Patents

Literature

40 results about "Acetone synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The acetone oxime so obtained contains the small amount of sodium chloride, but is otherwise almost pure for the most synthesis purposes. Crude acetone oxime is purified by crystallization from petroleum ether (with boiling point 60-80° C) or cyclohexane.

Process for preparing palladium-resin catalyst

InactiveCN1457927APromote exchangeIncrease profitOrganic-compounds/hydrides/coordination-complexes catalystsMethyl isobutyl ketoneIon exchange

The present invention discloses the preparation process of Pd / resin catalyst, and is especially the preparation process of Pd / resin catalyst for the one-step process to synthesize methyl isobutyl ketone. Pd-containing acid solution and resin are made to produce ion exchange to obtain the catalyst with high activity and high selectivity. The present invention has raised Pd utilization, and the catalyst may be used in hydroetherification of gasoline, synthesis of methyl isobutyl ketone with acetone and other reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

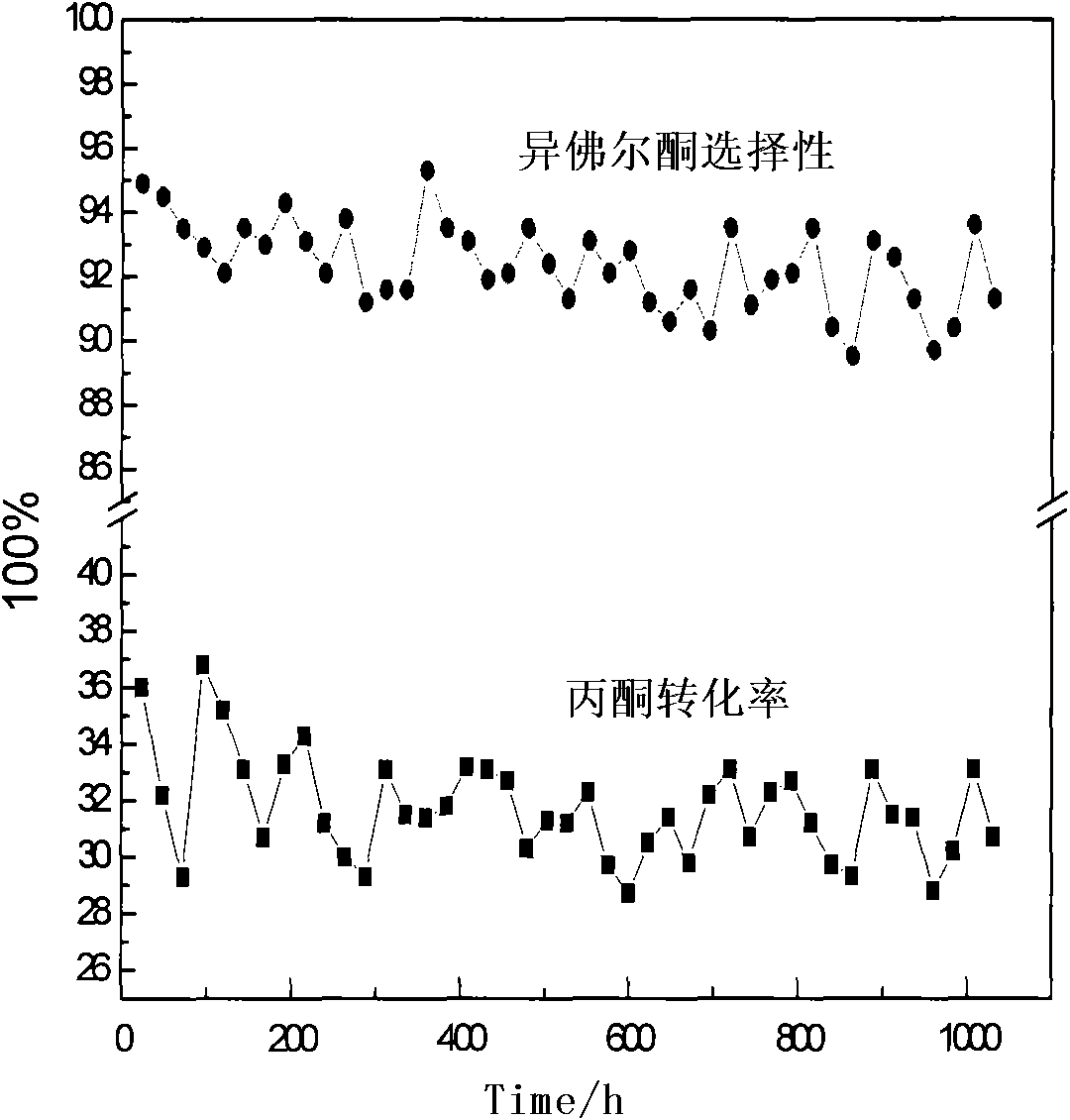

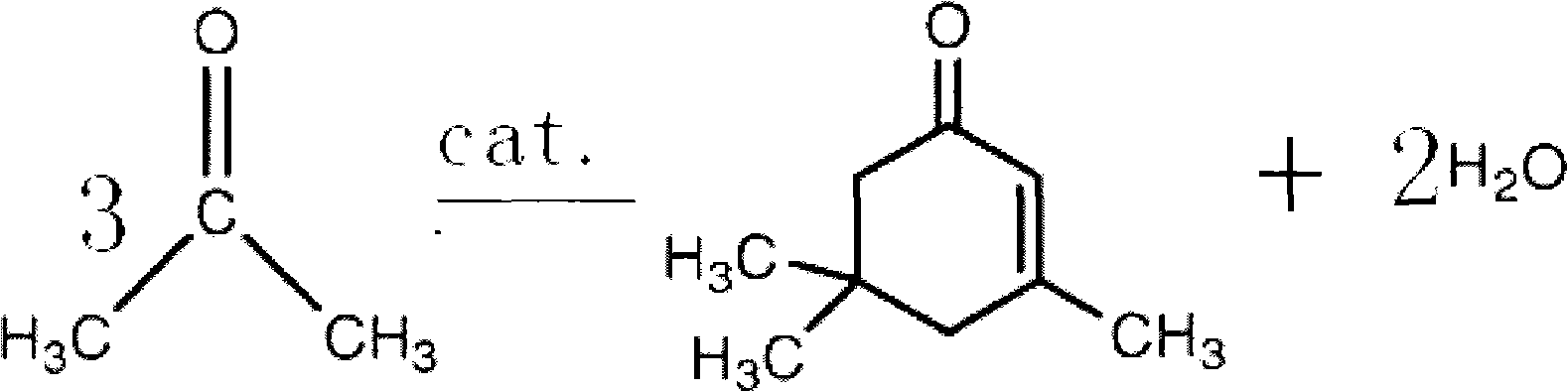

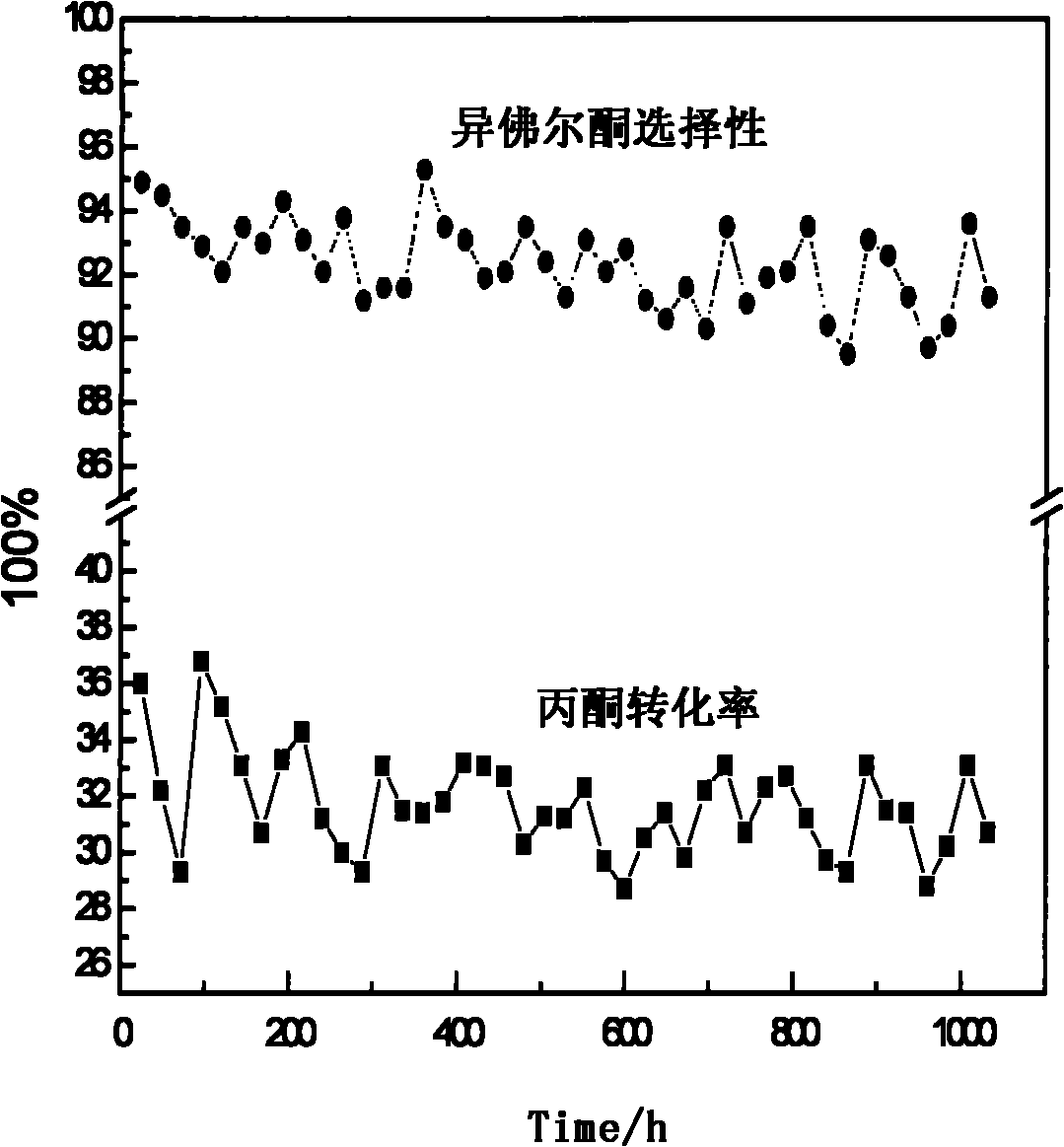

Heterogeneous catalytic method for synthesis of isophorone from acetone

ActiveCN101875602AMild reaction conditionsTechnical securityPhysical/chemical process catalystsOrganic compound preparationCatalytic methodFixed bed

The invention relates to a heterogeneous catalytic method for synthesis of isophorone from acetone. Acetone is used as a raw material, and a magnesium-aluminum composite oxide is used as a catalyst for carrying out catalytic synthesis to obtain isophorone; the magnesium-aluminum composite oxide comprises MgO, Al2O3 and MgAl2O4, the molar ratio of magnesium to aluminum is 0.3-3, the specific surface area is 80-150m<2> / g, and the pore volume is 0.2-0.3cm<3> / g; a fixed bed reactor is used for carrying out synthetic reaction, 20ml of 20 to 40-mesh catalyst is added into a stainless steel reactor of which the inner diameter is 10mm, the reactor is heated to the reaction temperature from the room temperature at the rate of 10 DED C / min after being qualified through an air-tight test, and then, the analytically pure acetone raw material is injected into the reactor by a duplex plunger pump through a preheater; the reaction temperature is 220-290 DEG C; the reaction pressure is normal pressure; and the air speed of the acetone liquid is 0.1-1.0 / h, the selectivity reaches 94.5%, the conversion rate reaches 44.8%, and the stability reaches 1000 hours.

