Efficient method and device for preparing sulfuric acid from desulfurization waste liquid of coking plant

A technology for desulfurization waste liquid and sulfuric acid production, which is applied in chemical instruments and methods, steam generation methods using heat carriers, separation methods, etc., can solve the problem that the by-product dilute sulfuric acid solution cannot be digested internally, the combustion process is difficult to adjust, and the heat energy Problems such as low utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

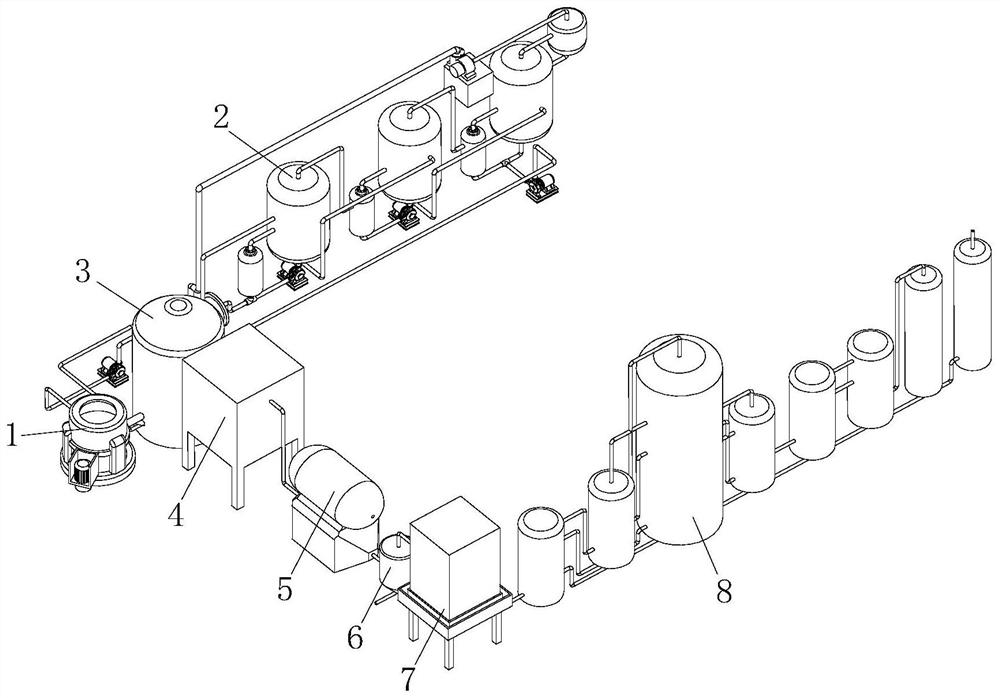

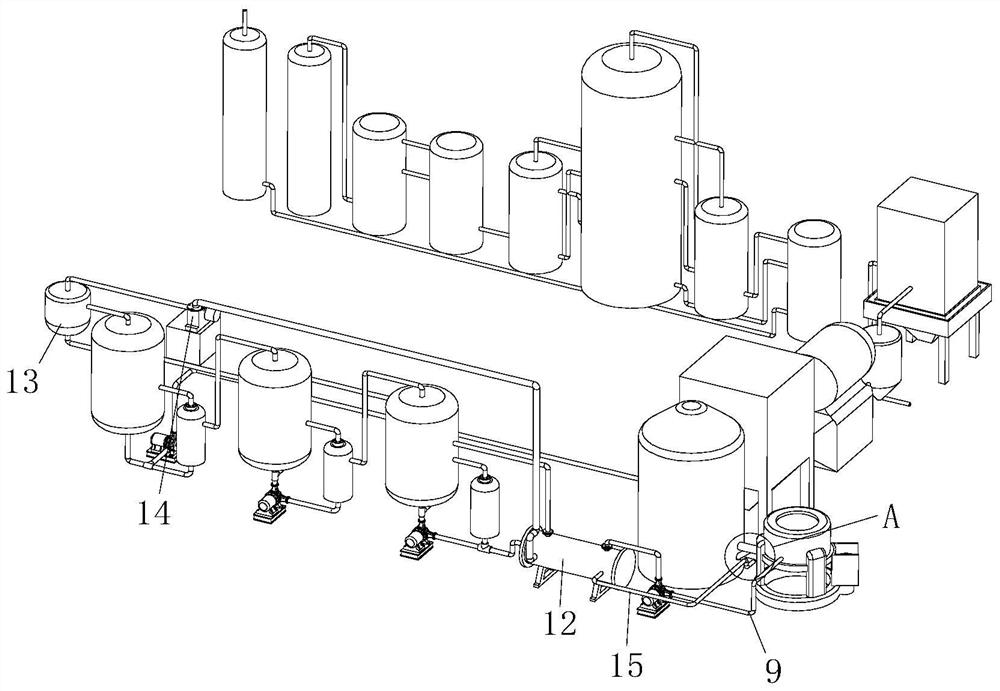

[0058] The working steps of a device for producing sulfuric acid from desulfurization waste liquid in a coking plant:

