Double-effect evaporation final-effect vapour system

A double-effect evaporation and flash chamber technology, applied in the field of ammonium phosphate production technology systems, can solve the problems of water vapor waste, kinetic energy consumption, large sewage volume, etc., and achieve the effect of saving water resources and coal resources, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

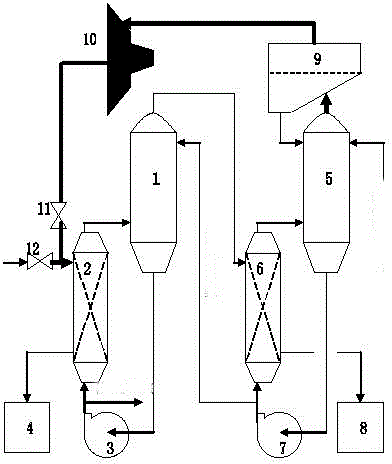

[0019] figure 1 As shown, a double-effect evaporation final-effect steam system includes the I-effect slurry flash chamber 1, the I-effect slurry heater 2, the I-effect slurry circulation pump 3, the I-effect condensate collection tank 4, and the final effect material Slurry flash chamber 5, final effect slurry heater 6, final effect slurry circulation pump 7, final effect condensate collection tank 8, final effect demister 9, steam compressor 10, compressed steam regulating valve 11 and fresh steam Refill valve 12. The upper part of the final effect slurry flash chamber 5 is externally connected with the feed of dilute ammonium phosphate slurry, and the bottom of the final effect slurry flash chamber 5 is connected to the final effect slurry heater 6 in two ways through the final effect slurry circulation pump 7 The lower part of the process and the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com