Adding device capable of easily oxidizing precious alloys

A precious alloy and easy-to-oxidize technology, which is applied in the field of adding devices for easy-to-oxidize precious alloys, can solve the problems of instability and low yield of precious alloys, achieve convenient operation, increase the yield of precious alloy elements, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

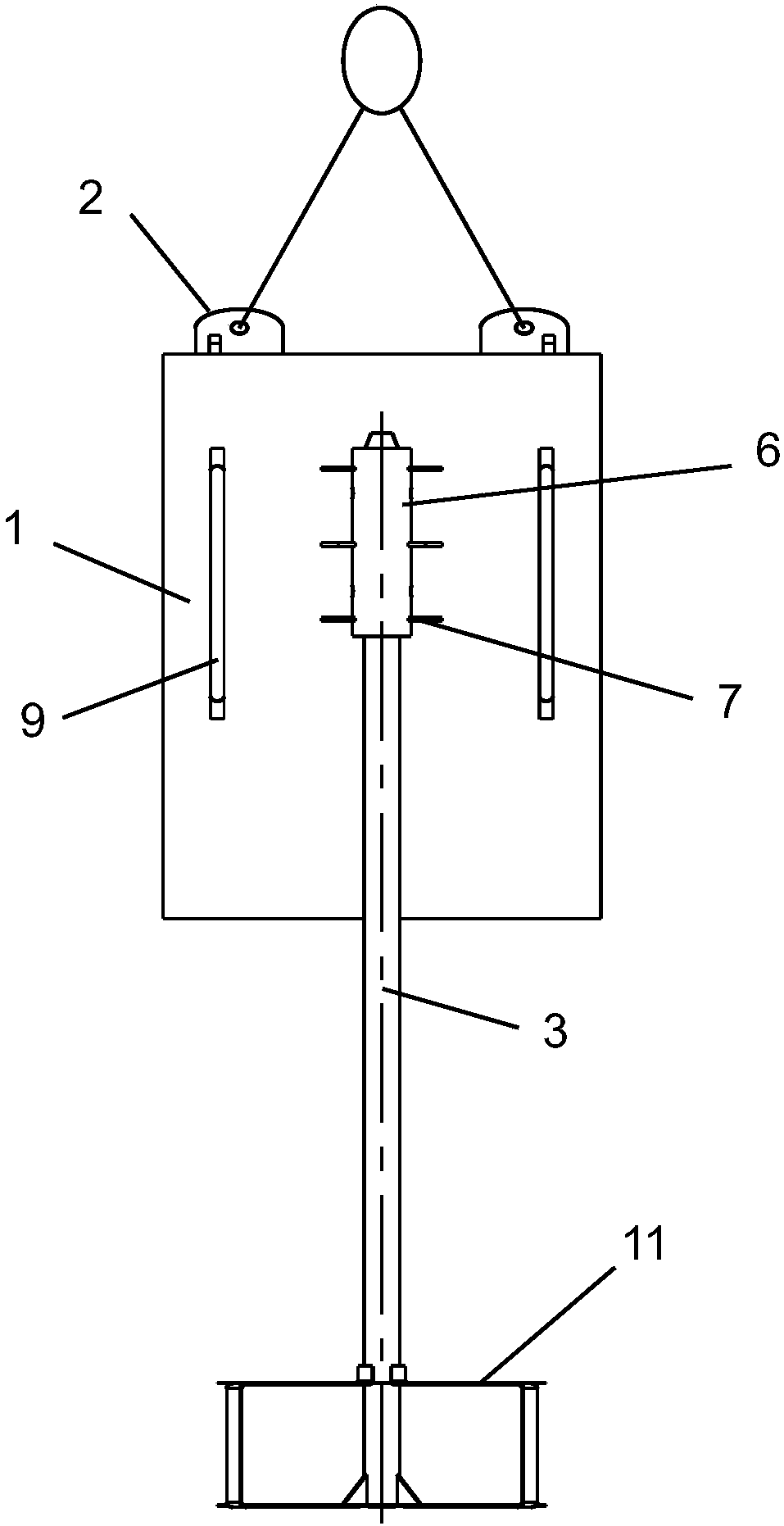

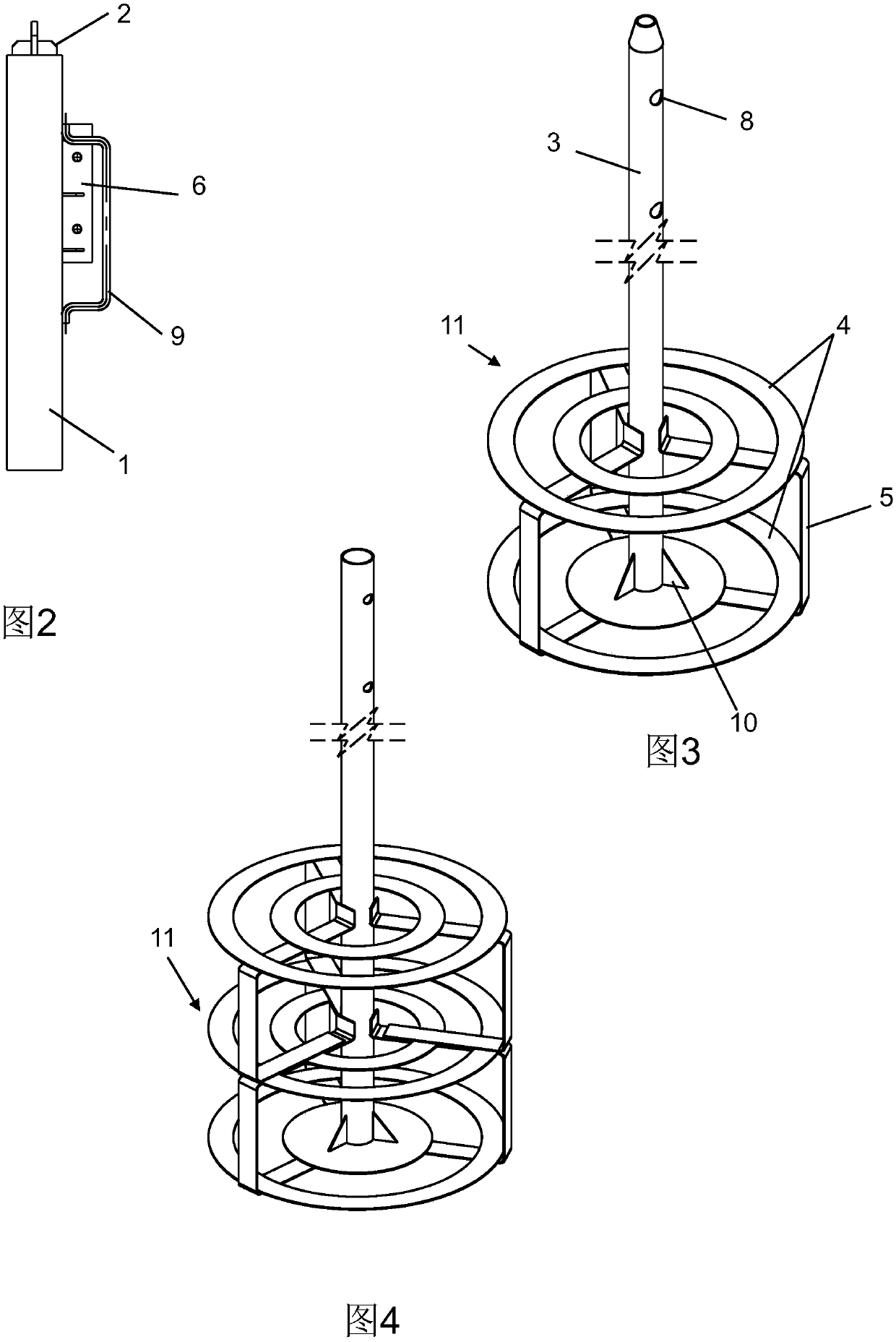

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The adding device of the easily oxidizable precious alloy of the present invention is as Figure 1-Figure 4 As shown, it mainly includes a briquetting mechanism and a silo mechanism. The briquetting mechanism includes a briquetting block 1, a pair of lifting lugs 2 arranged on the upper end of the briquetting block 1, and a detachable connecting part arranged on one side of the briquetting block 1. The silo mechanism includes several layers of silos 11 and booms 3. The silo 11 includes annular flat steel frames 4 composed of several concentric rings, several flat steel frames 4 radially connected to the concentric rings and axially connected to adjacent annular flat steel frames 4. The steel connecting beam 5, the lower end of the boom 3 extends into the center of the silo 11 and is connected with the bottom annular flat steel frame 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com