Process for preparing magnesium hydroxide whisker

A technology of magnesium hydroxide and magnesium salt whiskers, applied in magnesium hydroxide, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficulty in obtaining fibrous magnesium hydroxide, unstable needle-like crystals, and long time. , to achieve the effect of being beneficial to the application, shortening the production cycle and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

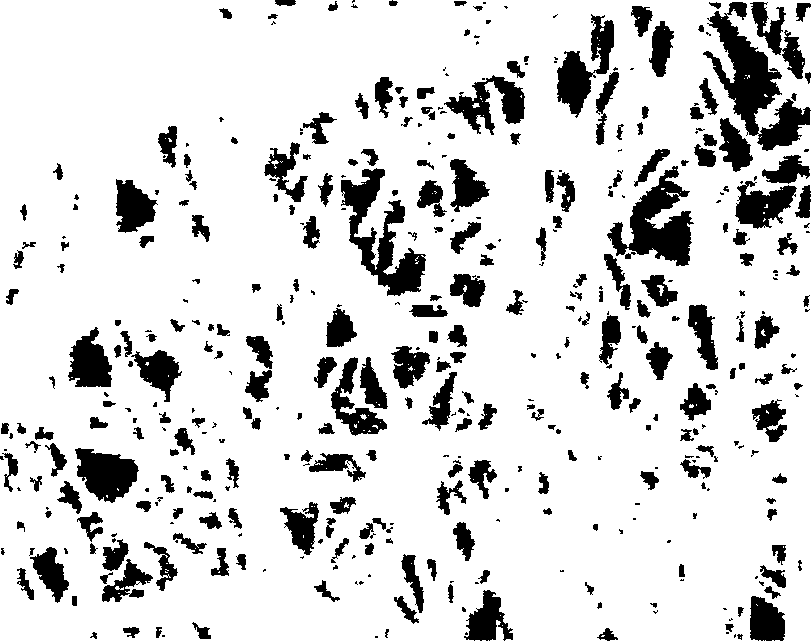

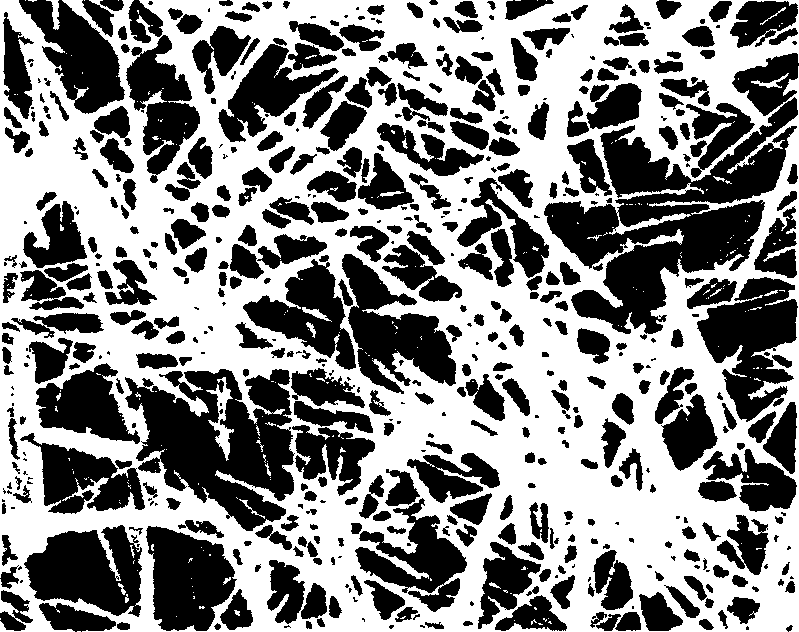

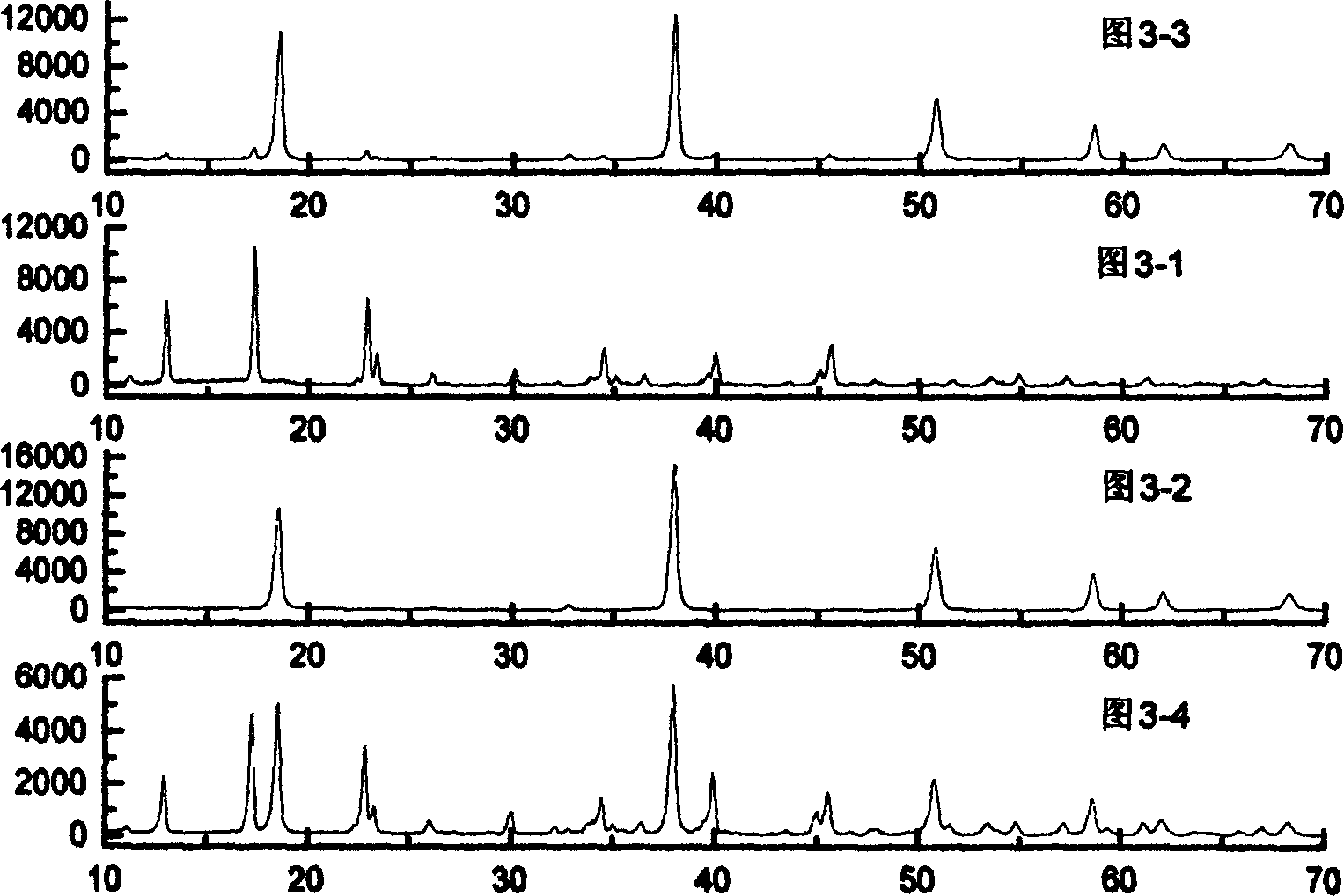

[0028] Select crystalline magnesite, which is a special product in Northeast my country, calcinate at 750-1000°C for 1-10 hours, and then pulverize. After analysis, the pulverized matter contains magnesium oxide > 95%. Get 484 grams (12mol) of the magnesium oxide powder, add 8 liters of water, grind it into a slurry (remove sediment and impurities), and put it into a reaction kettle; add 3 liters of sulfuric acid aqueous solution with a concentration of 1mol / L while stirring, and then add alkali Formula magnesium sulfate crystal nucleation promoter 10 grams, make it fully mix uniformly; Heating at 150 ℃, reaction under pressure 0.45Mpa 2 hours; A small amount of samples were taken out and dried in an electric oven. The dry matter was observed by scanning electron microscope, and it was fibrous crystal. The diameter is 0.2-1 μm, the length is 20-100 μm, and the quality is uniform. Its electron microscope photos are as follows: figure 1 . X-ray diffraction analysis, the stru...

Embodiment 2

