Spiral falling-film evaporator

A falling-film evaporator and spiral technology, applied in the field of spiral falling-film evaporators, can solve the problems of reduced evaporation efficiency of falling-film evaporators, slowed down flow rate of annular liquid film, and reduced heat transfer efficiency of annular liquid film, etc. To achieve the effect of improving convective heat transfer efficiency, improving evaporation concentration efficiency, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

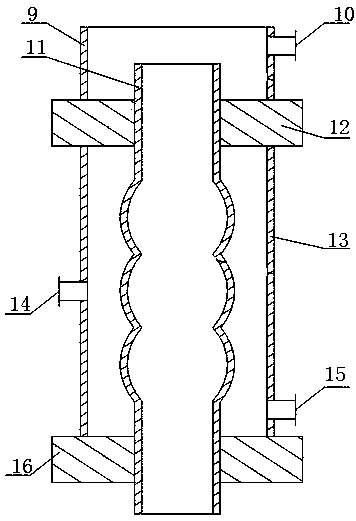

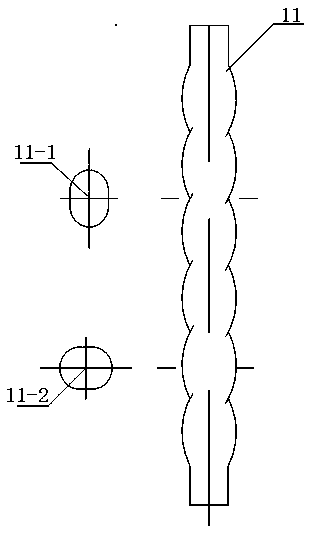

[0011] The evaporated raw liquid enters the upper cylinder 9 from the evaporation raw liquid inlet 10, and the heating steam enters the shell 13 from the heated steam inlet 14. When the liquid level of the evaporated raw liquid in the upper cylinder 9 rises to the upper tube of the spiral falling film tube 11 When the mouth is opened, the film will be distributed from the upper nozzle to the inside of the tube, and a uniform annular liquid film will be formed on the inner wall of the spiral falling film tube 11. When the annular liquid film flows downward under the action of gravity, it will flow along the spiral falling film. The spiral channel formed by the inner wall of the tube 11 changes the speed and direction periodically, so that the evaporated solution is always in a turbulent state; in the spiral falling film evaporator, the annular liquid film quickly absorbs the shell during the downward flow. The thermal energy of the steam in 13 raises the temperature of the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com