A kind of silver ruthenium double metal doped graphene catalyst and its preparation method and application

A graphene and catalyst technology, applied in the field of silver ruthenium bimetal doped graphene catalyst and its preparation, can solve the problems of difficult control of the reaction process, cumbersome synthesis process, high production cost, etc., achieve good application prospects, and reduce side reaction products , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

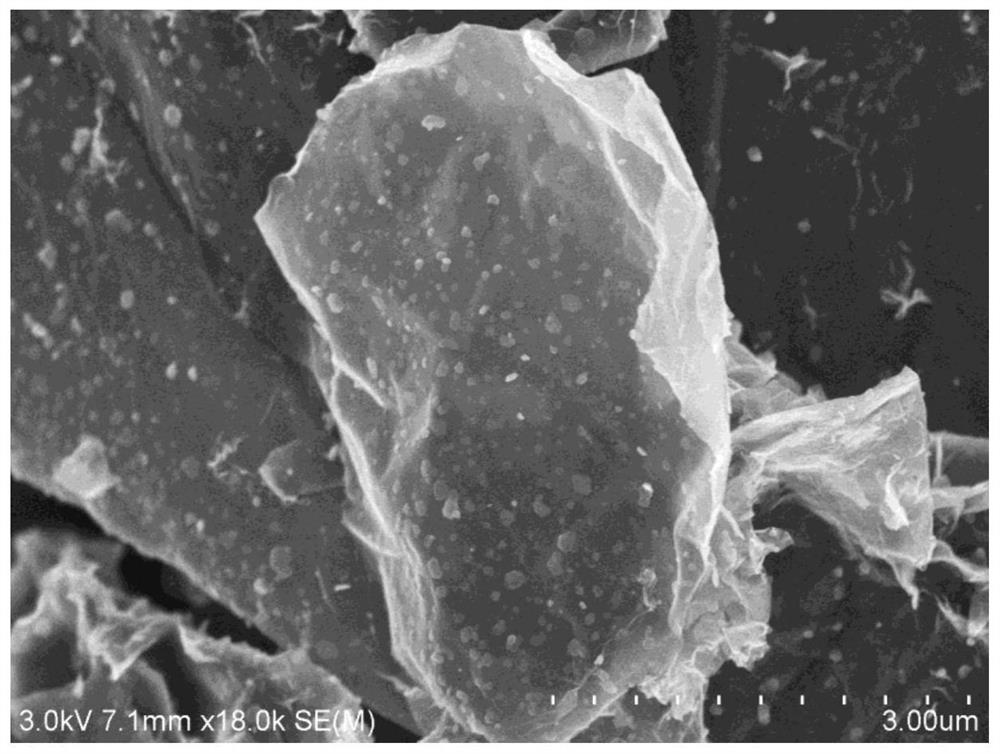

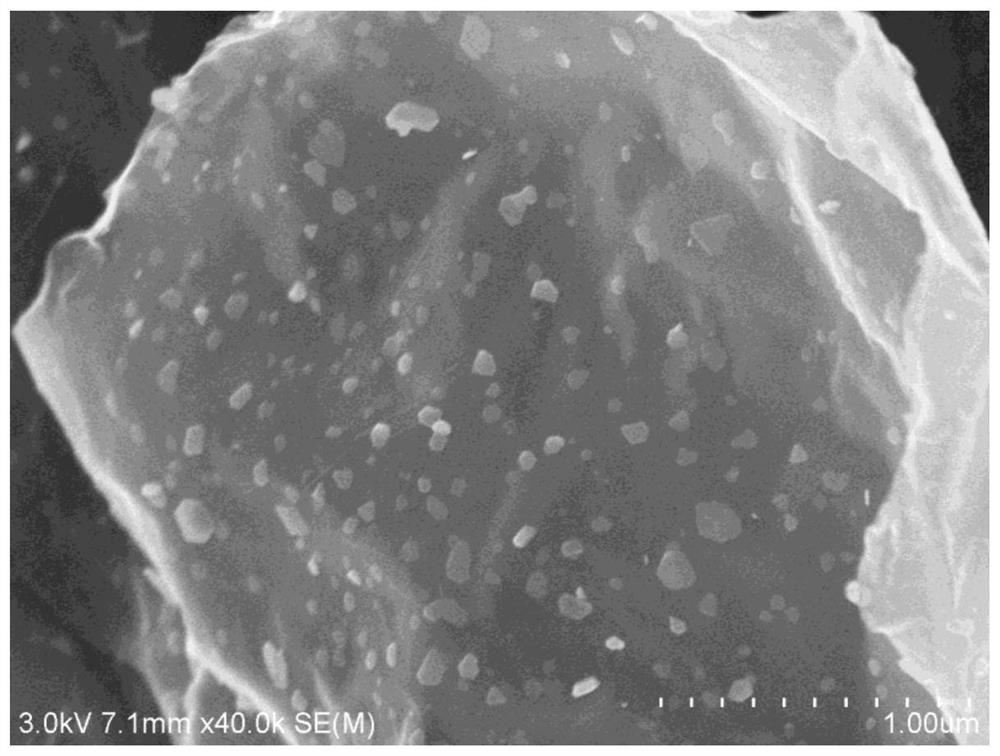

Image

Examples

Embodiment 1

[0023] Preparation of graphene-supported silver-ruthenium bimetallic catalysts:

[0024] First treat 6.0g of graphite with 5mL of 37% hydrochloric acid, add 1.5g of iodobenzene diacetate to oxidize, then use ultrasonic vibration until the graphene oxide aqueous solution is clear and free of particles, add 1g of dinitrophenylhydrazine and reflux at 50°C for 30h. Filter and dry to obtain graphene, and 1.0g of AgBF 4 with 1.1 g of RuCl 3 Dissolve in 10mL of ethylene glycol, stir in an ice bath, remove the ice bath after all the solids are dissolved; add 5g of graphene, adjust the pH of the mixture to 7, place it under hydrothermal conditions at 80°C, and react for 2 hours; After the reaction, cool, centrifuge, wash, and vacuum dry to obtain the product; roast the product in a high-temperature muffle furnace, first raise the temperature to 500°C, keep the temperature stable for 4 hours, and finally store it in a vacuum desiccator to obtain the silver ruthenium bismuth Metal-dope...

Embodiment 2

[0028] Preparation of graphene-supported silver-ruthenium bimetallic catalysts:

