Desulfurization wastewater zero discharge system for gradient utilization of flue gas waste heat and working method thereof

A technology for desulfurization wastewater and flue gas waste heat, which is applied in the treatment of gaseous effluent wastewater, chemical instruments and methods, heating water/sewage treatment, etc., and can solve the problems of high operating costs, high operating pressure of reverse osmosis membranes, and unsatisfactory operating effects, etc. problems, to achieve the effect of increasing heat exchange area, improving heat utilization efficiency, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

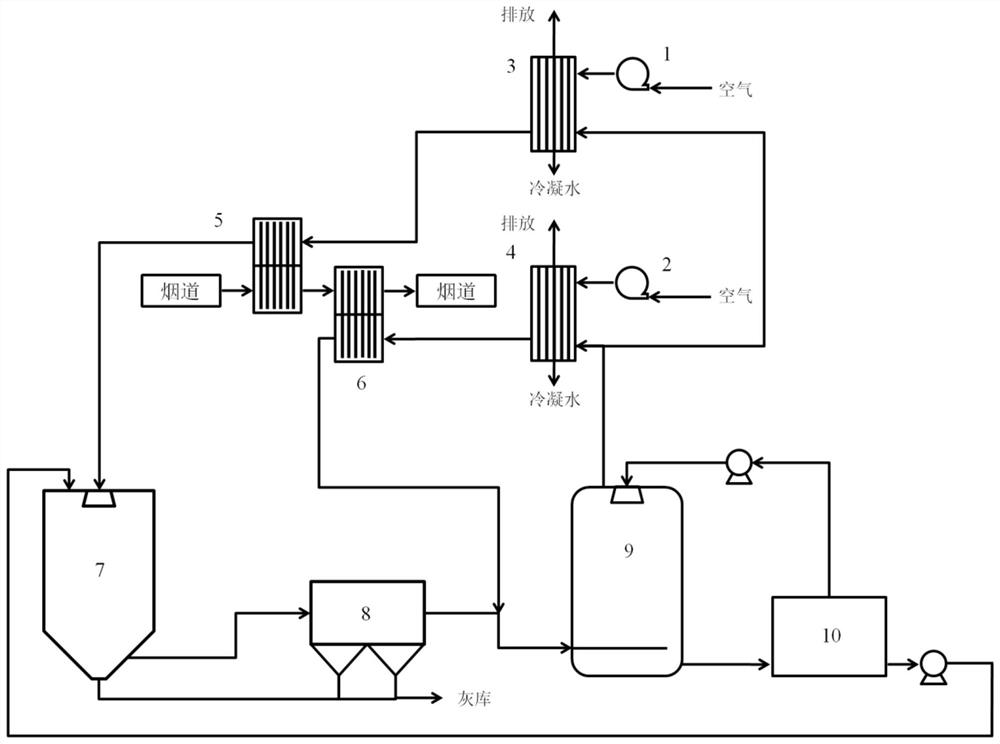

[0032] Such as figure 1 , is the desulfurization waste water zero discharge system for cascade utilization of flue gas waste heat of the present invention, comprising a first air intake device 1, a second air intake device 2, a first air heat exchanger 3, a second air heat exchanger 4, a first Flue gas heat exchanger 5 , second flue gas heat exchanger 6 , spray drying tower 7 , dust collector 8 , evaporative concentration tower 9 and desulfurization waste water pool 10 .

[0033] The first air intake device 1 is connected to the cold side inlet of the first air heat exchanger 3, the cold side outlet of the first air heat exchanger 3 is connected to the cold side inlet of the first flue gas heat exchanger 5, and the second air inlet The device 2 is connected to the cold side inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com