MVR evaporation system, and starting and preheating method thereof

An evaporation system and evaporation temperature technology, applied in the direction of evaporation, separation methods, evaporator accessories, etc., can solve the problems of complex system configuration, low preheating efficiency, long time, etc., achieve simplified system structure, short preheating time, and avoid The effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

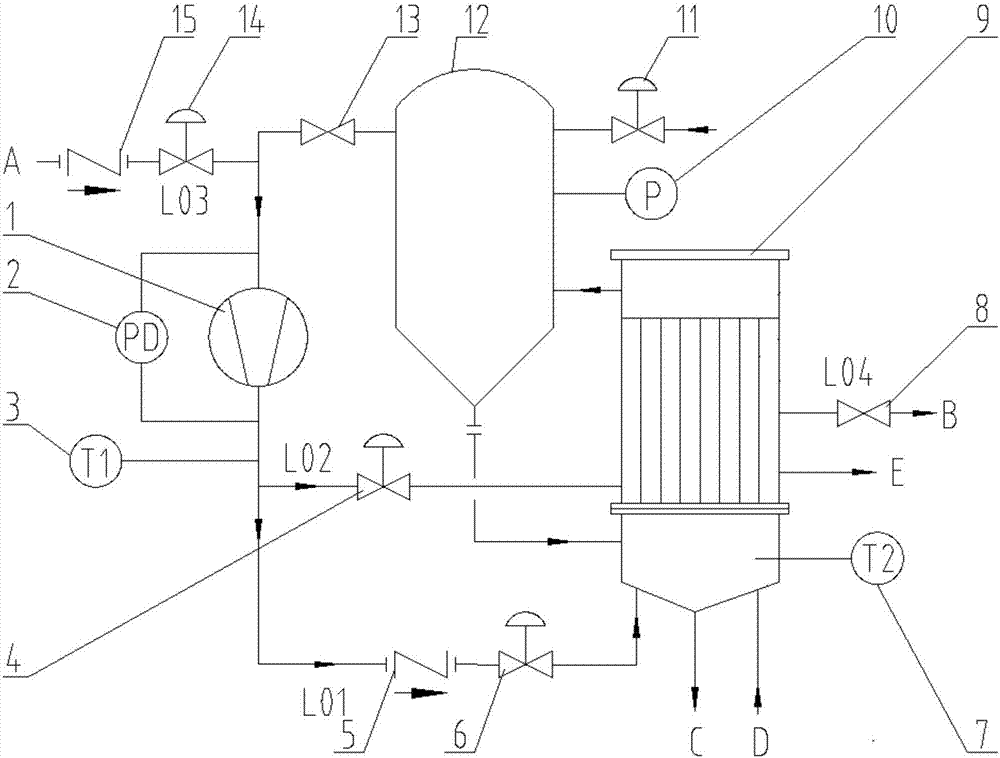

[0022] A kind of MVR evaporation system provided by this embodiment, such as figure 1 Shown: comprise steam compressor 1, the separator 12 that is connected with steam compressor 1 and heat exchanger 9; Said heat exchanger 9 comprises tube side and shell side; The outlet of described steam compressor 1 passes through the first tube The road L01 and the second pipeline L02 are respectively connected to the inlet below the tube side of the heat exchanger 9 and the inlet below the shell side; the outlet of the tube side of the heat exchanger 9 is connected to the inlet below the separator 12 through a pipeline; The upper outlet of the separator 12 is connected to the inlet of the steam compressor 1 through a pipeline.

[0023] This embodiment also includes a third pipeline L03 installed at the inlet of the steam compressor 1 for replenishing water; a first check valve 15 and a third pneumatic valve 14 are installed on the third pipeline L03. It also includes an exhaust pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com