Sewage treatment device for synthesis reaction of phenol and acetone

A sewage treatment device and synthesis reaction technology, which is applied in the direction of neutralization water/sewage treatment, heating water/sewage treatment, extraction water/sewage treatment, etc. It can solve the problems of removal rate less than 98%, difficult separation, high content, etc. problems, to achieve the effect of convenient separation and purification, high recovery rate and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

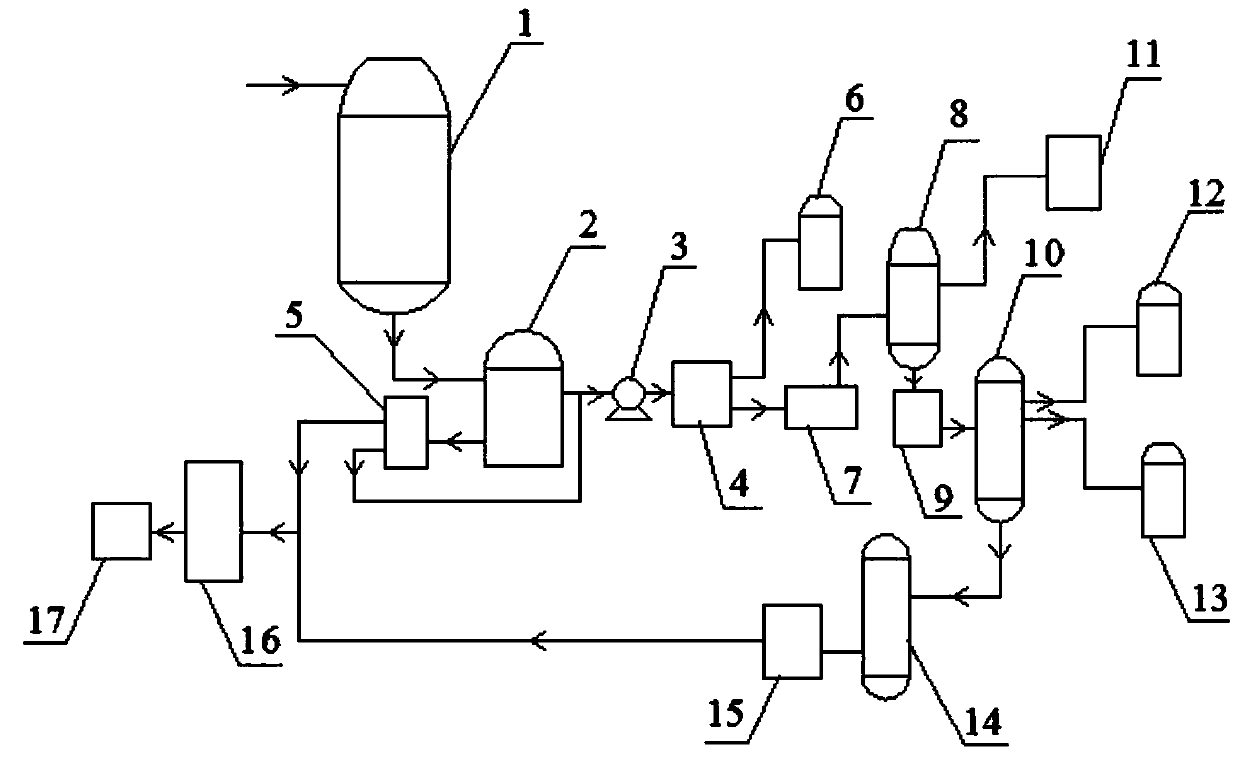

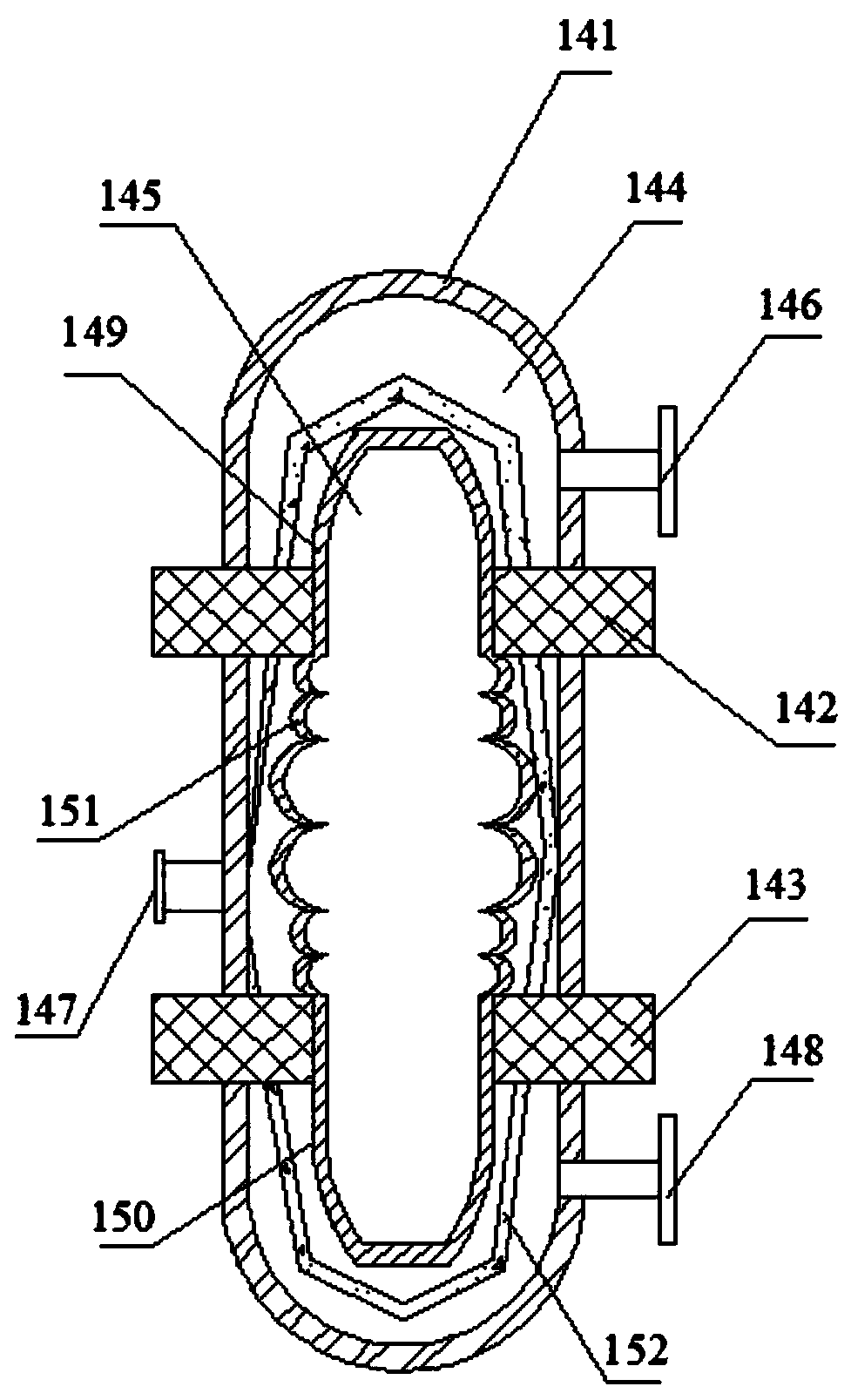

[0039] refer to Figure 1-2 As shown, this embodiment provides a sewage treatment device for the synthetic reaction of phenol and acetone, including a first neutralization tank 1, a first water circulation chamber 2, an oil-water separator 4, a circulating lye tower 8, and a rectification tower 10 , the second neutralization tank 11, the falling film evaporator 14.

[0040] Wherein, the first neutralization tank 1 is filled with NaOH solution, which is used to neutralize the sewage produced in the process of synthesizing phenol acetone by the cumene method; the bottom of the first neutralization tank 1 passes through the first water circulation chamber 2 Pipeline connection, the side wall of the first neutralization kettle 1 is connected with a pipette pump 3 through a pipeline, and the first water circulation chamber 2 is connected with the oil-water separator 4 through a pipette pump 3 . The first water circulation chamber 2 is used to circulate, heat and stir the solid pha...

Embodiment 2

[0047] refer to Figure 1-2 As shown, the present embodiment provides a sewage treatment method suitable for the synthetic reaction of phenol and acetone, which specifically includes the following steps:

[0048] S1, the sewage produced in the process of synthesizing phenol-acetone by cumene method is passed into the first neutralization kettle 1 filled with NaOH solution together for neutralization reaction, and distilled for 40-50min at 100-105°C, so that the neutralization reaction occurs The solid-phase precipitate is passed into the first water circulation chamber 2 after being released from the bottom of the kettle, and the liquid phase part after distillation and condensation is sucked into the oil-water separator 4 using the pipetting pump 3; wherein, the content of each main component in the sewage is as follows: acetone 80- 110mg / L, Hydroxyketone 320-360mg / L, Phenol 6-15mg / L, Formaldehyde 15-18mg / L, Methanol 16-20mg / L, Cumene 5-10mg / L, Sodium Sulfate 3200-3800mg / L; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com