Patents

Literature

38results about How to "Improve evaporation and concentration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

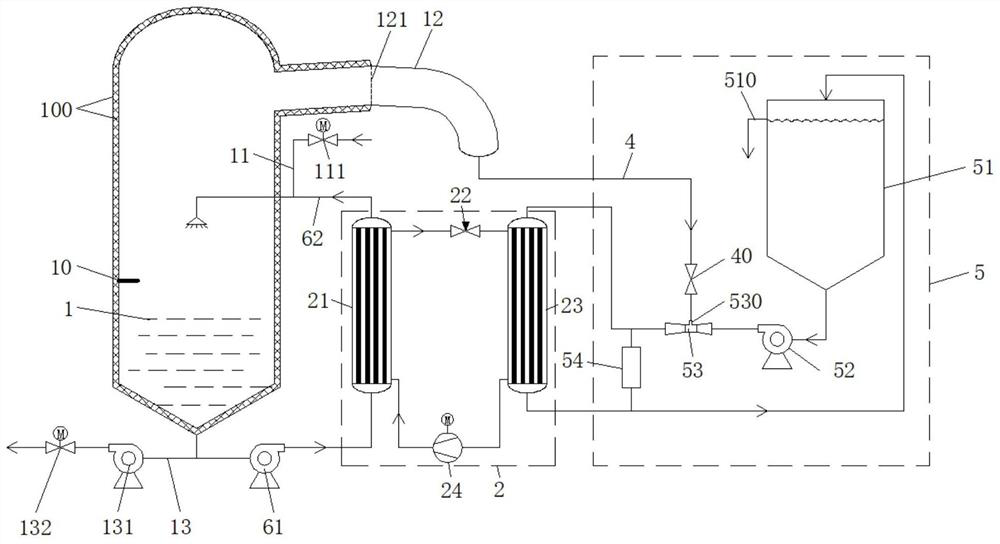

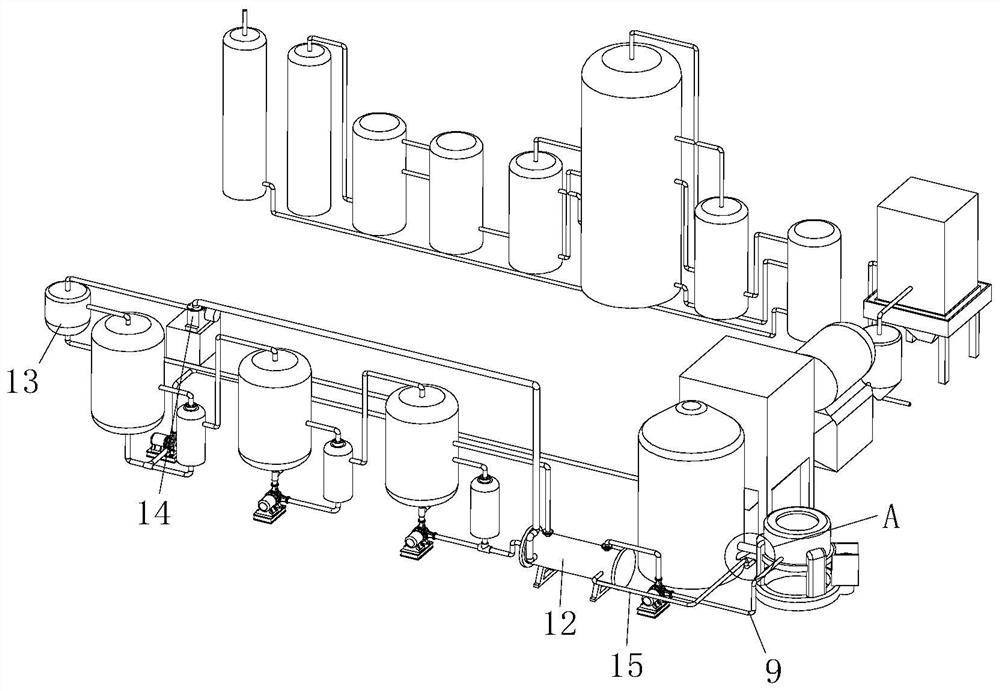

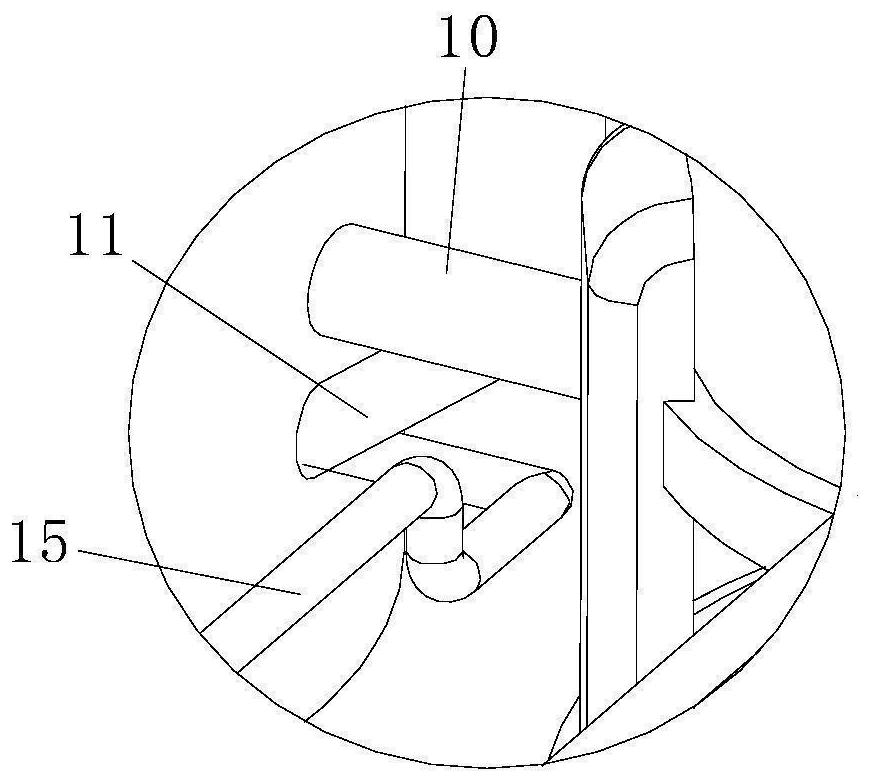

Novel heat pump evaporation heat recovery combined device and efficient effluent concentration method

ActiveCN105731572AImprove evaporation and concentration efficiencyIncrease temperatureHeat recovery systemsWater/sewage treatmentEvaporationEngineering

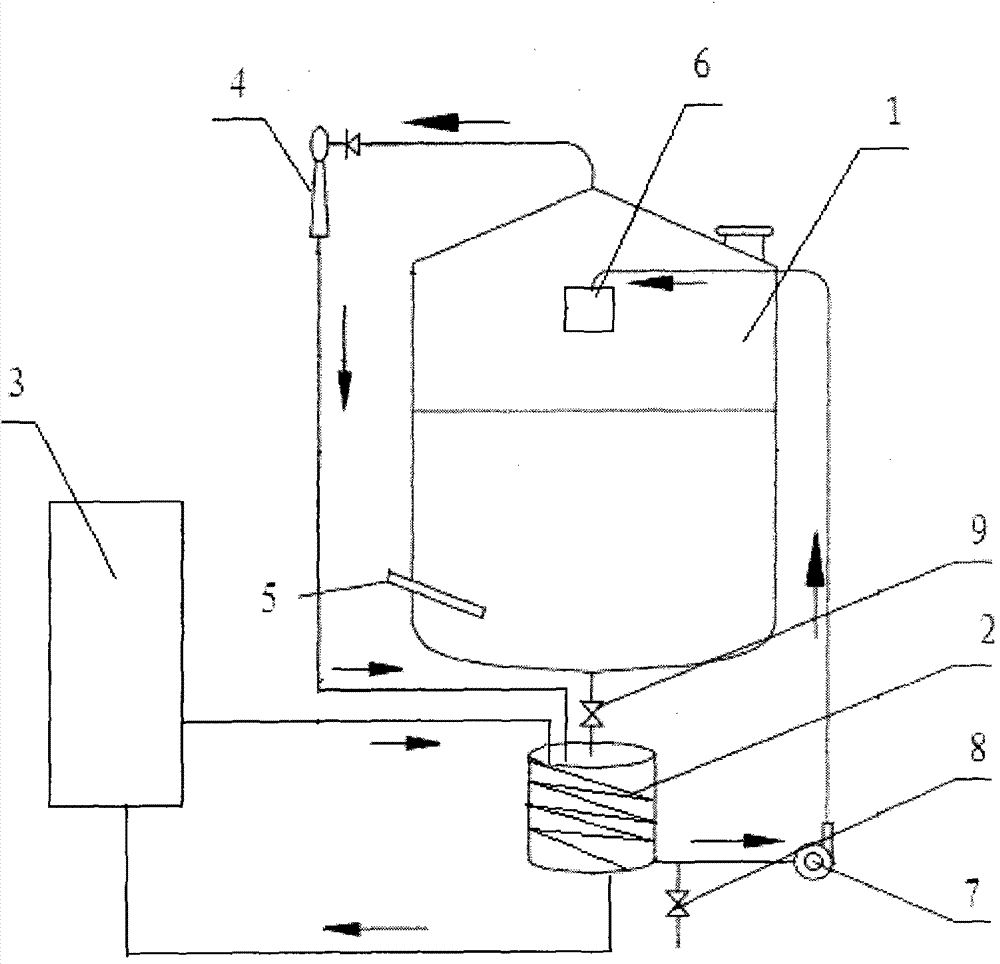

The invention discloses a novel heat pump evaporation heat recovery combined device and an efficient effluent concentration method.A suction pump is utilized for sucking effluent into an evaporation tank and spraying the effluent towards filler, hot and dry air exhausted by a heat pump and the sprayed effluent carry out heat exchange, water in the effluent is evaporated, and a concentrated solution obtained in the evaporation tank is circulated through the suction pump and enters the evaporation tank to be evaporated continuously; hot air obtained after heat exchange is sent back to the heat pump from the top of the evaporation tank, subjected to heat recovery through a heat recovery device in the heat pump and then passes through an evaporator to obtain condensate water and first cooling gas; before the effluent enters the evaporation tank, a heat exchanger is arranged to utilize the first cooling gas for preheating the effluent, the preheated effluent enters the evaporation tank and is sprayed towards the filler again, second cooling gas obtained after the first cooling gas releases heat is sent back to a condenser of the heat pump, and the hot and dry air is obtained under the action of the condenser.In this way, on the premise of not increasing energy consumption, evaporation and concentration efficiency is greatly improved.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

Environment-friendly treatment method of caustic-soda-containing sodium hypochlorite waste liquor

ActiveCN104478151APromote crystallizationRealize energy saving and consumption reductionTreatment involving filtrationWaste water treatment from gaseous effluentsExhaust fumesProcess engineering

The invention discloses an environment-friendly treatment method of caustic-soda-containing sodium hypochlorite waste liquor. A NaOH solution can form caustic-soda-containing sodium hypochlorite waste liquor after absorbing chlorine waste gas. The method comprises the following steps: the waste liquor is concentrated at 80 DEG C above, whereinNaClO is decomposed into NaCl and NaClO3 in the concentration process; the NaCl crystal is precipitated and removed by filtering; the filtered caustic-soda-containing waste liquor flows back and continues absorbing the chlorine waste gas; the obtained waste liquor is subjected to the operation above repeatedly until the NaClO3 concentration is saturated in the waste liquor; the NaClO3 crystal is precipitated and removed by filtering at 20-25 DEG C; and the filtered caustic-soda-containing waste liquor is subjected to cyclic use continuously. The NaCl and NaClO3 obtained in the treatment process can be used as chemical raw materials after being treated. The method has the advantages of low equipment investment and simple technique, and is easy to operate; and the cyclic utilization of the sodium hydroxide can greatly lower the cost for absorbing waste chlorine gas, thereby saving the wastewater treatment cost of the enterprise and lowering the environmental pollution.

Owner:东营市广利临港产业园有限公司 +1

Environment-friendly and efficient production method of high-purity silver nitrate

PendingCN111732120AImprove filtration efficiency and filtration qualityHigh product purityFiltration circuitsSilve compoundsNitric oxideNitrogen oxides

The invention discloses an environment-friendly and efficient production method of high-purity silver nitrate. The method includes steps of: firstly, performing a reaction on a silver ingot with nitric acid to obtain a silver nitrate solution; purifying the silver nitrate solution, and sequentially carrying out efficient evaporation under reduced pressure, efficient crystallization, solid-liquid separation, drying, crushing and packaging operations. According to the method, a finished product of 1150-1210 kg of high-purity silver nitrate crystals can be produced from the time when 800-850 kg of silver ingots enter a production line for 22-22.5 hours; hydrogen peroxide is used for absorbing nitric oxide into nitric acid for cyclic utilization; after impurities are removed through the impurity removing agent, filtration is conducted through combination of the negative-pressure filter element and the positive-pressure filter element, efficient solid-liquid separation of silver nitrate isachieved through a suction filtration mode of combination of the pneumatic diaphragm pump and vacuum negative pressure after efficient reduced-pressure evaporation; compared with the prior art, the production method of high-purity silver nitrate has the advantages of being environmentally friendly, efficient, low in cost and high in quality.

