Heat pump evaporation heat recovery combination device and waste liquid high-efficiency concentration method

A combined device and heat pump evaporation technology, applied in heat recovery systems, chemical instruments and methods, energy-saving heating/cooling, etc., can solve problems such as difficult to improve, waste of heat energy, increased operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

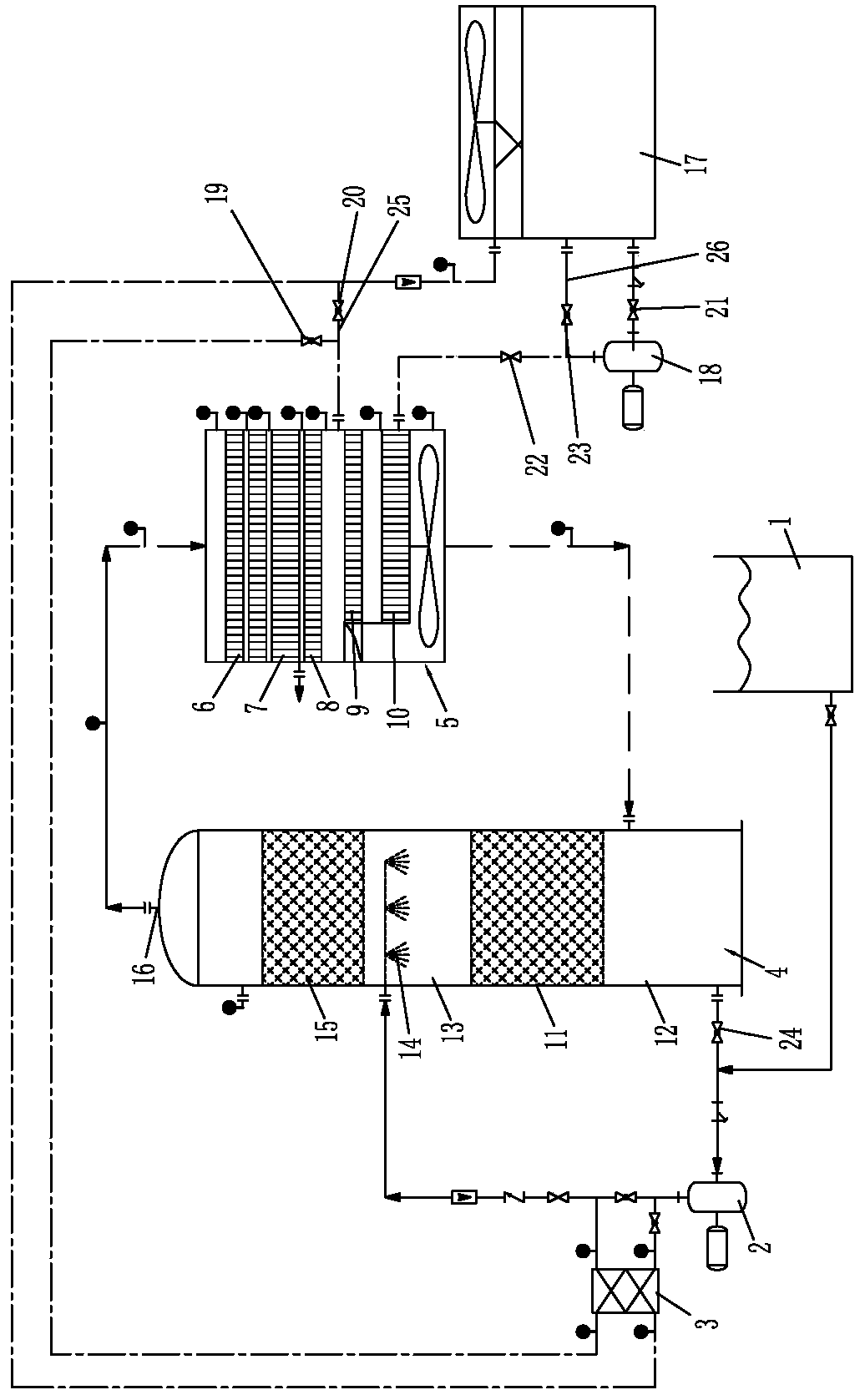

[0036] Please refer to figure 1 As shown, it shows the specific structure of the embodiment of the present invention. This new heat pump 5 evaporation heat recovery combination device includes a waste liquid storage tank 1, a circulation pump 2, a heat exchanger 3, an evaporation tank 4 and a heat pump 5 , wherein, the heat pump 5 has a heat recovery device 6, an evaporator and a condenser. Here, the evaporator includes a primary evaporator 7 and a secondary evaporator 8 connected in sequence, and the condenser includes a sequential The first-stage condenser 9 and the second-stage condenser 10 are connected; of course, multi-stage or single-stage designs can also be designed as required.

[0037] The aforementioned heat exchanger 3 has a first medium channel and a second medium channel, and the aforementioned waste liquid storage barrel 1 is connected to the inlet of the aforementioned first medium channel through a circulation pump 2; the aforementioned evaporator 4 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com