Controllable temperature deep cooling processing system based on self supercharging cryogenic fluids conveying technology

A technology of cryogenic treatment and low-temperature fluid, which is applied in household refrigeration equipment, lighting and heating equipment, household appliances, etc., and can solve problems such as slow cooling rate, fast cooling rate, and large thermal shock of liquid method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

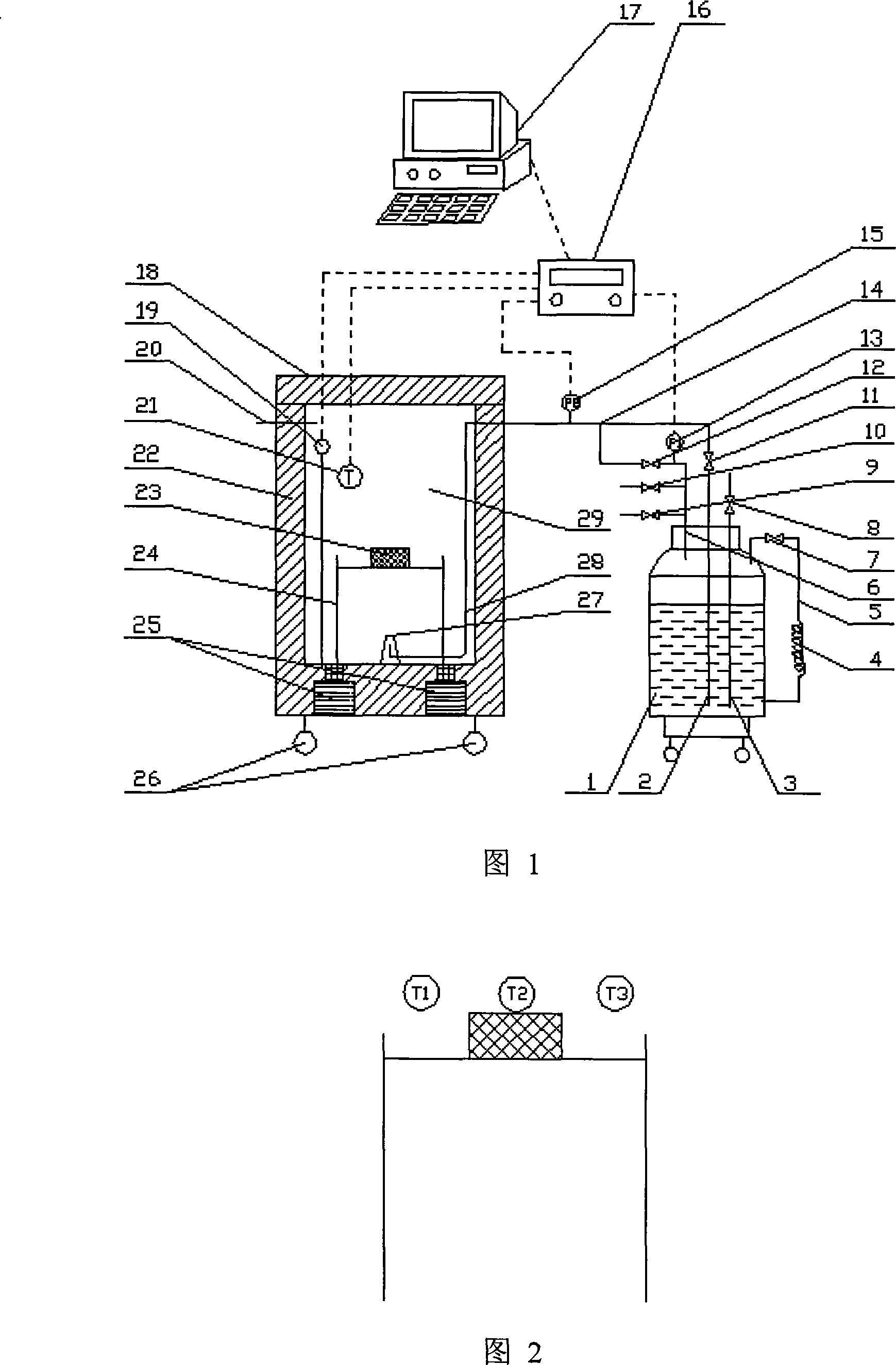

[0011] As shown in Figure 1, the temperature-controllable cryogenic treatment system of the self-pressurized low-temperature fluid delivery technology includes a liquid nitrogen storage tank 1, an infusion pipe 2, a liquid injection pipe 3, a vaporizer 4, a self-pressurization circuit 5, a gas delivery pipe 6, an automatic Boost regulating valve 7, liquid injection valve 8, safety valve 9, manual pressure relief valve 10, infusion valve 11, gas delivery valve 12, pressure sensor P113, tee pipe 14, pressure sensor P2 15, data acquisition instrument 16, computer 17. Cryogenic treatment chamber top cover 18, liquid level gauge 19, exhaust pipe 20, thermometer 21, cryogenic treatment chamber box 22, workpiece to be processed 23, shelf 24, support structure 25, moving wheel 26, porous baffle 27. Cooling medium delivery pipe 28, cryogenic treatment chamber 29; the box body 22 of the cryogenic treatment room has a double-layer structure of inner and outer walls, the inner and outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com