Ink-jet type 3D printer

A 3D printer, inkjet technology, applied in the field of additive manufacturing, can solve the problems of powder coating car weight, affect printing quality, complexity and other problems, and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

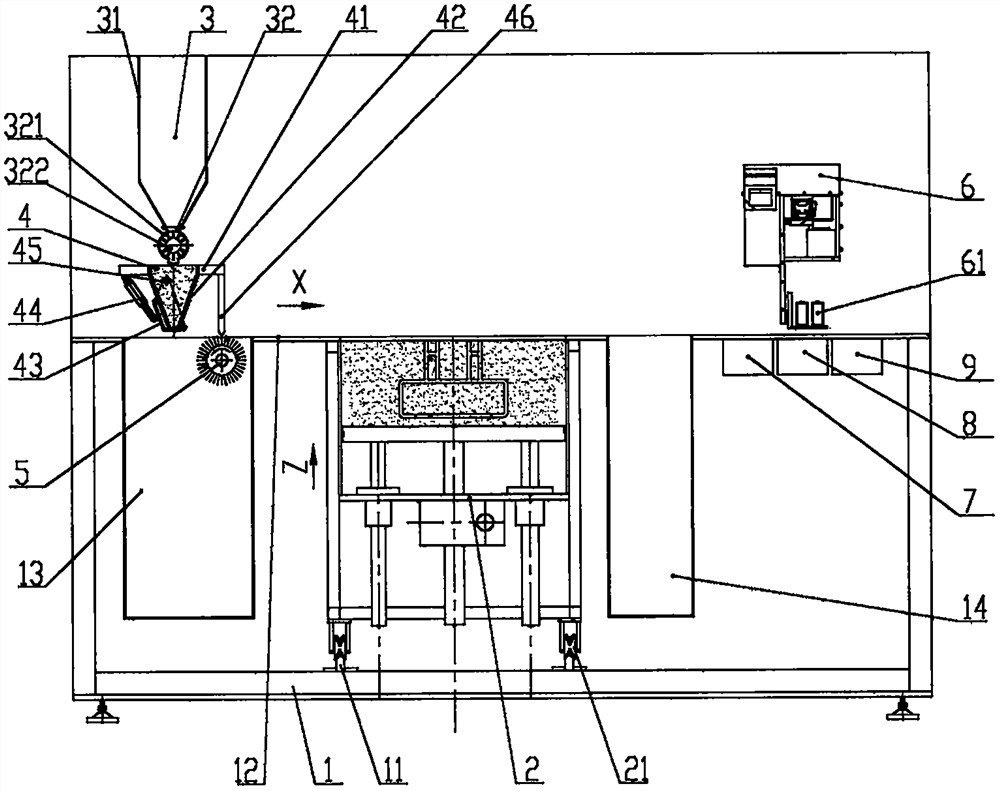

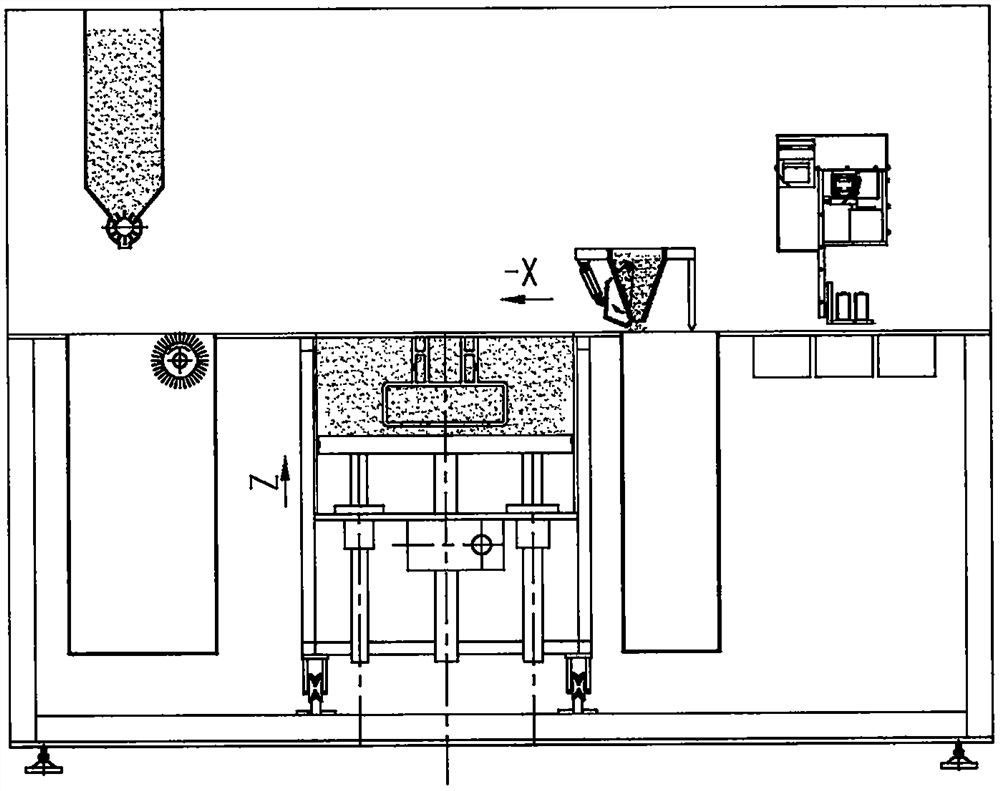

[0023] like figure 1 Sum figure 2 As shown, this is a positive cross-sectional view of the inkjet 3D printer embodiment, and a shaped cylinder moving guide rail 11 is mounted on the frame 1, and the forming cylinder system 2 is formed in a forming cylinder moving roller 21, and the shaped cylinder moving roller 21 is mounted. The forming cylinder moves the guide rail 11, and can be moved along the guide rail, and the left-filled collector box 13 and the right falling material collecting box 14, the feed system 3 are mounted on the left and right side of the forming cylinder system below the working surface 12 of the frame. Mounted above the worksheet, a scraper cleaning system 5 is mounted in the left stock collector box 13 below the feeding system 3, the print test device 7, the nozzle cleaning device 8, the shutdown head moisturizing protective device 9 is installed at work Next 12, close to the right falling collector box 14, the picking cart 4 and the ink jet print cart 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com