Pressure type microwave reactor

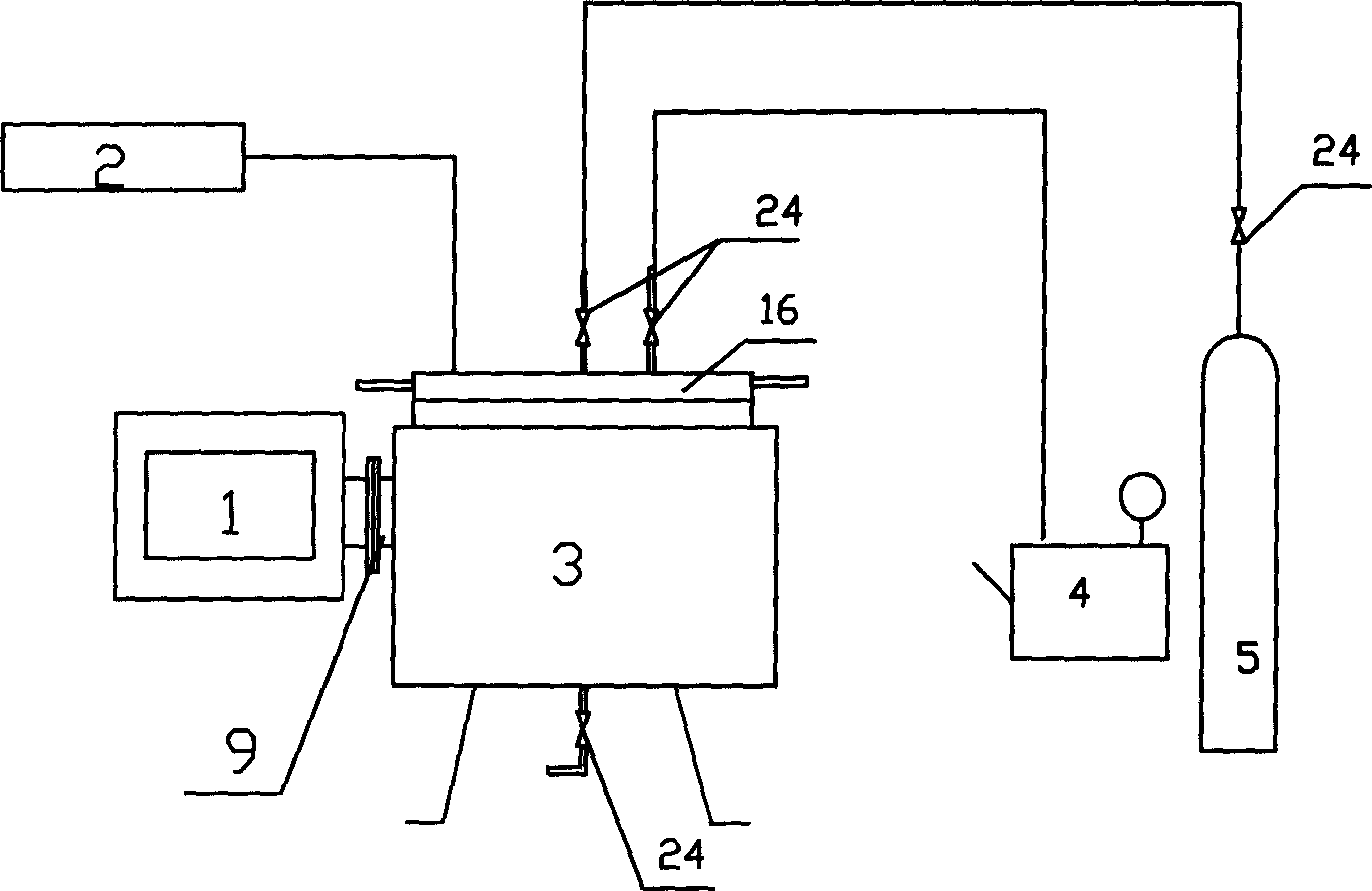

A microwave reaction and pressure type technology, applied in the field of pressure vessels, can solve problems such as difficult production, cumbersome operation, and structural feature determination, and achieve the effects of fast heating speed, wide application, and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