Owner:中船重工黄冈贵金属有限公司

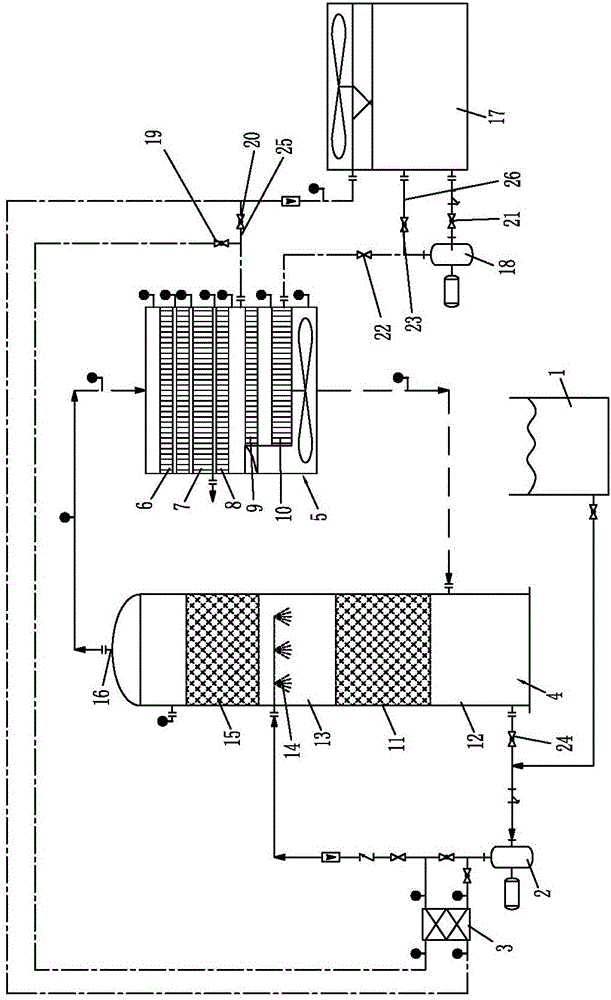

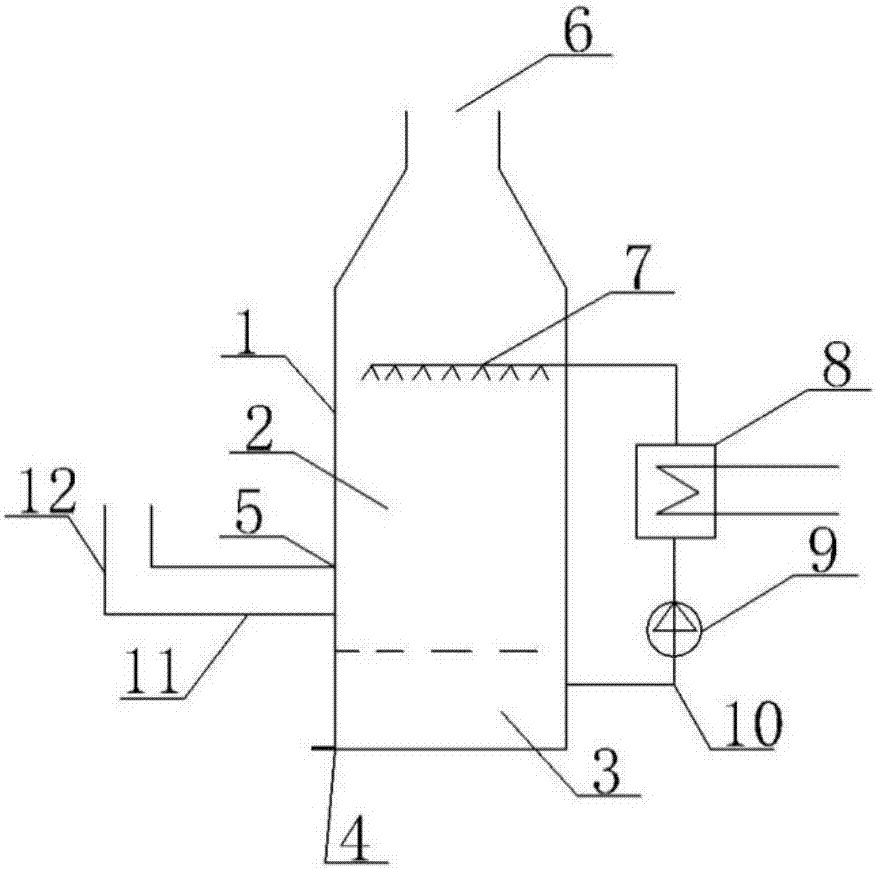

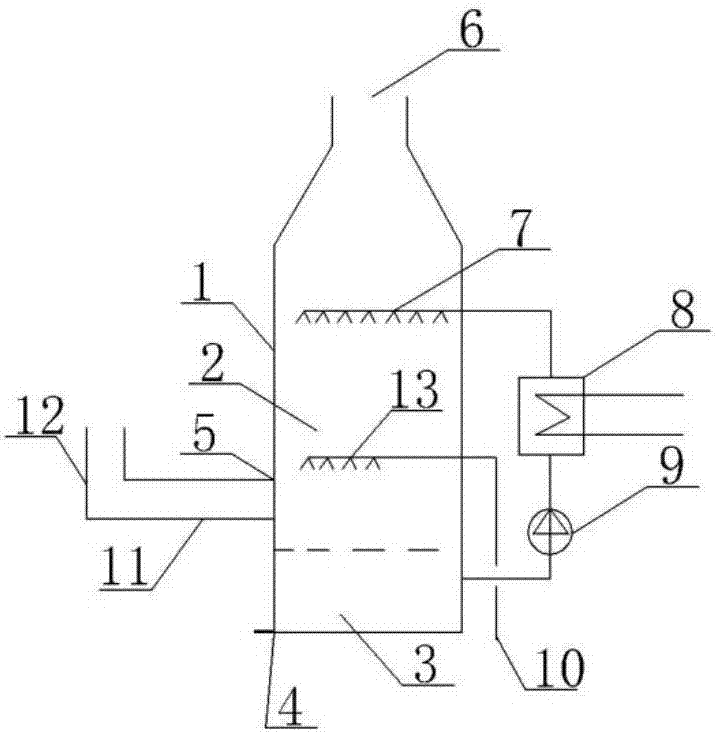

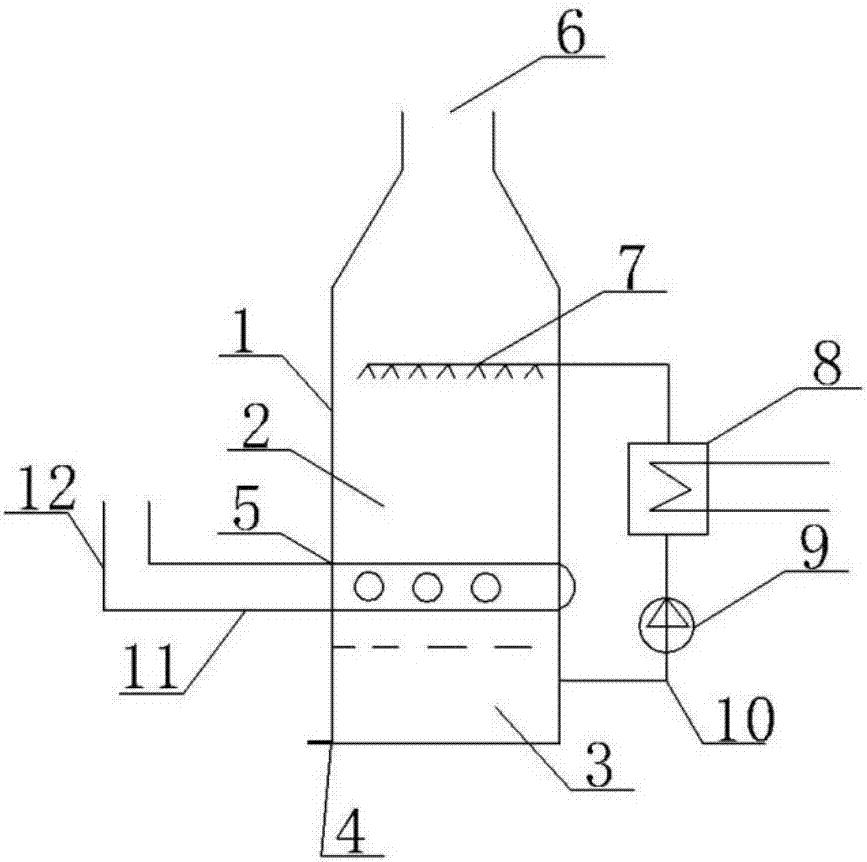

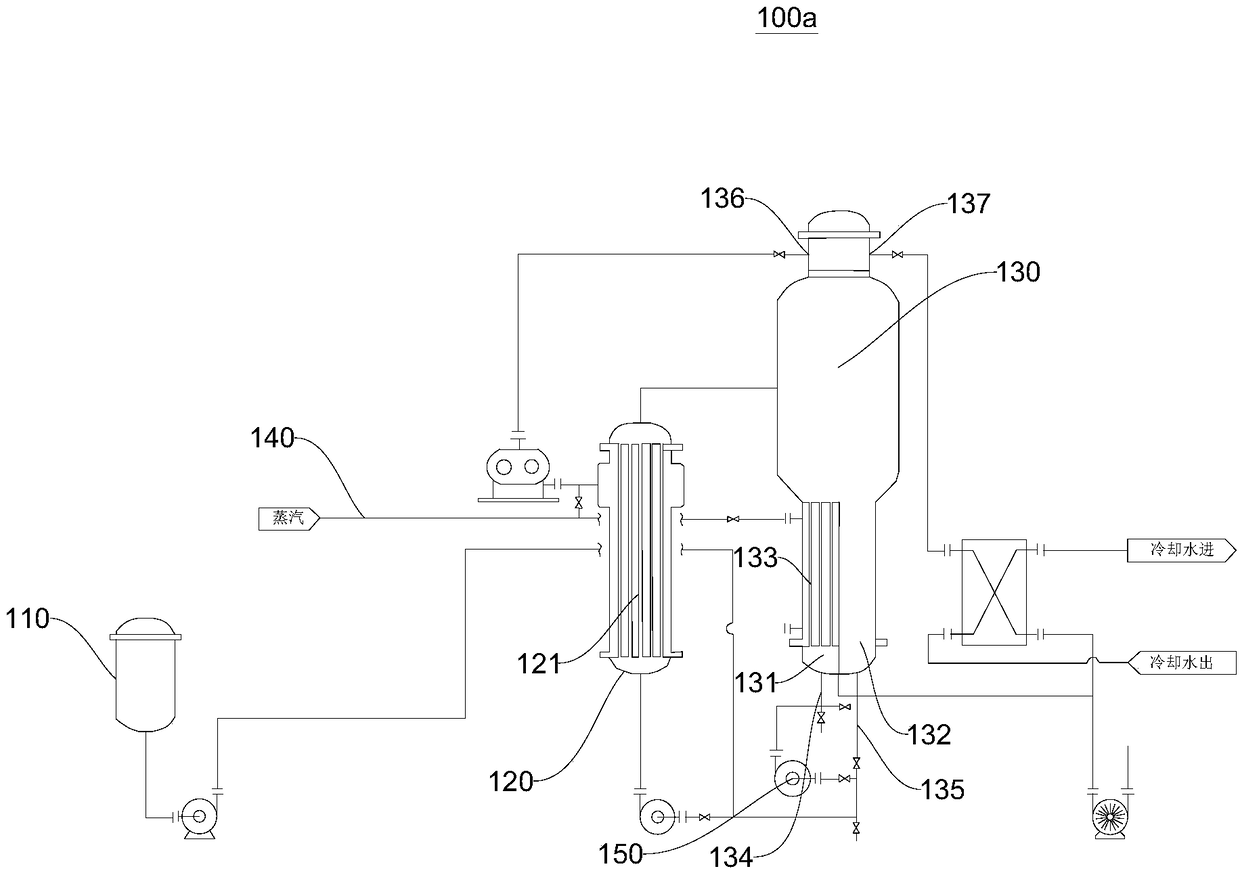

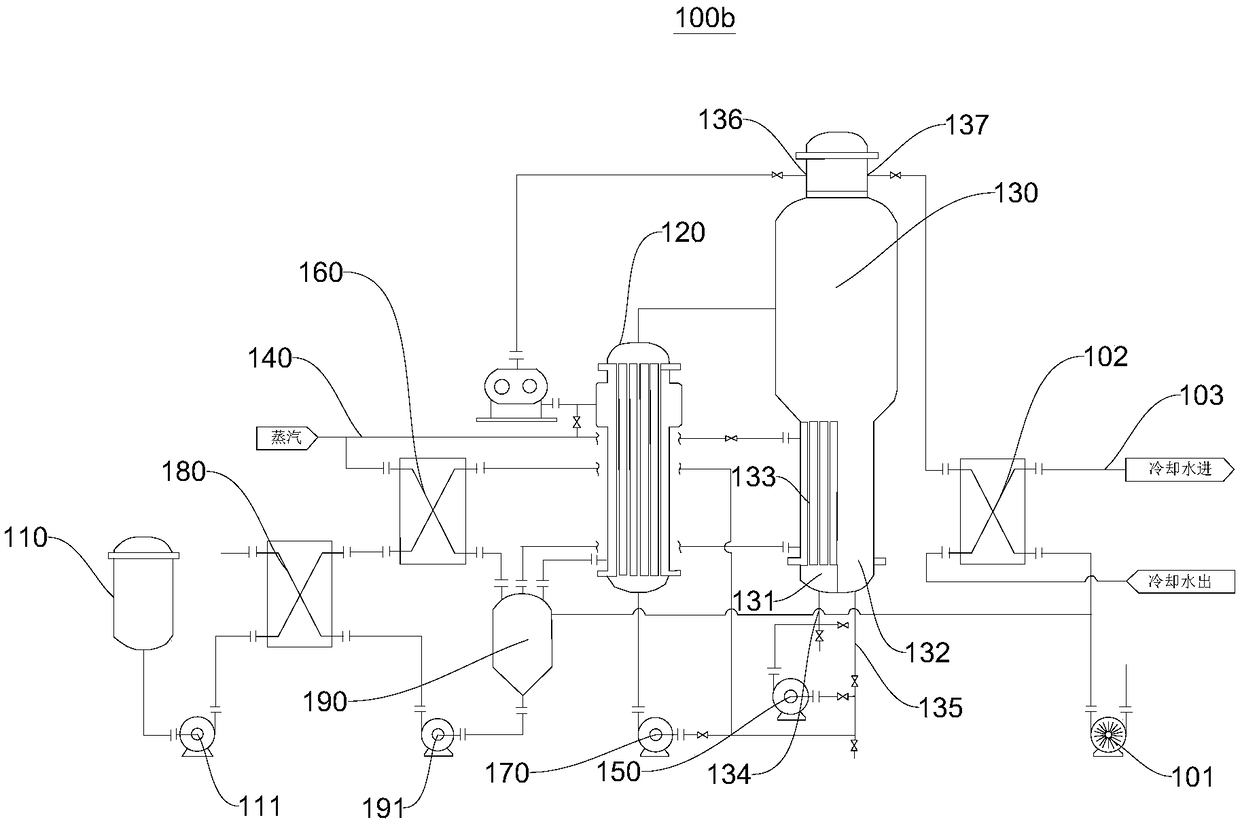

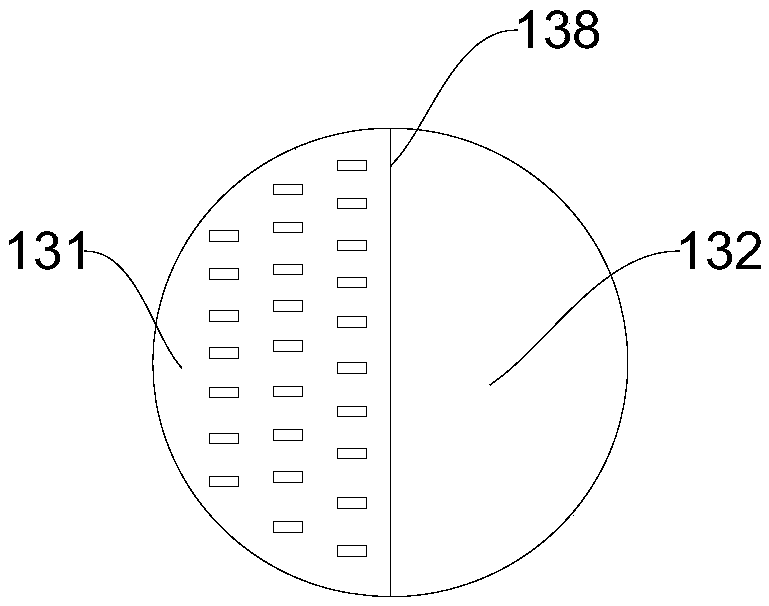

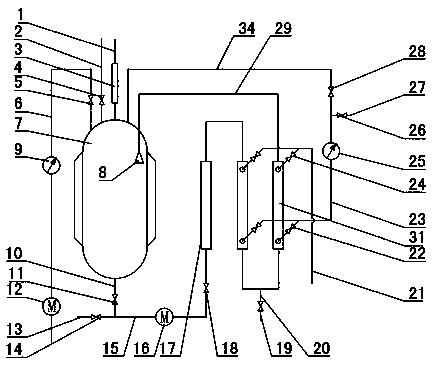

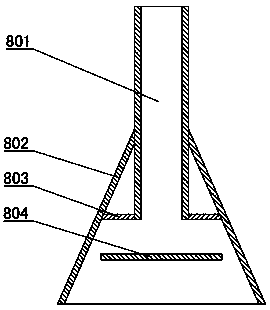

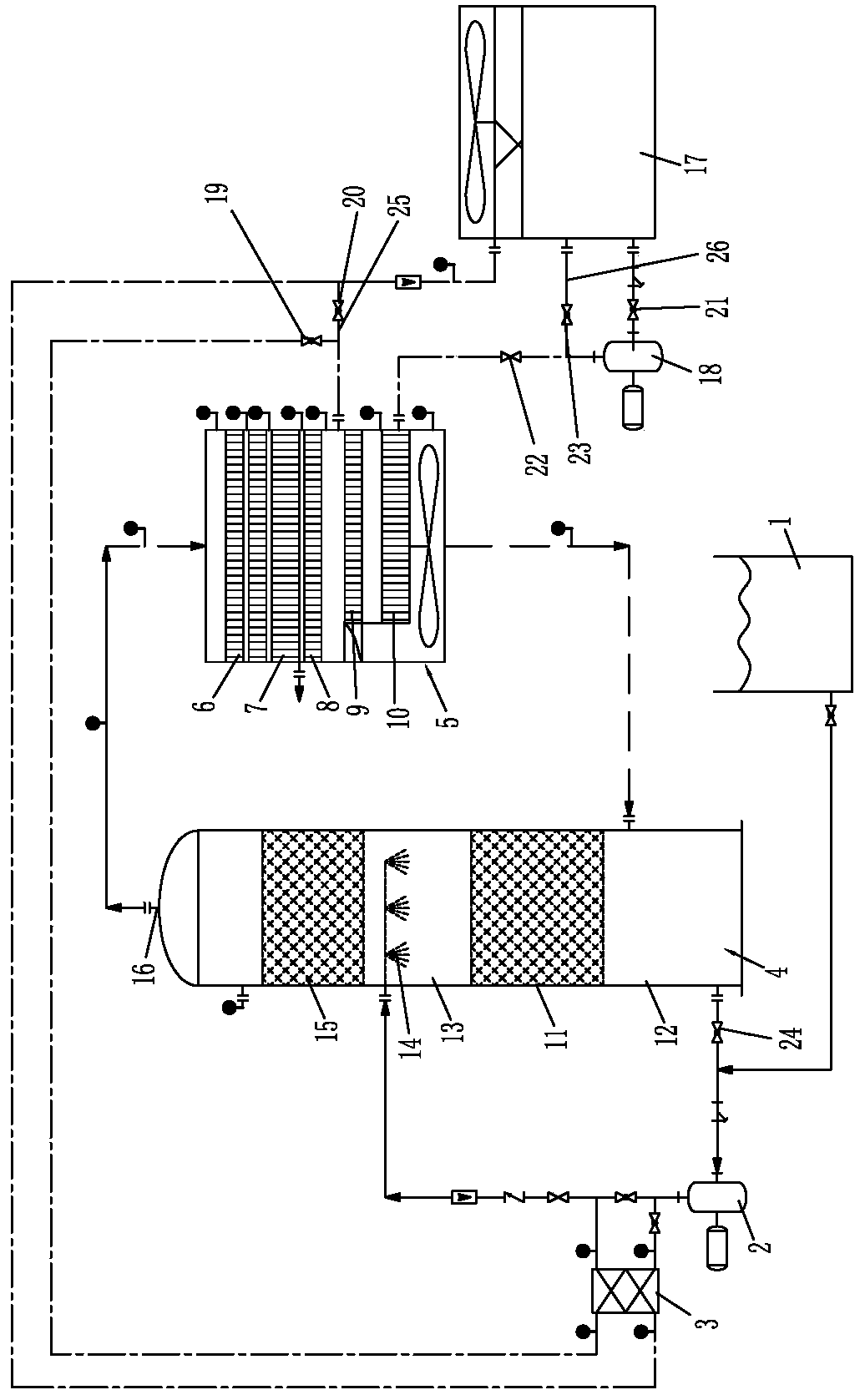

Heat pump vacuum low-temperature evaporation concentration system

ActiveCN111747468ALiquify and cool downReduce demandSpecific water treatment objectivesWater/sewage treatment by heatingWastewaterEngineering

