Method for improving blast furnace bituminous coal injection proportion

A furnace bituminous coal, proportional technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as increasing the use of low-quality coal and shortage of high-quality coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Use a sealed fan to purge the coal mill, bag box and pulverized coal bin with nitrogen for 5 times to discharge the air in the pulverizing system, and then keep the flow of nitrogen at 6000m 3 / h, the content of foreign gas in the nitrogen of the milling system is ≤8%;

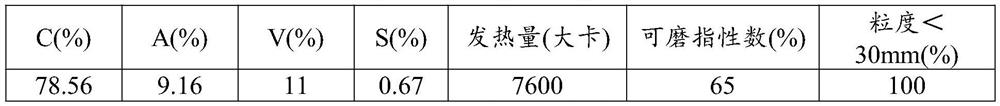

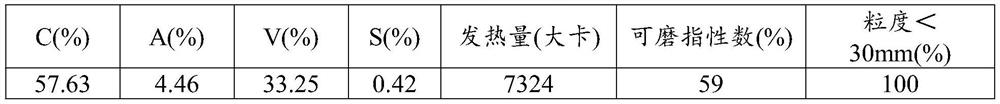

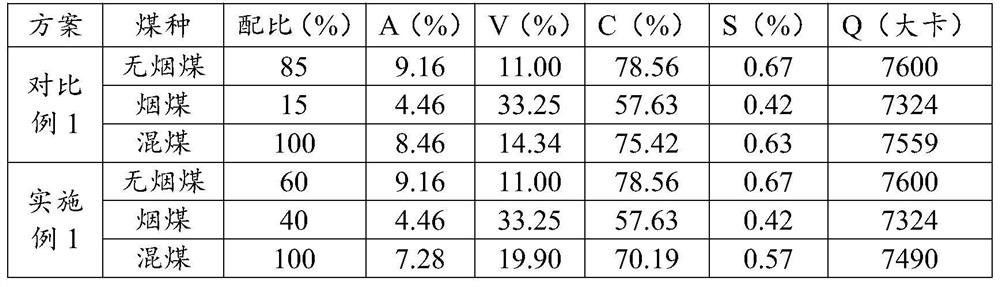

[0056] 60 kg of anthracite (performance parameters are shown in Table 1) and 40 kg of bituminous coal (performance parameters are shown in Table 2) were fed into two batching hoppers through the crane respectively, and then passed through the open coal feeder, flat belt, large The inclination and reversible belts are transported to the raw coal bunker, and then transported to the coal mill through the closed coal feeder, and the pulverization is carried out through the grinding rollers and grinding discs in the coal mill to obtain the injection coal; then vacuumized by the exhaust fan, The pulverized coal is transported to the bag box, and then the pulverized coal (performance parameters are shown in Ta...

Embodiment 2

[0059] The same as the method of Example 1, the difference is: the air supply temperature of the blower is 1240 ° C, and the oxygen enrichment of the air supply is 9800m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com