Material drying equipment and application thereof

A technology for drying equipment and materials, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of production stagnation, material falling obstruction, bonding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

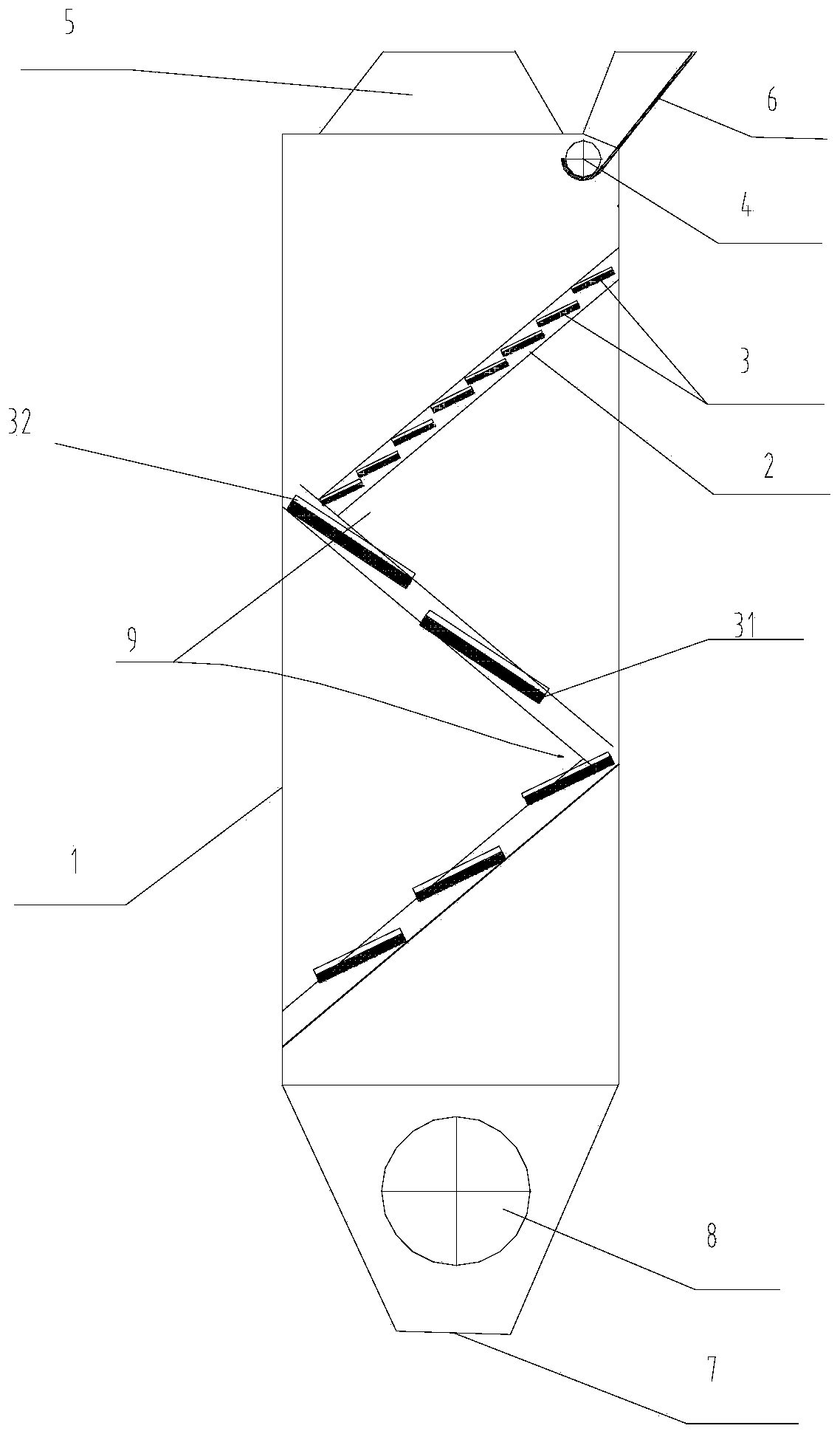

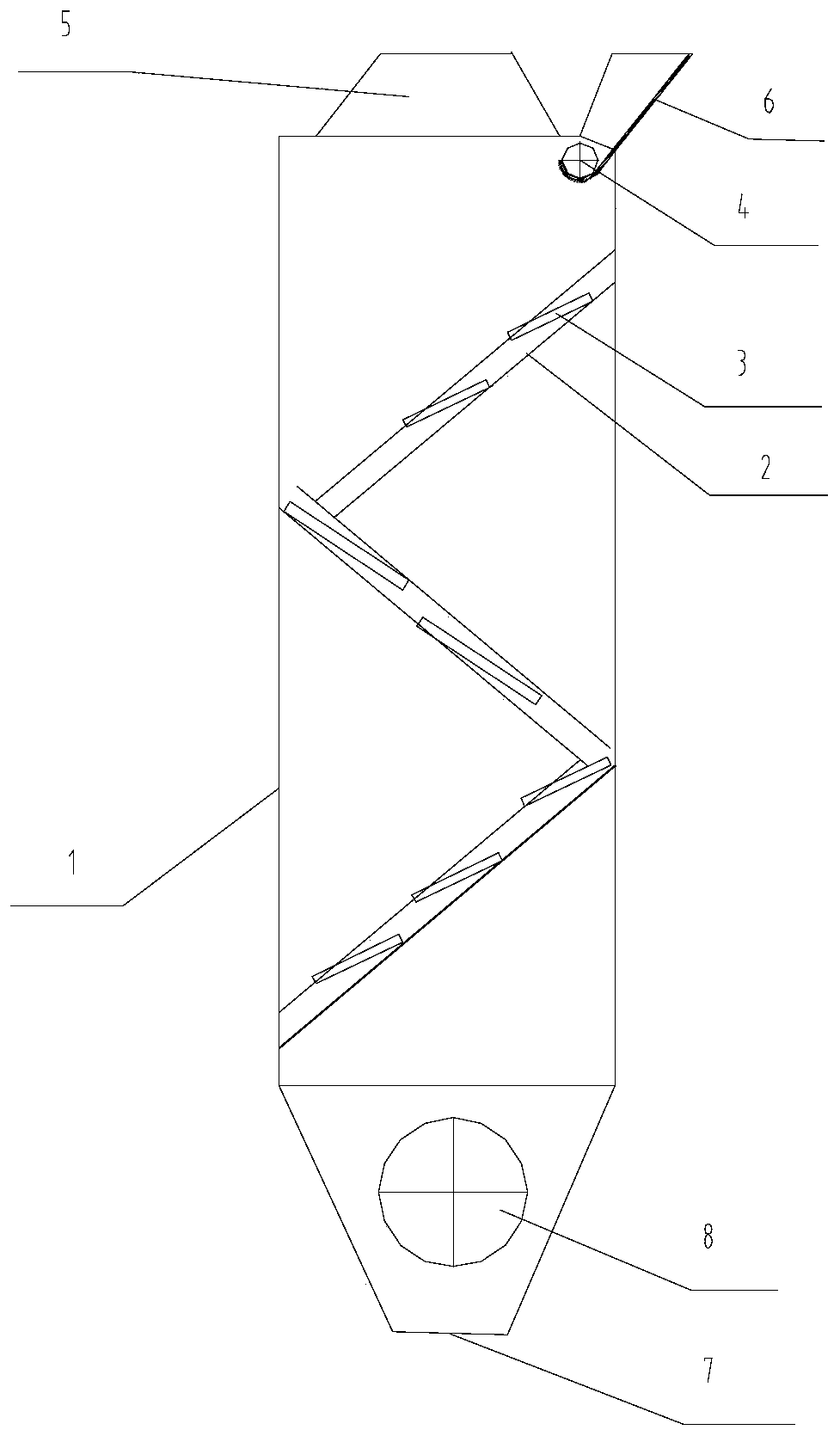

[0053] This embodiment provides a drying equipment for crushed coal, referring to figure 1 As shown, it includes a housing 1, and the inside of the housing 1 is provided with a material falling and returning mechanism 2 that is generally in the shape of a "Z". The material falling and returning mechanism 2 has three transmission sections that are inclined relative to the vertical direction, and each transmission section is provided with 10 A material guide plate 3 for delivering materials.

[0054] The downward inclination directions of the material guide plates 3 in the same transmission section are consistent, and the downward inclination directions of the material guide plates 3 in two adjacent transmission sections are opposite. In this embodiment, the inclination angle formed by the material guide plate and the horizontal line is 40°.

[0055] The material falling and returning mechanism 2 has a plurality of corners 9 . In this embodiment, two corners 9 are provided. T...

Embodiment 2