The invention discloses a heat pump vacuum low-temperature evaporation concentration system. The system comprises an evaporation tank, a heating Carnot cycle system, a negative-pressure suction pipeline and a clean water circulation system; the upper part of the evaporation tank is connected with a wastewater inflow pipe and a steam discharge pipe; a wastewater heating system is arranged between the bottom of the evaporation tank and the wastewater inflow pipe; the clean water circulation system comprises a water tank, a water pump, a venturi and a heat dissipation and cooling device which aresequentially connected through a pipeline; one end of the negative-pressure suction pipeline is connected with the steam discharge pipe, the other end of the negative-pressure suction pipeline is connected with the introduction pipe of the venturi; a stop valve is arranged on the negative-pressure suction pipeline; the heat release side inlet of an evaporator in the heating Carnot cycle system isconnected with the water outlet end pipeline of the venturi, and the heat release side outlet of the evaporator is connected to the water tank. The heat pump vacuum low-temperature evaporation concentration system provided by the invention has the advantages of low-temperature stable operation, high evaporation concentration efficiency, low maintenance cost and long service life, realizes removalof water vapor, condensed water and non-condensable gas, and improves the evaporation and concentration efficiency of the evaporation tank.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

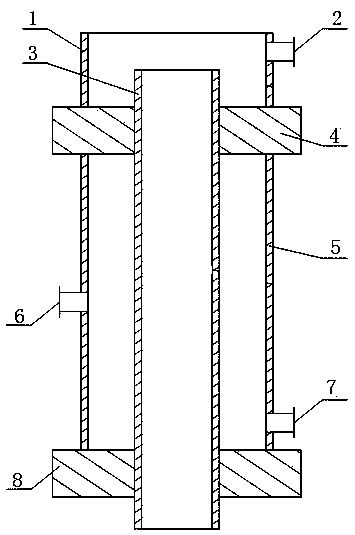

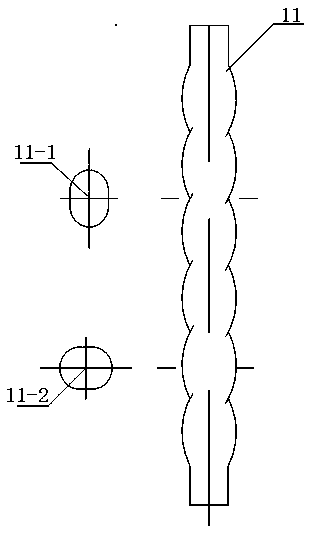

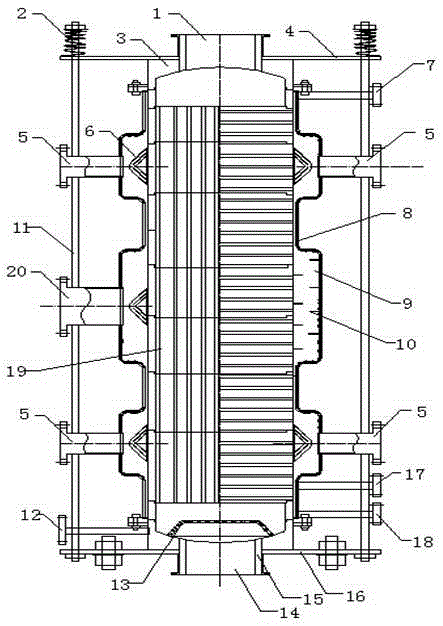

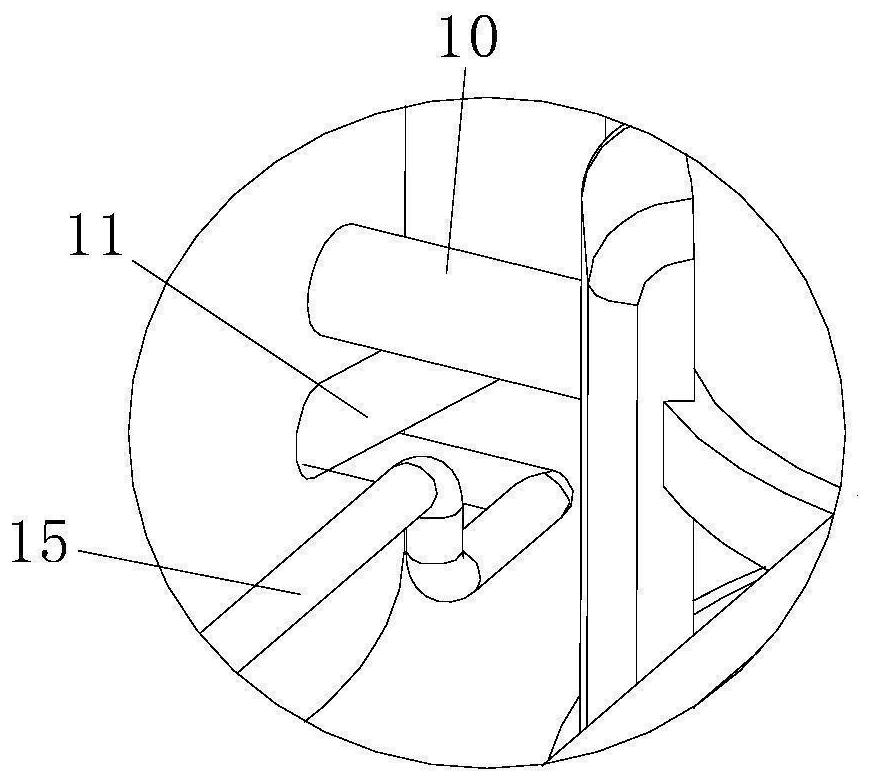

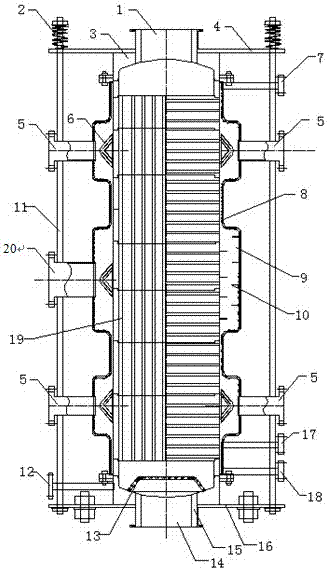

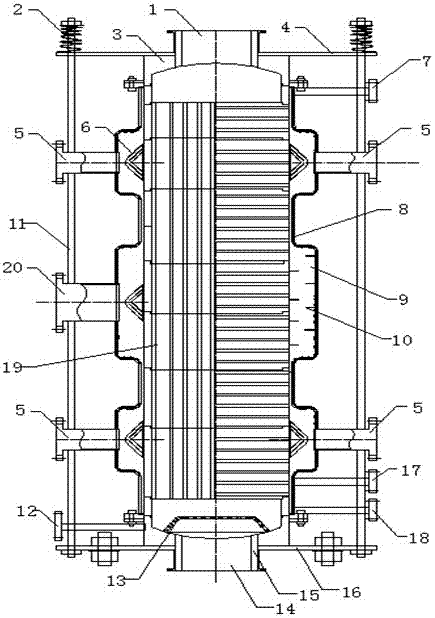

Spiral falling-film evaporator

PendingCN107823903AImprove evaporation and concentration efficiencyImprove convective heat transfer efficiencyEvaporationChemical industryEngineering

The invention provides a spiral falling-film evaporator, and belongs to the field of chemical industry production. The spiral falling-film evaporator comprises an upper barrel, an evaporated stock solution inlet, a spiral falling-film tube, an upper tube plate, a shell, a heating steam inlet, a condensed water outlet and a lower tube plate. The upper end of the upper tube plate is connected with the upper barrel, the evaporated stock solution inlet is formed in the upper end of a side surface of the upper barrel, the lower end of the upper tube plate is connected with the shell, the heating steam inlet is formed in the middle of a side surface of the shell, the condensed water outlet is formed in the bottom of a side surface of the shell, the lower end of the shell is connected with the lower tube plate, the spiral falling-film tube is arranged between the upper tube plate and the lower tube plate, an upper orifice of the spiral falling-film tube extends out of the upper portion of theupper tube plate and is close to the evaporated stock solution inlet, and a lower orifice of the spiral falling-film tube extends out of the lower portion of the lower tube plate. The spiral falling-film evaporator has the advantage that the evaporation concentration efficiency of the spiral falling-film evaporator can be improved.

Owner:江苏迈克化工机械有限公司

Graphite evaporator and automatic control system thereof

ActiveCN105396304AIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesAutomatic controlEngineering

The invention provides a graphite evaporator. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

Sewage treatment device for synthesis reaction of phenol and acetone

InactiveCN110228885AHigh recovery rateLow costFatty/oily/floating substances removal devicesWater contaminantsChemistryMulti effect

The invention discloses a sewage treatment device for a synthesis reaction of phenol and acetone. The device is formed through assembly connection of a neutralization kettle, an oil-water separator, asettling tank, a falling-film evaporator, a rectification tower, evaporation crystallization chambers and other equipment through pipelines. Wastewater produced by the rectification tower mainly comprises low-boiling organic matter and a sodium sulfate salt, multi-effect operation is carried out after the wastewater is introduced into the falling-film evaporator so as to achieve sufficient gas-liquid separation, and after the high-boiling sodium sulfate aqueous solution is introduced into a second evaporation crystallization chamber, centrifugal separation and washing are performed on the high-boiling sodium sulfate aqueous solution and sodium sulfate crystal produced in a first evaporation crystallization chamber so as to complete high-purity extraction of sodium sulfate, wherein the recovery rate is high, direct recycling utilization is performed, and the sewage treatment cost is reduced greatly; and the phenol removal rate reaches 99.5% or above after the sewage is treated, the removal rate of acetone, methanol and CODcr reaches 98.5-99.6%, the extraction rate of sodium sulfate reaches 92% or above, and the purity is larger than 95%.

Owner:实友化工(扬州)有限公司

Evaporation concentrator

InactiveCN104771916ASave energyImprove evaporation and concentration efficiencyEvaporator accessoriesEvaporationEngineering

The invention belongs to the technical field of chemical equipment and relates to an evaporation concentrator. The evaporation concentrator comprises an evaporation pot with a material liquid to be condensed and a heat exchanger. A temperature sensor is arranged in the evaporation pot. The bottom of the evaporation pot is communicated with an inlet of the heat exchanger by a pipe. An outlet of the heat exchanger is connected to an atomizer installed on the upper part of the evaporation pot by a pipe so that a material liquid circulation loop is formed. The pipe between the evaporation pot and the heat exchanger is provided with a pot bottom valve. An outlet pipe of the heat exchanger is provided with a material liquid pump. The heat exchanger comprises a heat transferring medium coiler. The heat transferring medium coiler is connected to a solar heat collector. The evaporation concentrator utilizes solar energy to provide material liquid heating heat for the heat exchanger, saves energy and has high evaporative concentration efficiency.

Owner:TIANJIN FORINT TRANSCENDENTAL TECH DEV CO LTD

Waste water concentration device

PendingCN107445232AIncrease temperatureIncrease profitSpecific water treatment objectivesUsing liquid separation agentFlue gasWastewater

The invention relates to the technical field of environment-protecting equipment. In order to solve the technical problems of low evaporation efficiency and high flue gas quantity requirement in the prior art, the invention provides a waste water concentration device. The waste water concentration device comprises a tower body; an evaporation chamber and a tower pool communicated with the evaporation chamber are arranged in the tower body; the evaporation chamber is arranged above the tower pool; a concentrated liquid outlet is formed above the tower pool; a flue gas inlet is formed in the lower part of the evaporation chamber or above the tower pool; a flue gas outlet is formed in the upper part of the evaporation chamber; a first spraying device is arranged in the tower body between the flue gas inlet and the flue gas outlet; the first spraying device and the tower pool are connected with a waste water heater and a circulating pump through pipelines; and a waste water feeding port is formed in the tower body or in a channel communicated with the tower body. The waste water concentration device has the characteristics of good concentration effect, low cost and high evaporation efficiency.

Owner:北京兴晟科技有限公司

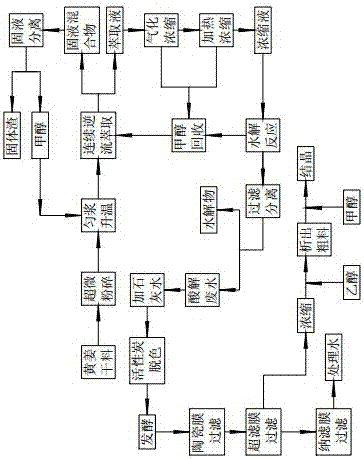

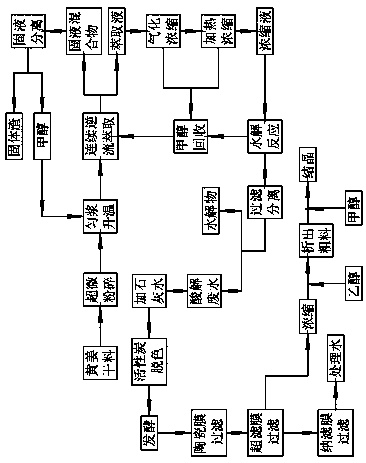

Process for producing saponin and rhamnose from turmeric

ActiveCN107417763ARealize green and clean productionHigh yieldSugar derivativesSteroidsAlcoholHydrolysate

A process for producing saponin and rhamnose from turmeric belongs to the technical field of saponin extraction. The method comprises the following steps of: (1) pulverizing a dried turmeric material; (2) mixing the sieved material with low molecular alcohol and stirring into homogenate; (3) heating the homogenate and then sending into a ceramic membrane extraction apparatus for extraction; (4) adding acid liquor into the concentrated mixed liquid for hydrolysis, filter pressing the solid-liquid mixture after hydrolysis, and drying to obtain a hydrolyzate; (5) mixing the hydrolyzate with petroleum ether, sending into the ceramic membrane extraction apparatus for extraction, performing crystallization separation on the extracted mixed liquid to obtain a saponin crystal substance; (6) adding the acid hydrolysis waste water in step (4) into lime water for neutralization, and then decolorizing, separating, concentrating and crystallizing to obtain the rhamnose. The process for producing saponin and rhamnose from turmeric achieves the clean production of the saponin, the acid hydrolysis waste water generated during production is less than 5% of a traditional process, and the yield of saponin is improved by 30% or above.

Owner:刘玉通

Traditional Chinese medicine concentrating device and traditional Chinese medicine concentrating process

