Thrust water hydraulic cylinder

A water-hydraulic and thrust technology, applied in the hydraulic field, can solve problems such as unsolved sealing problems of thrust water-hydraulic cylinders, difficult promotion and application, hydraulic oil pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

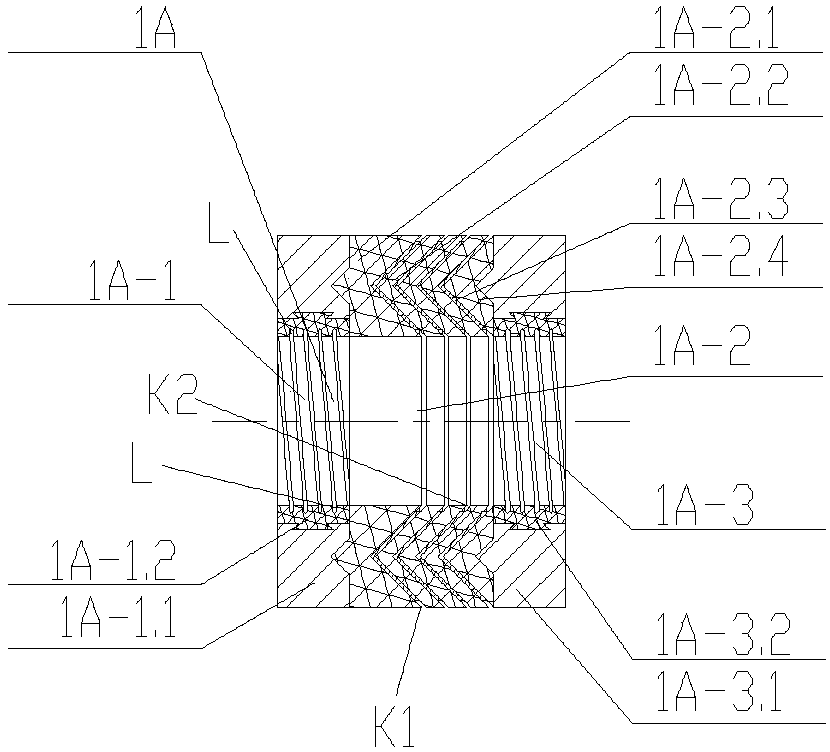

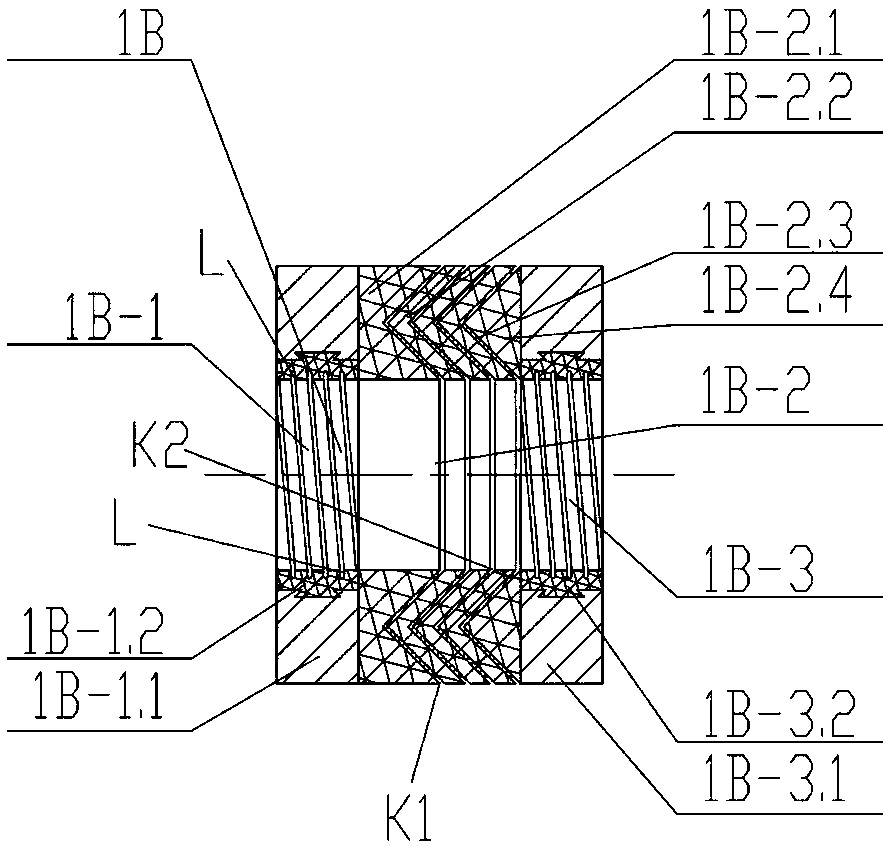

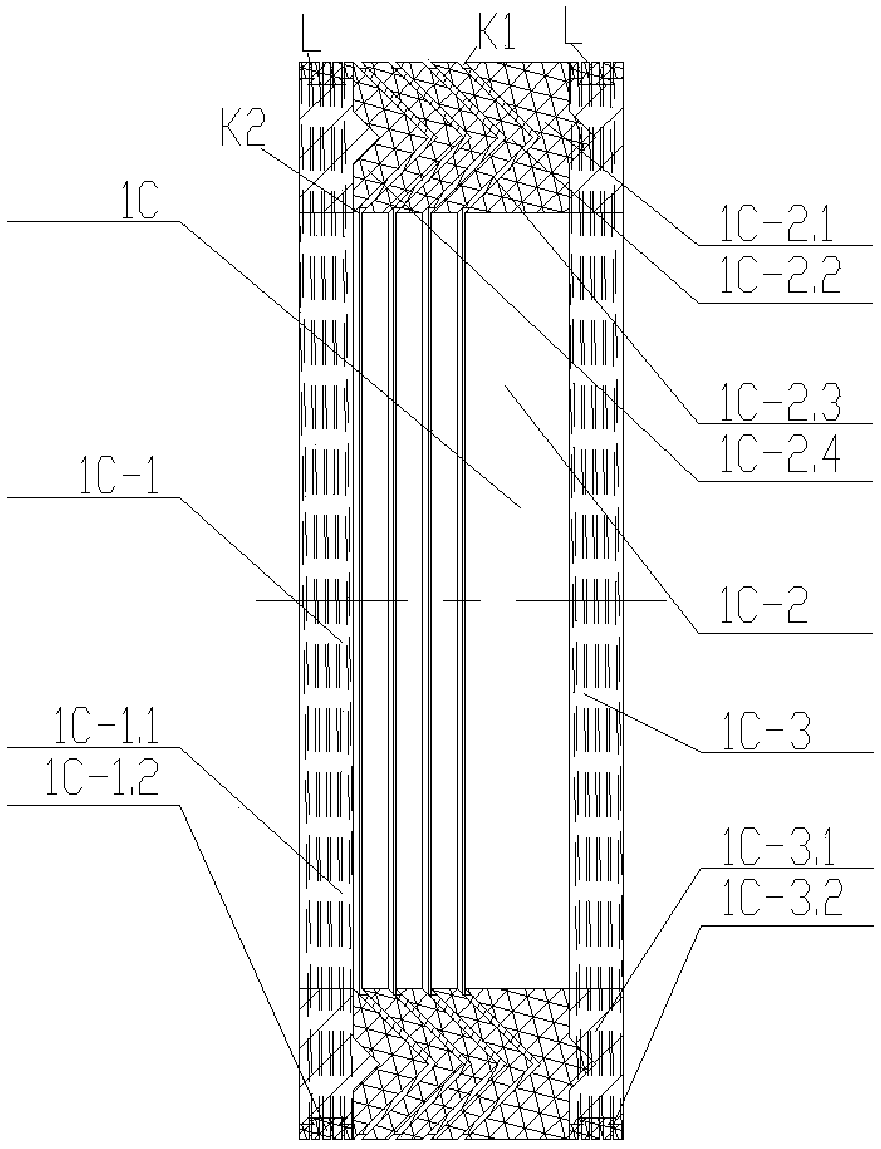

[0056] In the above summary of the invention and the following embodiments, in order to distinguish the parts of components with the same name in each embodiment, “A”, “B” and “C” are respectively added before / after the names of the parts of components with the same name And "D" and words such as "front", "back", "left" and "right", there is no special order meaning. The matching connection part of the valve plate A and the valve plate B of the drainage check valve of the present invention, the matching connection part of the valve plate C and the valve plate D of the water suction check valve, the cooperation of the drainage check valve block and its embedded end cover One steel ball and several one-way flow channels are provided for the connection part and the water-absorbing one-way valve block and the matching connection part embedded in the end cover, and the "several" here are preferably 3 to 7; the length Several pressurized water inlets and outlets and several pressuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com