Recovery method of fine catalyst metal obtained after electrolysis and purification of synthetic diamond powder

A technology of synthetic diamond and electrolytic purification, applied in the field of fine catalyst metal recovery after electrolytic purification of powder synthetic diamond, can solve the problems of noble metal corrosion of anode, high cost of equipment consumption of acid, high labor intensity of employees, etc., so as to avoid noble metal corrosion Serious phenomenon, avoid serious anode passivation, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

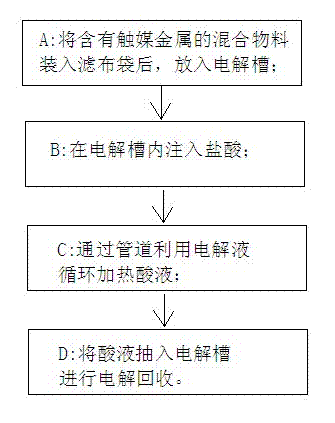

[0031] 1. Divide 300Kg of the mixed material containing catalytic metal into 60 diaper bags, tie the mouth tightly and put it into the electrolytic cell;

[0032] 2. Inject 600Kg of hydrochloric acid with a mass concentration of 10% into the electrolytic cell, and the concentration of hydrochloric acid is kept constant through the flow meter;

[0033] 3. Use the electrolyte circulation to heat the acid solution through the pipeline to keep the temperature of the acid solution at 30°C;

[0034] 4. The reaction was carried out for 4 days, and the measured pH value was 1.12. The acid solution was pumped into the electrolytic cell for electrolytic recovery.

[0035] After physical and chemical analysis, the metal content in the good material bag was confirmed, and the measured metal content was only 9% of the original metal content, which proved that 91% of the metal had been dissolved into the acid solution.

Embodiment 2

[0037] 1. Divide 300Kg of the mixed material containing catalytic metal into 60 diaper bags, tie the mouth tightly and put it into the electrolytic cell;

[0038] 2. Inject 900Kg of hydrochloric acid with a mass concentration of 10% into the electrolytic cell, and the concentration of hydrochloric acid is kept constant through the flow meter;

[0039] 3. Use the electrolyte circulation to heat the acid solution through the pipeline to keep the temperature of the acid solution at 40°C;

[0040] 4. The reaction was carried out for 4 days, and the measured pH value was 1.12. The acid solution was pumped into the electrolytic cell for electrolytic recovery.

[0041] After physical and chemical analysis, the metal content in the good material bag was confirmed, and the measured metal content was only 8% of the original metal content, which proved that 92% of the metal had been dissolved into the acid solution.

Embodiment 3

[0043] 1. Divide 400Kg of mixed materials containing catalytic metals into 60 plastic bags, tie the mouth tightly and put them into the electrolytic cell;

[0044] 2. Inject 1600Kg of hydrochloric acid with a mass concentration of 15% into the electrolytic cell, and the concentration of hydrochloric acid is kept constant through the flow meter;

[0045] 3. Use the electrolyte circulation to heat the acid solution through the pipeline to keep the temperature of the acid solution at 50°C;

[0046] 4. The reaction was carried out for 3 days, and the measured pH value was 1.12. The acid solution was pumped into the electrolytic cell for electrolytic recovery.

[0047] After physical and chemical analysis, the metal content in the good material bag was confirmed, and the measured metal content was only 9% of the original metal content, which proved that 91% of the metal had been dissolved into the acid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com