Low heat value burnt gas high-temperature air combustion system and method

A high-temperature air and combustion system technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of gas leakage, affecting the safe operation of the system, and affecting the safety of the system, so as to prevent accidental combustion and leakage, improve The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

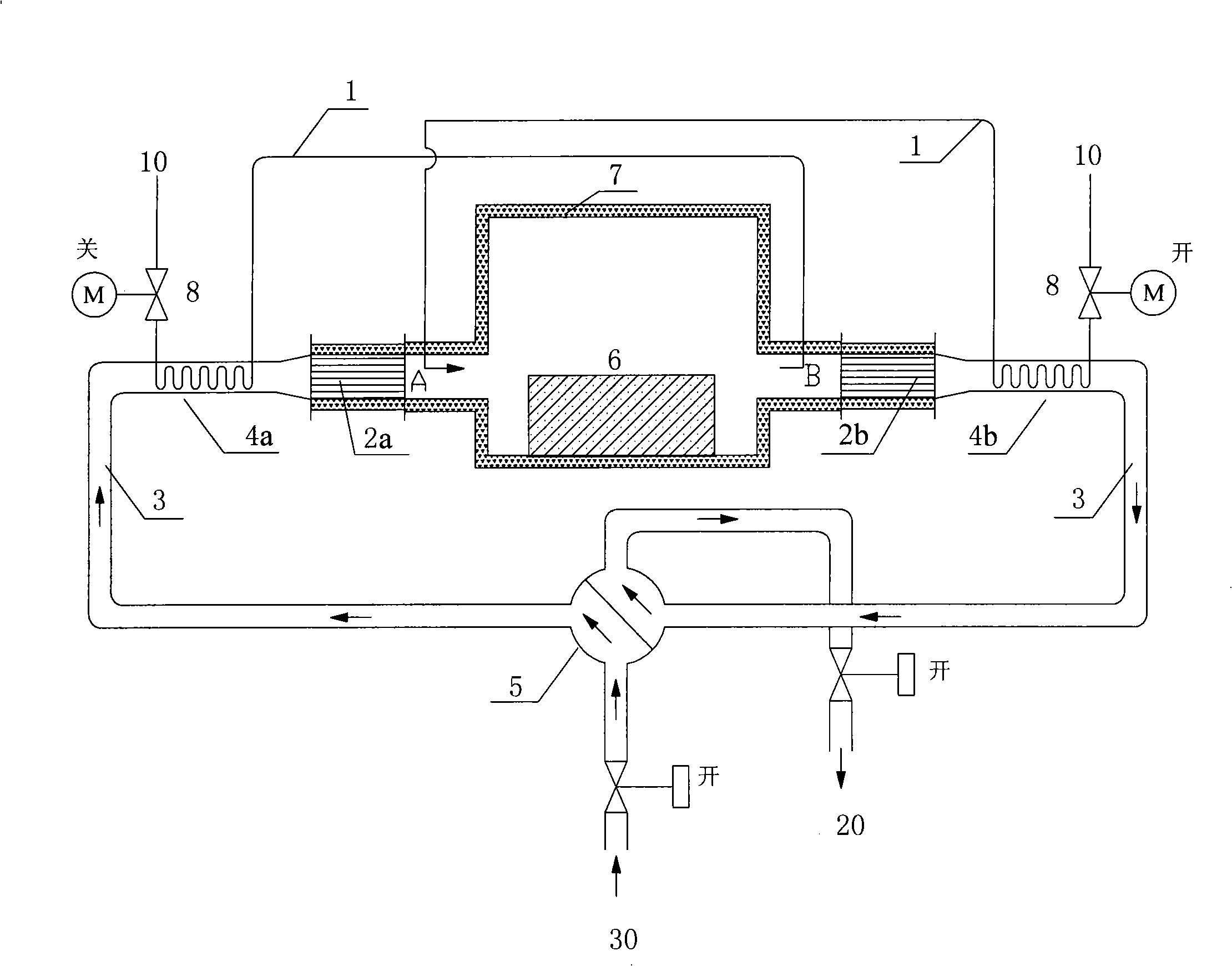

[0023] A novel low calorific value gas high temperature air combustion system, including fuel pipeline 1, regenerators 2a and 2b, gas passage 3, two gas preheaters 4a and 4b, four-way reversing valve 5, workpiece 6, insulation layer 7 , gas solenoid valve 8, gas 10, flue gas 20, air 30, the two regenerators 4a and 4b are placed in the two gas passages 3, and the gas preheaters 4a and 4b are respectively placed in the regenerator After 4a and 4b.

[0024] When the burner A is in operation, the high-temperature flue gas 20 generated by the combustion first passes through the regenerator 2b, so that the sensible heat of the high-temperature flue gas 20 is accumulated in the regenerator 2b. The low-temperature flue gas 20 from the regenerator passes through the gas preheater 4b to preheat the gas 10, and is transported to the working burner A through the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com