Owner:PETROCHINA CO LTD

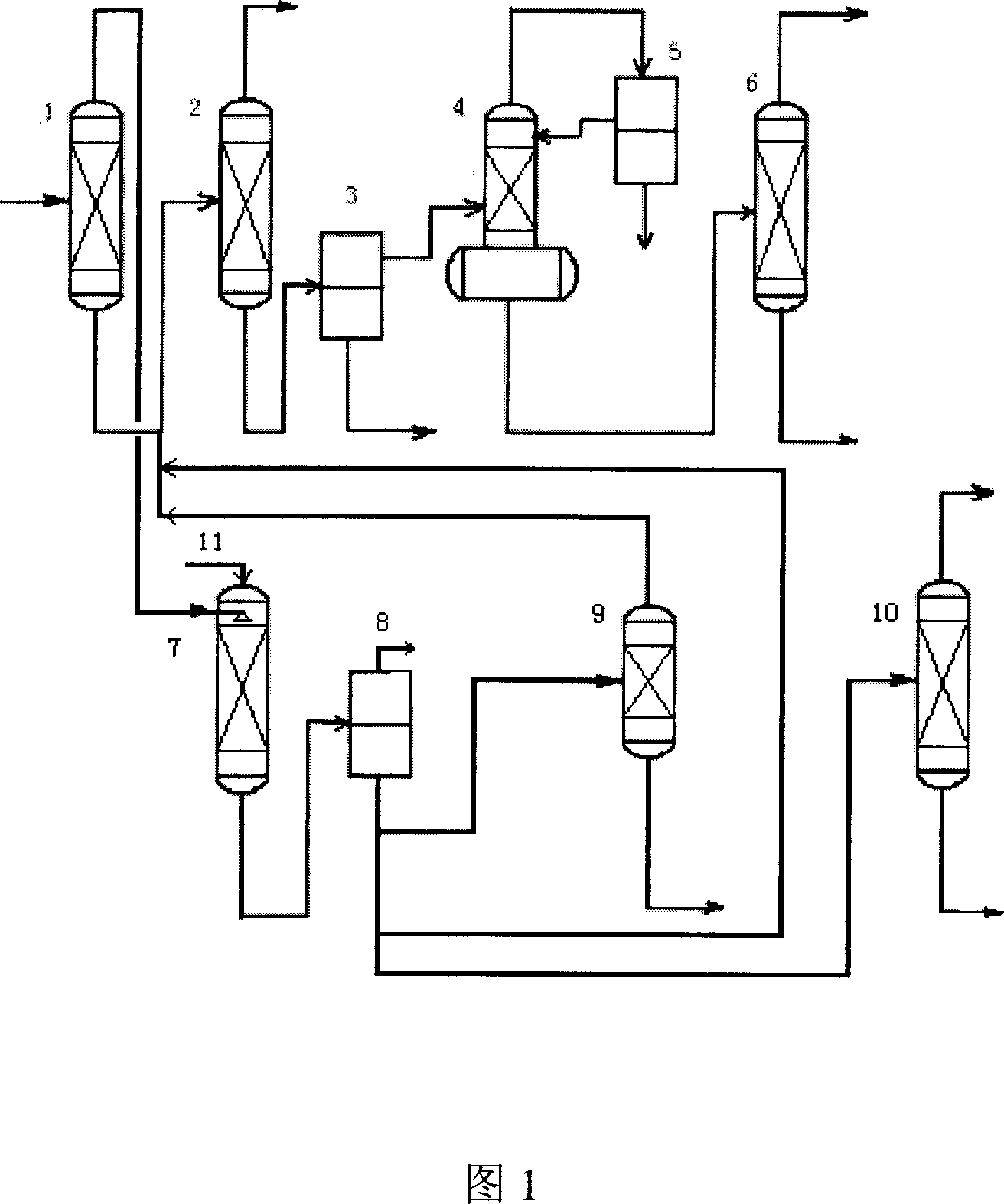

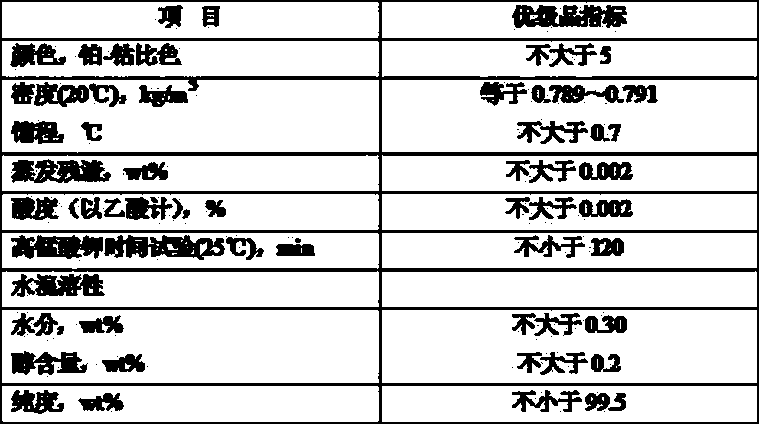

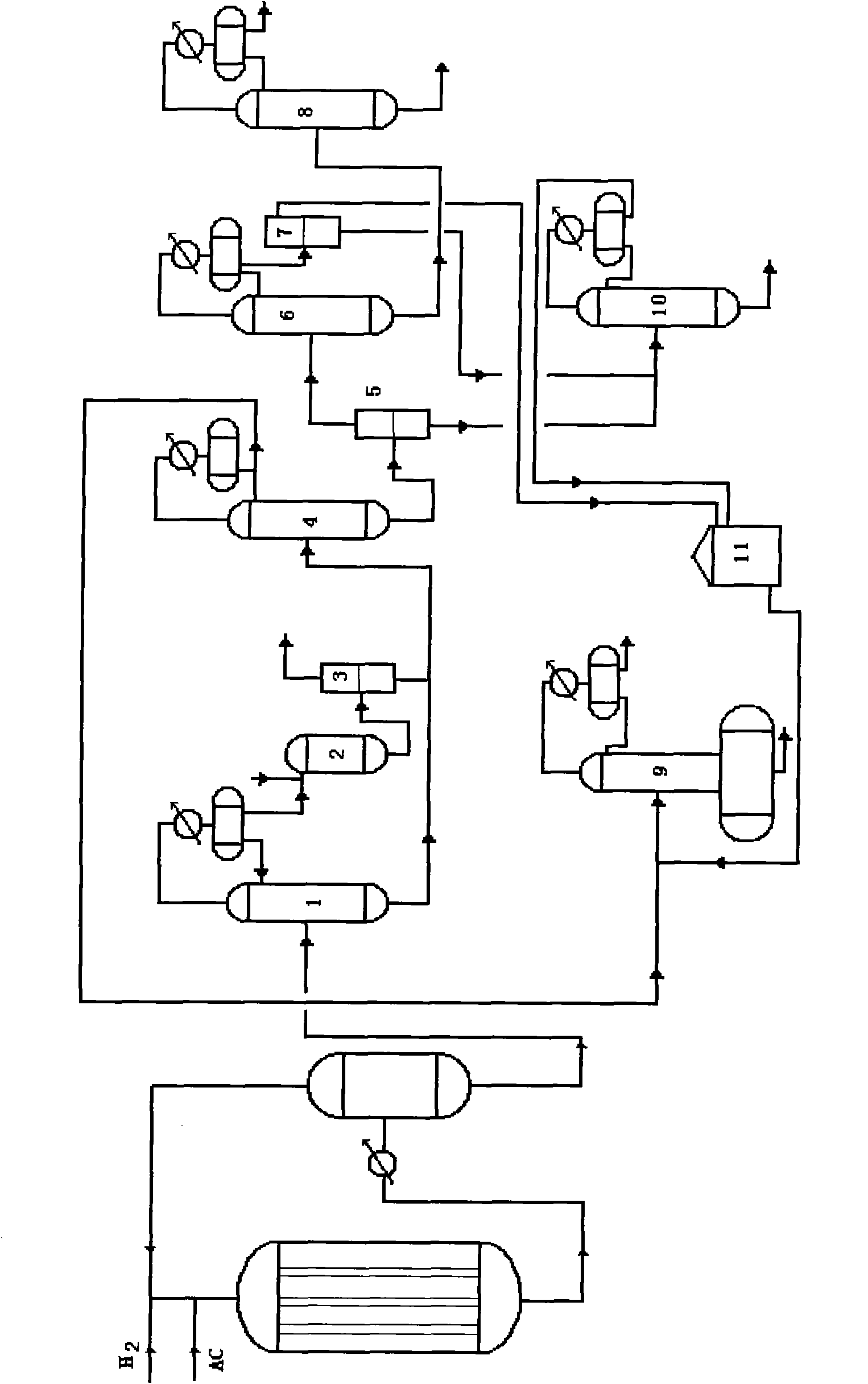

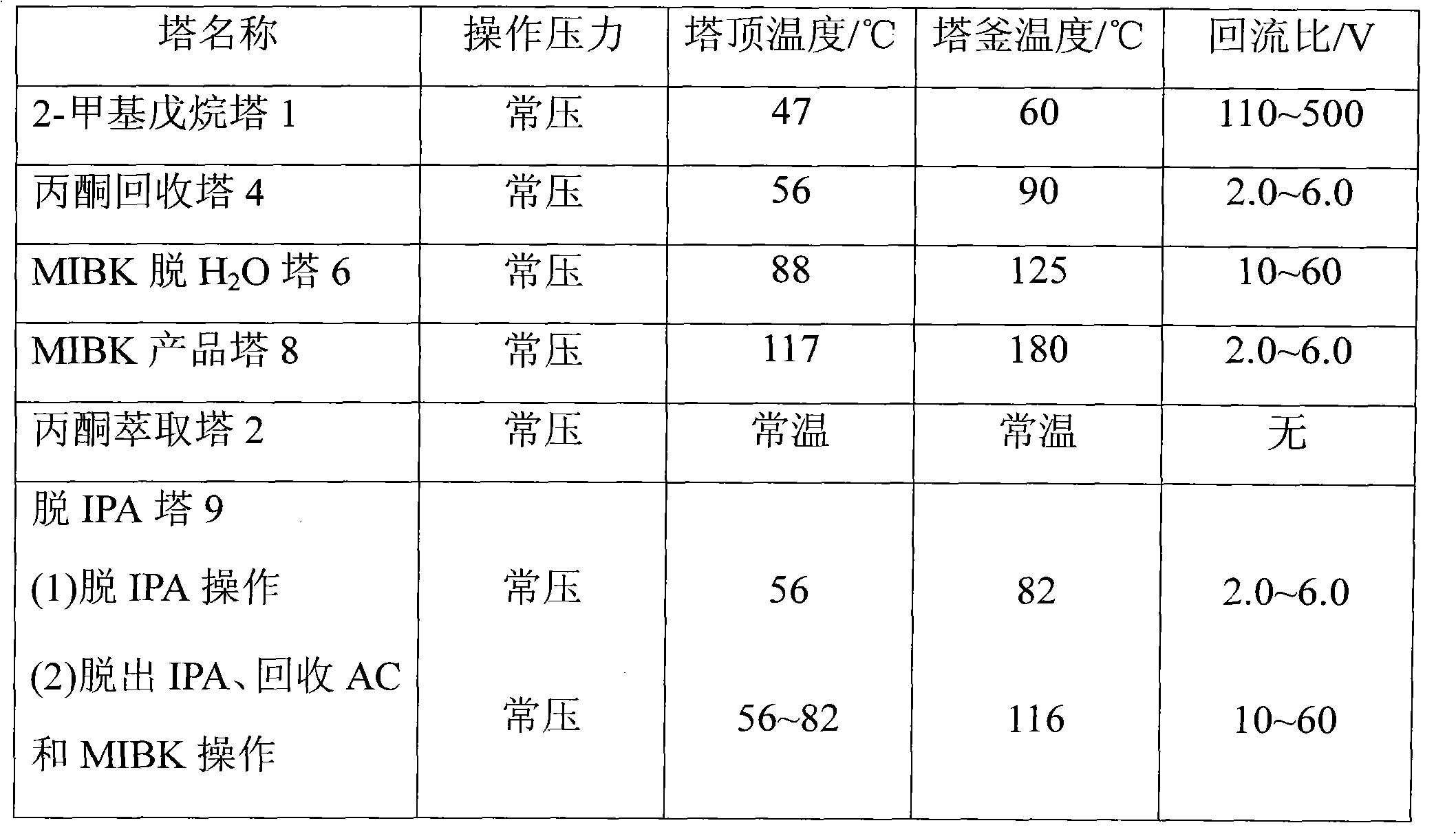

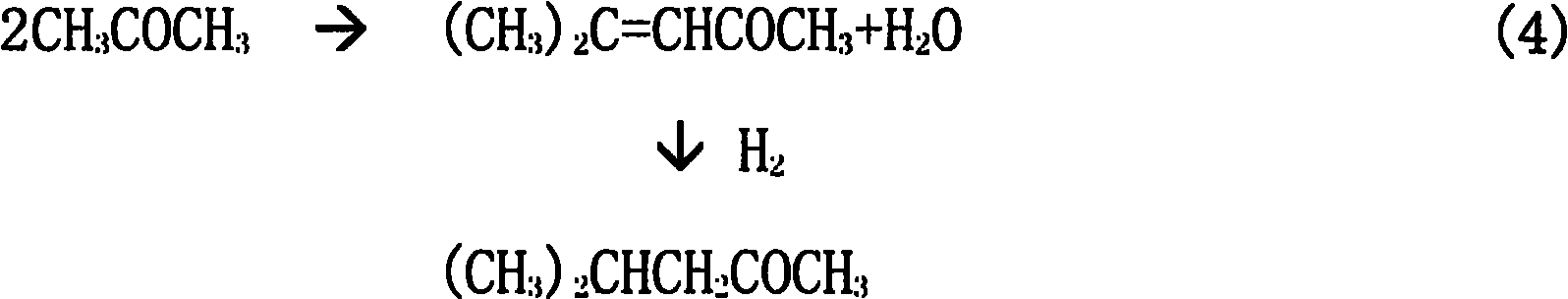

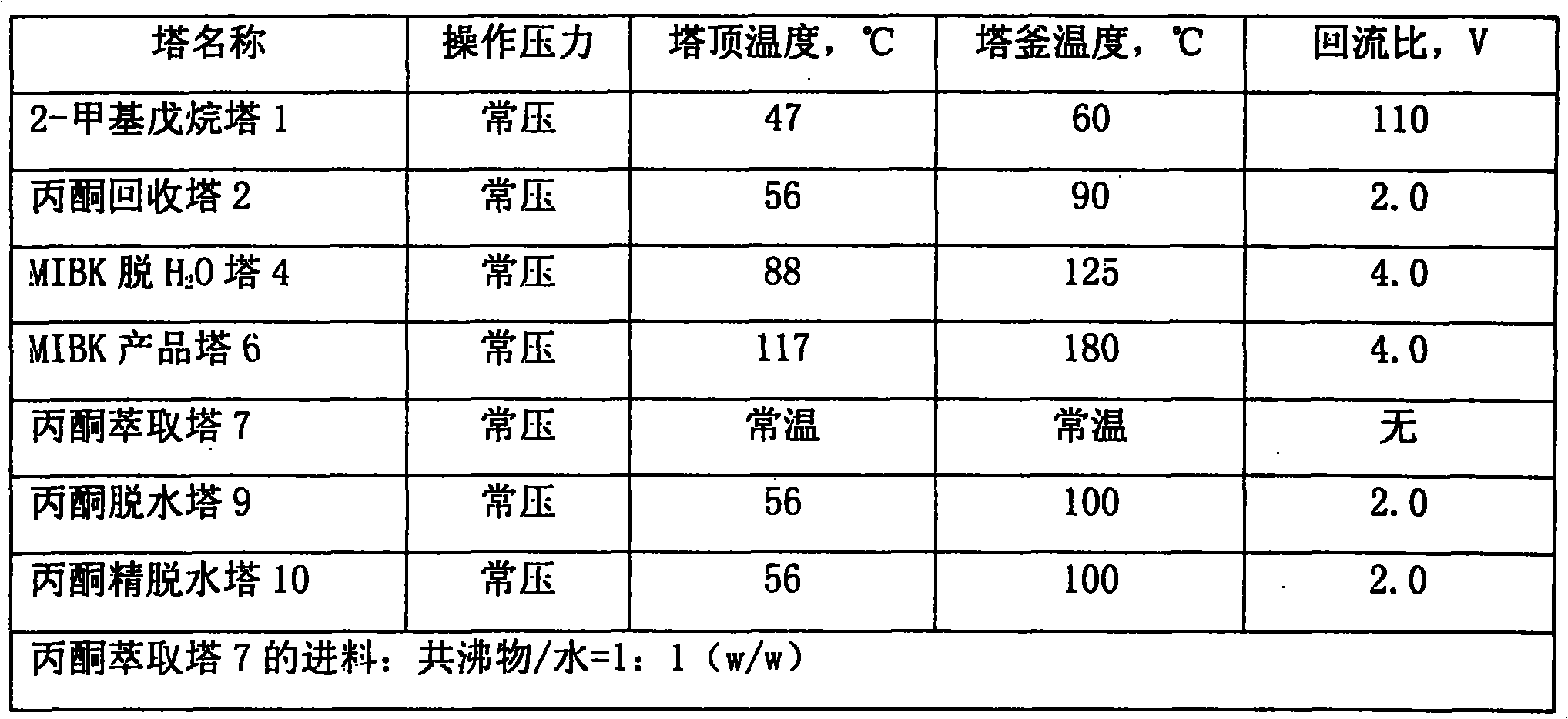

Process for separating methylisobutanone synthesized from acetone

ActiveCN1951893AReduce consumptionGuarantee product qualityOrganic compound preparationCarbonyl compound separation/purificationMethyl isobutyl ketoneEconomic benefits

The invention discloses a separating method of methyl isobutyl ketone synthesized by acetone, which is characterized by the following: increasing acetone extracting and recycling step based on four-tower flow path; recycling acetone in the 2-methyl pantane / acetone azeotropic material; reducing the consumption of acetone and manufacturing cost; improving product competitive power and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly and simple preparation method for synthesizing isophorone from acetone

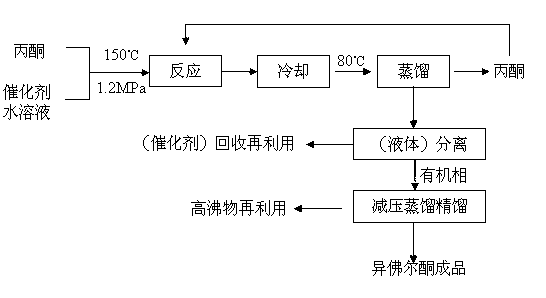

InactiveCN102976910AHigh Boiler ReductionImprove conversion rateOrganic compound preparationCarbonyl compound preparationPotassium hydroxideReaction temperature

The invention relates to an environment-friendly and simple preparation method for synthesizing isophorone from acetone. The method is based on a liquid condensation method and comprises the steps of pouring acetone and a strong alkaline catalyst sodium hydroxide aqueous