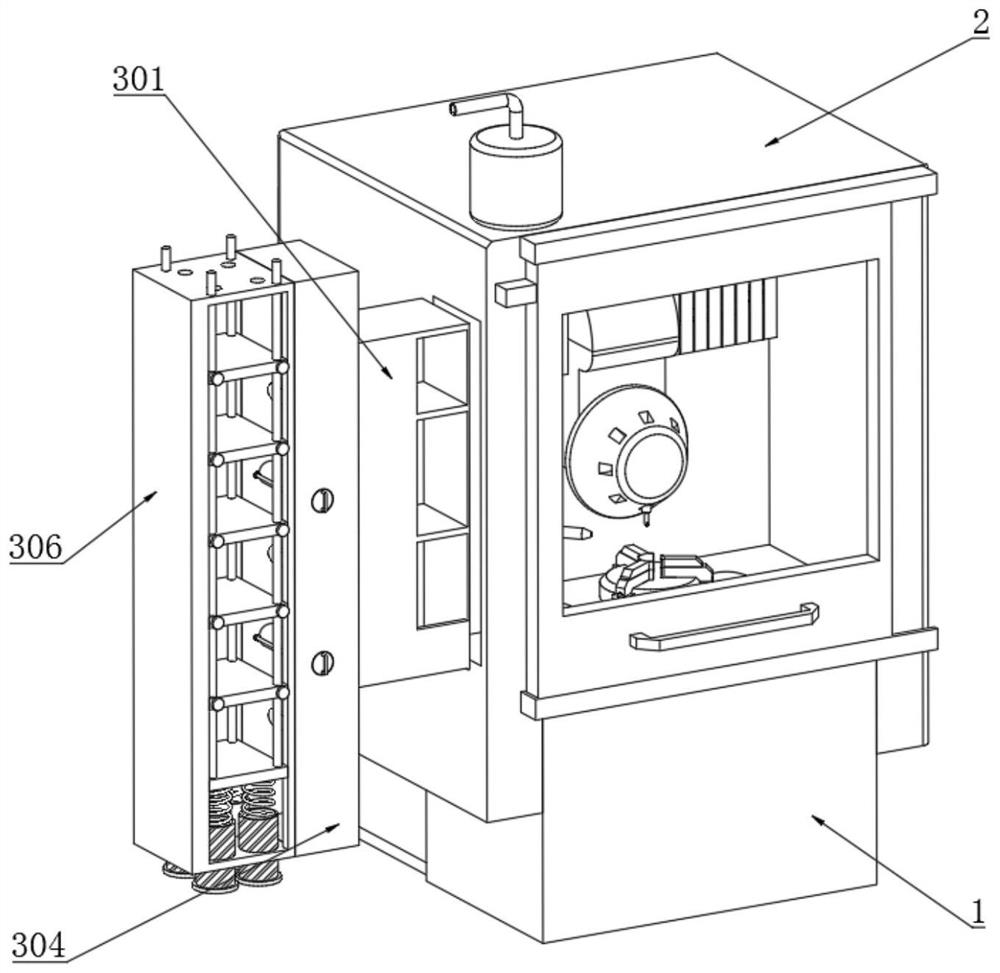

[0059] Example: such as Figure 1-15 As shown, the present invention provides a technical solution, a multi-dimensional protective cutting processing machine tool, including an operating table 1, a protective shell 2 is installed on the top of the operating table 1, and a heat treatment assembly 3 is installed on the side end surface of the protective shell 2. The side end surface of the shell 2 is provided with a mounting groove 4 at the position corresponding to the heating box 301. The back of the console 1 is fixedly mounted with a multi-axis knife arm 6, and the bottom end of the multi-axis knife arm 6 is fixedly mounted with a knife rest 7. The console 1 A corrugated water outlet pipe 8 is fixedly installed on the top;

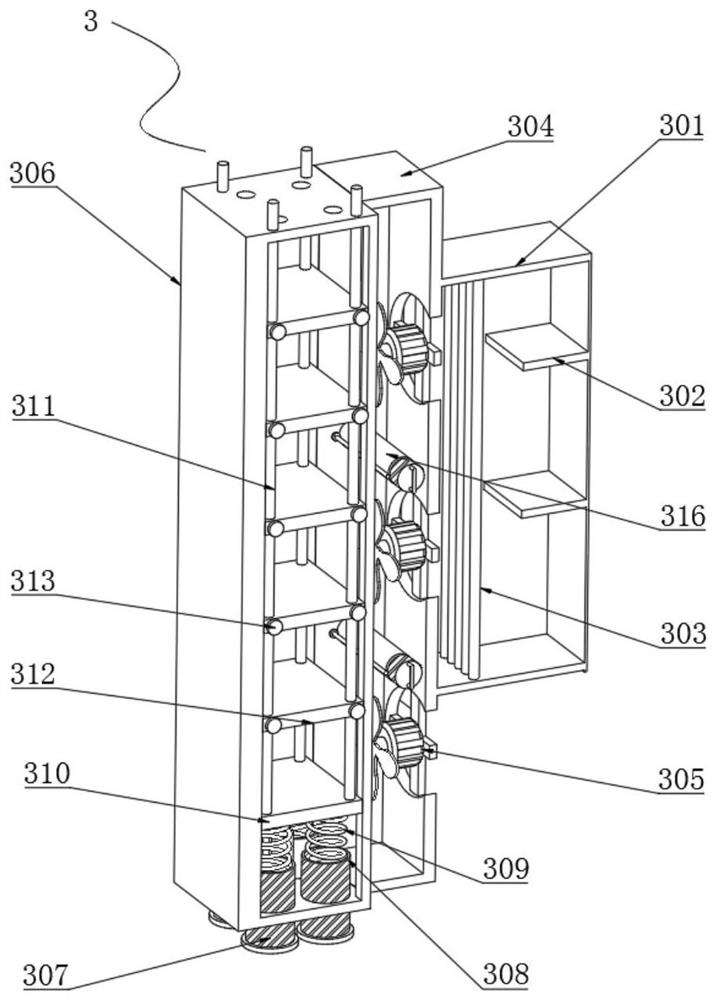

[0060] The heat treatment assembly 3 includes a heating box 301, a partition 302, a resistance heating rod 303, a bellows 304, a fan 305, a drying box 306, a height-adjusting screw cylinder 307, a height-adjusting groove 308, a support spring 309, a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com