Preparation method and application of high-temperature high-pressure corrosion inhibitor capable of resisting corrosion by H2S and CO2

A high-temperature, high-pressure, and corrosion-inhibiting technology, applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve problems such as pipe wall bursting, achieve simple production process, good anti-corrosion effect, excellent corrosion resistance The effect of erosion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

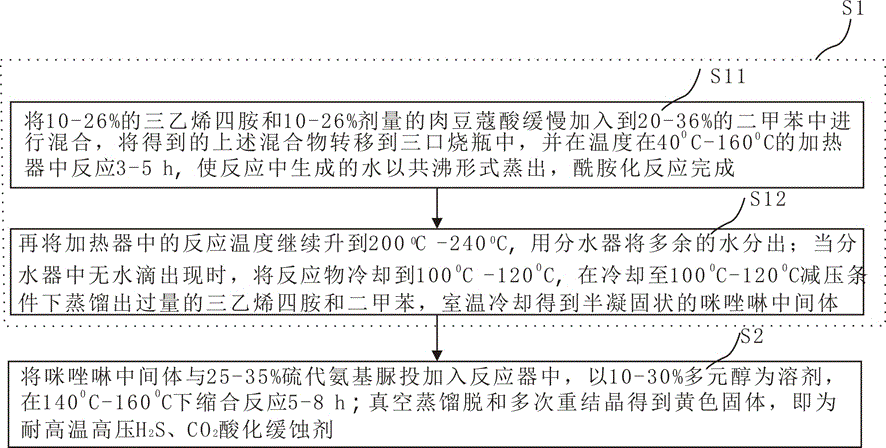

[0029] see figure 1 , the anti-H of the present invention 2 S, CO 2 A method for preparing a corroded high-temperature and high-pressure corrosion inhibitor. The raw materials of the corrosion inhibitor include: 10-26% triethylenetetramine, 10-26% myristic acid, 20-36% xylene, thio Semicarbazide 25-35% and polyol 10-30%;

[0030] The preparation method of this corrosion inhibitor comprises the following steps:

[0031] Step S1, using myristic acid and triethylenetetramine to undergo amidation reaction to obtain an imidazoline intermediate; this step is specifically: step S11, mixing 10-26% triethylenetetramine and 10-26% dose of myristic acid Slowly join in the 20-36% dimethylbenzene and mix, the above-mentioned mixture obtained is transferred in the three-necked flask, and at a temperature of 40 o C-160 o React in the heater of C for 3-5h, make the water generated in the reaction steam out with azeotropic form, and the amidation reaction is completed;

[0032] Step S12,...

Embodiment 1

[0046] 1mol of myristic acid and 2mol of triethylenetetramine were added to 1mol of xylene, and the above mixture was transferred to a three-necked flask, and in a reactor at 130 o C heating reaction 4h, cooled to 110 o After C decompression distills off excessive triethylenetetramine and dimethylbenzene, obtains imidazoline intermediate; Then 1mol imidazoline intermediate and 1.5mol thiosemicarbazide are added in 1mol n-octanol and transferred in the there-necked flask, 140 in the reactor o C After heating and reacting for 5 hours, vacuum distillation and recrystallization several times to obtain a yellow solid which is the corrosion inhibitor.

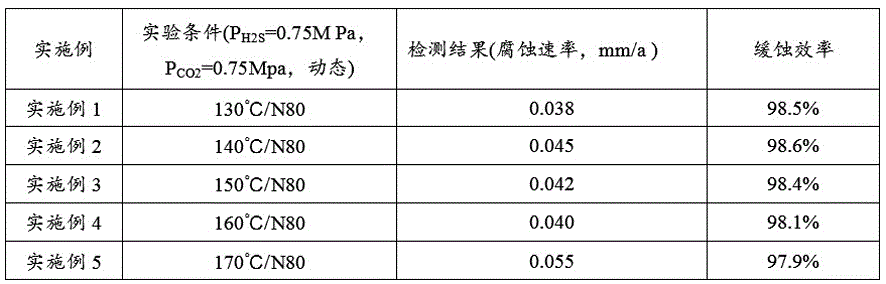

[0047] Using the weightlessness method, at 130 o Under C, put Q235 steel in H containing 100mg / L corrosion inhibitor 2 S, CO 2 In the coexisting hydrochloric acid solution, the corrosion treatment was carried out for 72 hours, and compared with the corrosion treatment of Q235 steel without corrosion inhibitor. The weight loss te...

Embodiment 2

[0049] 1.5mol myristic acid and 1.5mol triethylenetetramine were added to 1.5mol xylene, and the above mixture was transferred to a three-necked flask, and in the reactor at 140 o C heating reaction 3h, cooled to 110 o After C decompression distills off excessive triethylenetetramine and dimethylbenzene, obtains imidazoline intermediate; Then imidazoline intermediate and 1.5mol thiosemicarbazides are added in 1.5mol n-octanol and transferred in the there-necked flask, 130 in the reactor o After heating and reacting in C for 6 hours, the yellow solid obtained by vacuum distillation and recrystallization several times is the corrosion inhibitor.

[0050] According to the method of Example 1 at a temperature of 140 ° C, the corrosion inhibition performance was tested and compared. The experimental data showed that after adding the corrosion inhibitor, the corrosion rate of Q235 steel was 0.045mm / a, which was lower than the national corrosion standard of 0.076mm / a. a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com