solution or a strong alkaline catalyst potassium hydroxide aqueous solution in an autoclave; adding microscale auxiliary catalysts of magnesium oxide, aluminum oxide, calcium oxide, barium oxide and a rare metal element of lanthanum; changing a reaction condition to lower reaction activation energy; heating to a temperature of 150 DEG C; reacting for 2 hours at a constant temperature with continuously stirring; cooling to a temperature of 80 DEG C; distilling and refluxing the unreacted acetone for use in the next time; standing residues in the autoclave; separating the liquid and draining out the aqueous solution for use in the next time; distilling the remained materials; and distilling the isophorone out to obtain a finished product. With the method, the formation of high-boiling residues and other by-products is reduced; conversion rate of acetone is increased; and selectivity for isophorone is increased. The environment-friendly and simple preparation method is short in reaction time, low in reaction temperature and simple and environment-friendly in process, and can meet modern requirements and realized production automation and production industrialization.

Owner:张锦碧

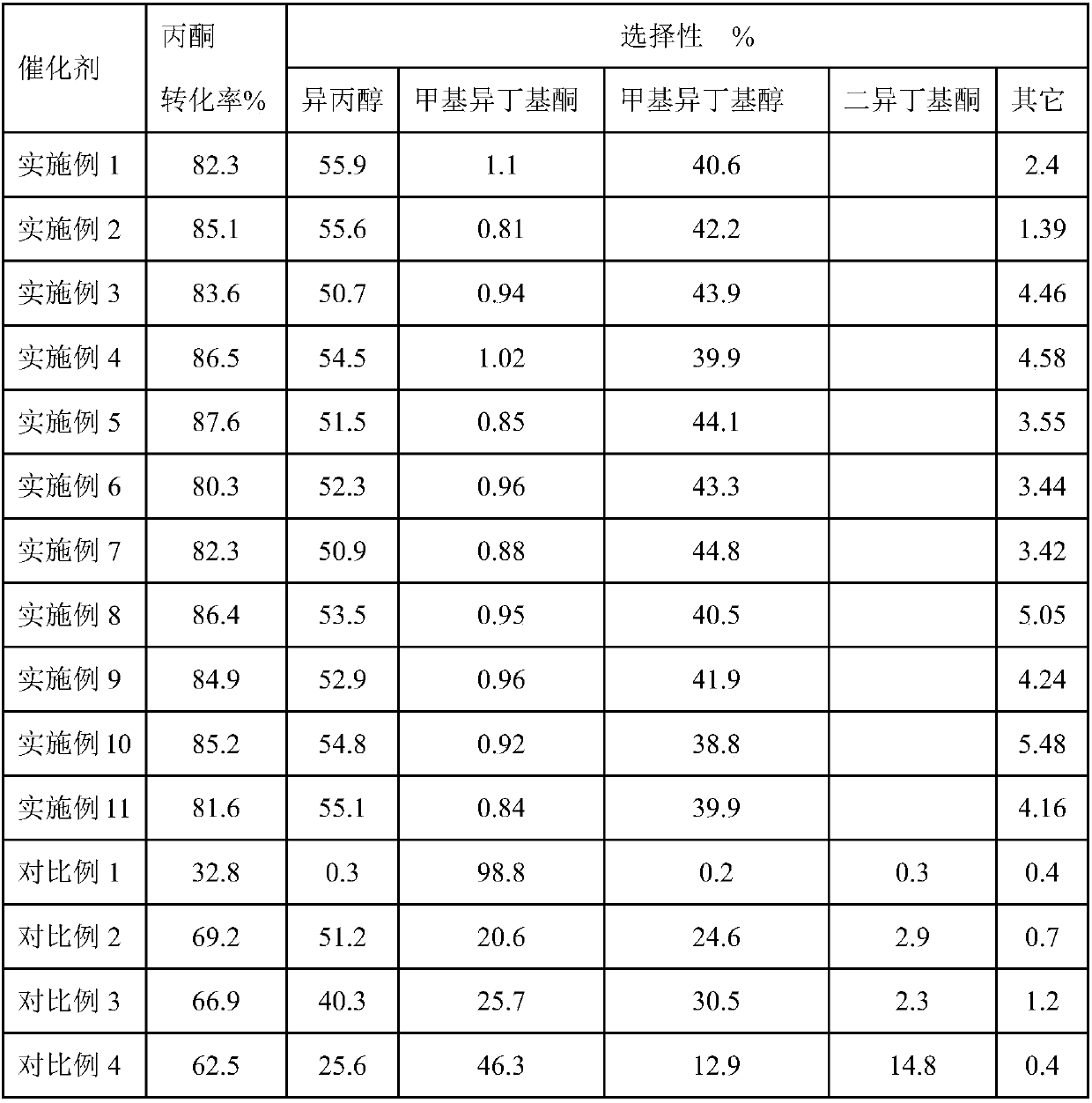

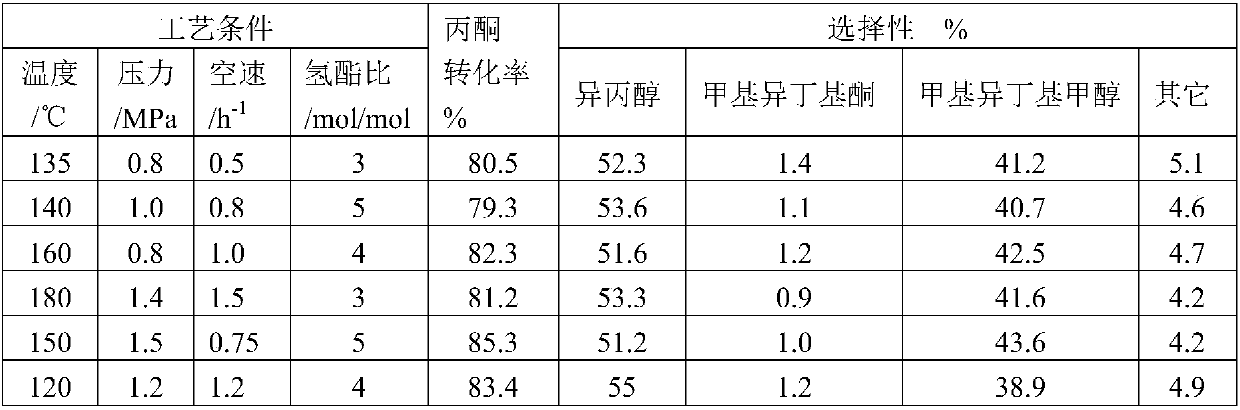

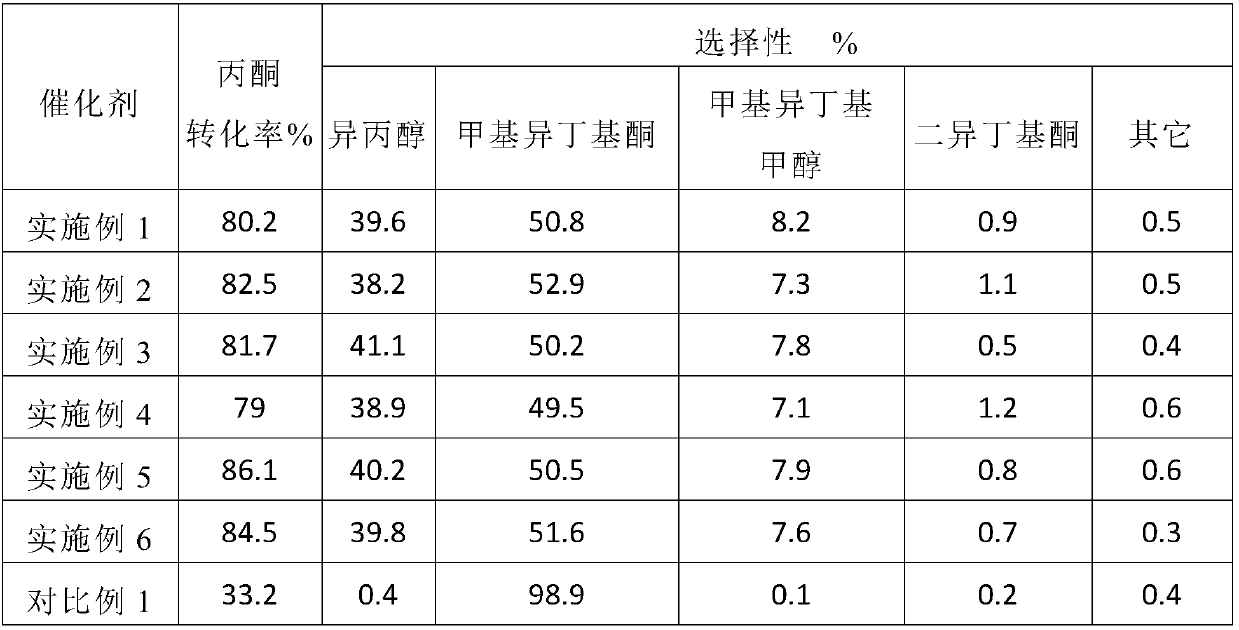

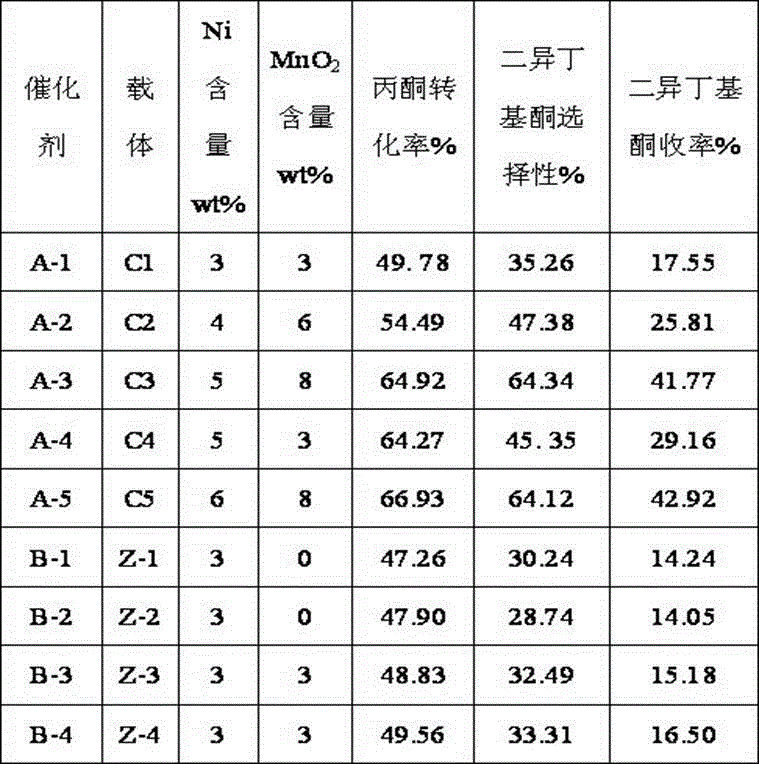

Catalyst for synthesizing methyl isobutyl alcohol and isopropanol from acetone, and preparation method and application of the catalyst

