Lithium bromide absorption type refrigerating device driven by waste heat of cruise ship diesel engine

An absorption refrigeration and diesel engine technology, which is applied in the direction of machine operation, refrigerator, refrigeration and liquefaction, can solve safety risks and other problems, and achieve the effect of avoiding severe corrosion and simplifying pipeline design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

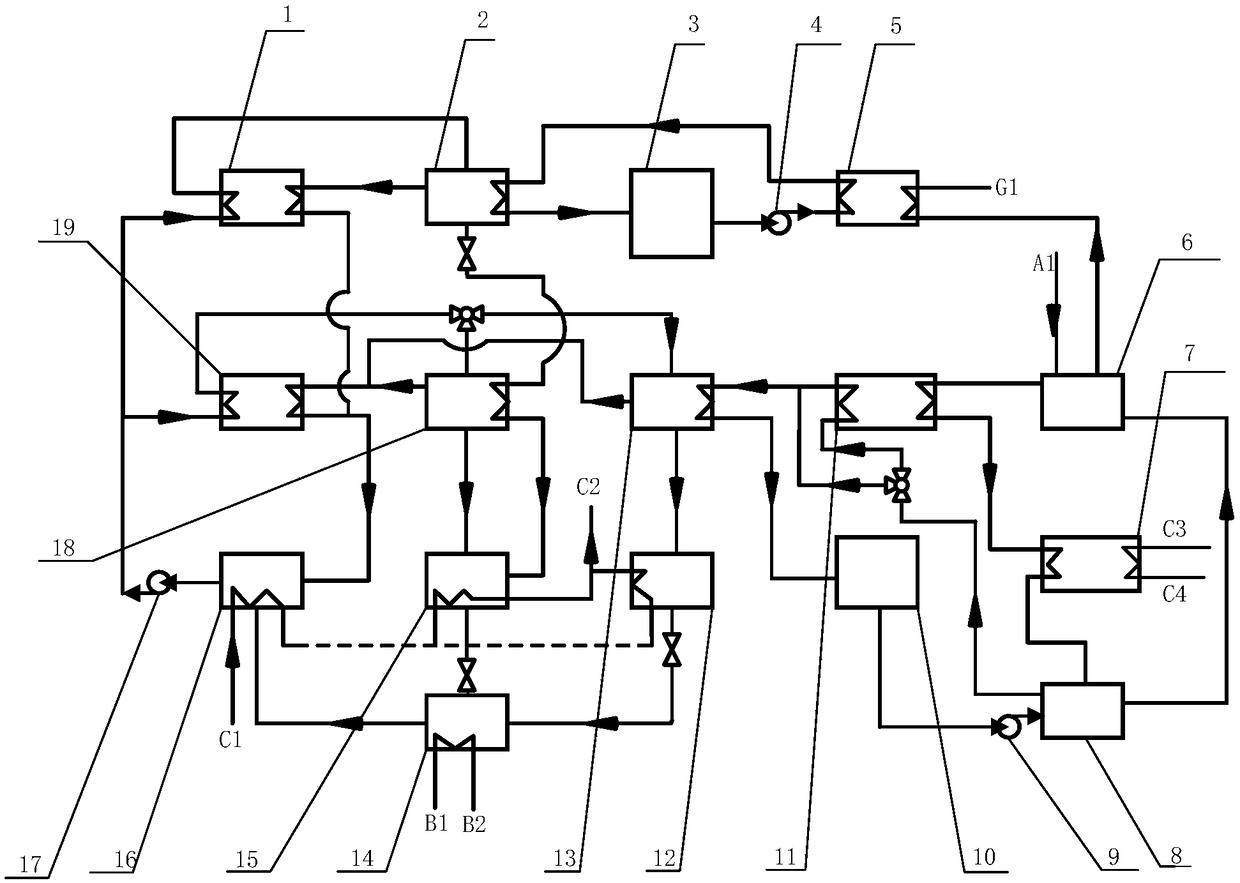

[0022] This embodiment includes high pressure generator 2, low pressure generator 13, low pressure generator 18, condenser 12, condenser 15, evaporator 14, absorber 16, generator pump 17, heat exchanger 1, heat exchanger 19, Flue gas heat exchanger 5, high temperature heat source water pump 4, high temperature heat source water tank 3, turbocharger 6, two-stage intercooler, liner cooling water tank 8, liner cooling water pump 9, diesel engine, exhaust manifold and intake Gas header and connecting pipes and throttle valves of various components.