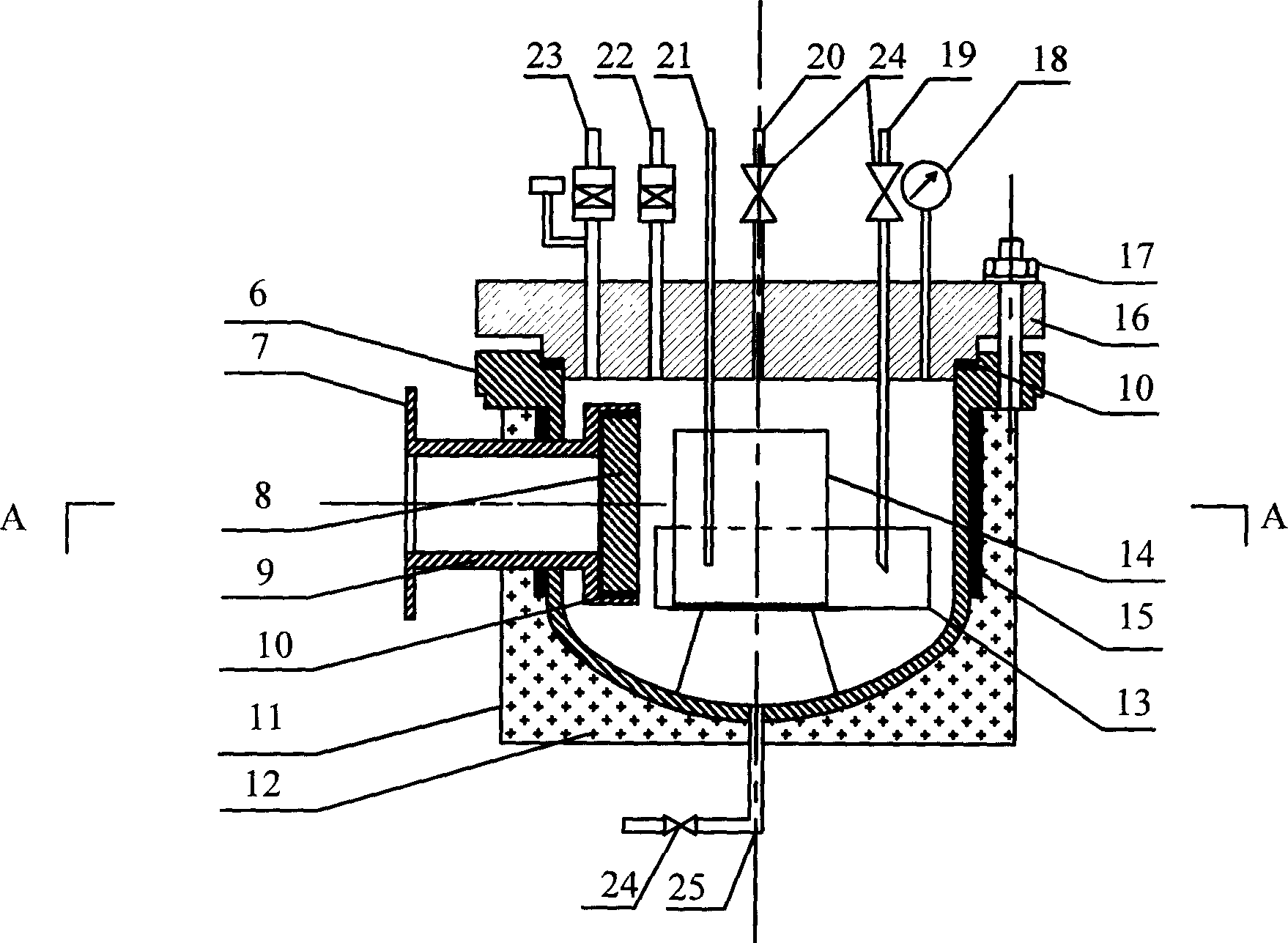

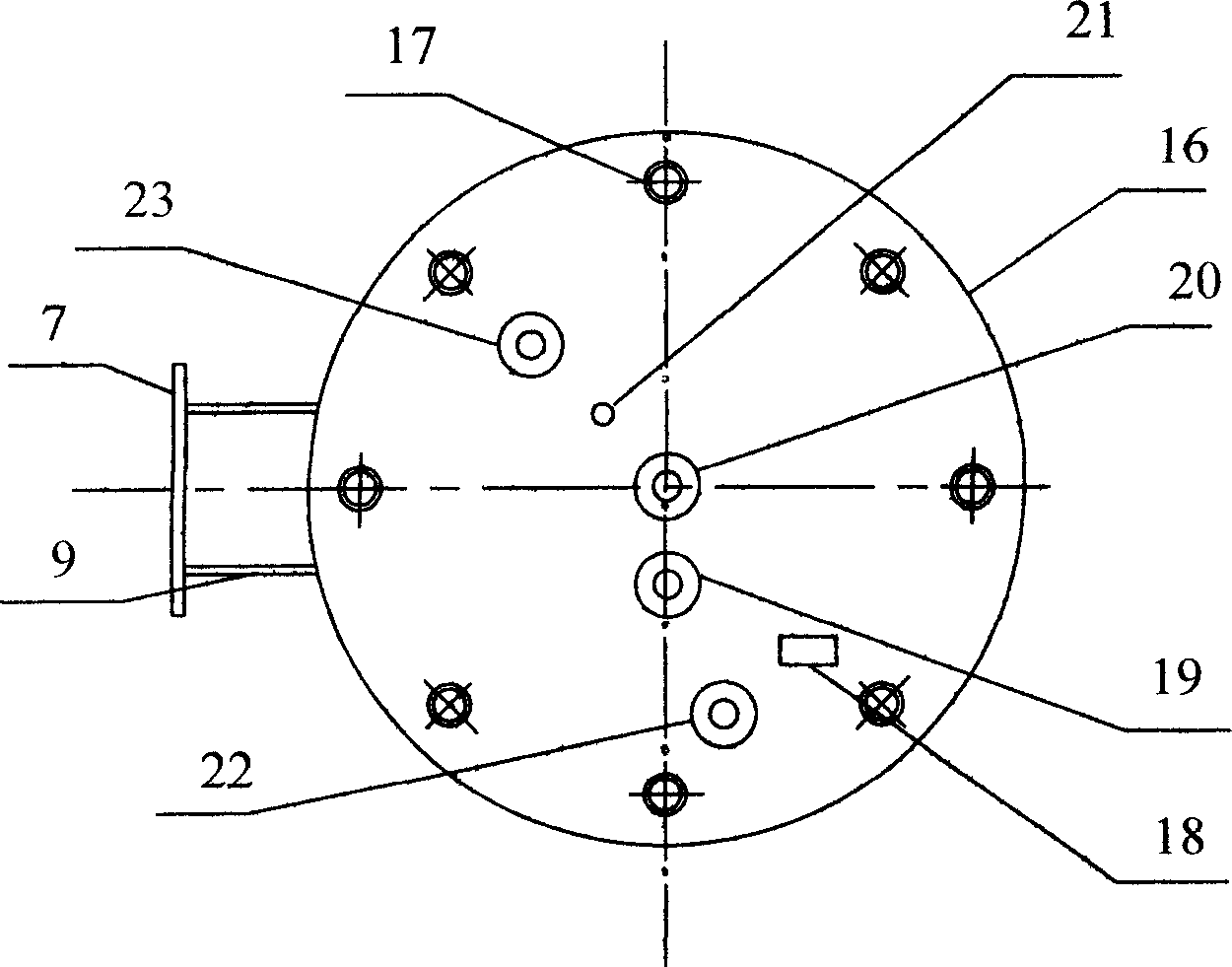

Method used

Image

Examples

Embodiment 1

[0032] For the development and experiment of the present invention, a set of small-scale experimental equipment is specially designed. The factory design pressure is 5MPa and the design temperature is 250°C. Size is the rectangle of 90 * 45mm, and the size of circular quartz glass is Φ 120 * 18mm. The stage [14] is a 500ml experimental beaker, and the liquid stage [13] is a plastic beaker of Φ 110 * 40mm.

[0033] Using the above-mentioned experimental device, taking heating water to 160°C as an example, the operation details of this device will be further explained. The operation steps are as follows:

[0034] Preparation

[0035] First, adjust the knob on the automatic pressure relief solenoid valve [23] to a working pressure of 0.7MPa, (at 160°C, the saturated vapor pressure of water is 0.61MPa) the working pressure must be greater than the saturated vapor pressure at this temperature;

[0036] Secondly, turn on the switch on the reactor controller [2] to preheat the jacke...

Embodiment 2

[0046] xx oil refinery production wastewater treatment

[0047] The distillation wastewater retrieved from the xx refinery has a small amount of impurities in the water, which is relatively transparent but has a strong pungent smell. The purpose of the treatment is to degrade the COD of the refinery wastewater by using microwaves and implementing high temperature and high pressure in the reactor. The specific implementation steps are as follows:

[0048] Preparation

[0049] First of all, sampling analysis, using the potassium dichromate method to measure the COD value of the water sample, the COD content is about 5000mg / L;

[0050] Next, turn on the switch on the reactor controller [2] to preheat the jacket [15] to 50°C to 60°C;

[0051] Then, the selection of parameters: microwave input power 660w, treatment water volume 400ml, reaction temperature 200°C, pressure upper limit 1.6MPa, residence time 10 minutes, activated carbon catalyst is selected, and the dosage is 4% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com