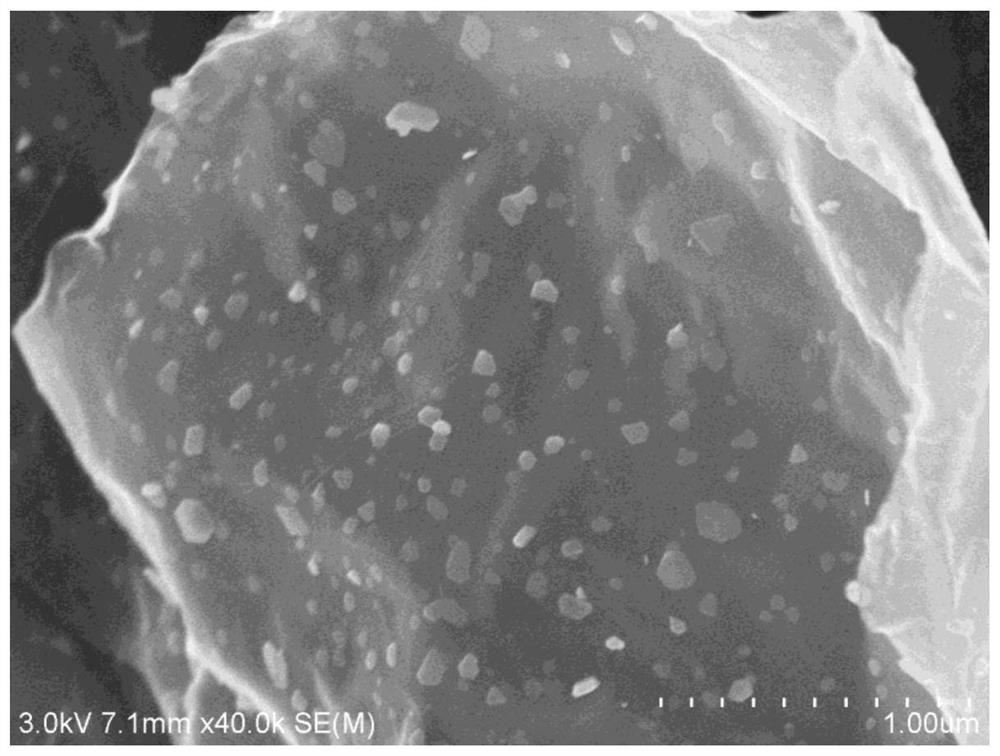

ActiveCN109701536AShould not be lostEvenly distributedOrganic compound preparationHydroxy compound preparationEvaporationCopper oxide

The invention relates to the field of catalysts and provides a catalyst for synthesizing methyl isobutyl alcohol and isopropanol from acetone, and a preparation method and an application of the catalyst. The catalyst includes, on the basis of total weight, a) 0.5 to 8 parts of at least one of copper or copper oxides; b) 0.5 to 10 parts of at least one of cobalt or cobalt oxides; c) 82 to 99 partsof a supporter which is selected from at least one of silicon oxide, aluminum oxide and zirconium oxide after high-temperature roasting titanium modification. In the catalyst, the active components, Cu and Co, are supported on the titanium-modified supporter through an ammonia evaporation method, so that distribution of the metal active components is more uniform and interaction between the activecomponents and the supporter is enhanced, thus improving activity and stability of the catalyst. The catalyst is low in cost due to use of the low-content non-noble metals, Cu and Co. The catalyst can be used for not only preparing the methyl isobutyl alcohol but also co-producing the isopropanol. The catalyst makes an industrial production device to have stronger adaptive capability on market and can increase enterprise profit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Palladium/alumina catalyst and preparation method thereof

ActiveCN104588041AGood pre-vulcanization effectHigh activityPhysical/chemical process catalystsPresent methodMethyl isobutyl ketone

The invention discloses a preparation method of a sulfuration mode Pd / Al2O3 catalyst. The method comprises the following steps: 1, preparing a sodium alkyl xanthate solution and a palladium-containing dipping liquid which is acidic; 2, dipping an alumina carrier in the palladium-containing dipping liquid, filtering, drying, spraying parts of the palladium-containing dipping liquid, and drying to obtain a catalyst intermediate; and 3, adding the catalyst intermediate to the remaining palladium-containing dipping liquid, dipping, drying, and roasting to obtain the sulfuration mode Pd / Al2O3 catalyst. A volume ratio of the palladium-containing dipping liquid used for spraying to the palladium-containing dipping liquid used for dipping is 1.0:1.0-1.0:3.0, and preferably 1.0:1.5-1.0:2.5. The catalyst obtained through the method realizes higher activity, higher selectivity and longer life than present catalysts prepared through present methods in the synthesis process of methyl isobutyl ketone from acetone.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Cobalt-based catalyst for synthesizing methyl isobutyl ketone from acetone

ActiveCN107930657ALow costImprove stabilityMolecular sieve catalystsOrganic compound preparationPalladium catalystSilicon oxide

The invention relates to a catalyst, and belongs to the technical field of applications and development of acetone downstream products, wherein cobalt and tin are used as main active components, fluorine is used as an auxiliary agent component, aluminum oxide, silicon oxide or an aluminum oxide-silicon oxide composite carrier with rich pH value is selected to promote a reaction, the catalyst is used under a mild reaction condition, an one-step acetone synthesis process is used, the yield of methyl isobutyl ketone in the application of the catalyst of the present invention is higher than the yield of methyl isobutyl ketone in the application of the palladium / resin catalyst used in the current industrial apparatus, and a large amount of isopropanol are by-produced. According to the present invention, the obtained catalyst has the ideal stability, has the cost significantly lower than the cost of the existing palladium catalyst, and has good economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

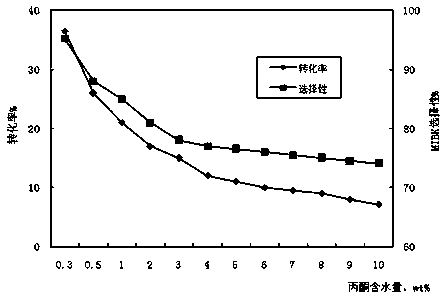

Temporary stopping method for synthesis technology of methyl isobutyl ketone by acetone

ActiveCN108084003AAvoid it happening againRapid coolingOrganic compound preparationCarbonyl compound preparationTemporary StoppingMethyl isobutyl ketone

The invention discloses a stopping method for synthesis technology of methyl isobutyl ketone by acetone through a one step method. The method comprises the following steps: 1) an apparatus uses a precious metal resin catalyst; after stopping, a water content of acetone is increased to greater than 0.3 wt%-0.5wt%; 2) the temperature of a catalyst bed layer is reduced to 105+ / -5 DEG C, the water content of acetone is increased to greater than 0.5 wt%-1.0wt%; 3) the temperature is continuously reduced, when the temperature of the catalyst bed layer is reduced to 5-30 DEG C, the water content of acetone is increased to greater than 0.5 wt%-20wt%; 4) optionally, the step 3) is repeated for 0-4 times; 5) when the temperature of the catalyst bed layer is reduced to 85+ / -5 DEG C, the water contentof acetone is kept, or routine acetone charging is switched; and 6) the temperature of the catalyst bed layer is continuously reduced to 40-60 DEG C, feeding stops, and working is finished. The method can realize rapid cooling and stopping of the apparatus, and reduces the influence of the current stopping method for a subsequent separating system.

Owner:CHINA PETROLEUM & CHEM CORP +1

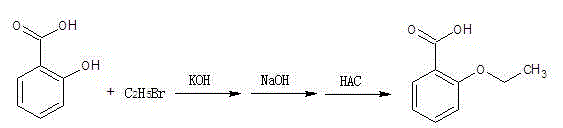

Method for synthesizing o-ethoxybenzoic acid from salicylic acid and acetone

ActiveCN103553909ALow costSimple processPreparation from carboxylic acid saltsOrganic compound preparationAcetic acidFiltration

The invention relates to a method for synthesizing o-ethoxybenzoic acid from salicylic acid and acetone, which comprises the following steps: adding salicylic acid, acetone and potassium hydroxide into a reaction bulb, dropwisely adding bromoethane while stirring at room temperature, heating under reflux for 9-15 hours, recovering the acetone under reduced pressure, adding water and liquid alkali, heating under reflux for 2-4 hours, cooling to room temperature, regulating the pH value to 3-4 with glacial acetic acid, cooling to 1-15 DEG C, separating by vacuum filtration, washing with water, and carrying out vacuum drying to obtain the o-ethoxybenzoic acid, wherein the salicylic acid:potassium hydroxide:bromoethane:liquid alkali mol ratio is 1:(2.0-2.5):(2.1-2.5):1.3. The method has the advantages of simple technique, low raw material cost, high yield and good quality, and is convenient to operate and convenient for industrial production.

Owner:苏州诚和医药化学有限公司

Catalyst for synthetic reaction of 1-methoxy-2-acetone and preparation method thereof

InactiveCN107790128ASolution to short lifeHigh selectivityOrganic compound preparationPreparation by dehydrogenationActive componentReaction temperature

The invention discloses a catalyst for synthetic reaction of 1-methoxy-2-acetone and a preparation method thereof. The catalyst is prepared by means of a sol-gel process from a main active component,metallic copper element accounting for 15-30% by mass of the catalyst, an auxiliary active component, IA or IIA metallic element accounting for 1-6% by mass of the catalyst, and the balance, a silicondioxide support. The catalyst prepared via the method o the invention has high catalytic activity, good selectivity, long catalyst life, capability of being suitable for industrial continuous production and the like. 1-Methoxy-2-propanol is subjected to direct dehydrogenation reaction under the reaction temperature of 230-270 DEG C, reaction pressure of normal pressure and mass space velocity of1-4 h<-1> to generate 1-methoxy-2-acetone, material conversion rate may reach 70% and above, and 1-methoxy-2-acetone selectivity may reach 98% and above.

Owner:CHINA CATALYST HLDG CO LTD

Preparation method for sulfuration palladium/alumina catalyst

ActiveCN103801409AExtended operating cycleEasy to manufactureOrganic compound preparationCatalyst activation/preparationMethyl isobutyl ketoneXanthate

The invention discloses a preparation method for a sulfuration palladium / alumina catalyst. The method comprises the following steps: preparing an impregnating solution containing palladium and impregnating an alumina carrier in a part of the impregnating solution containing palladium; then adding a proper amount of a sodium alkyl xanthate solution drop by drop, wherein a catalyst intermediate is obtained after impregnation; and impregnating the catalyst intermediate in the rest impregnating solution containing palladium and carrying out drying and roasting so as to obtain the sulfuration palladium / alumina catalyst. The method provided by the invention overcomes the disadvantage of mismatching between a hydrogenation function and a condensation dehydration function of a conventional oxidized palladium / alumina catalyst for synthesis of methyl isobutyl ketone from acetone, and when used for synthesis of methyl isobutyl ketone from acetone, the prepared catalyst has superior reaction activity than catalysts used in conventional processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Emergency stop method of acetone one-step synthesis MIBK device and acetone synthesis MIBK method

PendingCN110105183AHigh activityAvoid swelling and crushing problemsCatalyst protectionOrganic compound preparationNitrogenCooling water temperature

The invention relates to an emergency stop method of an acetone one-step synthesis MIBK device and an acetone synthesis MIBK method. The emergency stop method is characterized by including the steps of firstly, stopping heating the raw material acetone; secondly, lowering the temperature of cooling water, controlling the cooling rate of the cooling water to be 1-15 DEG C / h when the temperature ina reactor is higher than 75+ / -5 DEG C, and controlling the cooling rate of the cooling water to be 10-30 DEG C / h when the temperature in the reactor is lower than 75+ / -5 DEG C until the temperature inthe reactor is lowered to be 15-35 DEG C; thirdly, stopping feeding the material acetone into the reactor; fourthly, guiding process water into the reactor to wet a catalyst, wherein the volume ratioof the guided process water to the catalyst is 0.35-1.2; fifthly, stopping the discharging of the reactor and stopping the feeding of nitrogen so that stopping can be completed. The emergency stop method is high in stopping speed and well protects the catalyst.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

