Roller type composting reactor with composting tail gas waste heat recovery and purification functions

A composting reactor and waste heat recovery technology, applied in the field of composting reactors, can solve the problems of large floor space, difficulty in realizing composting exhaust heat and nitrogen recovery and utilization, high construction and operation costs, achieving material preheating and promoting microorganisms. The effect of breeding and increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

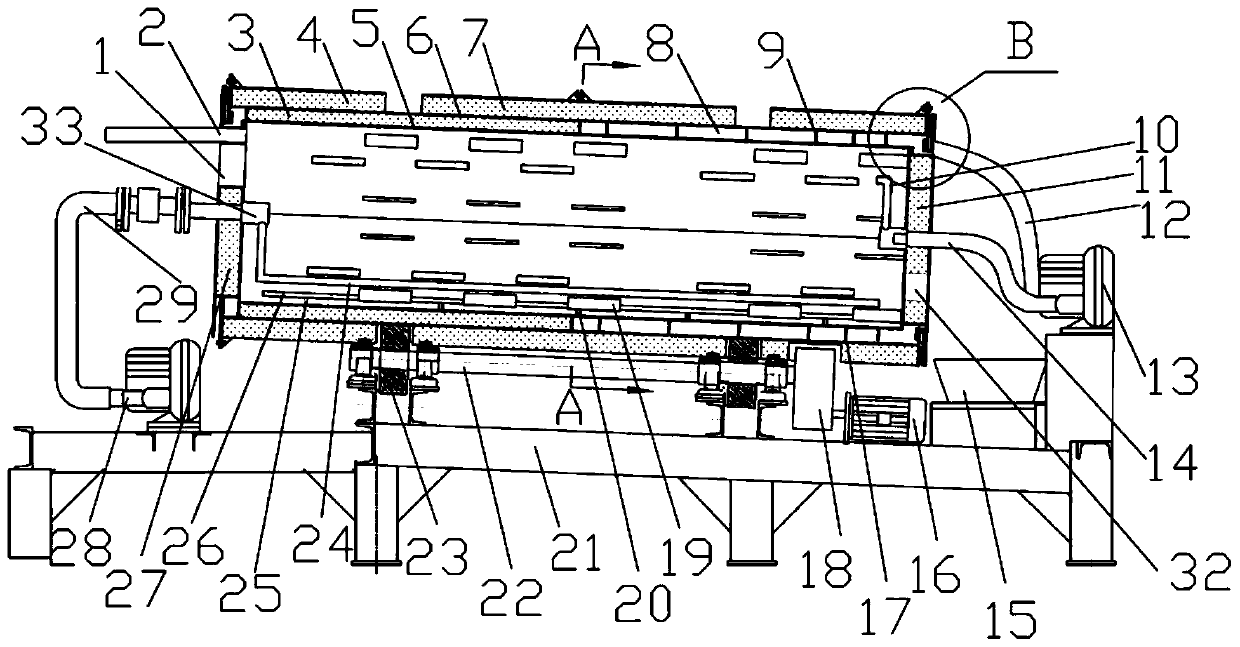

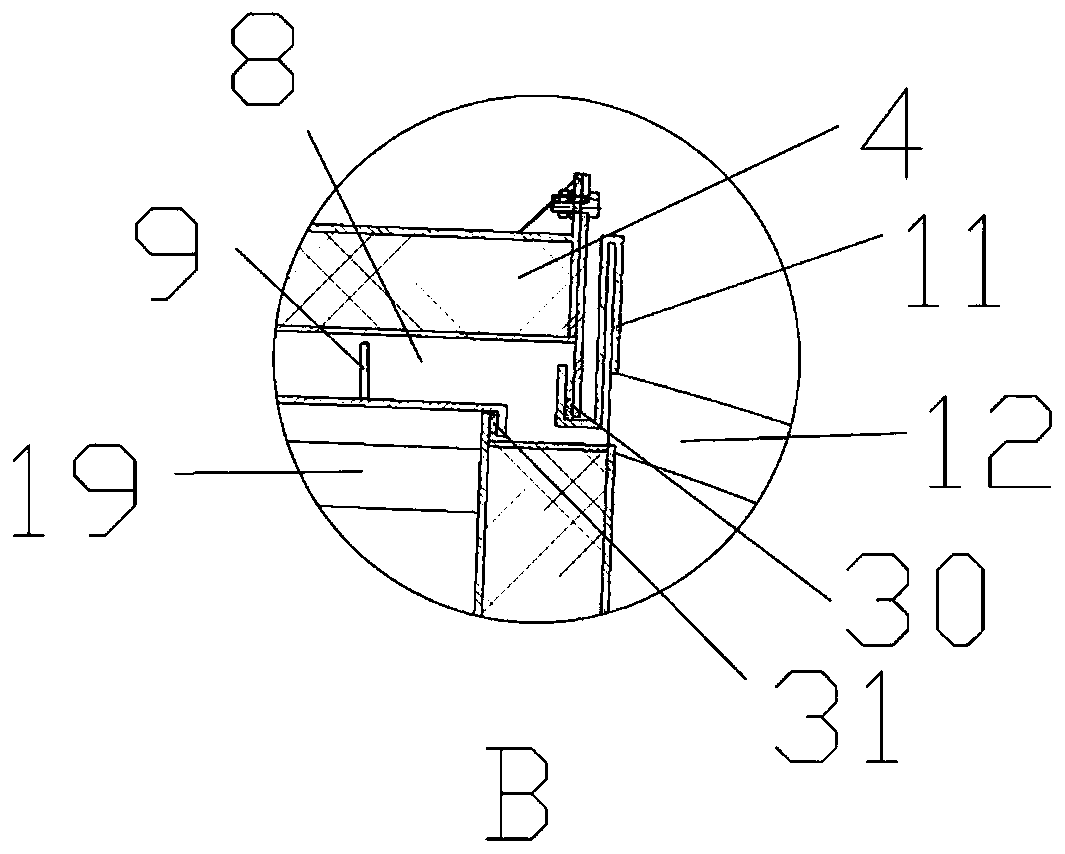

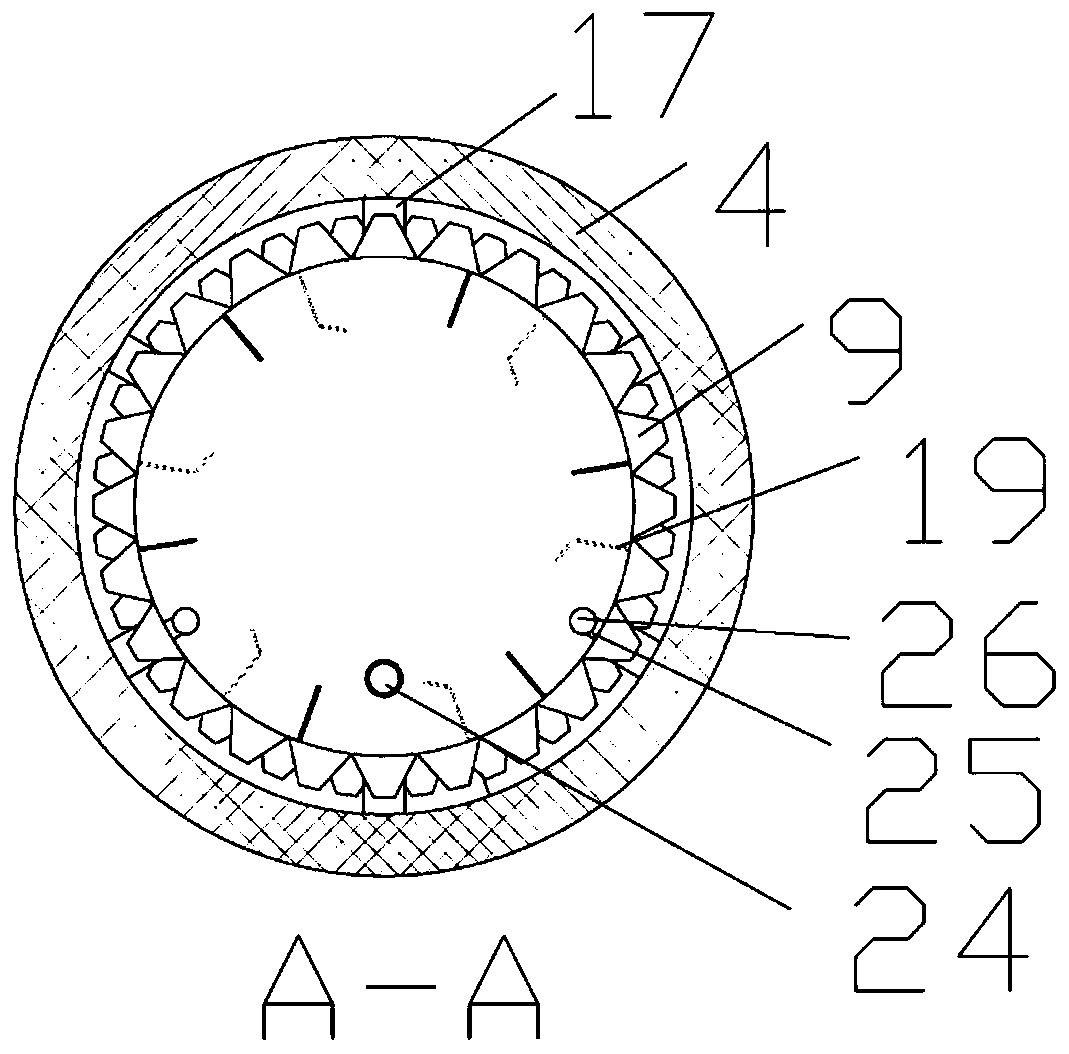

[0021] Such as Figure 1 ~ Figure 3 As shown, the invention provides a drum-type composting reactor with waste heat recovery and purification functions of compost tail gas, including a fermentation drum, an aeration system, a tail gas recovery system, a tail gas utilization system, a power system and a monitoring system. Among them, the fermentation drum is installed on the base 21, the feed end of the fermentation drum is connected with the existing raw material pretreatment system, and the discharge end is connected with the existing follow-up processing device; the aeration system is installed on the base at the lower part of the fermentation drum feed end , the exhaust end of the aeration system communicates with the interior of the fermentation drum through the feed end of the fermentation drum; The exhaust gas utilization system is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com