Sheet billet continuous casting and rolling dummy rolling method and control system thereof

A thin slab continuous casting and slab technology, applied in rolling force/roll gap control, metal rolling, metal rolling, etc., can solve problems such as low operating rate and long abnormal downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

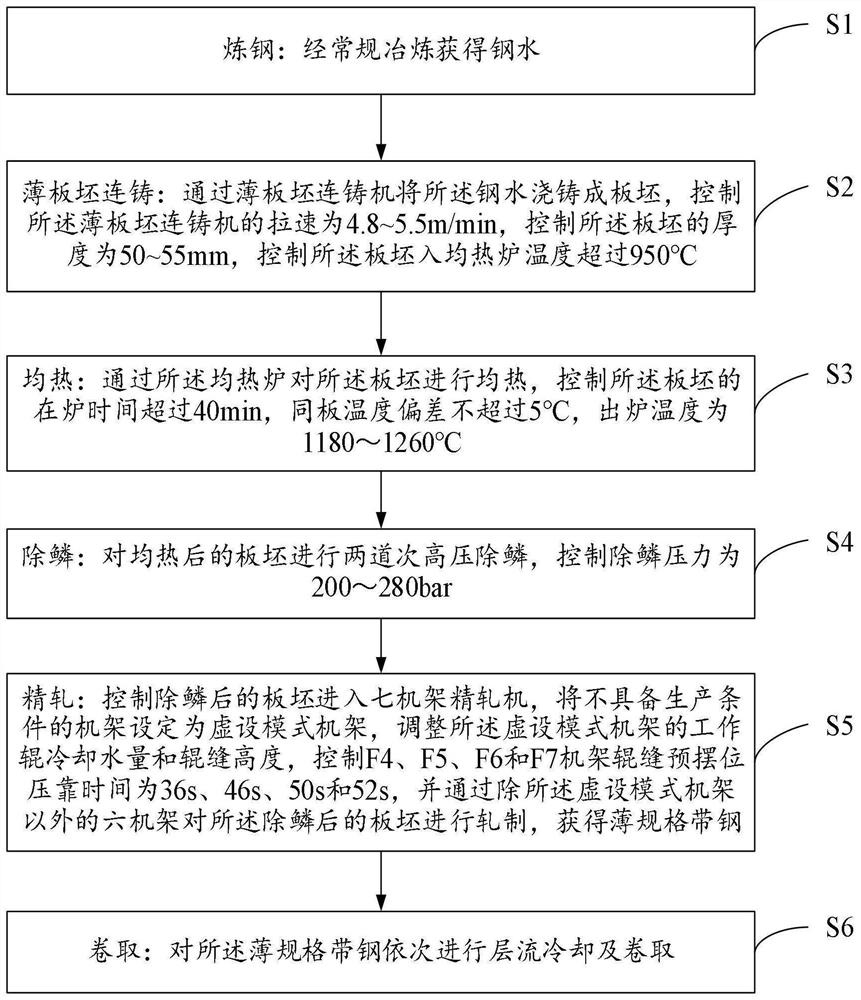

[0039] refer to figure 1 , figure 1 It is a schematic flow chart of a dummy rolling method for thin slab continuous casting and rolling in an embodiment of the present invention.

[0040] In this embodiment, the dummy rolling method of thin slab continuous casting and rolling is applied to an industrial computer, and the method includes:

[0041] 1) Steelmaking: molten steel is obtained through conventional smelting;

[0042] 2) Thin slab continuous casting: casting the molten steel into a slab through a thin slab continuous casting machine, controlling the casting speed of the thin slab continuous casting machine to be 4.8-5.5 m / min, and controlling the thickness of the slab to be 50 ~55mm, control the temperature of the slab entering the soaking furnace to exceed 950°C;

[0043] 3) Soaking: Soaking the slab through the soaking furnace, controlling the time of the slab in the furnace to exceed 40 minutes, the temperature deviation of the same plate does not exceed 5°C, and...

no. 2 example

[0069] Based on the same inventive concept, the embodiment of the present invention also provides a The thin slab continuous casting and rolling virtual rolling control system includes: a thin slab continuous casting machine, a soaking furnace, a high-pressure water descaling machine, a seven-stand finishing mill, laminar cooling equipment and a coiler.

[0070] The thin slab continuous casting machine is used to cast the molten steel into a slab after obtaining molten steel through conventional smelting, the casting speed of the thin slab continuous casting machine is controlled to be 4.8-5.5m / min, and the slab is controlled to The thickness of the slab is 50-55mm, and the temperature of the slab entering the soaking furnace is controlled to exceed 950°C;

[0071] The soaking furnace is used for soaking the slab, controlling the time of the slab in the furnace to exceed 40 minutes, the temperature deviation of the same plate does not exceed 5°C, and the temperature of the fu...

no. 3 example

[0077] Based on the same inventive idea, such as figure 2 As shown, the embodiment of the present invention also provides a computer-readable storage medium 200, on which a computer program 211 is stored, and when the program 211 is executed by a processor, the following steps are implemented:

[0078]Steelmaking: molten steel is obtained through conventional smelting; thin slab continuous casting: the molten steel is cast into slabs through a thin slab continuous casting machine, and the casting speed of the thin slab continuous casting machine is controlled to be 4.8 to 5.5 m / min, and the controlled The thickness of the slab is 50-55mm, and the temperature of the slab entering the soaking furnace is controlled to exceed 950°C; soaking: soaking the slab through the soaking furnace; descaling: soaking the soaked slab Carry out two passes of high-pressure descaling; finish rolling: control the slab after dephosphorization to enter the seven-stand finish rolling mill, set the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com