High-color-saturation silicon-based OLED micro display device and preparation method thereof

A micro-display and saturation technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of poor display effect and low color saturation of devices, and achieve reduced production costs, wide process window, Realize the effect of refined production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

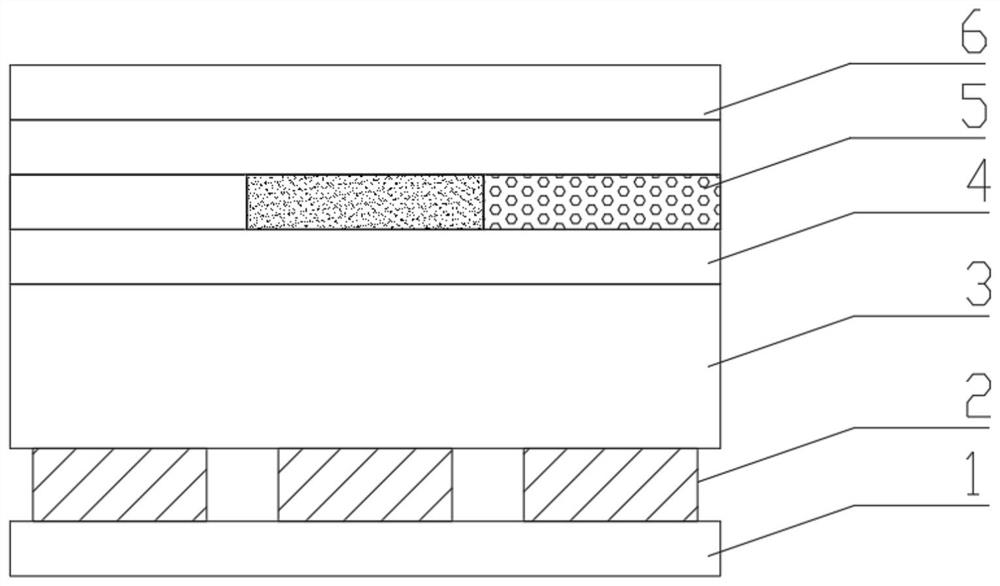

[0028] Embodiment 1: the preparation method of silicon-based OLED microdisplay, comprises the following steps:

[0029] In the first step, on the 8-inch 0.13µm silicon-based drive circuit, the three-layer anode Cr / Al / AlN is prepared by PVD methods such as electron beam evaporation, thermal evaporation, and ion beam-assisted deposition. The total thickness of the three-layer anode is controlled at 20 ~100nm, among which, the thickness of metal Cr is 5~40nm, the thickness of metal Al is 20~50nm, and the thickness of AlN is 1~3nm.

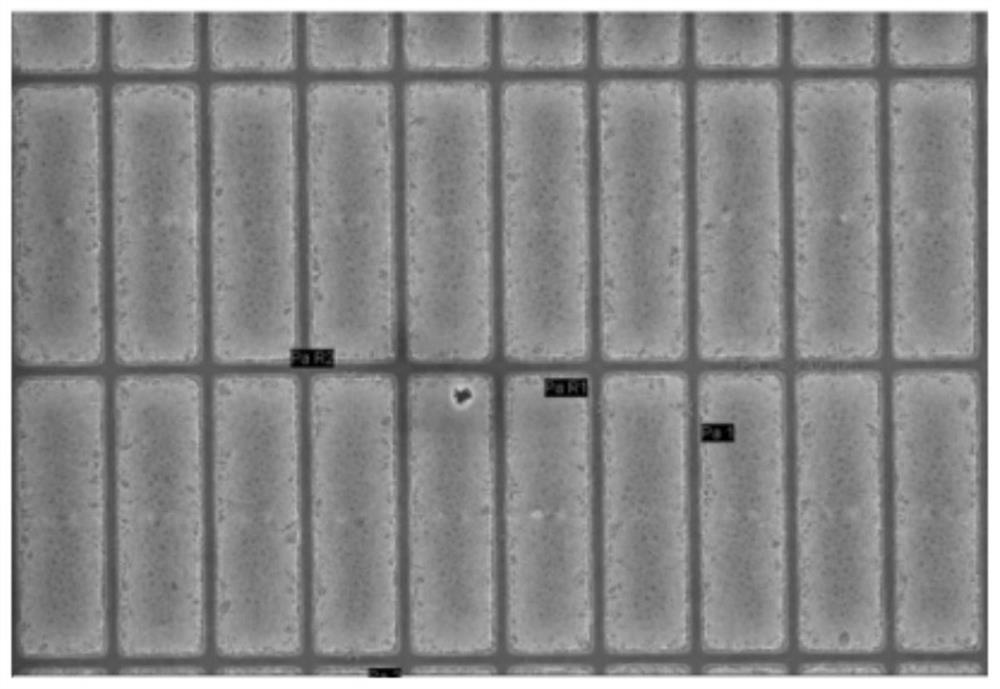

[0030] In the second step, the anode pixels are prepared by dry etching process, the pixel size is 3.3µm×9.9µm, and the pixel pitch is 0.8µm.

[0031] The third step is to prepare hole injection layer, hole transport layer, light emitting layer, electron transport layer, electron injection layer, translucent cathode Mg:Ag and anti-reflection layer with high refractive index by evaporation on the anode pixel points by masking. layer material. Wherein...

Embodiment 2

[0035] Embodiment 2: the preparation method of silicon-based OLED microdisplay, comprises the following steps:

[0036] In the first step, on a 12-inch 0.11µm silicon-based drive circuit, two layers of anode Al / AlN are prepared by PVD methods such as electron beam evaporation, thermal evaporation, and ion beam assisted deposition. The thickness of the two layers of anode is controlled in the range of 20~100nm. Among them, the thickness of metal Al is 20~50nm, and the thickness of AlN is 1~3nm;

[0037] In the second step, the anode pixels are prepared by dry etching process, the pixel size is 5µm×15µm, and the pixel pitch is 1µm.

[0038] The third step is to prepare hole injection layer, hole transport layer, light emitting layer, electron transport layer, electron injection layer, translucent cathode Mg:Ag and anti-reflection layer with high refractive index by evaporation on the anode pixel points by mask method. layer material.

[0039] The fourth step is to prepare red,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com