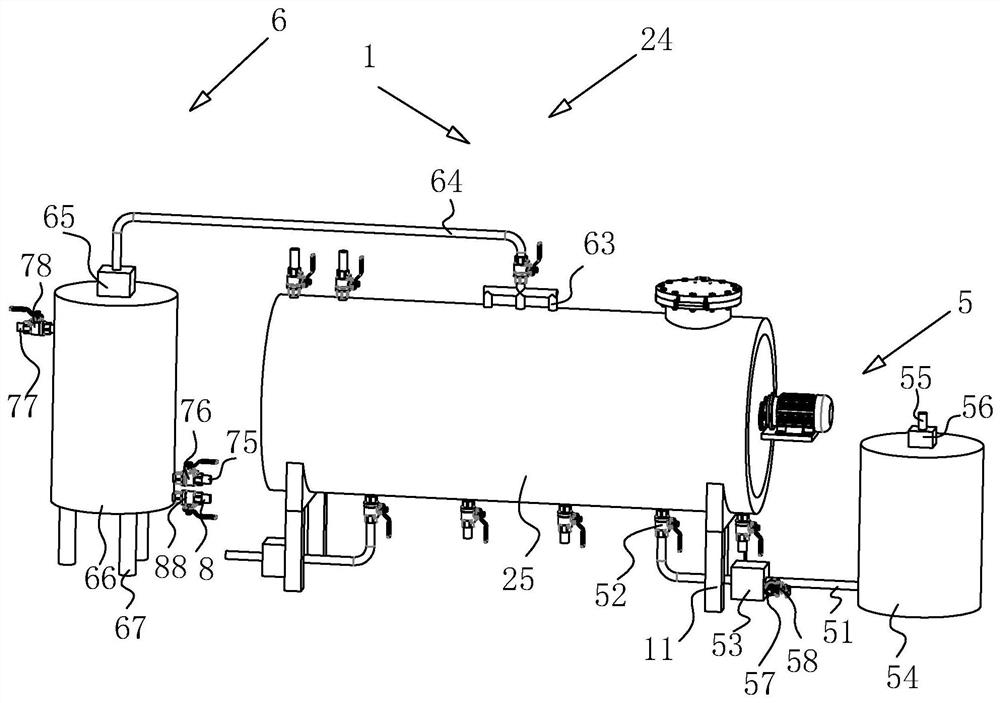

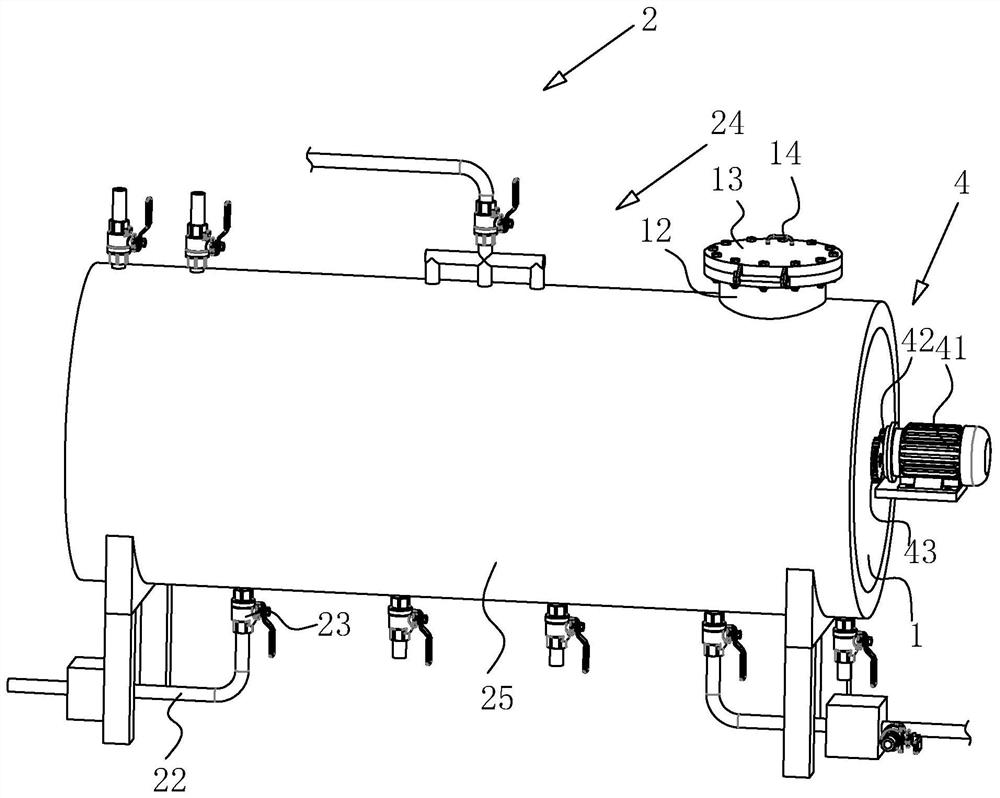

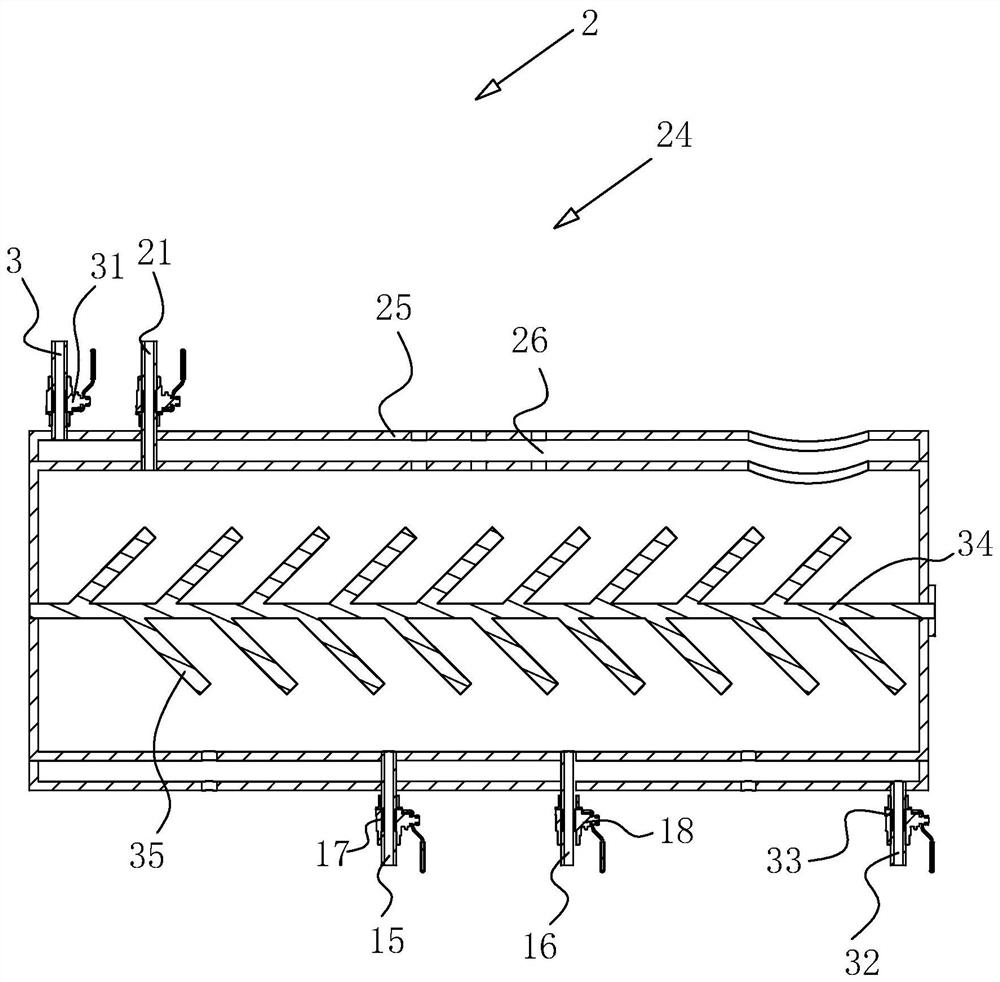

ActiveCN108905254AImprove evaporation and concentration efficiencyIncrease flexibilityEvaporator accessoriesMultiple-effect evaporationHigh concentrationMedicine

The invention provides a traditional Chinese medicine concentrating device and a traditional Chinese medicine concentrating process, and relates to the pharmaceutical technical field. The traditionalChinese medicine concentrating device includes a raw liquid tank, a main evaporation tank, a gas-liquid separating tank and a steam conveying pipeline; the outlet end of the raw liquid tank is connected with the inlet end of the main evaporation tank, and the output end of the main evaporation tank is connected with the input end of the gas-liquid separating tank; a plurality of first evaporationpipes are arranged in the main evaporation tank, the bottom of the gas-liquid separating tank is provided with a first material chamber and a second material chamber; a plurality of second evaporationpipes are arranged in the first material chamber; a first gas outlet of the top of the gas-liquid separating tank is connected with heating chambers of the first evaporation pipes on the main evaporating tank through a steam compressor. The traditional Chinese medicine concentrating process can significantly reduce energy consumption, can directly obtain high-concentration concentrate, and is suitable for large-scale industrialized application.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

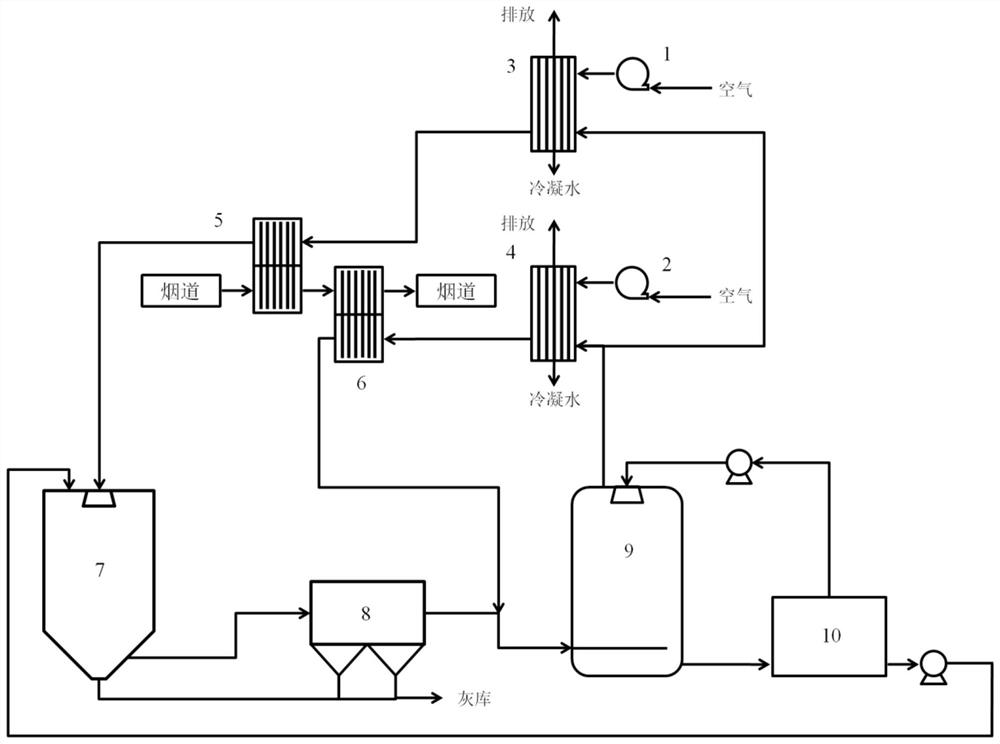

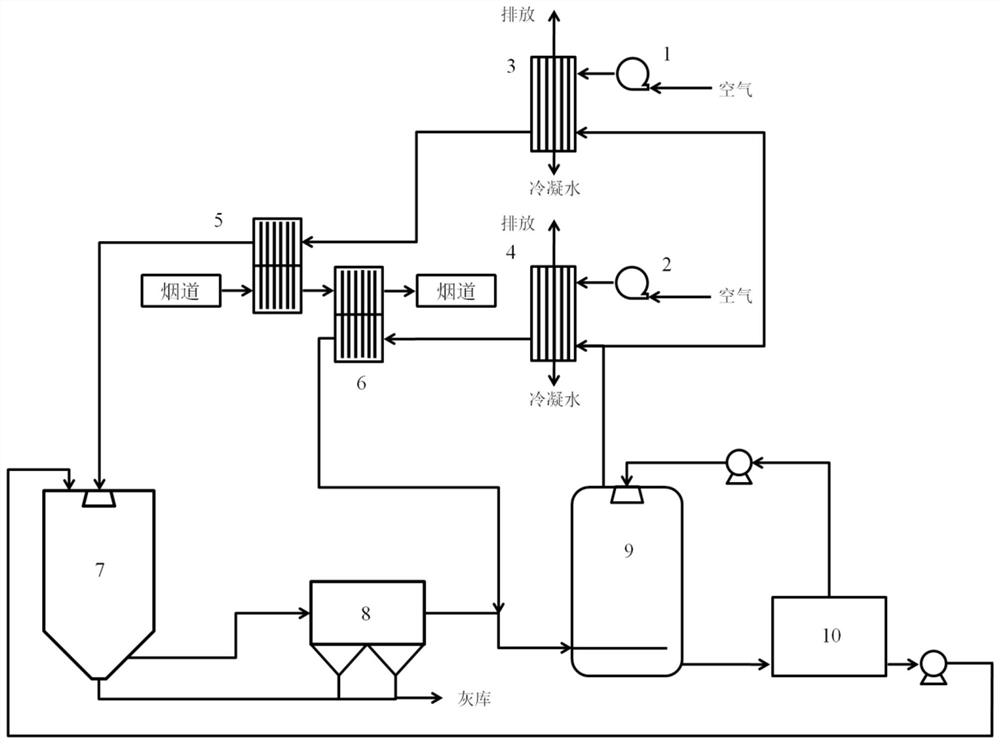

Desulfurization wastewater zero discharge system for gradient utilization of flue gas waste heat and working method thereof

ActiveCN112239242AReasonable designAchieve warm-upSpecific water treatment objectivesWaste water treatment from gaseous effluentsFlue gasSpray dried

The invention discloses a desulfurization wastewater zero discharge system for gradient utilization of flue gas waste heat and a working method of the desulfurization wastewater zero discharge system,and belongs to the technical field of desulfurization wastewater treatment. The system comprises a first air inlet device, a second air inlet device, a first air heat exchanger, a second air heat exchanger, a first flue gas heat exchanger, a second flue gas heat exchanger, a spray drying tower, a dust remover, an evaporation concentration tower and a desulfurization wastewater pool. High-temperature flue gas at the tail of a boiler is used for increasing the air temperature, desulfurization wastewater is evaporated and dried by high-temperature air through gradient utilization of the temperature, the cooled air is used for concentrating and reducing the desulfurization wastewater, the dust remover is used for recovering dried salt in the wastewater, and the air heat exchanger is used forrecovering heat in air at an outlet of a system for preheating the air. Compared with a conventional desulfurization waste water zero-discharge method, waste heat in flue gas is fully utilized, concentration and drying of waste water are synchronously achieved, the influence on water balance and material balance of gas in an original flue is small, and good application prospects are achieved.

