Method and continuous system for treating wet organic waste

A technology for organic waste and treatment methods, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of high efficiency and improved energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

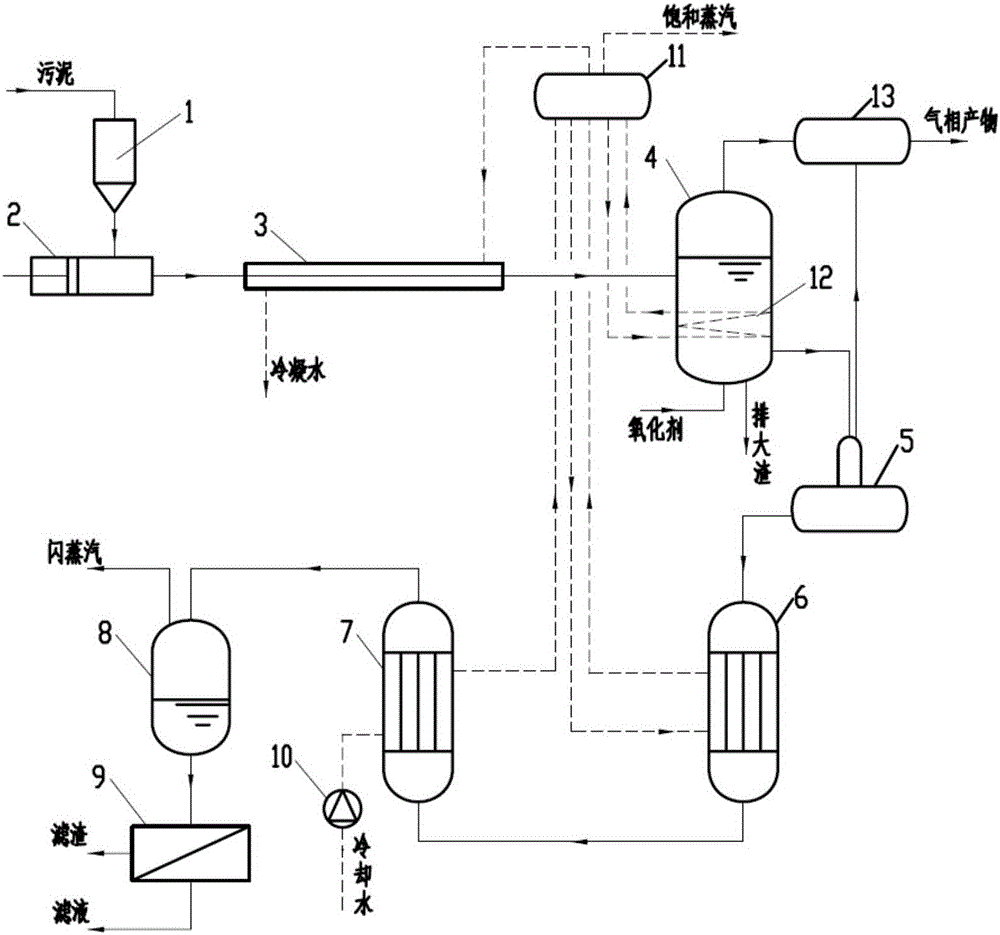

Method used

Image

Examples

Embodiment 1

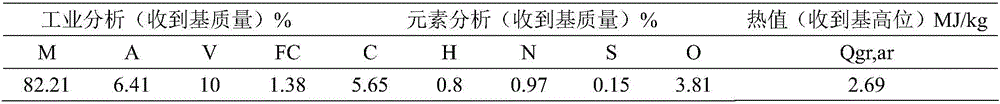

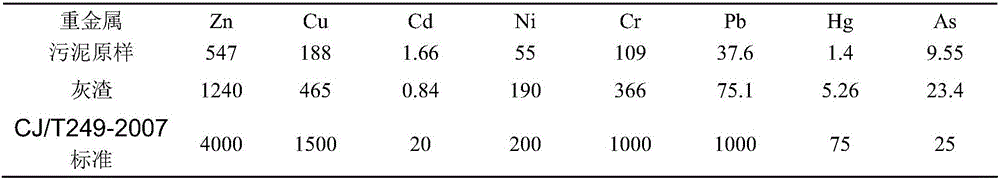

[0047] Using sludge with a water content of 82.21% from a sewage treatment plant as raw material and oxygen (99.99% oxygen + 0.01% nitrogen) as oxidant, the sludge hydrothermal oxidation reaction was carried out in a fully mixed flow reactor with a free liquid surface. The results of sludge industrial analysis, elemental analysis and calorific value analysis are shown in Table 1. The sludge treatment capacity is 10362.3kg / h, and the oxygen consumption is 2215kg / h. The sludge is pumped by the sludge pump under pressure, and the casing preheater outside the delivery pipeline heats it from normal temperature to about 150°C before being sent into the reactor. The liquid oxygen stored in the liquid oxygen tank is pressurized by the liquid oxygen pump, heated and vaporized by the vaporizer, and then sent to the reactor to undergo hydrothermal oxidation reaction with the sludge. The excess coefficient of oxidant in this process is 1.2.

[0048] The reaction temperature in the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com