Steel tube on-line cooling roller bed control method

A technology of cooling roller table and control method, which is applied in the direction of temperature control, metal rolling, manufacturing tools, etc., can solve the problems of failing to control the comprehensive mechanical properties of the microstructure, single process, lack of post-rolling cooling means, etc. Ensure smooth production of steel pipes, speed up production rhythm, optimize export alignment and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

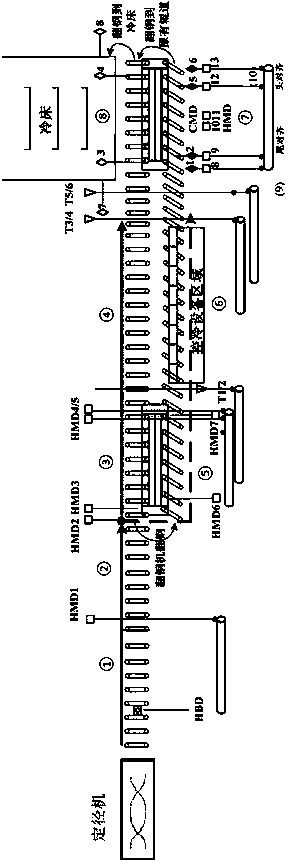

[0038] The online cooling roller table line is arranged next to the main conveying roller table line, and adopts V-shaped roller table, which is inclined at a certain angle. The online cooling roller line adopts the configuration of frequency conversion motor and gear reducer, and adopts an inclined arrangement with a certain angle. The online cooling roller table can rotate forward and reverse. Only forward rotation is possible under automatic conditions. Under manual conditions, it can rotate forward and reverse. The purpose of reverse rotation under manual conditions is to transport steel pipes that do not require cooling to the starting position.

[0039] Within a certain interval length, part of the online cooling roller table is equipped with an encoder for precise tracking of the position of the steel pipe. Steel pipe protection devices shall be installed on both sides of the online cooling roller conveyor line. Considering factors such as cooling water splashing du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com