Owner:HUANENG CLEAN ENERGY RES INST

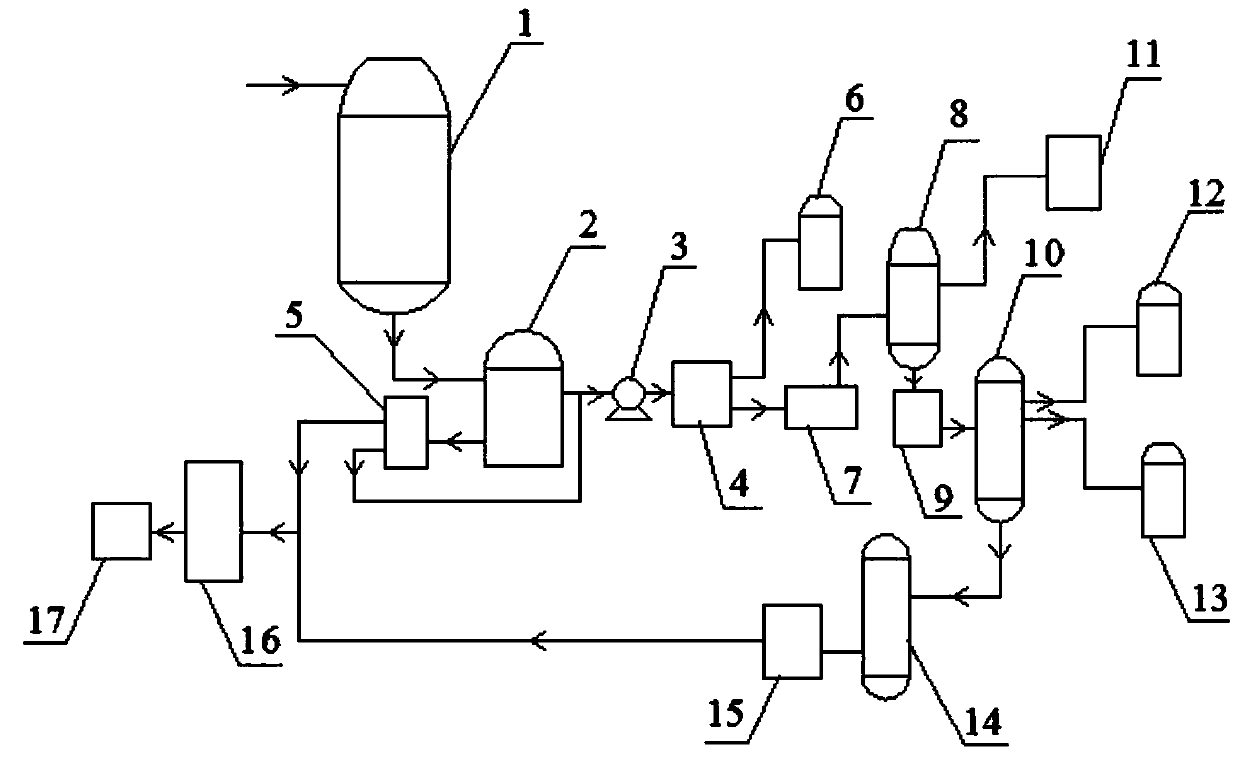

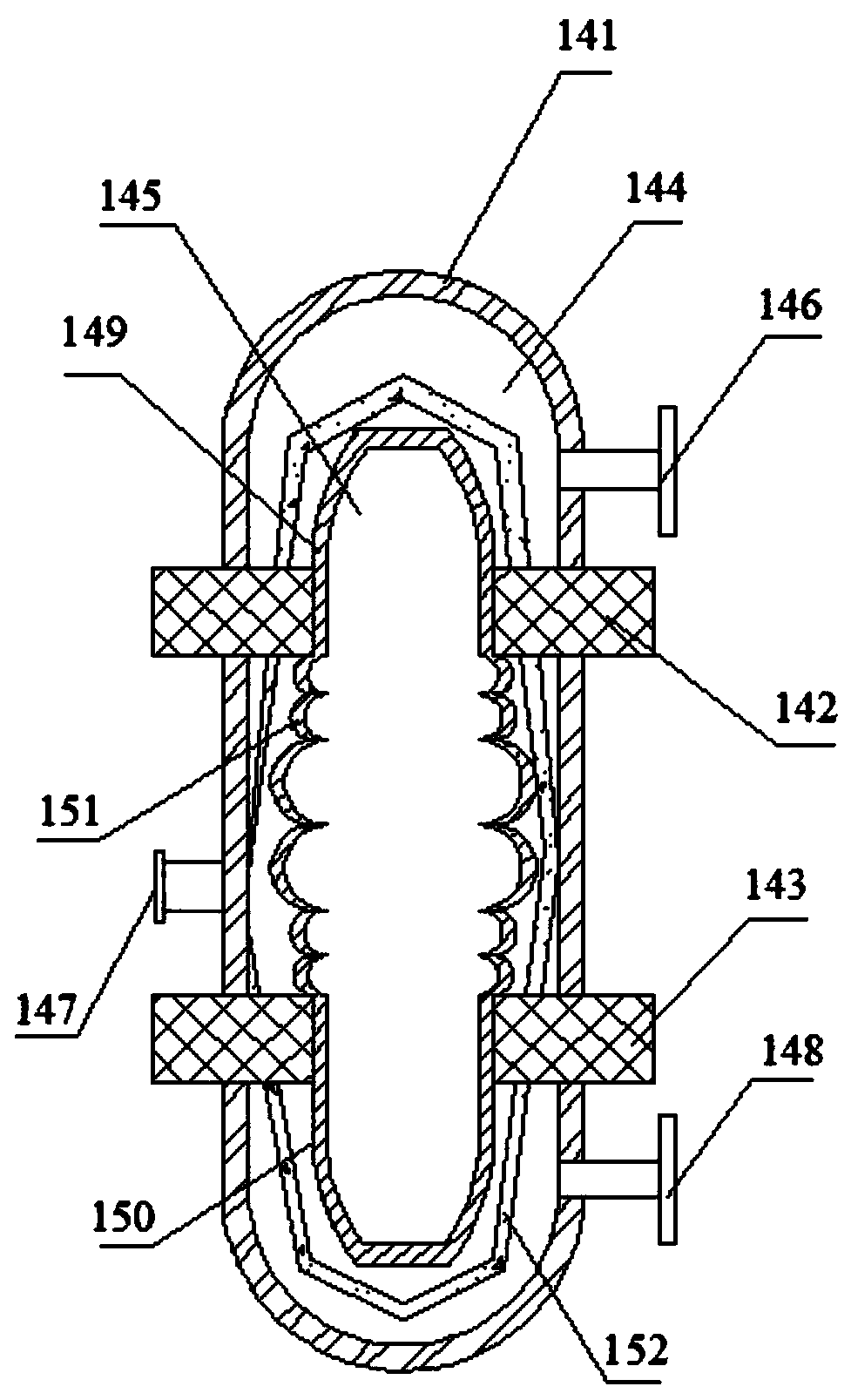

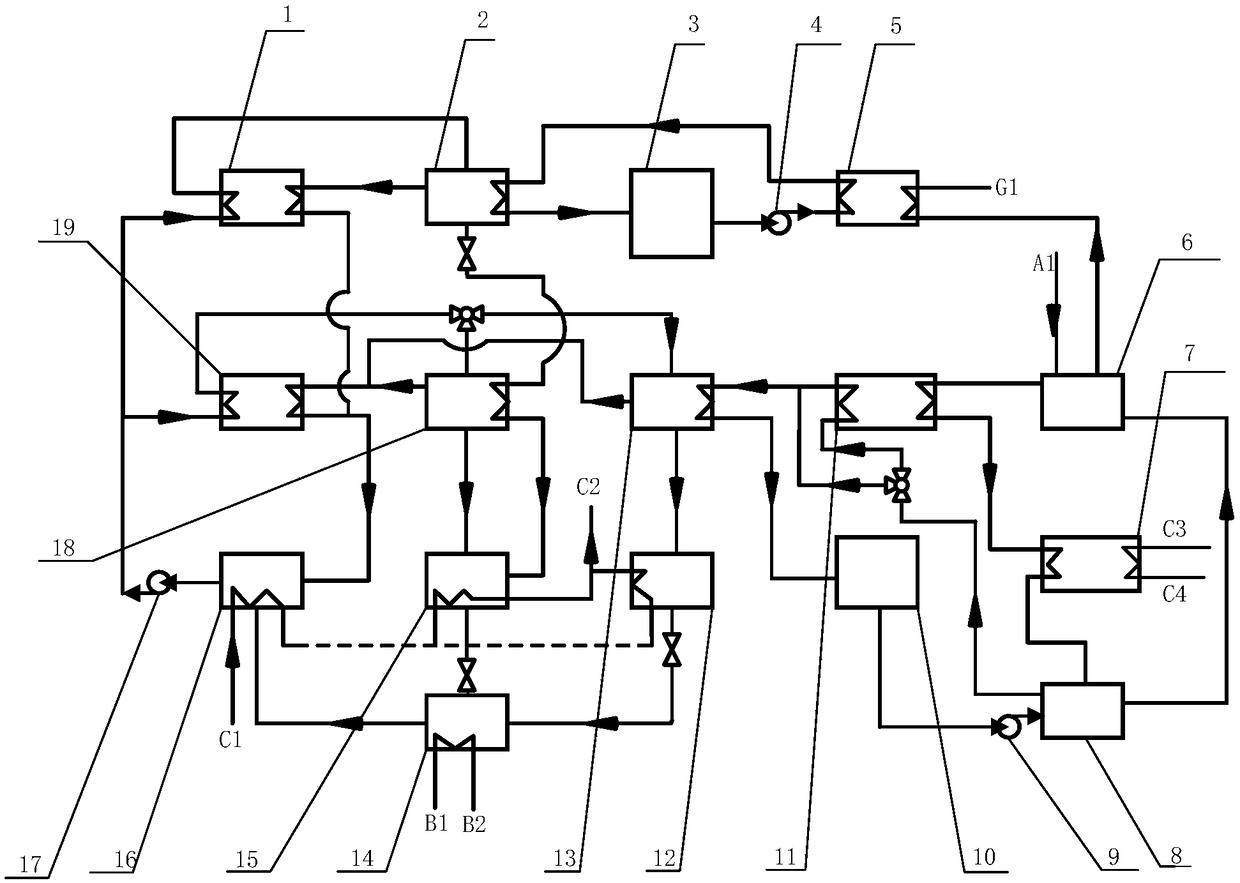

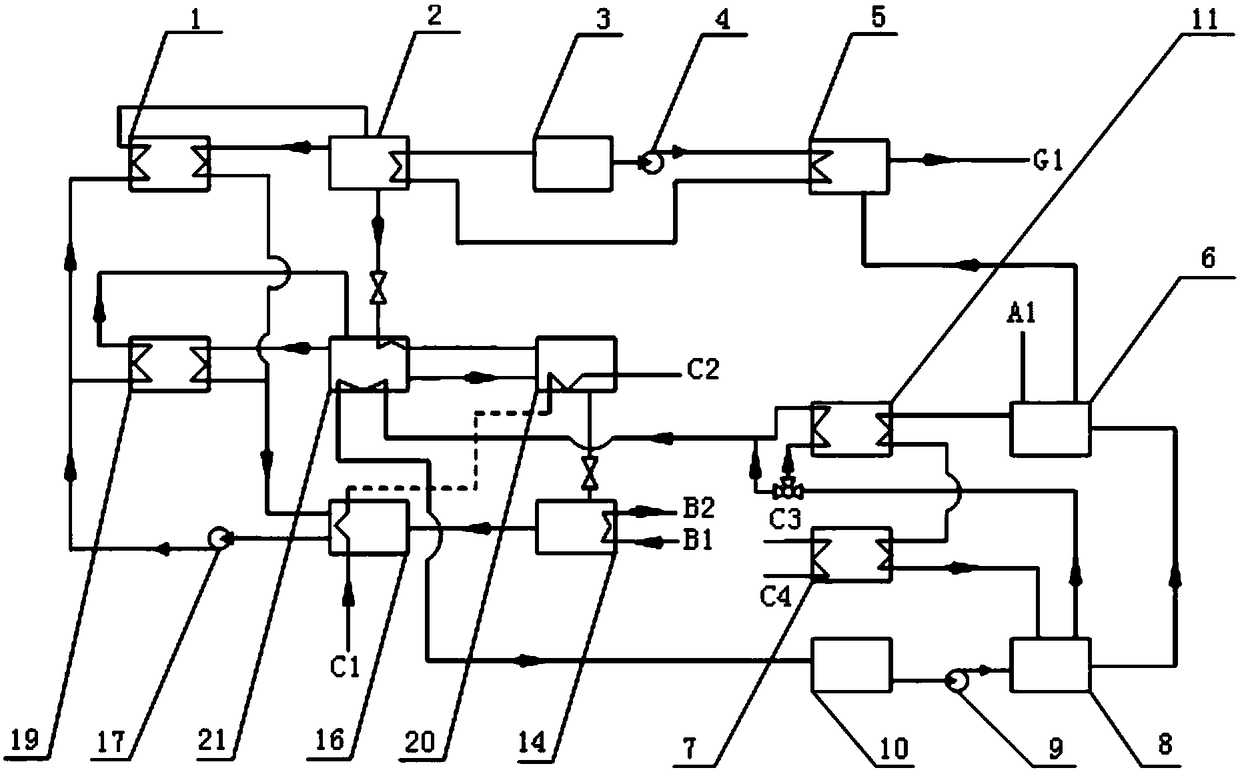

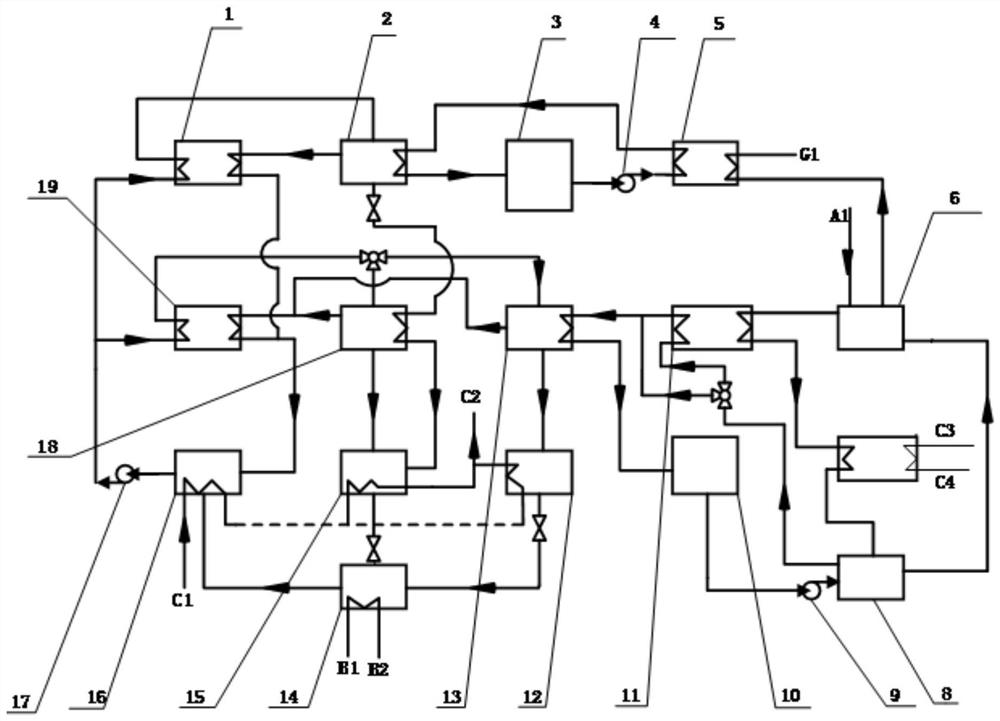

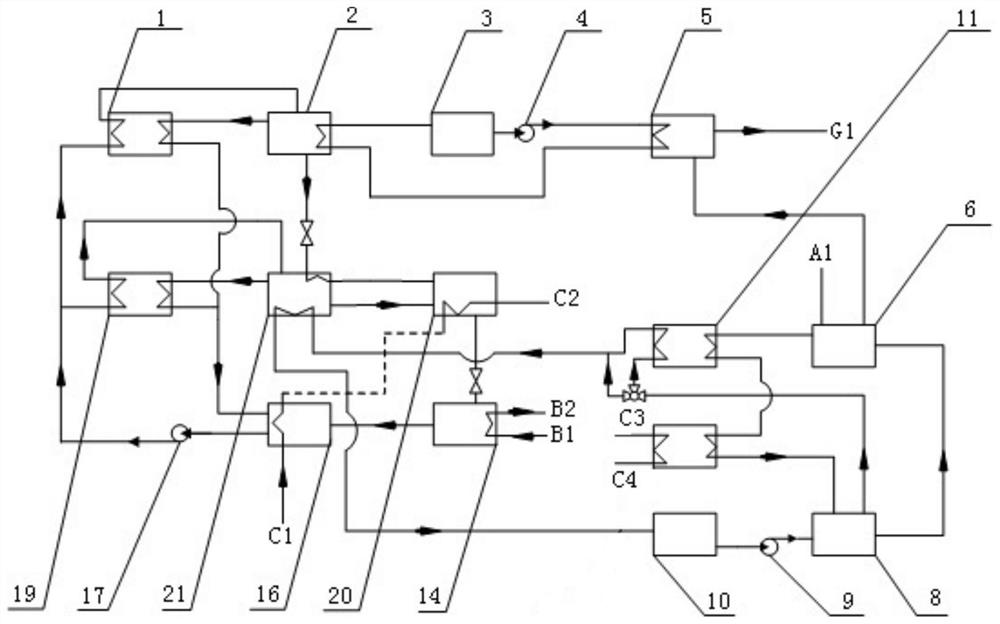

Lithium bromide absorption type refrigerating device driven by waste heat of cruise ship diesel engine

ActiveCN109323479AAvoid severe corrosionSimplify piping designClimate change adaptationEnergy efficient heating/coolingTurbochargerLithium bromide

The invention aims to provide a lithium bromide absorption type refrigerating device driven by waste heat of a cruise ship diesel engine. The device takes water as a refrigerant and takes a lithium bromide solution as an absorbent, and mainly comprises a high-pressure generator, low-pressure generators, a condenser, an evaporator, an absorber, a generator pump, heat exchangers, a flue gas heat exchanger, a high-temperature heat source water pump, a high-temperature heat source water tank, a turbocharger, a two-section intercooler, a cylinder sleeve cooling water tank, a cylinder sleeve coolingwater pump, a diesel engine, an exhaust air collecting pipe, an air inlet collecting pipe, and connecting pipelines of all components and a throttling valve and the like. According to the device, thewaste heat of the cruise ship diesel engine can be efficiently utilized, so that the refrigeration requirements under different working conditions and environments are met.

Owner:HARBIN ENG UNIV

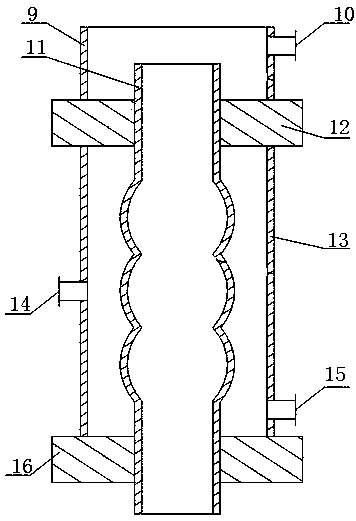

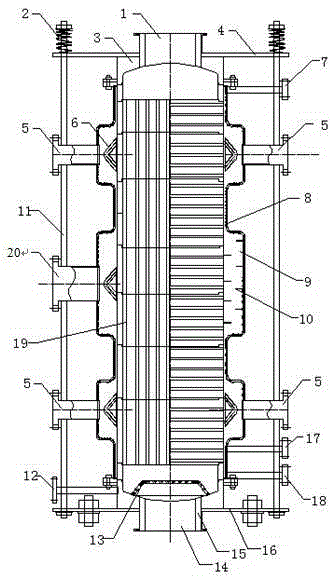

Graphite evaporator for concentration by evaporation and automatic control system thereof

ActiveCN105396303AIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesAutomatic controlEvaporation

The invention provides a graphite evaporator for concentration by evaporation. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; and automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger for concentration by evaporation.

Owner:PINGDINGSHAN XINRUIDA NEW MATERIAL TECH CO LTD

Efficient method and device for preparing sulfuric acid from desulfurization waste liquid of coking plant

ActiveCN111807332AAchieving processing powerAchieve environmental benefitsCombination devicesTreatment involving filtrationCoking plantAmmonium sulfate

The invention discloses a method and a device for preparing sulfuric acid from desulfurization waste liquid of a coking plant, and relates to the field of industrial wastewater treatment. The method comprises the following steps of: S1, centrifuging: centrifuging desulfurization waste liquid and sulfur foam to obtain sulfur paste and separated clear liquid; S2, concentration: concentrating the separated clear liquid to obtain sulfur slurry; S3, incineration: combusting the sulfur paste and the sulfur slurry in different areas; S4, dust removal and cooling: dedusting and then cooling sulfur dioxide flue gas generated by combustion; S5, drying and dehumidifying: removing impurities from the flue gas, dehumidifying the flue gas, dehydrating the flue gas, producing dilute sulfuric acid as a byproduct; S6, tail gas recovery: preparing industrial sulfuric acid from the treated sulfur dioxide gas, and returning the industrial sulfuric acid to a deamination system of a coking plant to remove ammonia in the coke oven gas to obtain ammonium sulfate; and S7, by-product recycling: neutralizing the dilute sulfuric acid concentrated solution obtained in S3 with dilute ammonia water, carrying outfiltering and concentrating to obtain an ammonium sulfate solution, and recovering the separated clear liquid. According to the invention, the technology for preparing sulfuric acid from desulfurization waste liquid and sulfur foam is upgraded, and the problems of high efficiency, energy conservation and environmental protection are thoroughly solved.