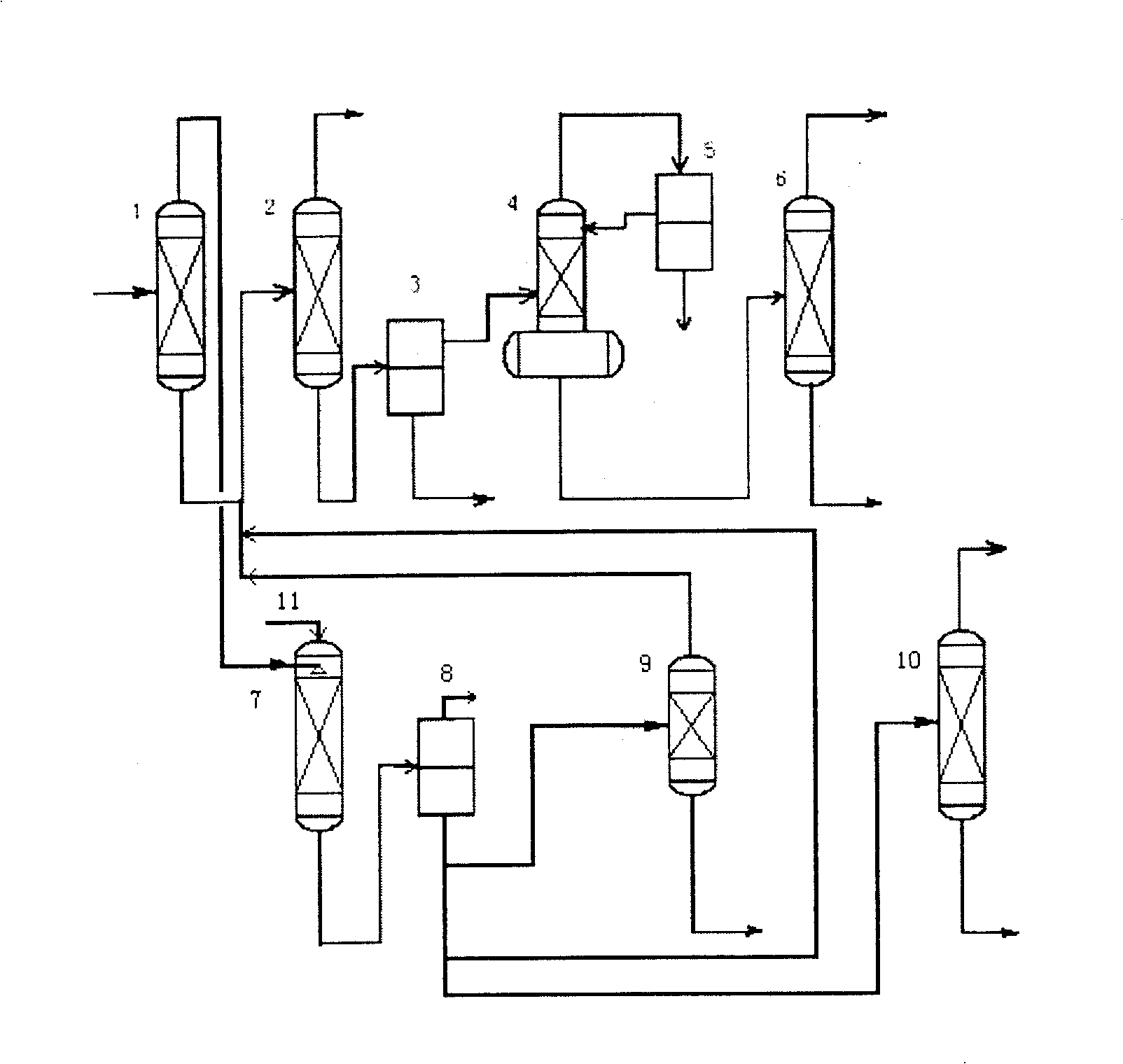

Device and method for producing methyl isobutyl ketone (MIBK) by using acetone (AC)

ActiveCN102050713BHigh recovery rateGuaranteed uptimeOrganic compound preparationCarbonyl compound separation/purificationMethyl isobutyl ketoneEconomic benefits

The invention relates to a method for producing methyl isobutyl ketone (MIBK) by using acetone (AC). An isopropyl alcohol (IPA) removing tower and a wastewater tower are added on the basis of the prior art; when the content of IPA in recovered AC is an arbitrary value in the range of 0.3 to 3 percent, the recovered AC is fed into the IPA removing tower to remove the IPA; when the content of the IPA in the recovered AC is less than 0.3 percent and is not increased any more, the recovered AC is directly fed into a reaction system; and part of oil phases of a phase separator on the top of an MIBK dehydrating tower and a product on the top of the wastewater tower are fed into the IPA removing tower to recover the AC and the MIBK. The aim can be fulfilled only by increasing less investment, the smooth operation of a production device is facilitated, the recovery rate of the AC and the yield of the MIBK are improved, and the consumption of the AC and energy is reduced, so that the production cost of the product is reduced, and the competitiveness of the product and the economic benefit of enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

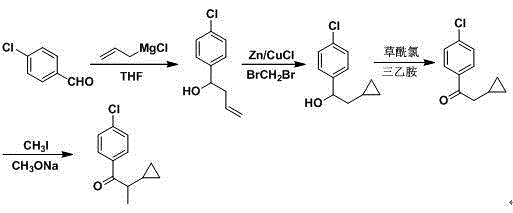

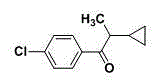

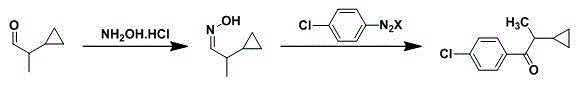

Synthetic method of 1-(4-chlorophenyl)-2-cyclopropyl-1-propanone

ActiveCN105152886ALow costHigh reaction yieldOrganic compound preparationOximes preparationChlorobenzenePtru catalyst

The invention relates to a synthetic method of 1-(4-chlorophenyl)-2-cyclopropyl-1-propanone. The synthetic method comprises steps as follows: (1), hydroxy lamine hydrochloride is dissolved in a solvent, alkali is added, the pH (potential of hydrogen) value is adjusted, a raw material of cyclopropyl propionaldehyde is added at the appropriate temperature for a reaction, and cyclopropyl acetaldoxime is obtained through extraction, concentration and drying after the reaction ends; (2), newly prepared p-chlorophenyl diazonium salt and a catalyst are added to cyclopropyl acetaldoxime at the lower temperature, acid is added, the mixture is heated to have a reaction, and 1-(4-chlorophenyl)-2-cyclopropyl-1-propanone is obtained through aftertreatment after the reaction ends. The synthetic route is shown in the specification. The synthetic method has the advantages as follows: the cost of raw materials is low, the overall yield of the reaction is high, the technological operation is safe, aftertreatment is simple and convenient, and the synthetic method has industrial application value.

Owner:RUDONG ZHONGYI CHEM

Process for separating methylisobutanone synthesized from acetone

ActiveCN100413837CReduce consumptionGuarantee product qualityOrganic compound preparationCarbonyl compound separation/purificationMethyl isobutyl ketoneEconomic benefits

The invention discloses a separating method of methyl isobutyl ketone synthesized by acetone, which is characterized by the following: increasing acetone extracting and recycling step based on four-tower flow path; recycling acetone in the 2-methyl pantane / acetone azeotropic material; reducing the consumption of acetone and manufacturing cost; improving product competitive power and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

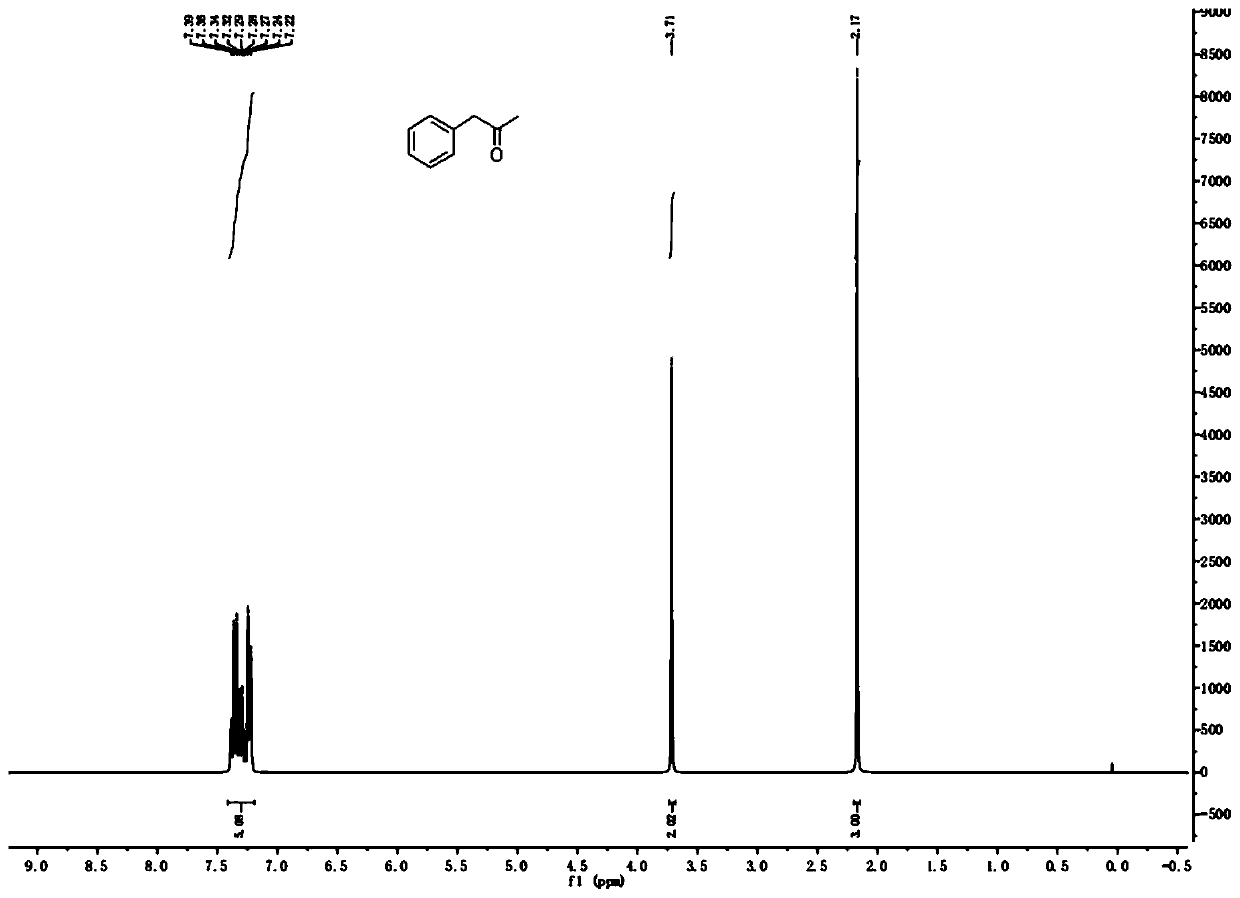

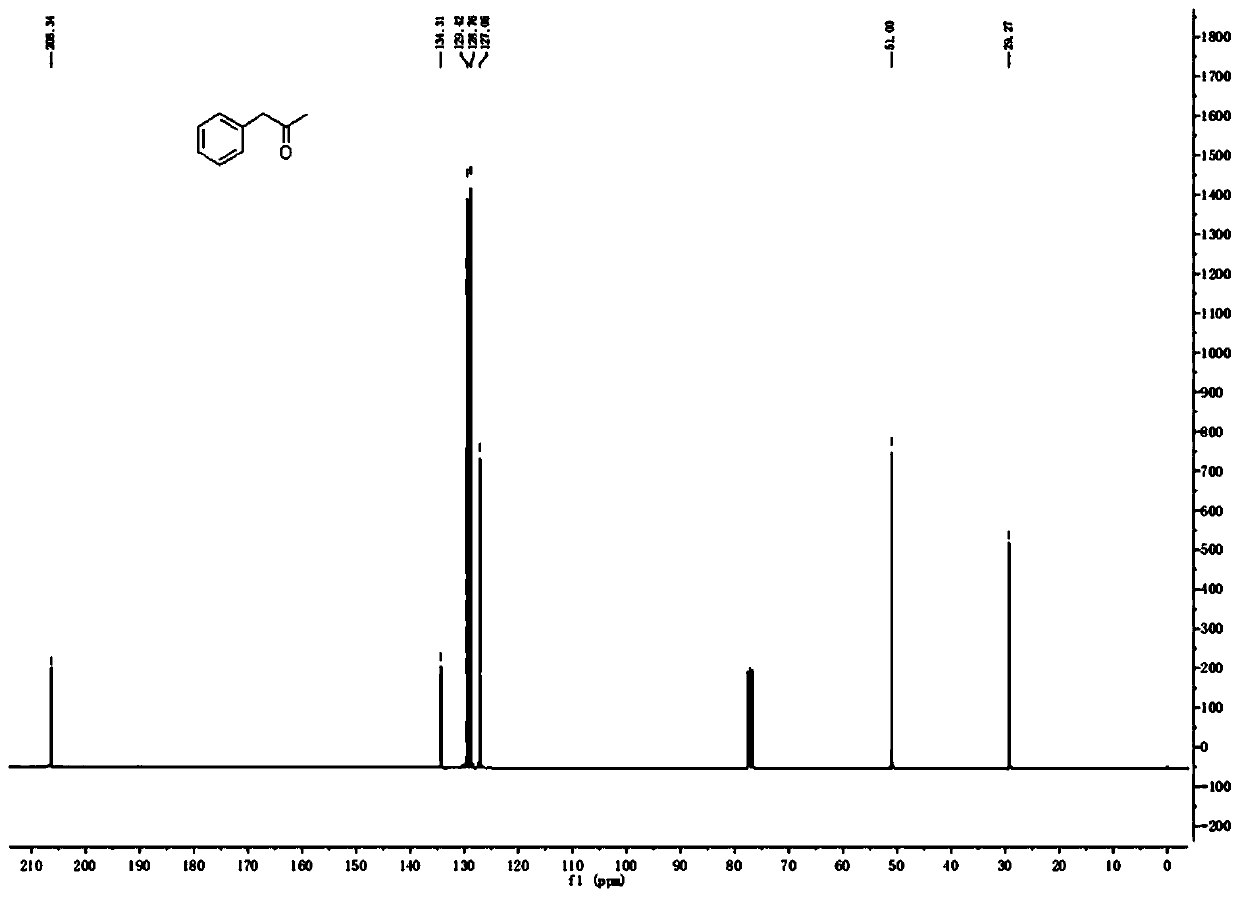

1-aryl-2-acetone compound preparation method

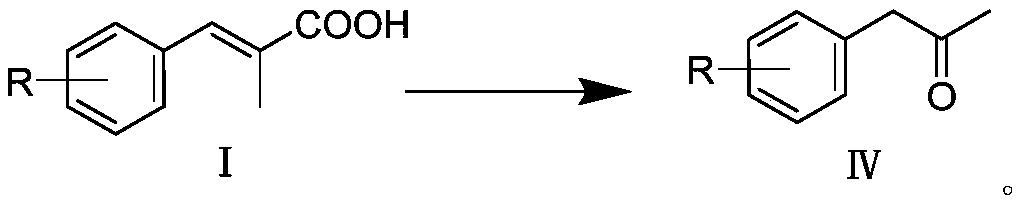

PendingCN110590529AFew reaction stepsImprove operational safetyOrganic compound preparationCarbonyl compound preparationArylStructural formula