[0059] S1: Pressure filtration, the desulfurization waste liquid and sulfur foam produced by the ammonia gas desulfurization of the coking plant are sent through the pipeline to the high-efficiency filter press 1 for separation to obtain sulfur paste and separated clear liquid;

[0060] S2: Concentration, introducing the separated liquid described in S1 into the multi-effect evaporator 2, through the multi-effect evaporator 2, the separated liquid is concentrated into sulfur slurry;

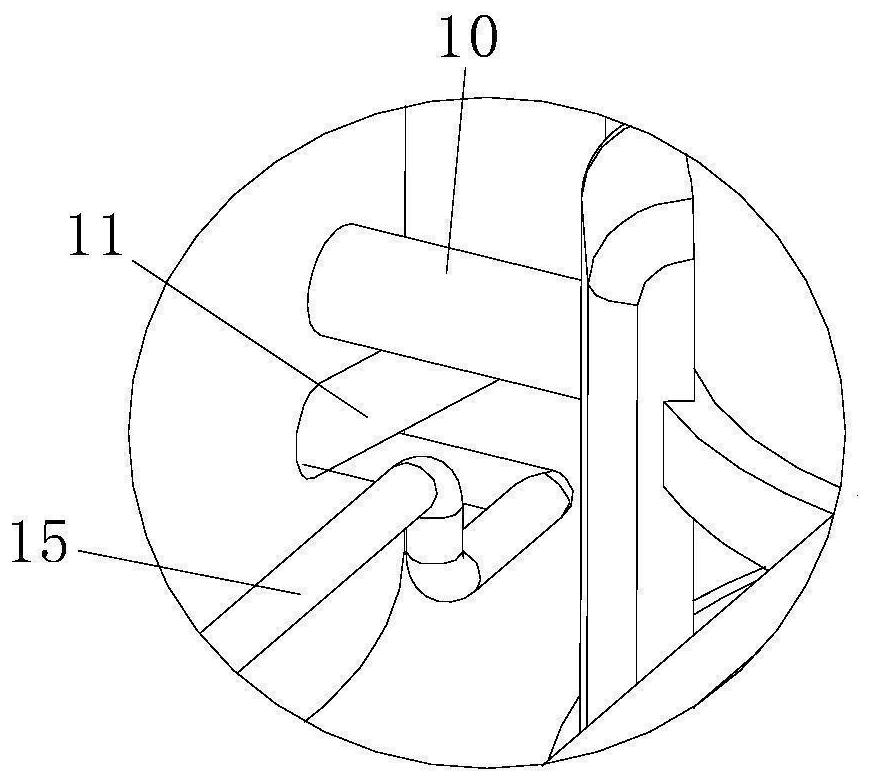

[0061] S3: incineration, the sulfur paste obtained in S1 and the sulfur slurry obtained in S2 are sent to the incinerator 3 through the screw feeder 10 and the pipeline respectively, and are burnt in zones in the incinerator 3 to generate sulfur dioxide flue gas;

[0062] S4: Dust removal and cooling, the sulfur dioxide flue gas from the incinerator 3 is first dedusted by the hi...

Embodiment 2

[0071] The working steps of a device for producing sulfuric acid from desulfurization waste liquid in a coking plant:

[0072] S1: Pressure filtration, the desulfurization waste liquid and sulfur foam produced by the ammonia gas desulfurization of the coking plant are sent through the pipeline to the high-efficiency filter press 1 for separation to obtain sulfur paste and separated clear liquid;

[0073] S2: Concentration, introducing the separated liquid described in S1 into the multi-effect evaporator 2, through the multi-effect evaporator 2, the separated liquid is concentrated into sulfur slurry;

[0074] S3: incineration, the sulfur paste obtained in S1 and the sulfur slurry obtained in S2 are sent to the incinerator 3 through the screw feeder 10 and the pipeline respectively, and are burnt in zones in the incinerator 3 to generate sulfur dioxide flue gas;

[0075] S4: Dust removal and cooling, the sulfur dioxide flue gas from the incinerator 3 is first dedusted by the hi...

Embodiment 3

[0084] The working steps of a device for producing sulfuric acid from desulfurization waste liquid in a coking plant:

[0085] S1: Pressure filtration, the desulfurization waste liquid and sulfur foam produced by the ammonia gas desulfurization of the coking plant are sent through the pipeline to the high-efficiency filter press 1 for separation to obtain sulfur paste and separated clear liquid;

[0086] S2: Concentration, introducing the separated liquid described in S1 into the multi-effect evaporator 2, through the multi-effect evaporator 2, the separated liquid is concentrated into sulfur slurry;

[0087] S3: incineration, the sulfur paste obtained in S1 and the sulfur slurry obtained in S2 are sent to the incinerator 3 through the screw feeder 10 and the pipeline respectively, and are burnt in zones in the incinerator 3 to generate sulfur dioxide flue gas;

[0088] S4: Dust removal and cooling, the sulfur dioxide flue gas from the incinerator 3 is first dedusted by the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com