Detecting tool and method for crystallizer protective slag

A mold mold powder and detection tool technology, which is applied in the direction of manufacturing tools, metal processing equipment, indicating equipment/measuring equipment configuration, etc., can solve the problem of inaccurate measurement of liquid slag layer, sintered layer, powder slag layer thickness, etc. Achieve the effect of simple production, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

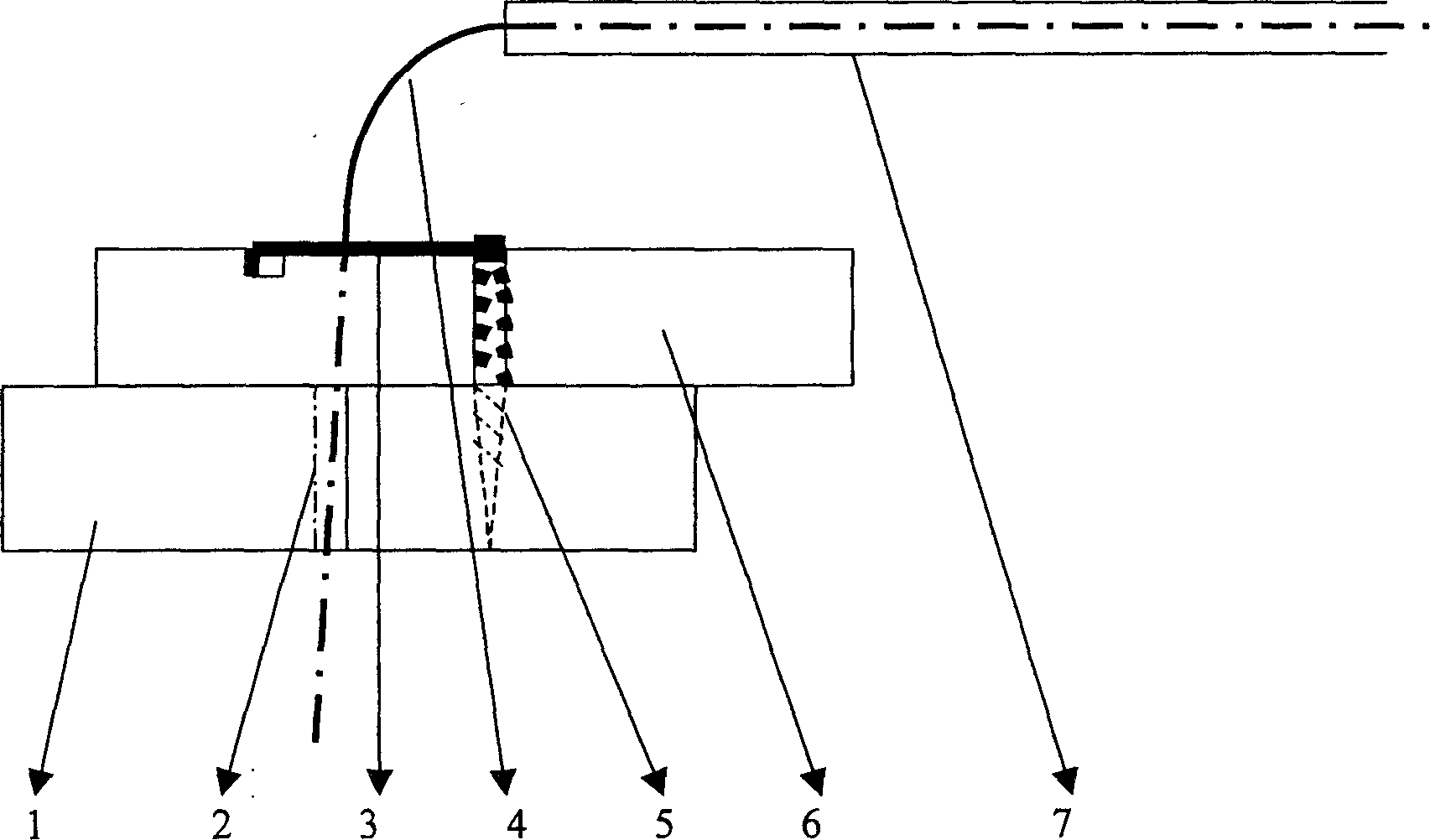

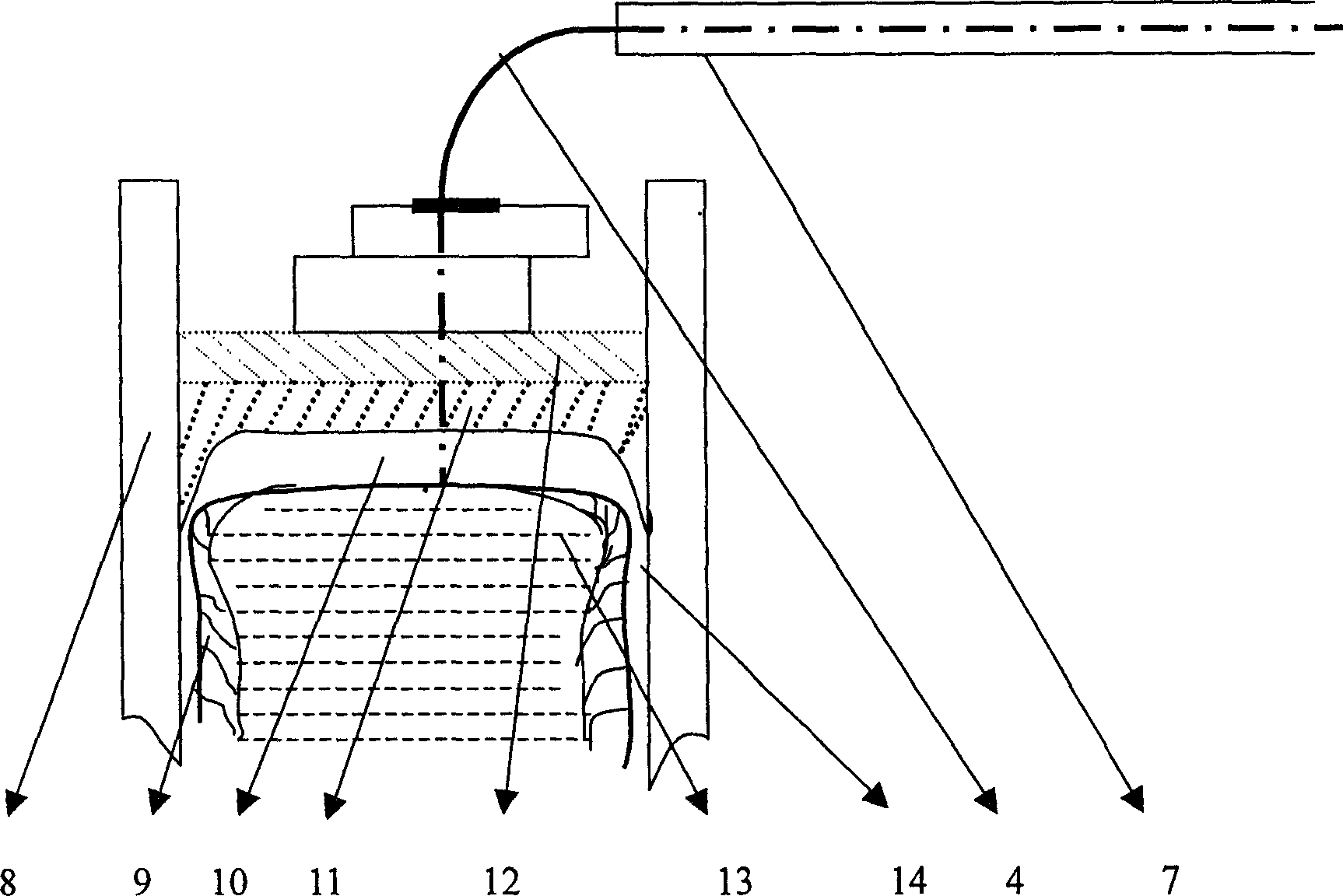

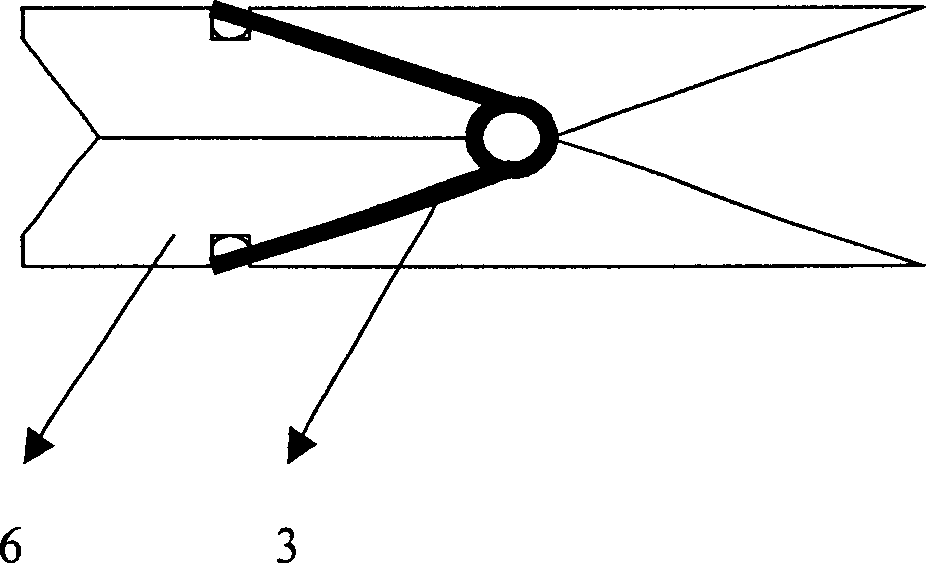

[0015] refer to figure 1 , 2 , 3, 4, a detection tool and detection method thereof for mold mold slag, made up of copper tube 7, wooden clip 6, plank 1, iron nail 5, copper-plated iron wire 4, copper tube 7 is long 0.7m, diameter It is 1 point, the diameter of the copper-plated iron wire 4 is 2mm, the length × width × thickness of the wooden board 1 is 70mm×50mm×15mm, the wooden clip 6 is fixed on the wooden board 1 by the iron nail 5, and there is a wooden clip spring 3 on the wooden clip, and the wooden board 1 The center is drilled with a through hole 2, and the diameter of the through hole 2 is 3mm. Copper-plated iron wire 4 is worn in the copper pipe 7. The copper-plated iron wire 4 is fixed by wooden clips 6, and then passes through 80mm from the through hole 2 in the center of the plank 1. During detection, the steel pourer holds the copper pipe 7 with his hand, inserts the copper-plated iron wire 4 passing through the wooden board 1 into the molten steel of the crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com