The invention discloses a 1-aryl-2-acetone compound preparation method, which comprises: (1) carrying out a reaction on (E)-2-methyl-3-aryl acrylic acid (I) as a starting raw material and diphenyl azidophosphate (DPPPA) in the presence of an organic alkali; (2) carrying out a heating reaction; and (3) adding an acidic aqueous solution into the reaction solution, and carrying out a reaction to obtain the 1-aryl-2-acetone compound with a structural formula (IV). According to the present invention, the method can solve the technical problems of difficultly available, highly-corrosive, highly toxic and highly explosive reagents, long steps, low yield, tedious operation and the like in the 1-aryl-2-acetone synthesis in the prior art, has characteristics of easily available raw materials, safe and simple operation, mild condition and high yield, and is suitable for industrial production.

Owner:ZHEJIANG PHARMA COLLEGE

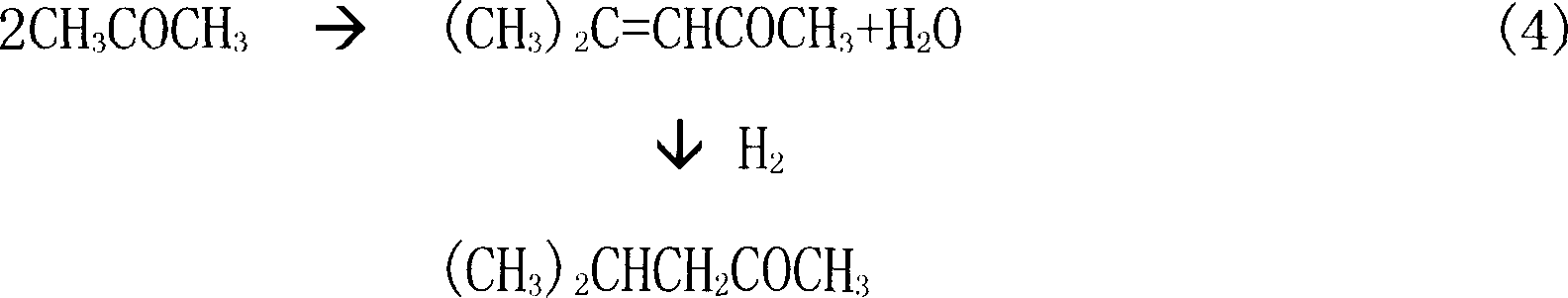

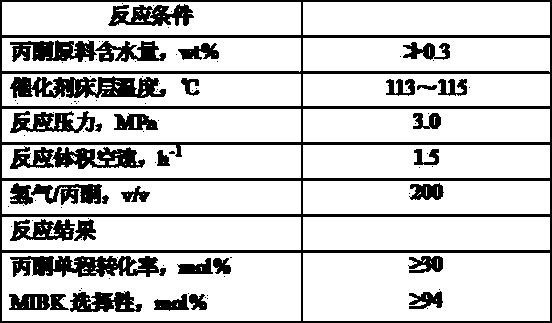

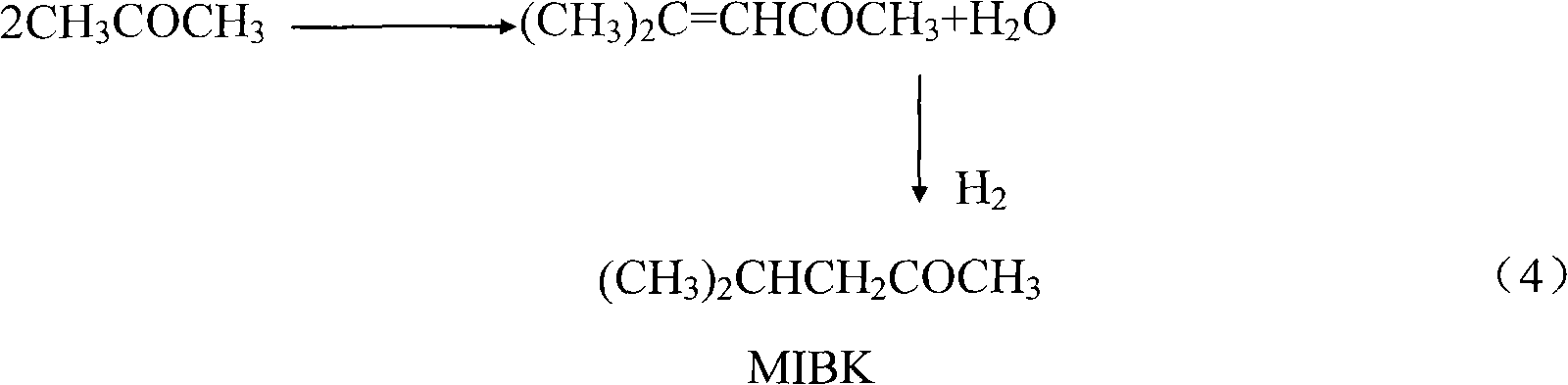

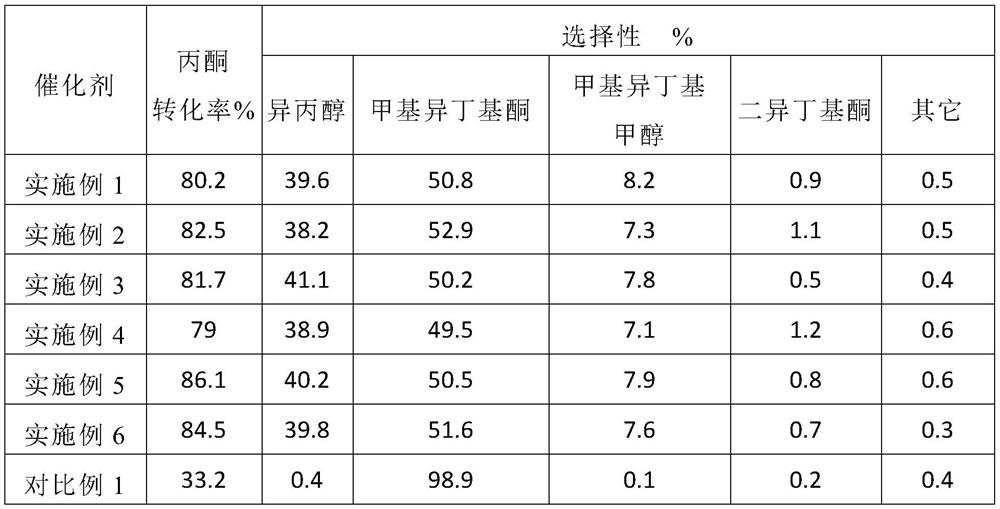

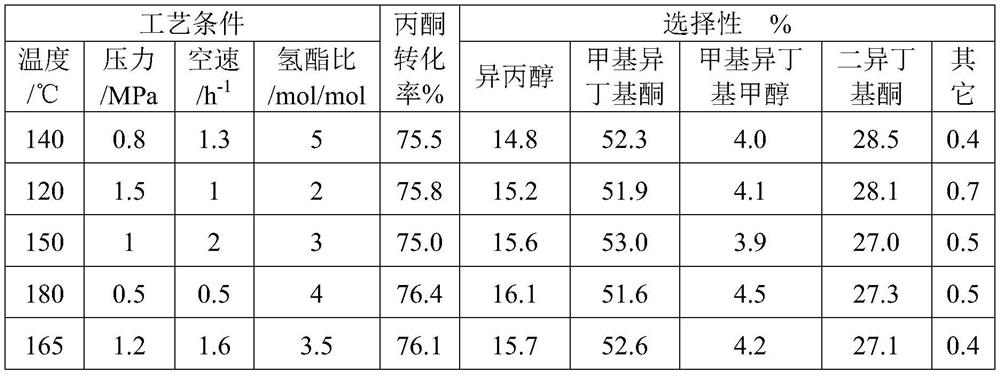

Technological process for synthesizing methyl isobutyl ketone and diisobutyl ketone with acetone

InactiveCN1218921CSimple production processModerate pHOrganic compound preparationCarbonyl compound preparationMethyl isobutyl ketoneReaction temperature

The invention discloses a one-step process of acetone and a process for forming methyl isobutyl ketone and diisobutyl ketone. The method uses Pd / ZrO2 as a catalyst, the Pd content is 0.5wt%, and at normal pressure, the reaction temperature is 423K, the space velocity is 2h-1, and the hydroketone molar ratio is 2. Under the operating conditions, in a fixed bed reactor, acetone The highest conversion rate is 62%, and the highest selectivity of methyl isobutyl ketone and diisobutyl ketone is 100%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of acetylacetone synthesis catalyst and preparation method thereof

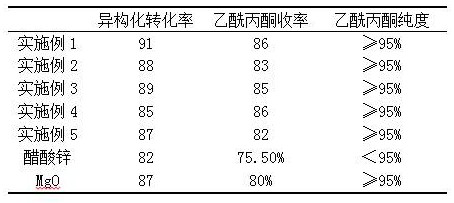

ActiveCN109675618BHigh yieldHigh purityMolecular sieve catalystsOrganic compound preparationPtru catalystIsomerization

The present invention relates to the technical field of organic synthesis, in particular to an acetylacetone synthesis catalyst and a preparation method thereof, comprising the following components in parts by weight: 10 parts of inorganic carrier materials, 0.5-2 parts of manganese oxide, 0.3-1 part of iron-based element oxidation Thing, 10-30 parts SAPO-11 molecular sieves. The preparation method comprises the following steps: mixing the inorganic carrier material and SAPO-11 molecular sieve in proportion, adding dilute sulfuric acid and deionized water, heating to 80°C and stirring for 30 minutes, and roasting at 250-400°C to obtain the catalyst carrier; manganese oxide and iron Grinding and pulverizing element oxides, adding them to the impregnating solution in proportion, stirring for 10-15min to obtain the impregnating solution; impregnating the catalyst carrier with the impregnating solution for 24-48h, drying at 110°C for 4h, and roasting at 350-500°C Get a catalyst. The catalyst obtained by the invention is used in the isomerization process of isopropenyl acetate, which can effectively improve the conversion rate of isomerization, thereby improving the yield and purity of acetylacetone.