Owner:山东绿知源环保工程有限公司

Double-effect evaporation final-effect vapour system

InactiveCN104888482ANo lossEnsure normal start and stopMultiple-effect evaporationThermal energyAutomatic control

The invention relates to a double-effect evaporation final-effect vapour system. According to the double-effect evaporation final-effect vapour system, a discharge pipe arranged on the lower part of a I-effect slurry flash chamber is communicated with a feed inlet of a I-effect slurry circulating pump; a vapour outlet pipe arranged on the top part of the I-effect slurry flash chamber is communicated with a vapour inlet of a final-effect slurry heater; a feed outlet of the I-effect slurry circulating pump is communicated with a feed inlet arranged on the lower part of a I-effect slurry heater; a discharge pipe arranged on the upper part of the I-effect slurry heater is communicated with a feed inlet of the I-effect slurry flash chamber; a liquor condensate pipe of the I-effect slurry heater is communicated with a I-effect liquor condensate collecting tank; a discharge pipe arranged on the lower part of a final-effect slurry flash chamber is communicated with a feed inlet of a final-effect slurry circulating pump; a feed outlet of the final-effect slurry circulating pump is communicated with a feed inlet arranged on the lower part of the final-effect slurry heater; a discharge pipe arranged on the upper part of the final-effect slurry heater is communicated with a feed inlet of the final-effect slurry flash chamber; and a liquor condensate pipe of the final-effect slurry heater is communicated with a final-effect liquor condensate collecting tank. Process flow is simple; automatic control is adopted; thermal energy of final-effect discharged vapour is used effectively; energy waste is reduced; no polluted water is generated; environmental pollution is avoided; production cost is reduced; and productivity is increased.

Owner:江苏瑞和化肥有限公司

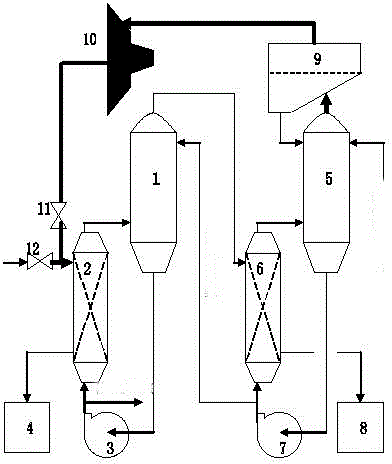

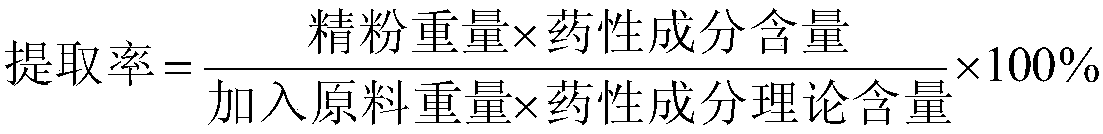

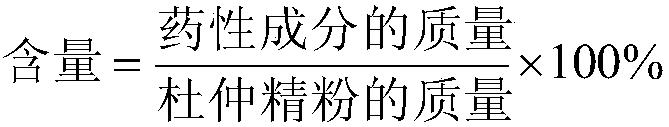

Production process of cortex eucommiae fine powder

InactiveCN108143762AIncrease concentrationReduce dosagePharmaceutical non-active ingredientsPlant ingredientsBiotechnologyHydrolysate

The invention belongs to the technical field of processing of cortex eucommiae, and particularly relates to a production process of cortex eucommiae fine powder. The production process is characterized by comprising the following steps: by adopting enzymatic hydrolysate filtrate obtained by degrading folium eucommiae or cortex eucommiae by adopting a biological enzyme method as a raw material, centrifugally separating, precipitating, concentrating, alcohol precipitating, separating, purifying, embedding by virtue of cyclodextrin, and drying, thus obtaining the cortex eucommiae fine powder. Theimprovement of the production process lies in twice centrifugal treatment, filtering and concentration prior to the alcohol precipitation, so that the concentration efficiency can be favorably improved, the production cost can be decreased, the quality of a product can be effectively protected, the heat exchanging efficiency is basically kept unchanged, the evaporation concentration efficiency can be improved, and the energy consumption can be effectively reduced.

Owner:山东贝隆杜仲生物工程有限公司

A kind of technology that adopts turmeric to produce saponin and rhamnose

ActiveCN107417763BRealize green and clean productionHigh yieldSugar derivativesSteroidsAlcoholHydrolysate

Owner:刘玉通

Liquid concentrating apparatus

InactiveCN105031955AIncrease evaporation rateIncrease kinetic energyEvaporation by sprayingTemperature controlWater baths

A liquid concentrating apparatus comprises a temperature control water-bath system and a negative pressure tank; the temperature control water-bath system comprises a water bath, the water bath is provided with a water injection hole, and a temperature measurement probe and a heating device are arranged in the water bath; and the upper end of the negative pressure tank is provided with a liquid adding port, the liquid adding port is provided with a tank cover, the bottom of the negative pressure tank is tapered in shape and is immersed in water in the water bath, the top of the tank cover is provided with an air discharging valve, one side of the tank cover is provided with an air exhaust hole, the bottom of the negative pressure tank is provided with a liquid discharging tube, the liquid discharging tube is provided with a first branch tube and a second branch tube, the first branch tube is used for discharging a concentrated liquid, the second branch tube is connected with the inlet end of an electric spray pump, the outlet end of the electric spray pump is connected with a jet tube, and the other end of the jet tube extends into the tank cover and is provided with a spray head. The apparatus has the advantages of continuous working, large throughput every time and high efficiency, and can completely meet liquid concentration and evaporation and solvent recovery requirements of general laboratories.

Owner:HENAN UNIV OF SCI & TECH

High-efficiency method and device for producing sulfuric acid from desulfurization waste liquid in coking plant

ActiveCN111807332BAchieving processing powerAchieve environmental benefitsCombination devicesTreatment involving filtrationDust controlCoking plant

The invention discloses a method and device for producing sulfuric acid from desulfurization waste liquid in a coking plant, and relates to the field of industrial wastewater treatment. The working method is: S1: centrifugation; centrifuging the desulfurization waste liquid and sulfur foam to obtain sulfur paste and separated clear liquid ;S2: Concentration; the separated supernatant is concentrated to obtain sulfur slurry; S3: Incineration; sulfur paste and sulfur slurry are burned in separate areas; S4: Dust removal and cooling; Gas removal, dehumidification, and dehydration; dilute sulfuric acid is produced as a by-product; S6: Tail gas recovery: the treated sulfur dioxide gas is made into industrial sulfuric acid, and returned to the deamination system of the coking plant to remove ammonia in coke oven gas and make ammonium sulfate ; S7: recovery of by-products; the dilute sulfuric acid concentrate obtained in S3 is neutralized with dilute ammonia water, filtered, concentrated to obtain an ammonium sulfate solution, and the separated clear liquid is recovered. The invention is an upgrade of the sulfuric acid production technology from desulfurization waste liquid and sulfur foam, and thoroughly solves the problems of high efficiency, energy saving and environmental protection.

Owner:山东绿知源环保工程有限公司

Heat pump evaporation heat recovery combination device and waste liquid high-efficiency concentration method

ActiveCN105731572BImprove evaporation and concentration efficiencyIncrease temperatureHeat recovery systemsWater/sewage treatmentLiquid wasteEnrichment methods

