Coking indirect final cooling tower circulation washing process

A technology of cyclic washing and final cooling tower, which is applied in the coking oven, petroleum industry, combustible gas purification, etc., can solve the problem of blockage of the final cooling part, and achieve the effect of wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

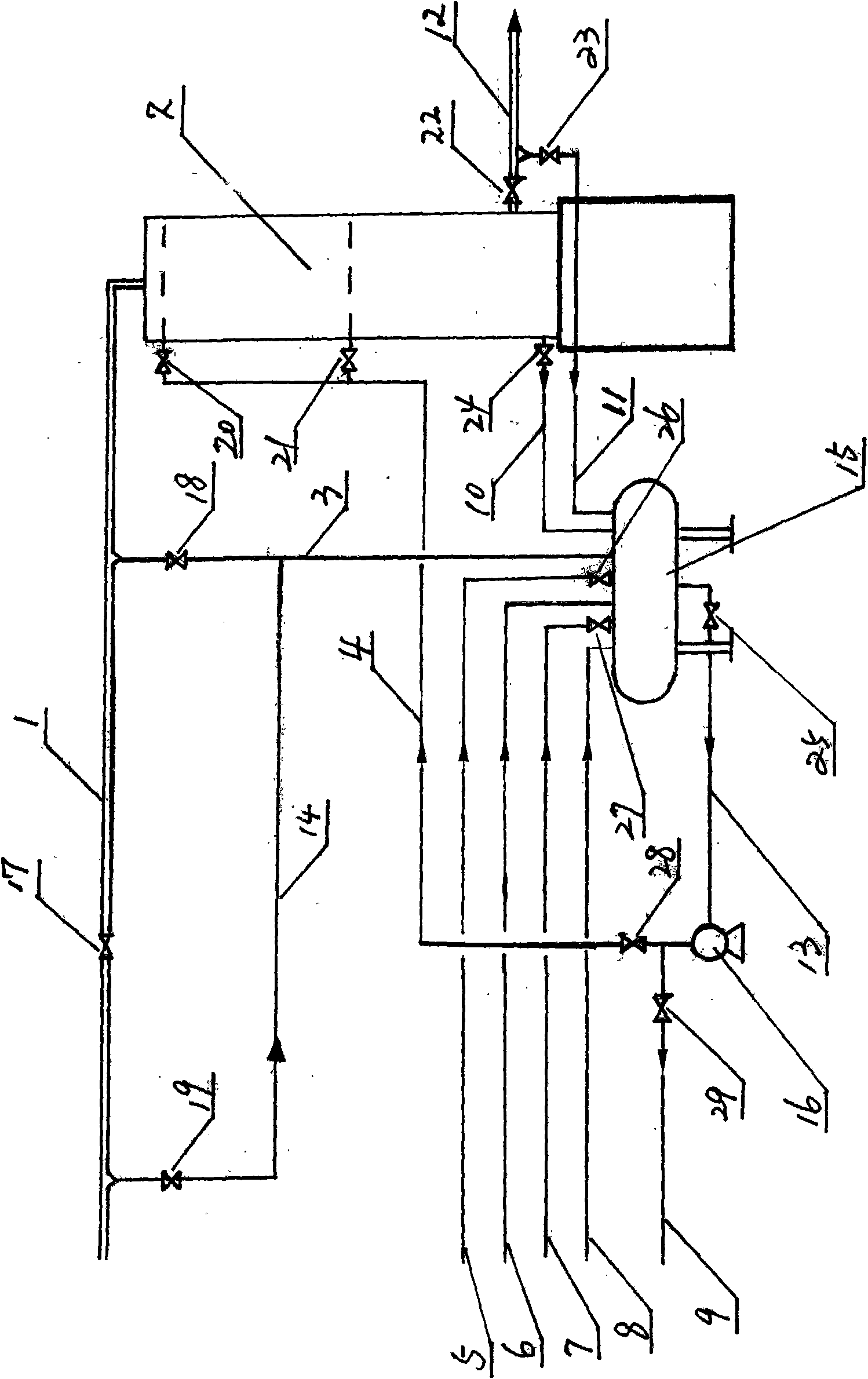

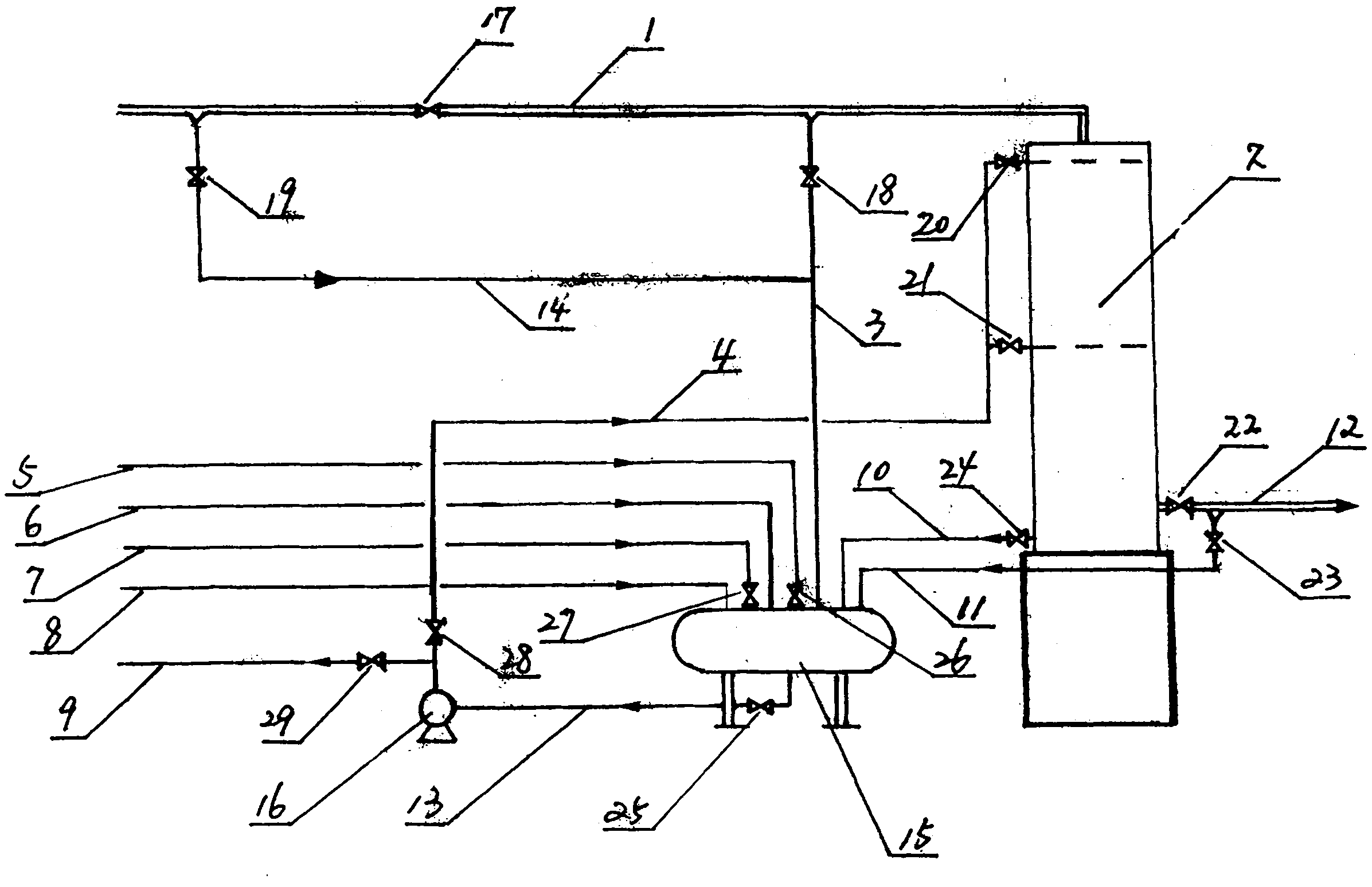

[0010] As shown in the figure, the gas pipeline 1 from the ammonium sulfate is connected to the final cooling tower 2, and a valve 17 is installed on the gas pipeline 1 from the ammonium sulfate, so that the coke oven gas from the ammonium sulfate section enters the horizontal tube final through the gas pipeline 1. The circulating water in the upper section of the cooling tower 2 and the cooling water in the lower section indirect heat exchange, reducing the gas from 55°C to 22-25°C, so that naphthalene and tar in the gas condense on the horizontal tube wall of the final cooling tower 2, The horizontal tube type final cooling tower 2 is connected with the gas washing benzene washing tower pipeline 12, and the gas after heat exchange through the horizontal tube type final cooling tower 2 is transported to the benzene washing tower through the gas washing benzene washing tower pipeline 12 for further purification, and the gas goes to the benzene washing tower for further purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com