Owner:陈军民

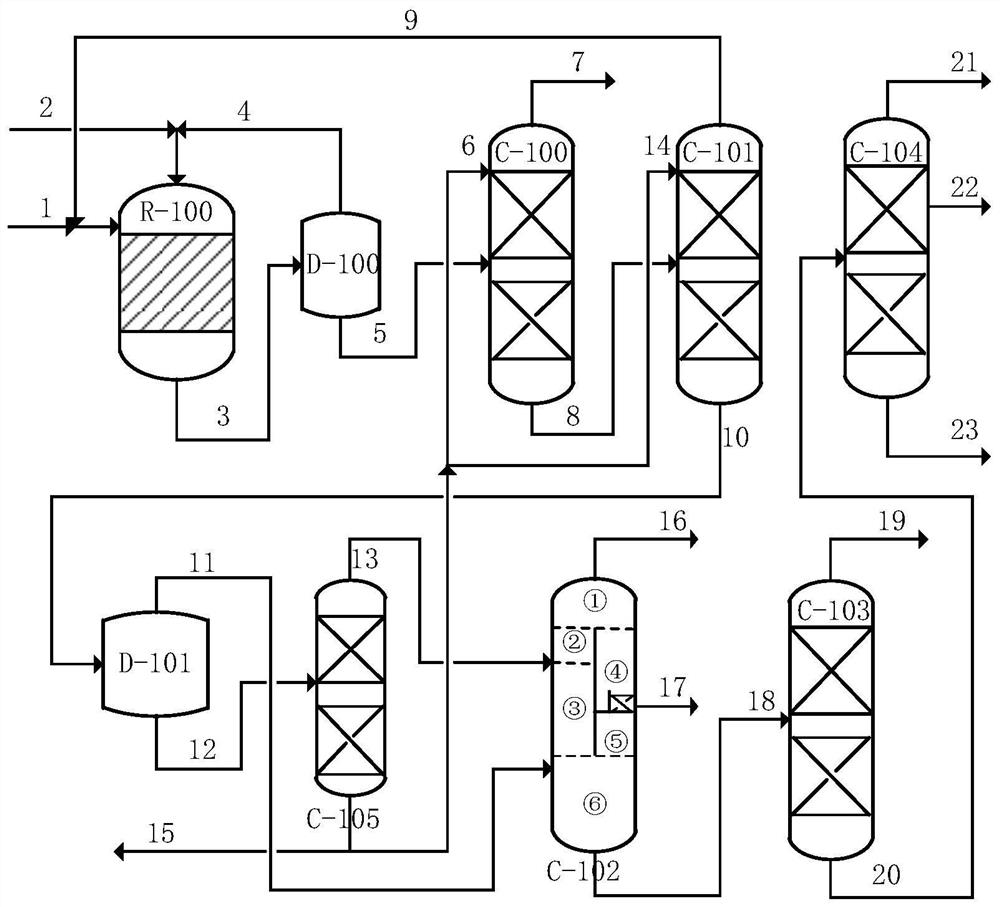

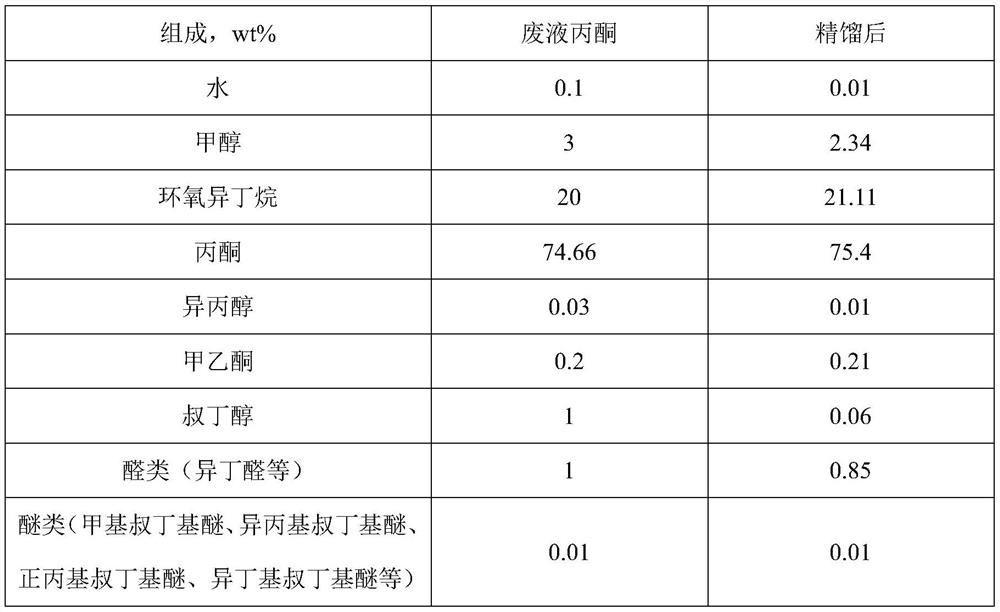

A kind of method that prepares the mibk of purification by industrial by-product waste liquid acetone

ActiveCN107915612BEfficient use ofResolve separation difficultiesOrganic compound preparationCarbonyl compound separation/purificationProcess engineeringEnvironmental engineering

Owner:WANHUA CHEM GRP CO LTD

A kind of sulfurized palladium/alumina catalyst and its preparation method and application

ActiveCN104588002BEasy to manufactureGood pre-vulcanization effectOrganic compound preparationCarbonyl compound preparationPresent methodOrganic solvent

The invention discloses a preparation method of a sulfuration mode Pd / Al2O3 catalyst. The method comprises the following steps: 1, preparing a palladium alkyl xanthate solution and an inorganic palladium salt-containing dipping liquid which is acidic; 2, dipping an alumina carrier in the palladium alkyl xanthate solution, filtering, and drying to obtain a catalyst intermediate; and 3, adding the catalyst intermediate to the inorganic palladium salt-containing dipping liquid, dipping, drying, and roasting to obtain the sulfuration mode Pd / Al2O3 catalyst. Palladium supported in step 2 accounts for 20-40wt% of total palladium (by palladium element) in the finished Pd / Al2O3 catalyst. The catalyst obtained through the method realizes higher activity, higher selectivity and longer life than present catalysts prepared through present methods in the synthesis process of methyl isobutyl ketone from acetone.

Owner:中石化(大连)石油化工研究院有限公司 +1

A kind of preparation method of sulfurized palladium/alumina catalyst

ActiveCN103801332BExtended operating cycleEasy to manufacturePhysical/chemical process catalystsOrganic compound preparationMethyl isobutyl ketoneXanthate

Owner:CHINA PETROLEUM & CHEM CORP +1

Cobalt-Based Catalysts for the Synthesis of Methyl Isobutyl Ketone from Acetone

ActiveCN107930657BLow costImprove stabilityMolecular sieve catalystsOrganic compound preparationPtru catalystMethyl isobutyl ketone

The invention relates to a catalyst, and belongs to the technical field of applications and development of acetone downstream products, wherein cobalt and tin are used as main active components, fluorine is used as an auxiliary agent component, aluminum oxide, silicon oxide or an aluminum oxide-silicon oxide composite carrier with rich pH value is selected to promote a reaction, the catalyst is used under a mild reaction condition, an one-step acetone synthesis process is used, the yield of methyl isobutyl ketone in the application of the catalyst of the present invention is higher than the yield of methyl isobutyl ketone in the application of the palladium / resin catalyst used in the current industrial apparatus, and a large amount of isopropanol are by-produced. According to the present invention, the obtained catalyst has the ideal stability, has the cost significantly lower than the cost of the existing palladium catalyst, and has good economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of palladium/alumina catalyst and preparation method thereof

ActiveCN104588041BGood pre-vulcanization effectHigh activityPhysical/chemical process catalystsPresent methodMethyl isobutyl ketone

The invention discloses a preparation method of a sulfuration mode Pd / Al2O3 catalyst. The method comprises the following steps: 1, preparing a sodium alkyl xanthate solution and a palladium-containing dipping liquid which is acidic; 2, dipping an alumina carrier in the palladium-containing dipping liquid, filtering, drying, spraying parts of the palladium-containing dipping liquid, and drying to obtain a catalyst intermediate; and 3, adding the catalyst intermediate to the remaining palladium-containing dipping liquid, dipping, drying, and roasting to obtain the sulfuration mode Pd / Al2O3 catalyst. A volume ratio of the palladium-containing dipping liquid used for spraying to the palladium-containing dipping liquid used for dipping is 1.0:1.0-1.0:3.0, and preferably 1.0:1.5-1.0:2.5. The catalyst obtained through the method realizes higher activity, higher selectivity and longer life than present catalysts prepared through present methods in the synthesis process of methyl isobutyl ketone from acetone.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Catalyst for synthesizing methyl isobutyl alcohol and isopropanol from acetone and its preparation method and application

ActiveCN109701536BShould not be lostEvenly distributedOrganic compound preparationHydroxy compound preparationPtru catalystIsobutyl alcohol

The invention relates to a catalyst for synthesizing methyl isobutyl alcohol and isopropanol from acetone, a preparation method and application thereof, in the field of catalysts. The catalyst for synthesizing methyl isobutyl alcohol and isopropanol from acetone includes the following components in parts by weight as a whole: a, 0.5 to 8 parts of at least one from copper or copper oxides; b, 0.5 parts ~10 parts from at least one of cobalt or cobalt oxide; c, 82 to 99 parts of carrier; said carrier is selected from at least one of silicon oxide, aluminum oxide and zirconium oxide modified by high-temperature roasting titanium. In the present invention, the active components copper and cobalt are loaded on the titanium-modified carrier through the ammonia distillation method, the distribution of the metal active component is relatively more uniform, the interaction between the metal active component and the carrier is enhanced, and the activity and stability of the catalyst are improved. And the catalyzer of the present invention adopts the non-precious metal component copper and cobalt of low composition, and cost is low; Not only can produce methyl isobutyl alcohol, also can co-produce isopropanol, industrial production device is stronger to the adaptability of market, enterprise Increased profitability.

Owner:CHINA PETROLEUM & CHEM CORP +1

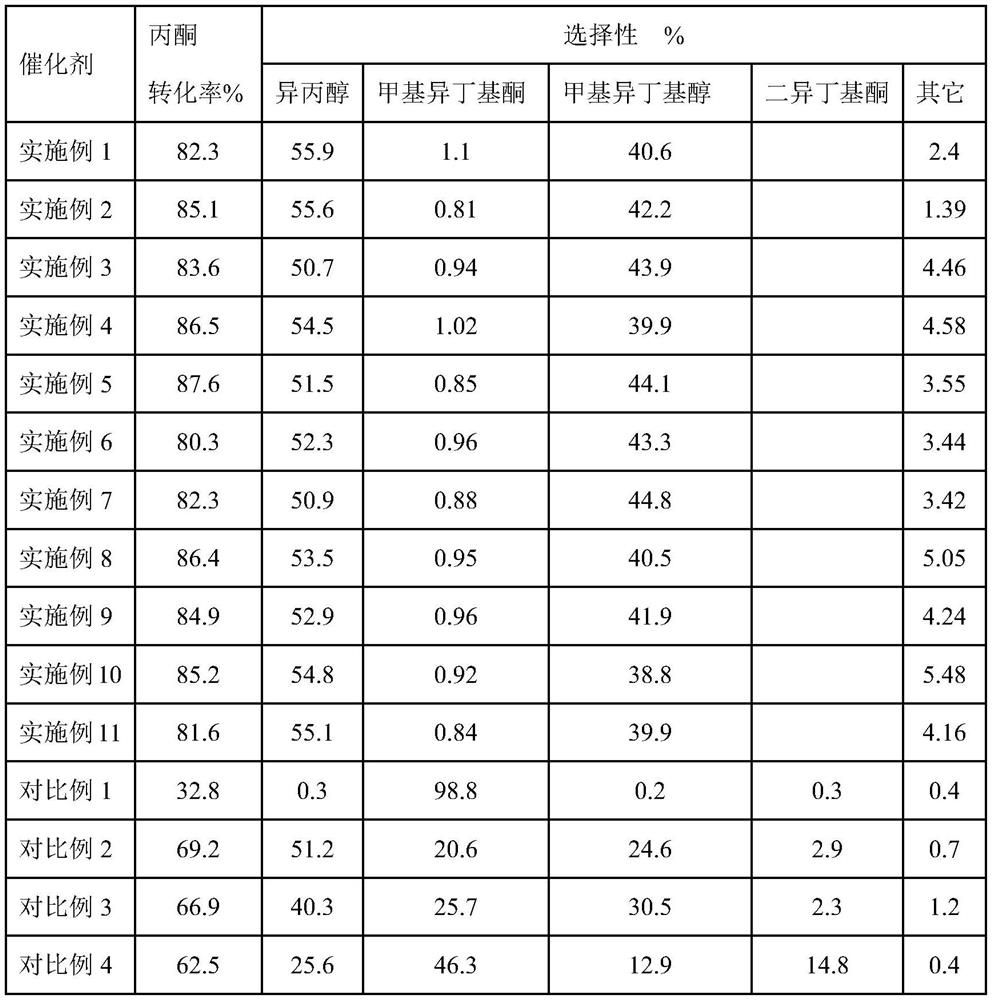

Catalyst for synthesizing diisobutyl ketone from acetone and preparation method thereof

ActiveCN104549348BPrevent crystallite meltingAvoid the phenomenon that the adsorption is hinderedOrganic compound preparationCarbonyl compound preparationDiisobutylketoneBULK ACTIVE INGREDIENT

The invention discloses a catalyst for synthesis of 2,6-dimethyl-4-heptanone from acetone and a preparation method for the catalyst. The catalyst comprises an active ingredient Ni and a carrier ZrO12-MnO2; based on the total weight of the catalyst, the content of the active ingredient Ni is 1 to 10 weight percent, preferably 3 to 6 weight percent, the content of MnO2 is 1 to 20 weight percent, preferably 5 to 10 weight percent, and the balance is ZrO2. The catalyst disclosed by the invention is applied to a reaction for synthesis of the 2,6-dimethyl-4-heptanone from the acetone, and has the characteristics that conversion rate of the acetone serving as a raw material is high; the selectivity of the 2,6-dimethyl-4-heptanone serving as a product is high, that is the yield of the 2,6-dimethyl-4-heptanone serving as a target product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acetone synthetic gasoline

The invention provides acetone synthetic gasoline. The acetone synthetic gasoline is characterized by comprising the following components in parts by weight: 16-29 parts of acetone, 11-17 parts of glyceride, 9-13 parts of ethylene glycol monobutyl ether, 5-14 parts of isopropanol and the balance of gasoline. The acetone synthetic gasoline has good intersolubility, can be used for improving the waterproof capability and effectively solving the problem of stratification of methanol and gasoline and is more practical.