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

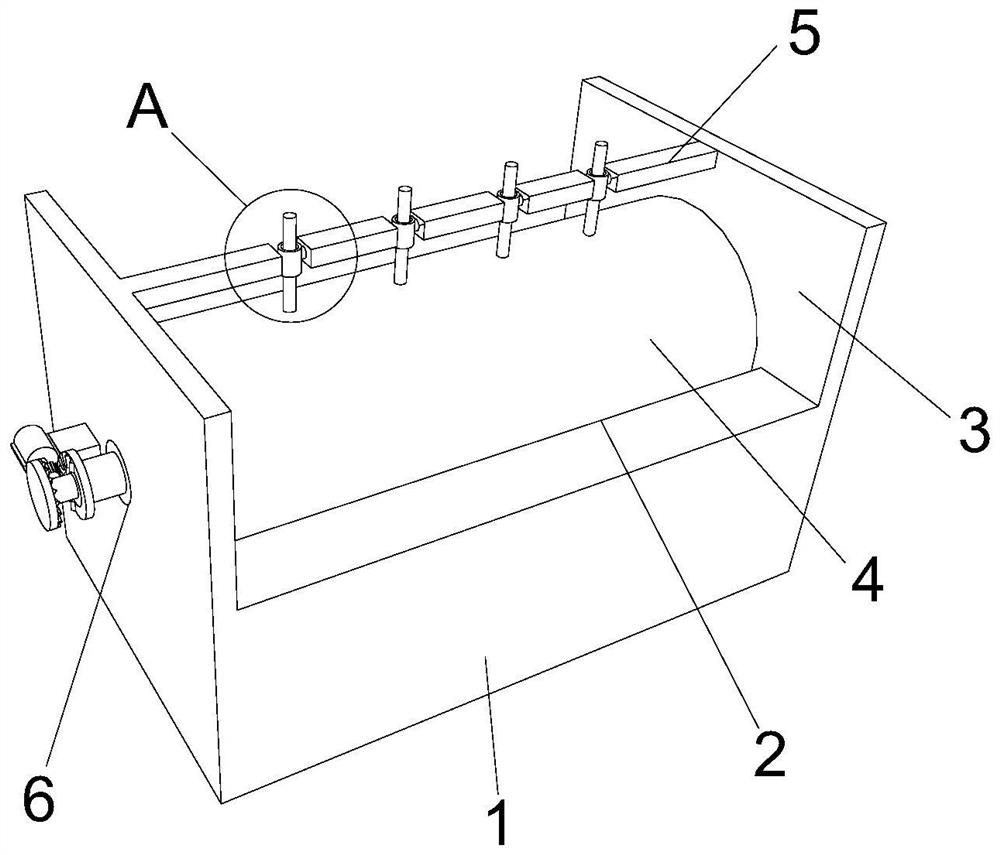

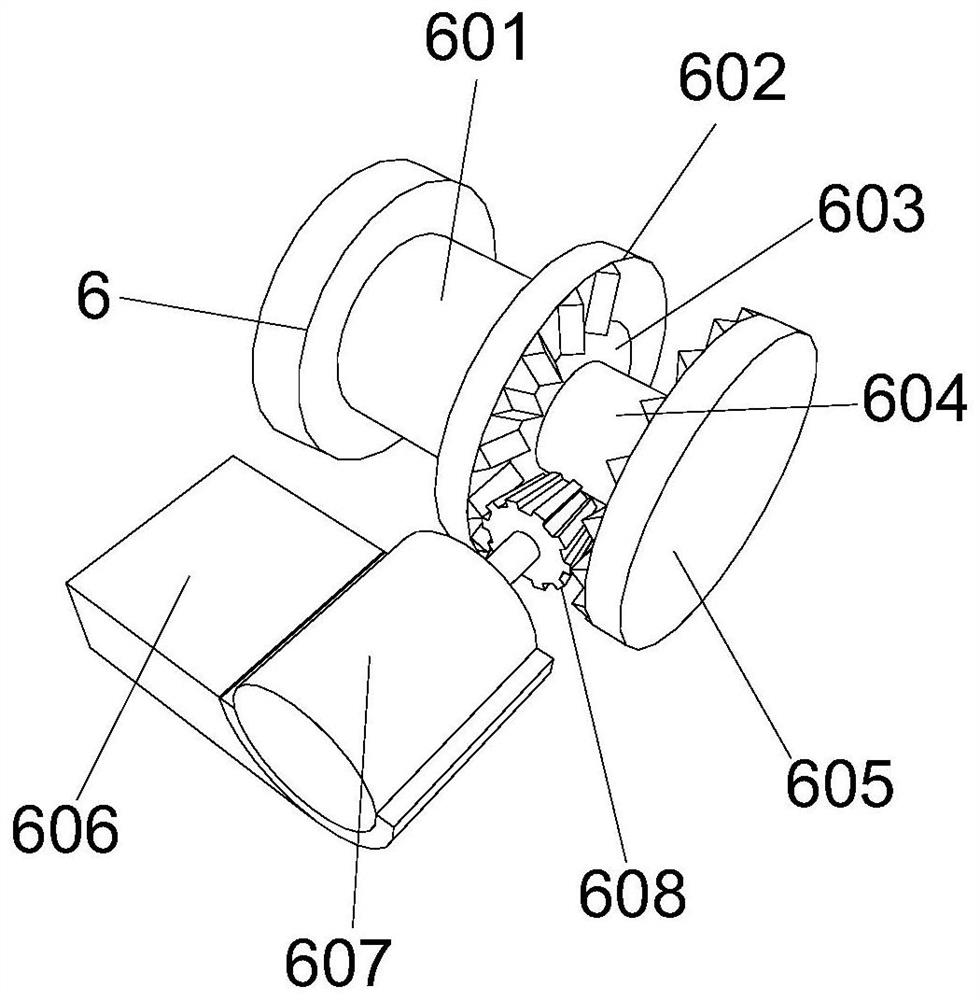

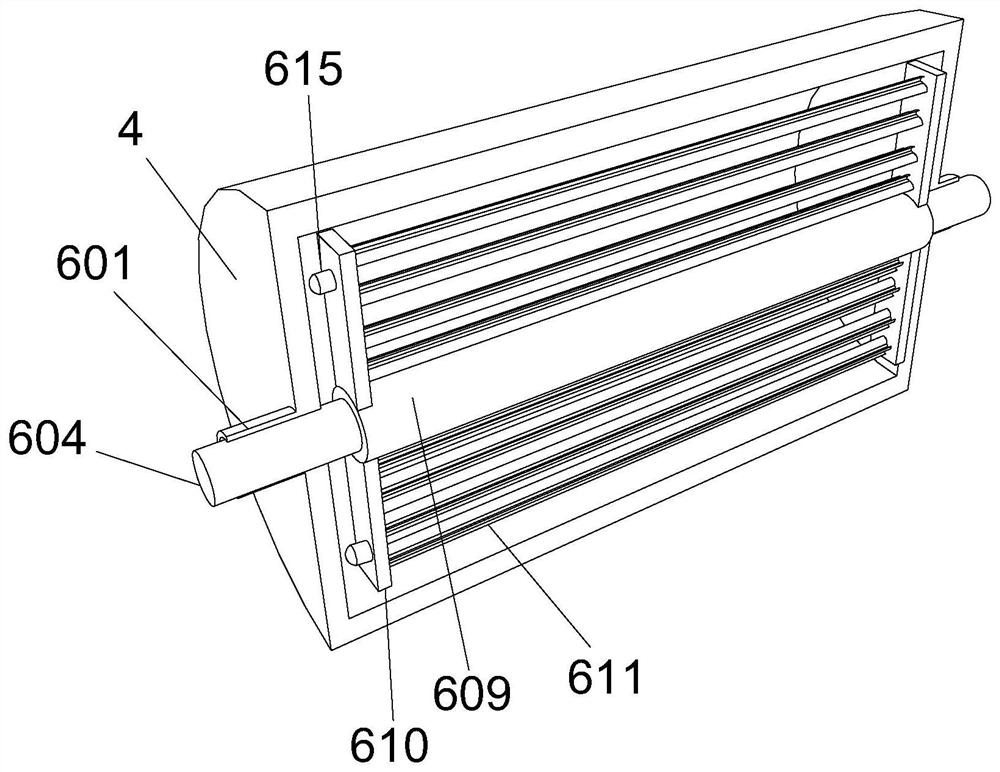

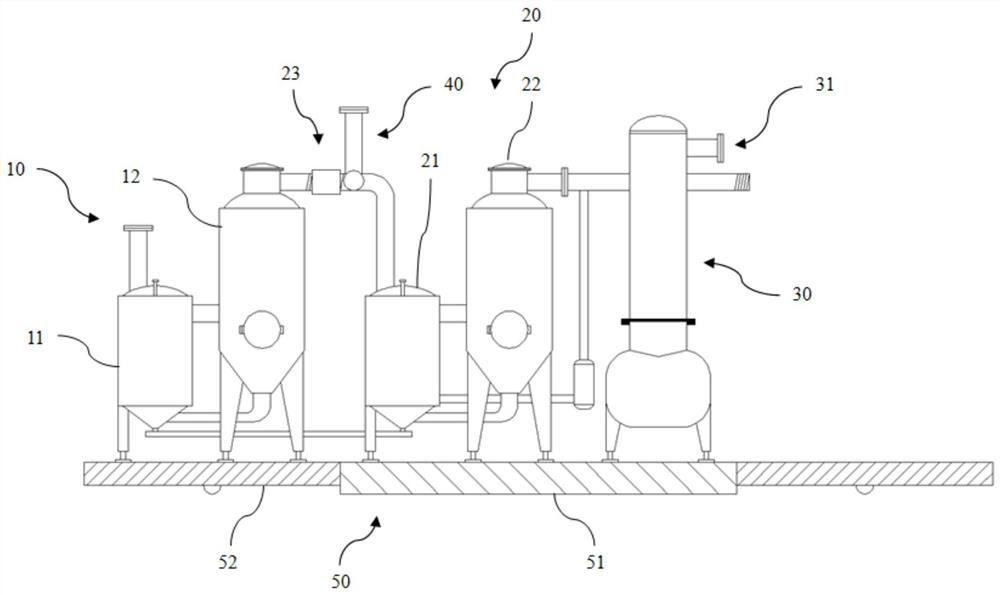

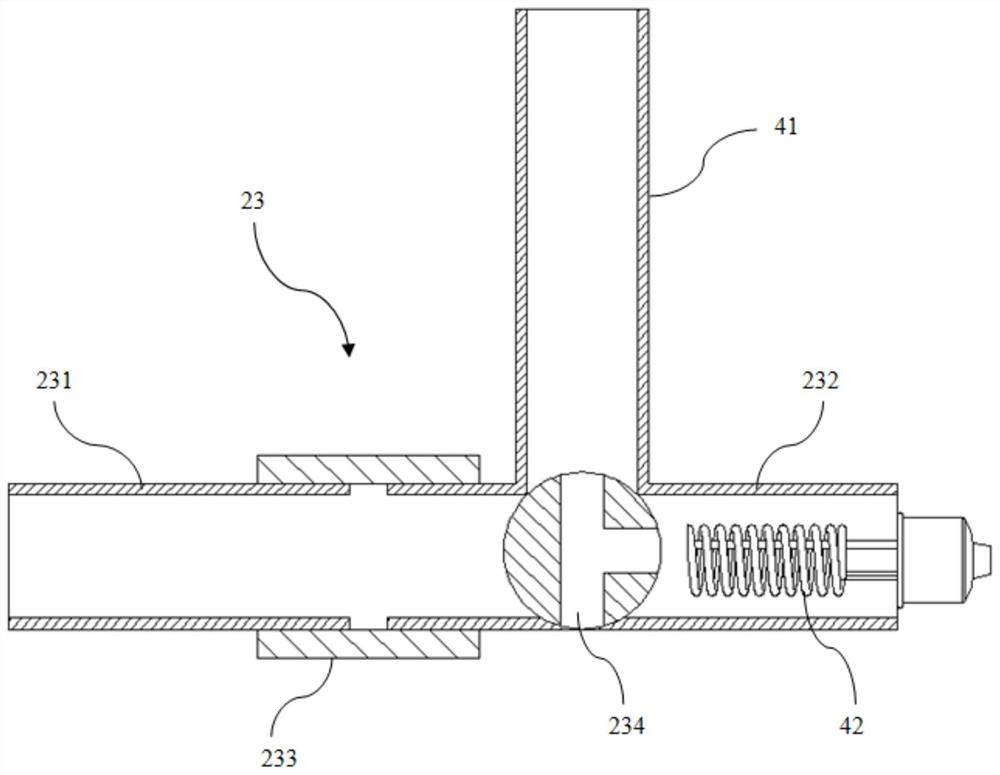

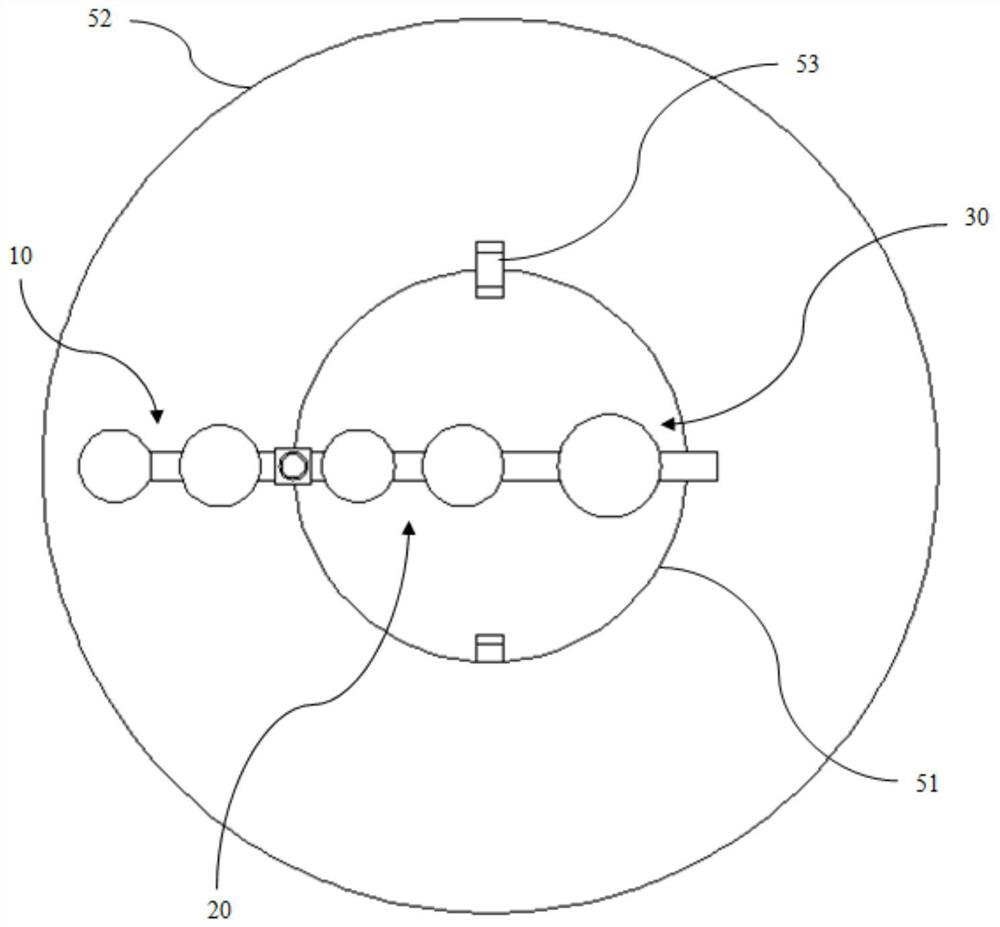

Evaporation and concentration device in the production of liquid glucosamine

ActiveCN112044103BImprove efficiencyHeating fastEvaporator accessoriesMechanical engineeringMechanics

The invention relates to the technical field of liquid glucosamine production, and discloses an evaporation and concentration device in the production of liquid glucosamine, which includes a water bath heating box. A side plate is fixedly installed vertically upward, a loading bucket is arranged horizontally inside the middle groove, and a cross bar is fixedly installed horizontally in the middle position of the upper ends of the two groups of side plates. In the present invention, after the connecting gear meshes with the teeth of the semi-linkage gear, the loading bucket will periodically rotate clockwise and counterclockwise under the action of its own gravity. The sleeve drives the auxiliary stirring rod to rotate through the stirring rod, so that the auxiliary stirring rod rotates continuously inside the loading bucket to stir the glucosamine solution inside the loading bucket, increasing the contact between the glucosamine and the inner wall of the lower end of the loading bucket, and improving the liquid inside the loading bucket. Evaporation efficiency.

Owner:SHANDONG RUNDE BIOTECH CO LTD

A lithium bromide absorption refrigeration device driven by the waste heat of cruise diesel engine

ActiveCN109323479BAvoid severe corrosionSimplify piping designClimate change adaptationEnergy efficient heating/coolingTurbochargerLithium bromide

The invention aims to provide a lithium bromide absorption type refrigerating device driven by waste heat of a cruise ship diesel engine. The device takes water as a refrigerant and takes a lithium bromide solution as an absorbent, and mainly comprises a high-pressure generator, low-pressure generators, a condenser, an evaporator, an absorber, a generator pump, heat exchangers, a flue gas heat exchanger, a high-temperature heat source water pump, a high-temperature heat source water tank, a turbocharger, a two-section intercooler, a cylinder sleeve cooling water tank, a cylinder sleeve coolingwater pump, a diesel engine, an exhaust air collecting pipe, an air inlet collecting pipe, and connecting pipelines of all components and a throttling valve and the like. According to the device, thewaste heat of the cruise ship diesel engine can be efficiently utilized, so that the refrigeration requirements under different working conditions and environments are met.

Owner:HARBIN ENG UNIV

A graphite evaporator and its automatic control system

ActiveCN105396304BIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesPlate heat exchangerAutomatic control

The invention provides a graphite evaporator. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

A zero-discharge system for desulfurization wastewater with cascaded utilization of flue gas waste heat and its working method

ActiveCN112239242BReasonable designAchieve warm-upSpecific water treatment objectivesWaste water treatment from gaseous effluentsFlue gasSpray dried

Owner:HUANENG CLEAN ENERGY RES INST

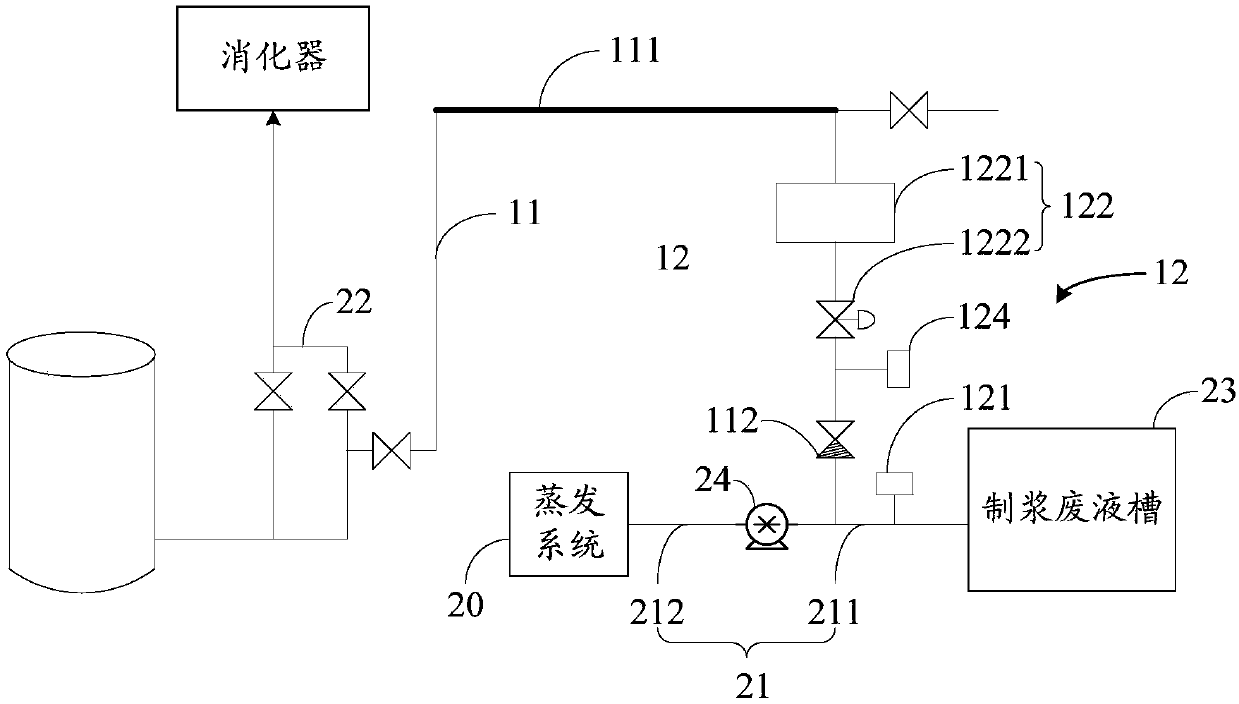

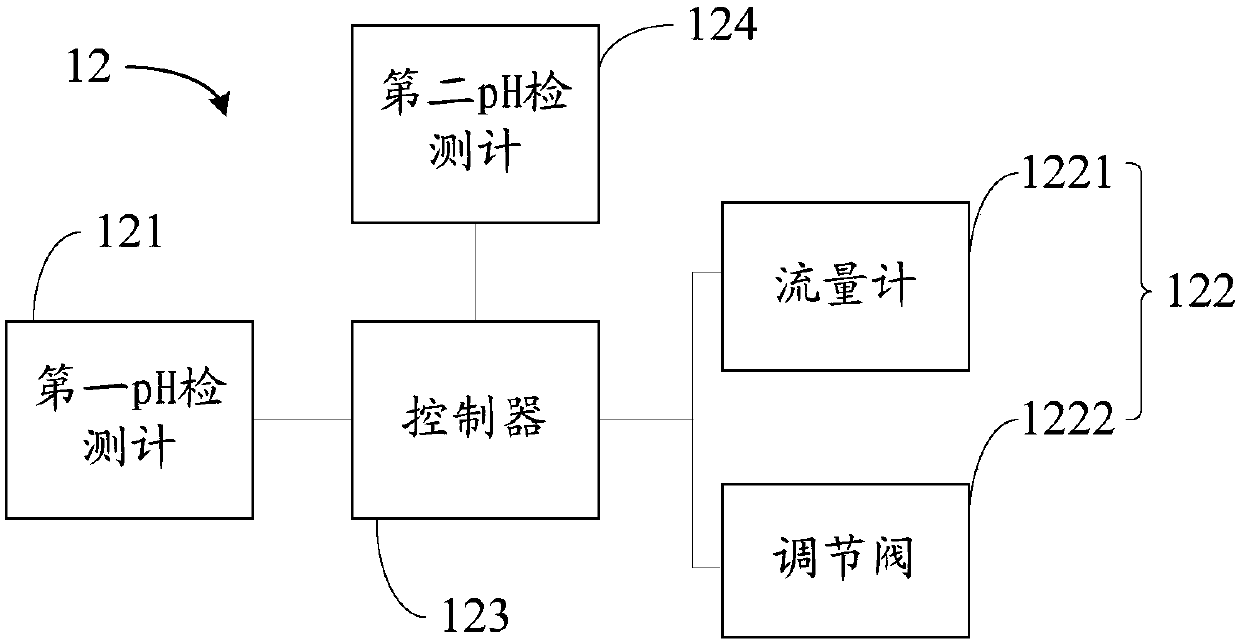

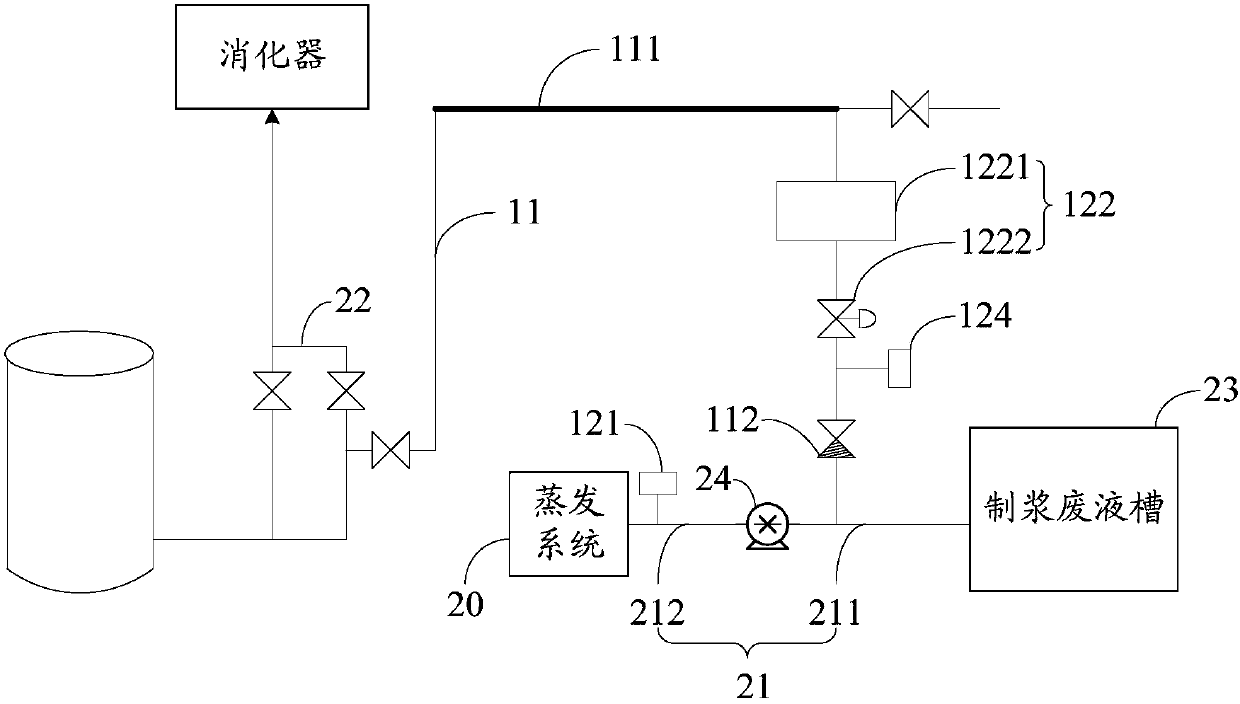

Pre-treatment system of pulping waste liquid

ActiveCN110054334AAvoid damageImprove evaporation and concentration efficiencyWater treatment parameter controlMultistage water/sewage treatmentLiquid wasteEvaporation

The invention embodiment provides a pre-treatment system of pulping waste liquid. The pulping waste liquid is slightly acidic, the pre-treatment system is arranged before an evaporation system of thepulping waste liquid, and comprises a first green liquid pipeline, and an adjusting controlling device; one end of the first green liquid pipeline is connected with a first pipeline which is used forintroduction of the pulping waste liquid into the evaporation system, and the other end is connected with an original green liquid pipeline, and is used for introducing the green liquid from the original green liquid pipeline into the first pipeline, so that the pH value of the pulping waste liquid is adjusted to a preset valve; the adjusting controlling device is arranged on the first green liquid pipeline and / or the first pipeline, and is used for adjusting and controlling the adding amount of the green liquid, so that the pH value of the pulping waste liquid is capable of satisfying presetrequirements before entering into the evaporation system. The above pre-treatment method is capable of reducing cost, and increasing recycling rate of the pulping waste liquid.

