Low-heat-value gas high-temperature air flameless combustion system and method

A high-temperature air and flameless combustion technology, which is applied in the direction of combustion method, combustion air/fuel supply, combustion using block fuel and gaseous fuel, etc., can solve gas leakage, combustion or explosion, and difficult adjustment of smoke flow distribution and other problems, to achieve the effect of preventing combustion and leakage, improving heat energy utilization efficiency, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

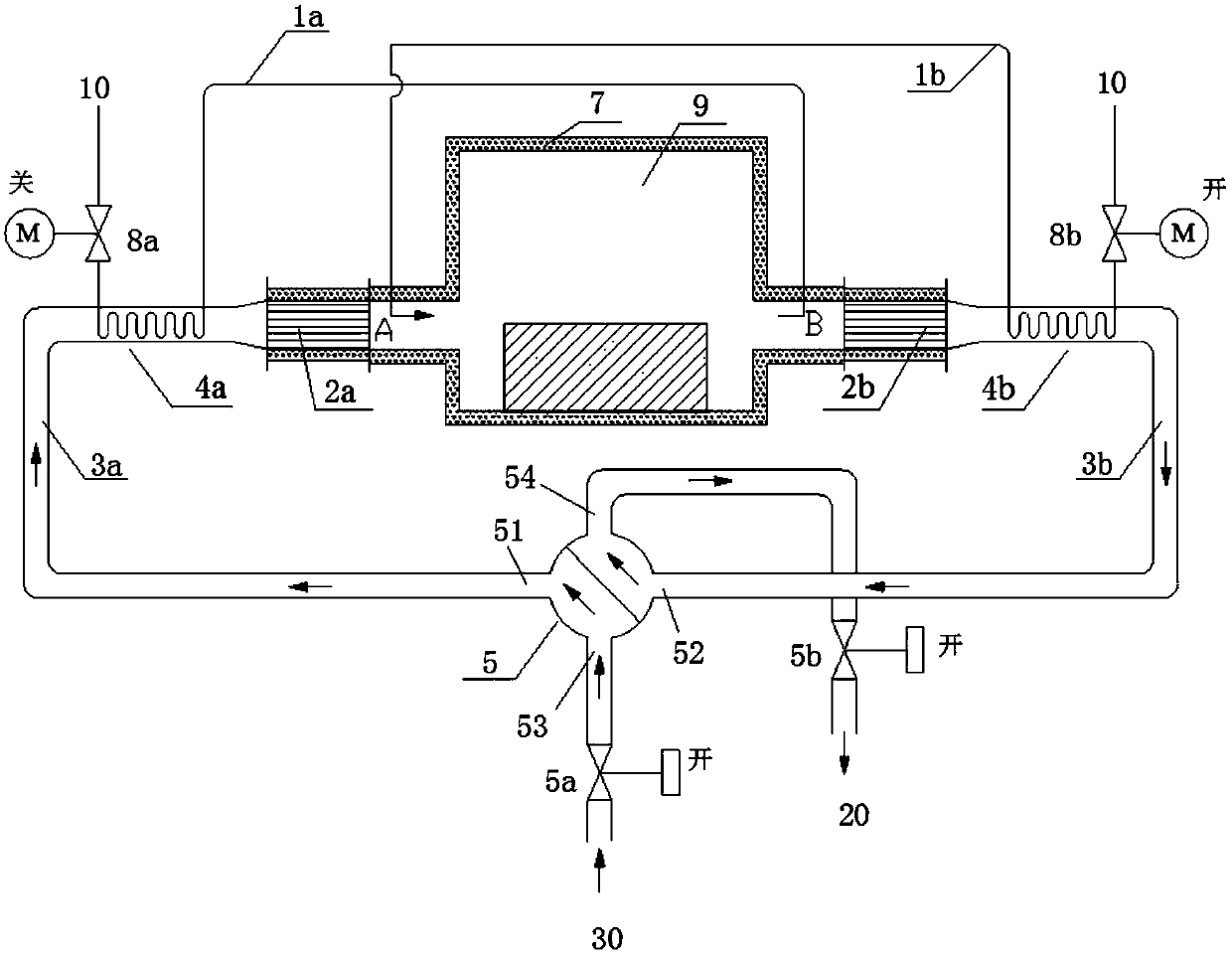

[0036] The following combination figure 1 , the technical content, structural features, achieved goals and effects of the present invention will be described in detail through preferred embodiments.

[0037] It should be noted that in this article, relative terms such as "first" and "second" are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply that there is a relationship between these entities or operations. There is no such actual relationship or order between them. It is to be understood that the terms so used are interchangeable under appropriate circumstances.

[0038] Such as figure 1 As shown, the low-calorific-value gas high-temperature air flameless combustion system provided by the present invention includes: a combustion chamber 9, which is symmetrically provided with a first burner A and a second burner B on both sides, and the first burner A It communicates with the second burner B throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com