Owner:江苏紫石化工科技有限公司

Catalyst for synthesizing methyl isobutyl ketone and diisobutyl ketone from acetone and its preparation method and application

ActiveCN109701570BLow costEasy to manufactureOrganic compound preparationCatalyst activation/preparationPtru catalystMethyl isobutyl ketone

The invention relates to a catalyst for synthesizing methyl isobutyl ketone and diisobutyl ketone from acetone, a preparation method and application thereof in the field of catalysts. The catalyst for synthesizing methyl isobutyl ketone and diisobutyl ketone from acetone is measured as 100 parts by the overall weight of the catalyst, and includes the following components: a, 0.5 to 10 parts of at least One; b, 0.5-10 parts of at least one selected from cobalt or cobalt oxides; c, 80-99 parts selected from bismuth-modified basic calcium phosphate. The preparation process of the catalyst of the present invention is relatively simple, easy to control, and the active components should not be lost; the catalyst of the present invention can not only produce methyl isobutyl ketone, but also diisobutyl ketone, and the industrial production device has better adaptability to the market. Strong, the cost of the bimetallic catalyst of the present invention is significantly lower than that of the existing palladium catalyst, and has better economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

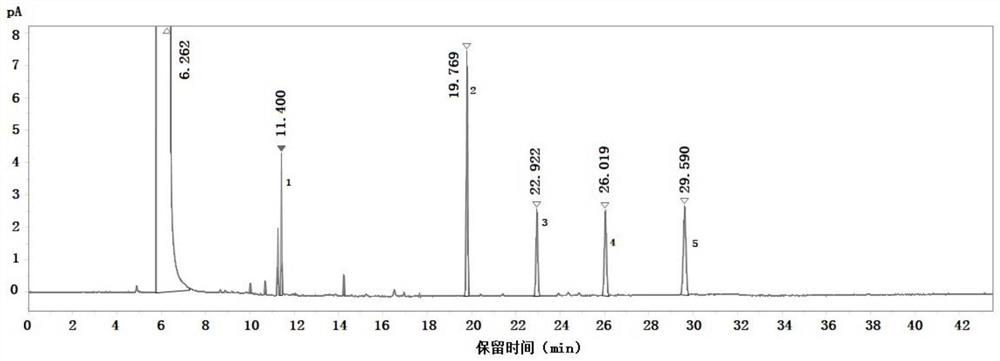

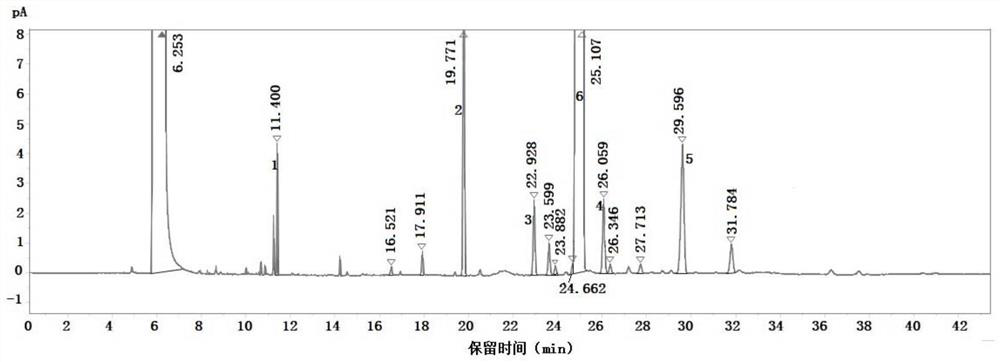

Detection method of p-methoxypropiophenone related substances

ActiveCN114858944AConducive to the true reflection of qualityTrue reflection of qualityComponent separationMedication riskPhysical chemistry

The invention relates to the technical field of chemical analysis, and particularly discloses a method for detecting p-methoxypropiophenone related substances. According to the method, ZB-1 (60m * 0.25 mm * 1.0 [mu] m) is adopted as a detection chromatographic column, the column temperature is set to be 38-42 DEG C and maintained for 2-10 min, then the temperature is increased to 170-190 DEG C at the rate of 38-42 DEG C / min and maintained for 30-40 min, the temperature of a sample inlet is 175-185 DEG C, the temperature of a detector is 245-255 DEG C, and the split ratio is (5-10): 1, so that simultaneous quantitative detection of various known impurities and unknown impurities in p-methoxypropiophenone is realized, and the detection accuracy is high. Compared with the prior art, the method has the advantages that the quality of the p-methoxypropiophenone can be truly reflected, the monitoring of the synthesis process of the p-methoxypropiophenone can be realized, the quality of the formoterol fumarate product can be improved, the medication risk can be reduced, and the practical value is high.

Owner:SHIJIAZHUANG NO 4 PHARMA

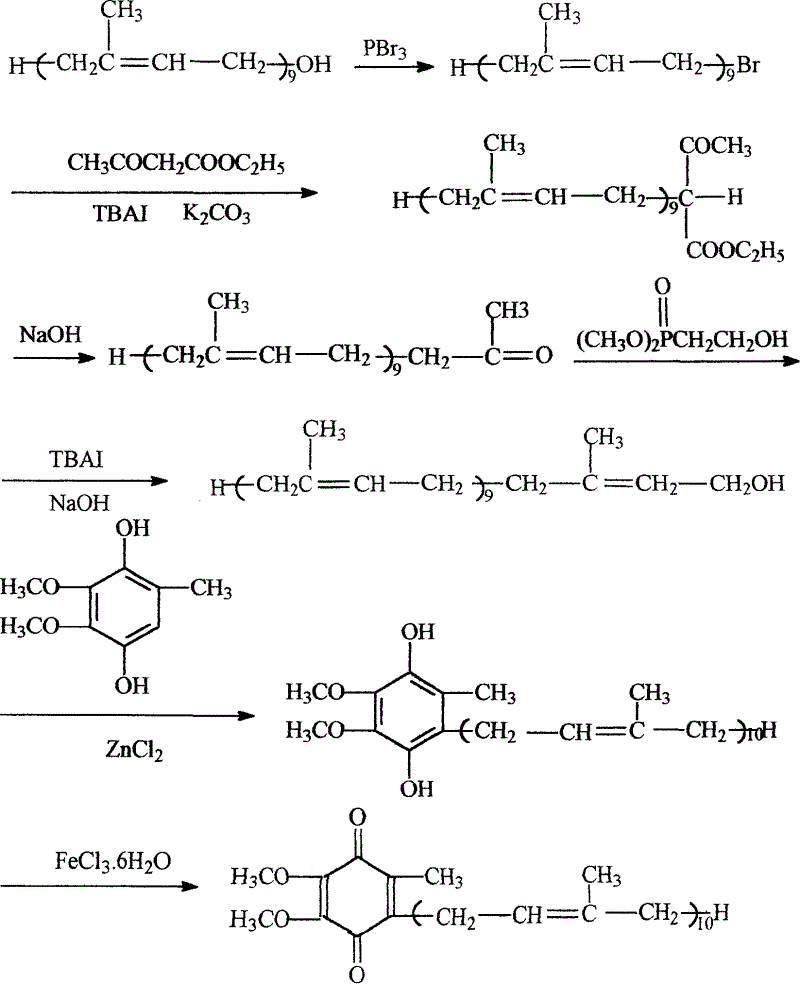

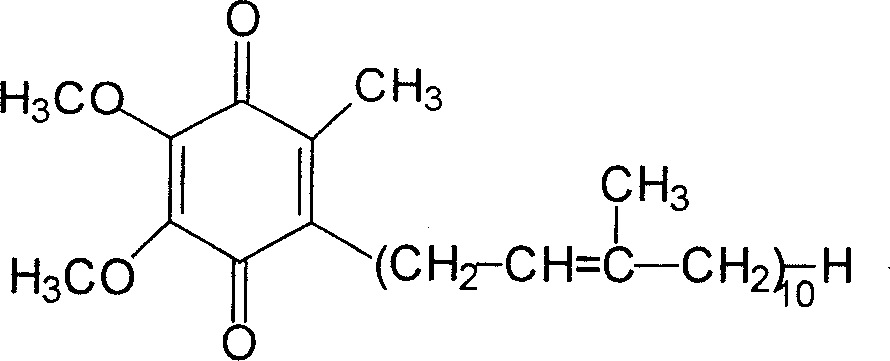

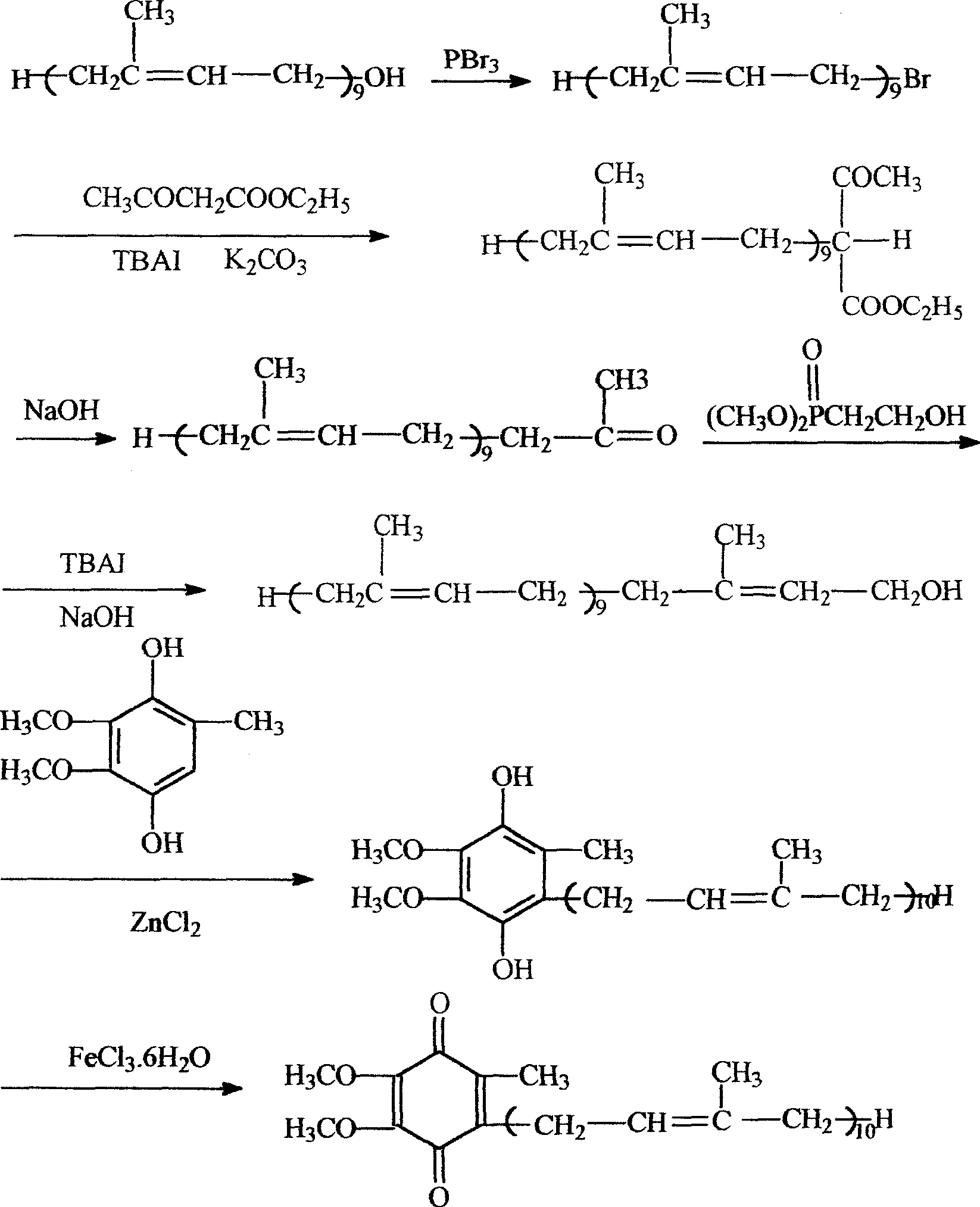

A novel process for synthesis of coenzyme Q10

InactiveCN1690036AThe synthesis method is simpleMild reaction conditionsOrganic compound preparationQuinone preparationPotassium carbonateSodium hydride

The new method of synthesizing coenzyme Q10 includes synthesizing solanin bromide with solanesol as material, synthesizing solanin acetone, synthesizing decaisoprene alcohol, and rearranging reaction to synthesize coenzyme Q10. The improvement includes the solid-liquid phase catalytic transferring process to synthesize solanin acetone with anhydrous potassium carbonate as base and small amount of tetrabutyl ammonium iodide as phase transfer catalyst; and the synthesis of decaisoprene alcohol through liquid-liquid phase transfer catalytic reaction between O, O-dimethyl-2-hydroxyethyl phosphonate and solanin acetone in both organic solvent and sodium hydroxide aqua phase with tetrabutyl ammonium iodide as phase transfer catalyst at normal temperature. The positive effect of the present invention includes mild reaction condition, simple process, easy control and easy industrial application.

Owner:杨凌萃健生物工程技术有限公司 +1

A kind of silver ruthenium double metal doped graphene catalyst and its preparation method and application

ActiveCN112452324BGenerate morePromote generationOrganic chemistryOrganic compound preparationDoped graphenePtru catalyst

The invention discloses a silver-ruthenium bimetal doped graphene catalyst and its preparation method and application. The catalyst includes a graphene carrier, and the graphene carrier is loaded with silver and ruthenium nanoparticles, and the mass ratio of silver and ruthenium nanoparticles is 0.5 ~1: 0.6~1.1, the diameter of silver and ruthenium nanoparticles is 100~800nm. The preparation method of this catalyst comprises the following steps: (1) prepare graphene; (2) make AgBF 4 with RuCl 3 Dissolving in ethylene glycol, adding graphene, and reacting under hydrothermal conditions; (3) cooling, centrifuging, washing, and vacuum drying to obtain the product; (4) roasting. The catalyst is used as a catalyst in the synthesis process of bisphenol F or 1-phenyl-3-p-nitrophenyl-acetone. When the catalyst is used in the synthesis of bisphenol F, it has excellent catalytic performance, significantly improves the yield of bisphenol F, and the side reaction products are effectively reduced; when used in the synthesis of 1-phenyl-3-p-nitrophenyl-acetone It has excellent catalytic performance, the product chemical selectivity is 100%, the yield is greater than 90%, and it can be recycled and reused.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com