Owner:GOLD EAST PAPER JIANGSU

A graphite evaporator for evaporation and concentration and its automatic control system

ActiveCN105396303BIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesAutomatic controlEvaporation

The invention provides a graphite evaporator for concentration by evaporation. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; and automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger for concentration by evaporation.

Owner:PINGDINGSHAN XINRUIDA NEW MATERIAL TECH CO LTD

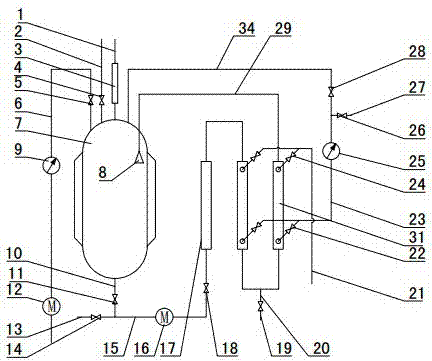

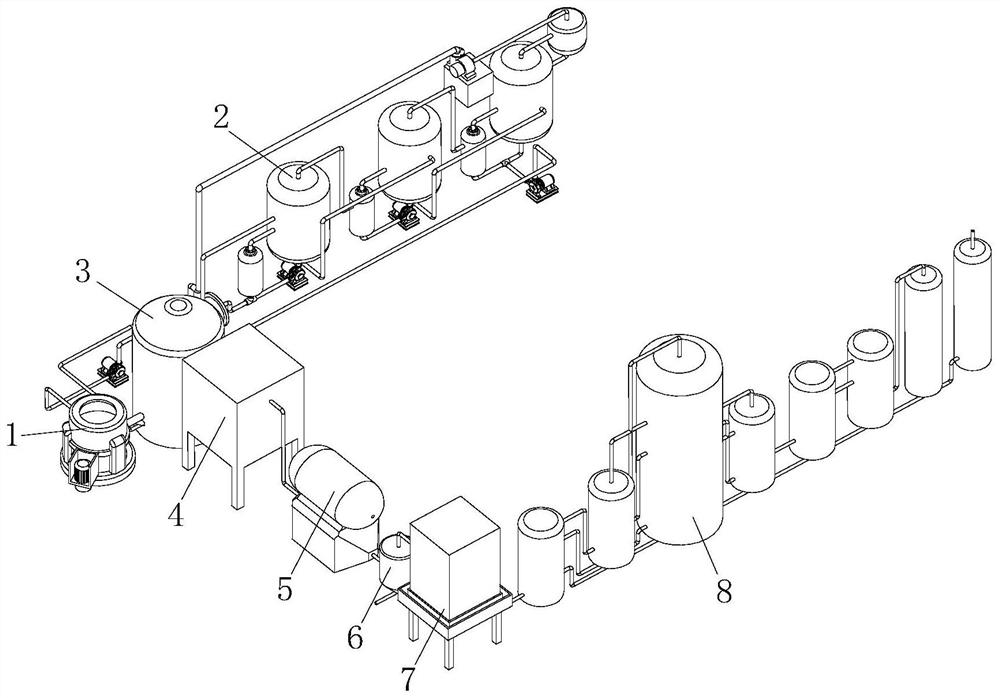

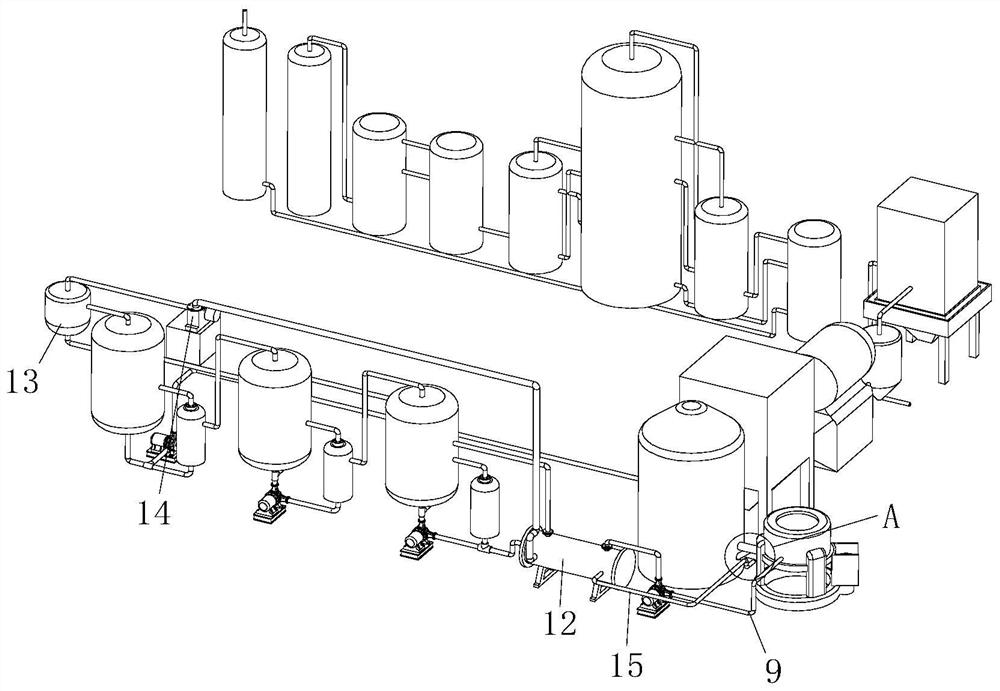

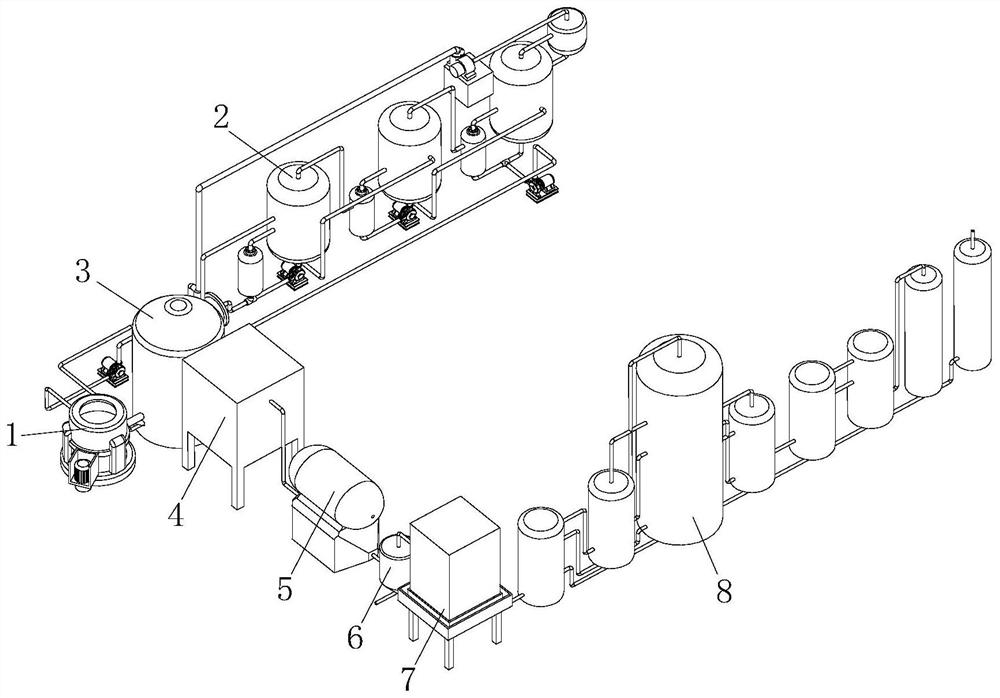

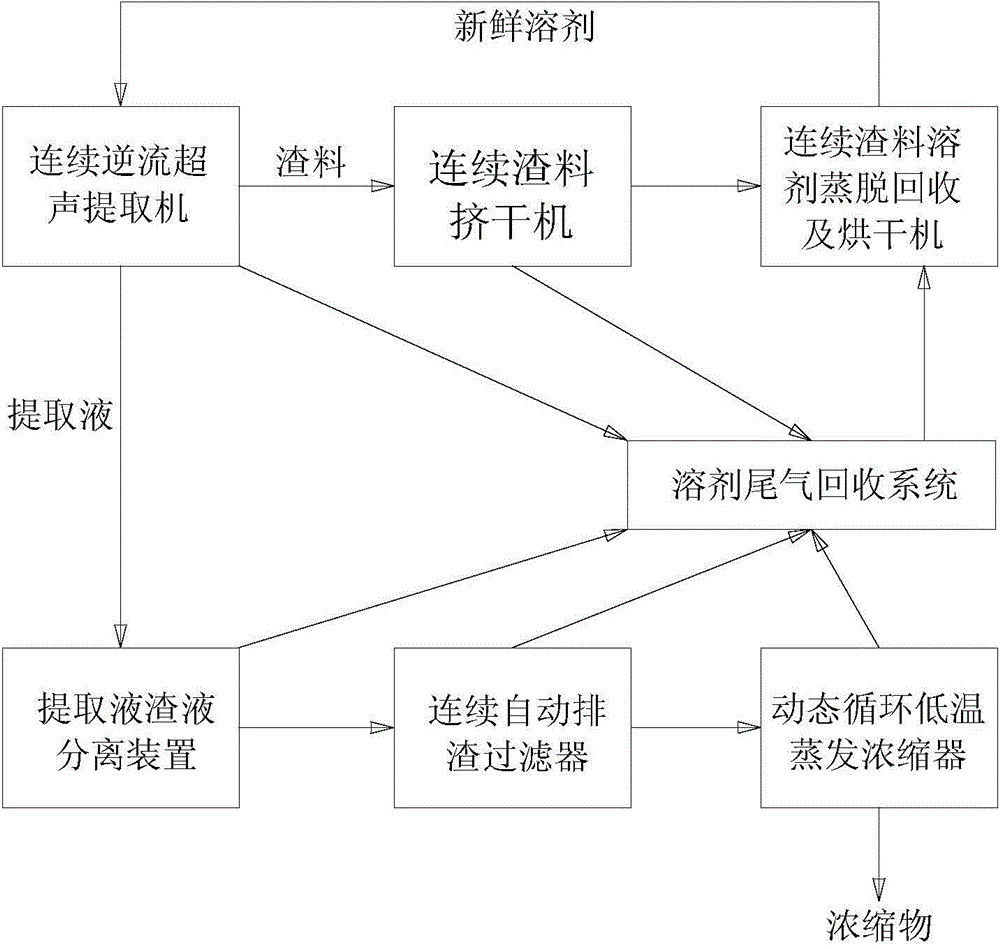

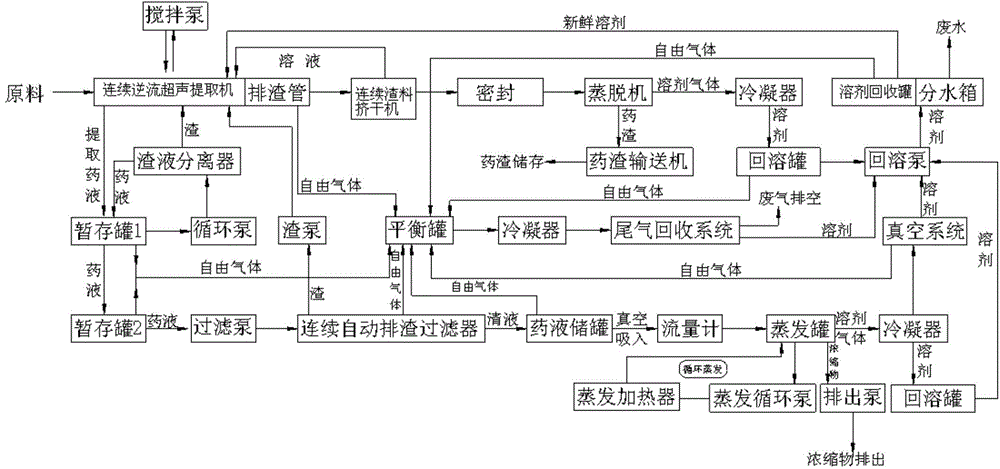

Complete equipment for continuous counter-current ultrasonic extraction

InactiveCN103520949BRealize the continuous operation of the whole processAchieve large-scale industrializationEnergy based chemical/physical/physico-chemical processesSolid solvent extractionSolvent evaporationEvaporation

The invention discloses complete equipment for continuous counter-current ultrasonic extraction, comprising a continuous counter-current ultrasonic extractor, a continuous residue drying machine, a continuous residue solvent evaporation recovering and drying machine, an extracting solution residue-liquid separator, a continuous automatic discharge filter and a dynamic circulating low-temperature evaporation concentrator, wherein the continuous counter-current ultrasonic extractor is sequentially connected with the extracting solution residue-liquid separator, the continuous automatic discharge filter, and the dynamic circulating low-temperature evaporation concentrator; a raw material is conveyed to the continuous counter-current ultrasonic extractor for extracting a liquid medicine by conveying equipment; the liquid medicine is input into the extracting solution residue-liquid separator for separating out the residue, then enters the continuous automatic discharge filter for further filtering out fine residue, enters the dynamic circulating low-temperature evaporation concentrator for evaporating and concentrating, so as to obtain concentrate. By adopting the complete equipment, the functions such as extracting, filtering, residue-liquid separating, concentrating, and recovering of solvent tail gas are organically combined together systematically; continuous operation and large-scale industrialization of all procedures are achieved; the maximization of the extracting efficiency and the minimization of the solvent dosage are also achieved.

Owner:四川省砚山中药饮片有限公司

Double-effect energy-saving evaporation and concentration system

ActiveCN113546434AIncrease the amount of steamIncrease temperatureEvaporator accessoriesEvaporator regulation/controlThermodynamicsEngineering

The invention discloses a double-effect energy-saving evaporation and concentration system, which can be used for preparing Geshan food retention removing particles. The system comprises a first-effect heater, a first-effect evaporator, a second-effect heater, a second-effect evaporator, a condenser and a vacuum pump which are connected in sequence, and further comprises a heating enhancing mechanism. The heating enhancing mechanism comprises a steam supplementing pipe, the first-effect evaporator is connected with the second-effect heater through a steam conveying pipe, the steam supplementing pipe communicates with the steam conveying pipe, and a one-way valve is arranged on the steam supplementing pipe. By using the double-effect energy-saving evaporation and concentration system, steam can be supplemented and added into the double-effect heater so as to increase the steam amount and temperature, so that the concentration efficiency of liquid medicine in the double-effect evaporator is accelerated, the steam in the single-effect evaporator is utilized to achieve the energy-saving effect, and the processing efficiency of the double-effect evaporator is improved.

Owner:红云制药(贵州)有限公司

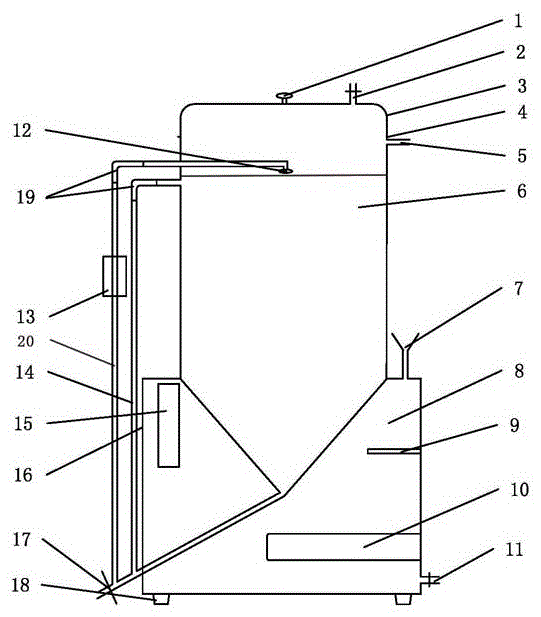

Concentrated juice preparation equipment and a preparation process thereof

PendingCN112772805AImprove evaporation and concentration efficiencyEasy to storeFood scienceFruit juiceAir pump

The invention relates to a concentrated juice preparation equipment and a preparation process thereof, and belongs to the technical field of concentrated juice processing. The concentrated juice preparation equipment comprises a support, an evaporation barrel is arranged at the upper end of the support, the lower end of the evaporation barrel is communicated with a feeding pipe and a discharging pipe, the outer side of the upper end of the evaporation barrel is communicated with at least one vacuumizing pipe, a horizontal stirring shaft is arranged in the evaporation barrel and provided with a plurality of stirring paddles, a driving mechanism for driving the stirring shaft to rotate is arranged on the outer side of the evaporation barrel, a shell is arranged on the outer side of a stirring barrel, a heating cavity is reserved between the shell and the evaporation barrel, the upper end of the shell is connected with an oil outlet pipe, the lower end of the shell is communicated with an oil inlet pipe. The upper end of the evaporation barrel is communicated with a plurality of air exhaust branch pipes, the air exhaust branch pipes are communicated with an air exhaust main pipe, and the air exhaust main pipe is provided with an air exhaust pump. The concentrated juice preparation equipment has the effect of high fruit juice concentration efficiency.

Owner:RUSHAN ZHONGCHENG FRUIT JUICE BEVERAGE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com