Damp-heat-resistant PC/ABS flame-retardant composite material and preparation method thereof

A flame retardant composite material and technology of heat and humidity resistance, applied in the field of polymer materials, can solve the problems of easy hydrolysis, reduced flame retardant effect, ester bond hydrolysis aging and yellowing, etc. Moisture and heat resistance, dense and stable carbon layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

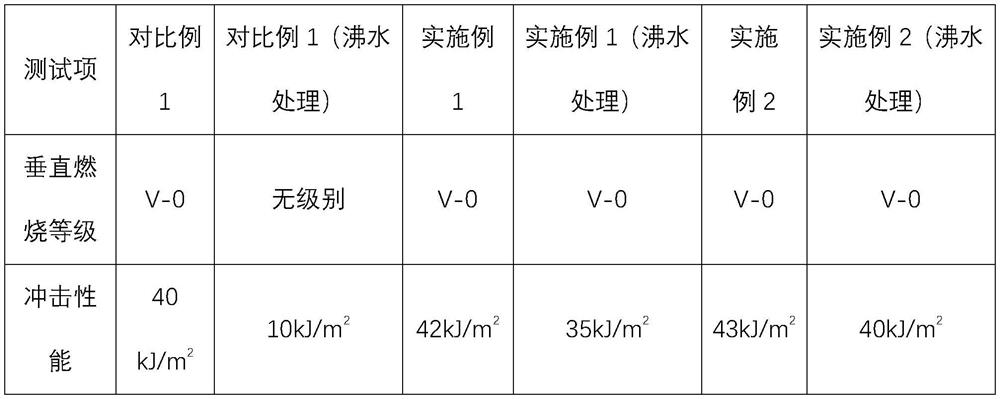

Embodiment 1

[0026] Obtain the heat and humidity resistant PC / ABS flame retardant composite material as follows:

[0027] (1) Prepare materials according to the following components and parts by weight: 60 parts of PC resin, 40 parts of ABS resin, 1 part of silane coupling agent KH-550, 5 parts of flame retardant BDP, auxiliary flame retardant KH-550-melamine benzene sulfonate 1 part salt, 0.4 parts of calcium silicate and zinc silicate as anti-moisture and heat stabilizer, the mass ratio of calcium silicate and zinc silicate is 1:1, and the sulfonation reaction temperature of auxiliary flame retardant melamine and benzenesulfonate 100°C (the molar ratio of melamine and benzenesulfonic acid is 1:1), the reaction temperature of melamine benzene sulfonate and coupling agent is 75°C (the molar ratio of KH-550 and melamine benzene sulfonate is 1:1);

[0028] (2) Dry PC resin, ABS resin, silane coupling agent, flame retardant, auxiliary flame retardant and moisture-heat resistant stabilizer in...

Embodiment 2

[0031] Obtain the heat and humidity resistant PC / ABS flame retardant composite material as follows:

[0032](1) Prepare materials according to the following components and parts by weight: 50 parts of PC resin, 50 parts of ABS resin, 2 parts of silane coupling agent KH-550, 2 parts of flame retardant BDP, auxiliary flame retardant KH-550-melamine benzene sulfonate Salt 3 parts, humidity and heat resistant stabilizer calcium silicate and zinc silicate 0.5 parts, the mass ratio of calcium silicate and zinc silicate is 2:1, the temperature of the sulfonation reaction of auxiliary flame retardant melamine and benzenesulfonate is 110°C (the molar ratio of melamine and benzenesulfonic acid is 1:2), the reaction temperature of melamine benzene sulfonate and coupling agent is 80°C (the molar ratio of KH-550 and melamine benzene sulfonate is 2:1).

[0033] (2) Dry PC resin, ABS resin, silane coupling agent, flame retardant, auxiliary flame retardant and moisture-heat resistant stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com