[0023] The specific implementation of this program is as follows:

[0024] The steam outlet of the high-pressure generator 2 is connected to the inlet of the steam heat exchange tube bundle in the low-pressure generator 18 through a steam pipeline. A throttle valve is provided at the inlet of the steam heat exchange tube bundle. The outlet of the steam heat exchange tube bundle is connected to the condenser 15 through a refrigerant water p...

specific Embodiment approach 2

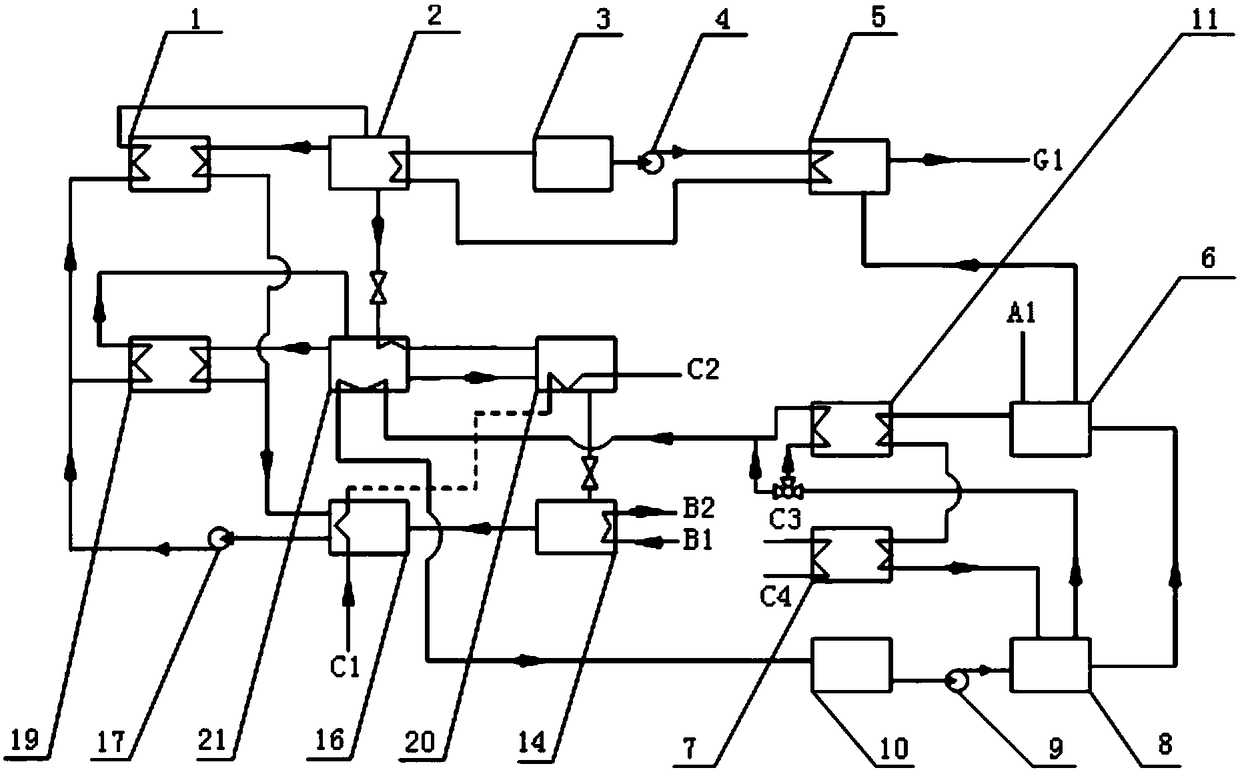

[0032] The difference between this embodiment and the first embodiment is that it combines the low-pressure generator 13 and the low-pressure generator 18 into one low-pressure generator 21, and the condenser 12 and the condenser 15 are combined into one condenser 20, and the high-pressure generator 2 The steam outlet is connected through the steam pipeline and the inlet of the steam heat exchange tube bundle in the low pressure generator 21. The steam heat exchange tube bundle and the low temperature heat source water heat exchange tube bundle are arranged together in the same low pressure generator 21 in a cross arrangement. The high-temperature steam generated by the high-pressure generator 2 is introduced into the low-pressure generator 21 through a pipeline, and heats the dilute solution in the low-pressure generator 21 together with the low-temperature heat source water. Other components and connection relationships are the same as in the first embodiment.

[0033] The diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com