[0030] Prepare magnesium sulfate aqueous solution: use 863 grams of magnesium sulfate heptahydrate (3.5 mol), add 8 liters of water to dissolve. Add 8 liters of water to 423 grams (10.5 mol) of calcined magnesite powder, and grind it into a slurry (to remove sediment and impurities). Put the two liquid materials prepared by the above method into the reaction kettle, add 15 grams of basic magnesium sulfate crystal nucleus promoter, and stir and mix. Then, it was heated at 150° C. and reacted for 2 hours under a pressure of 0.45 MPa. After cooling, the reaction product was taken out and soaked in water and crushed; then filtered to remove water, some samples were taken and dried in an electric oven, scanned electron microscope observation and X-ray diffraction analysis, the results were the same as in Example 1, it was a single crystal fiber magnesium salt whiskers. Put the dried magnesium salt whiskers of the remaining parts into the reaction kettle, add 9 liters of water, an...

Embodiment 3

[0032] Put the magnesium salt whisker prepared by the method of Example 1 into the reactor, add 8 liters of water, add 1.5 liters of ammonium hydroxide aqueous solution with a concentration of 4mol / L while stirring, and make it fully mixed. Then, the reaction was carried out at 60° C. and a stirring speed of 80 revolutions / minute for 2 hours. After cooling, the reaction product was taken out, soaked in water, stirred and dispersed; filtered, dried to remove water, and dried in an electric oven; 625 grams of white needles were collected, and the calculated conversion rate was 100%. The reaction product was observed by a scanning electron microscope and was a fibrous crystal. The diameter is 0.2-1 μm, the length is 10-60 μm, the quality is uniform, and its electron microscope photo is the same as figure 2 . X-ray diffraction analysis, all magnesium hydroxide, Mg(OH) 2 . (same Figure 3-2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com