[0029] First treat 9.0g of graphite with 12mL of 37% hydrochloric acid, add 1.5g of iodobenzene diacetate to oxidize, then use ultrasonic vibration until the graphene oxide aqueous solution is clear and free of particles, add 3g of dinitrophenylhydrazine and reflux at 100°C for 10h. Filter and dry to get graphene, and 2.0g of AgBF 4 with 2.2 g of RuCl 3 Dissolve in 14mL of ethylene glycol, stir in an ice bath, remove the ice bath after all the solids are dissolved; add 8g of graphene, adjust the pH of the mixture to 7, place it under hydrothermal conditions at 80°C, and react for 2 hours; After the reaction, cool, centrifuge, wash, and vacuum dry to obtain the product; roast the product in a high-temperature muffle furnace, first raise the temperature to 400°C, keep the temperature stable for 6 hours, and finally store it in a vacuum desiccator to obtain the silver ruthenium bismuth Metal-doped...

Embodiment 3

[0033] Preparation of graphene-supported silver-ruthenium bimetallic catalysts:

[0034] First treat 12.0g of graphite with 15mL of 37% hydrochloric acid, add 1.8g of iodobenzene diacetate for oxidation, then use ultrasonic vibration until the graphene oxide aqueous solution is clear and free of particles, add 5g of dinitrophenylhydrazine and reflux at 50°C for 20h, Filtration, drying to obtain graphene, 3.0g of AgBF 4 with 3.3 g of RuCl 3 Dissolve in 20mL of ethylene glycol, stir in an ice bath, remove the ice bath after all the solids are dissolved; add 10g of graphene, adjust the pH of the mixture to 11, place it under hydrothermal conditions at 80°C, and react for 2 hours; After the reaction, cool, centrifuge, wash, and vacuum dry to obtain the product; roast the product in a high-temperature muffle furnace, first raise the temperature to 300°C, keep the temperature stable for 10 hours, and finally store it in a vacuum desiccator to obtain the silver ruthenium bismuth Me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com