Micro-reactor suitable for micro-liquid mixing and biochemical reaction and manufacturing method thereof

A biochemical reaction and trace liquid technology, applied in the direction of chemical/physical/physicochemical process of energy application, can solve the problem of high fluid requirements and achieve the effect of achieving a uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

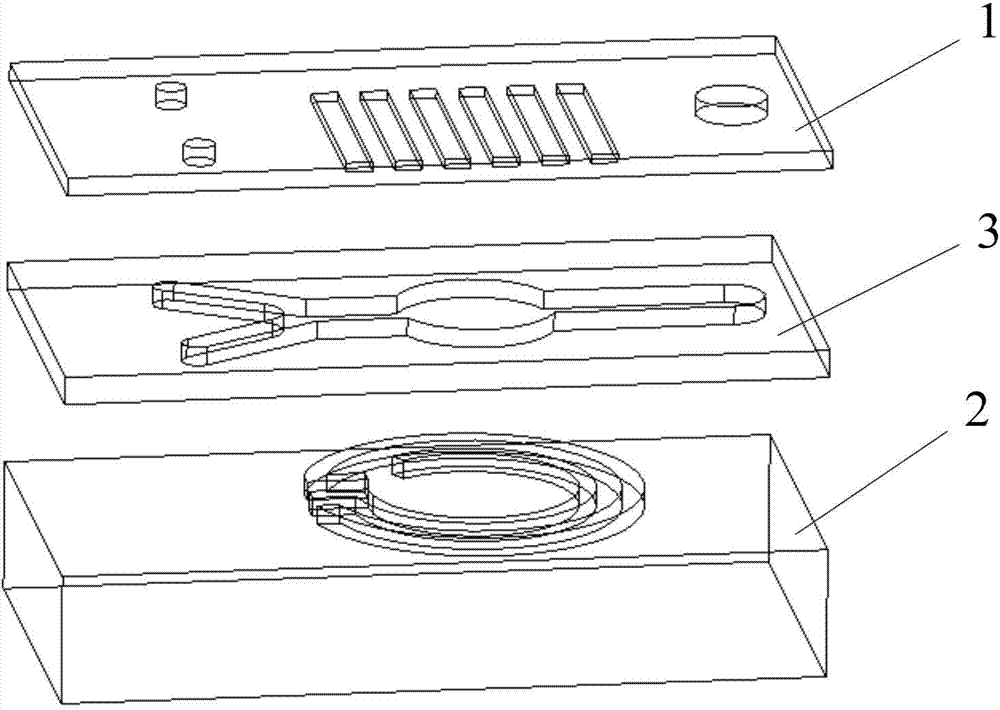

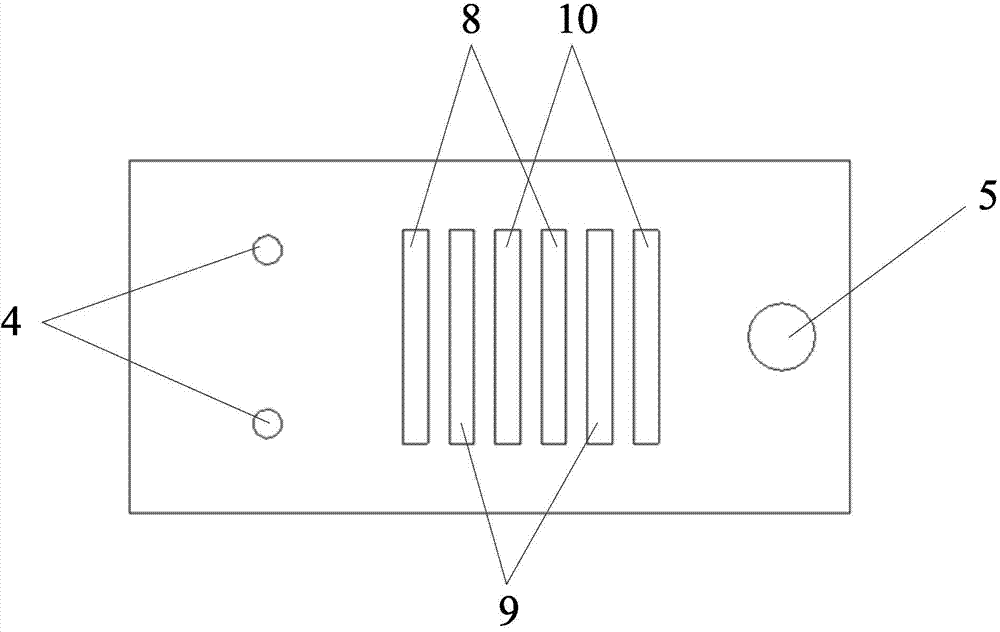

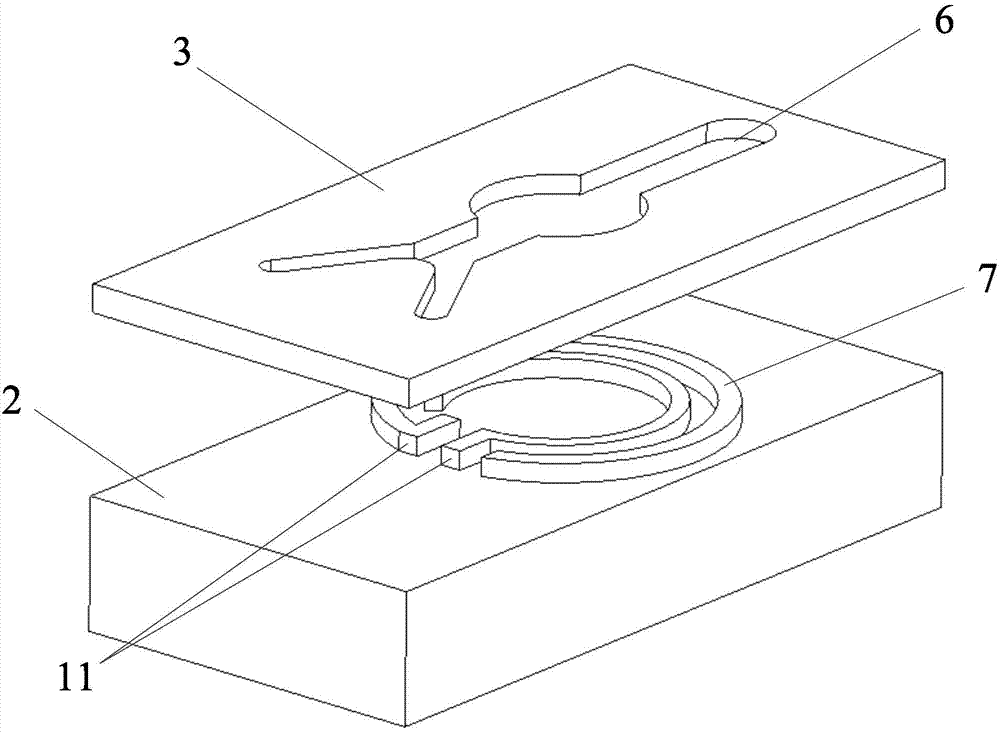

[0028] see Figure 1 to Figure 3 , the present invention is a kind of microreactor suitable for micro-liquid mixed biochemical reactions, comprising an upper cover plate 1 and a lower base plate 2 docked with the upper cover plate 1, wherein the upper cover plate 1 is a PDMS flat plate, and the lower base plate 2 is made of silicon The sheet is used as the base; the upper cover plate 1 is provided with a liquid inlet 4 and a liquid outlet 5, and the liquid inlet 4 and the liquid outlet 5 are respectively arranged on both sides of the temperature control structure. The inner side of the upper cover plate 1 is provided with a temperature control structure for controlling the temperature of the microfluidic reaction area in the micro-channel 6 , and the temperature control structure is facing the micro-channel 6 . The temperature control structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com