[0063] This embodiment provides a drying equipment for crushed coal, referring to figure 1 As shown, including the shell 1, the inside of the shell 1 is provided with a "Z"-shaped material falling and turning mechanism 2, and in each section of the "Z" shaped material falling and turning structure, there are 8 parallel material guide plate 3. The angle between the material guiding plate 3 and the horizontal line is 50°.

[0064] The material falling and returning mechanism 2 has a plurality of corners 9 . In this embodiment, two corners 9 are provided. The first material guide plate below each corner 9 is spatially in a position capable of catching the material on the material guide plate 3 above the corner 9 . And the first material guide plate below each corner 9 has a certain inclination angle to change the direction of motion of the material, and the direction of the downward inclination angle of the material guide plate 3 before and after the corner 9 is opposite to th...

Embodiment 3

[0071] The difference from Embodiment 1 is that the material guide plate 3 uses carbon steel as the skeleton support plate 31, and a smooth vacuum insulation panel is arranged on the upper surface of the carbon steel plate; in this embodiment, the thickness of the vacuum insulation panel is set to 10 mm.

[0072] After drying the pulverized coal, it was found that there is no problem of water vapor condensation on the surface of the vacuum insulation panel, and there is no phenomenon of sticking materials on the surface of the vacuum insulation panel during the drying process of the pulverized coal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com