Catalyst for synthesizing methyl isobutyl ketone and diisobutyl ketone from acetone and its preparation method and application

A technology of methyl isobutyl ketone and diisobutyl ketone is applied to the catalyst for synthesizing methyl isobutyl ketone and diisobutyl ketone from acetone and the field of preparation thereof, and can solve the problems of poor catalyst activity and high cost, Achieve the effect of enhancing corporate profitability, strong adaptability, and promoting even distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

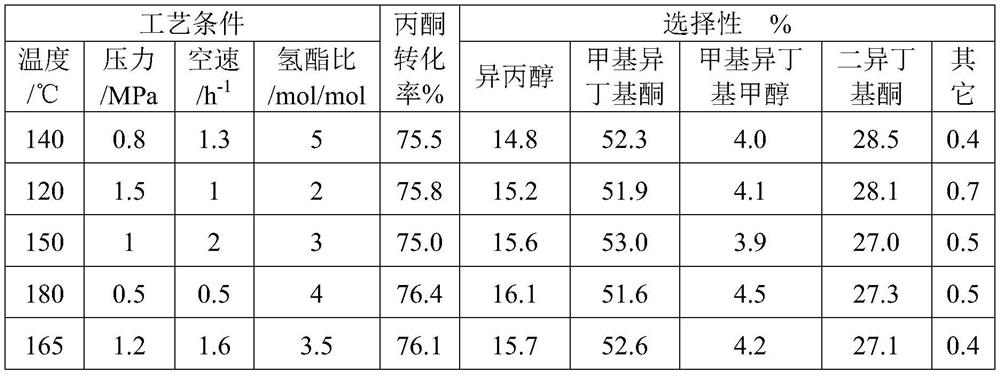

Examples

Embodiment 1

[0036] The 10ml hydrochloric acid solution that contains 7.44g bismuth chloride is mixed with the 100ml aqueous solution that contains 150g calcium nitrate to make solution I, takes by weighing 40.25g diammonium hydrogen phosphate and is dissolved in water and makes concentration be the solution II of 0.12mol / L, will Solution II was slowly added dropwise to solution I, the Ca / P molar ratio was 3, and at the same time, 0.05mol / L aqueous urea solution was added dropwise to adjust the pH value to 8.5, and stirred at 40°C for 5h to obtain slurry III; weigh 19.6 Add 24.4g nickel nitrate and 24.42g cobalt nitrate to the slurry III, and add dropwise 0.05mol / L urea aqueous solution to adjust the pH value of the solution, control the pH value of the precipitation end point to 7.0, and age the prepared slurry IV at 50°C for 10h , and then filtered and washed to obtain a wet filter cake; the filter cake was dried at 120°C for 2 hours, decomposed at 450°C, and hydrogen was introduced at a ...

Embodiment 2

[0038] The 10ml hydrochloric acid solution that contains 3.38g bismuth chloride is mixed with the 100ml aqueous solution that contains 140g calcium nitrate to make solution I, takes by weighing 32.2g diammonium hydrogen phosphate and is dissolved in water and makes concentration be the solution II of 0.10mol / L, will Solution II was slowly added dropwise to solution I, the Ca / P molar ratio was 3.5, and at the same time, 0.05mol / L aqueous urea solution was added dropwise to adjust the pH value to 9.0, and stirred at 60°C for 5h to obtain slurry III; weigh 21.7 Add 2 g of nickel sulfate and 20.03 g of cobalt nitrate to the slurry III, and add 0.05 mol / L aqueous urea solution dropwise to adjust the pH value of the solution, and control the pH value of the precipitation end point to 7.5, and age the prepared slurry IV at 90°C for 5 h , and then filtered and washed to obtain a wet filter cake; the filter cake was dried at 120°C for 2 hours, decomposed at 400°C, and hydrogen was intro...

Embodiment 3

[0040] The 10ml hydrochloric acid solution that contains 5.41g bismuth chloride is mixed with the 100ml aqueous solution that contains 140g calcium nitrate to make solution I, takes by weighing 97.35g dipotassium hydrogen phosphate and is dissolved in water and makes concentration be the solution II of 0.1mol / L, will Solution II was slowly added dropwise to solution I, the Ca / P molar ratio was 2.0, and at the same time, 0.05mol / L aqueous urea solution was added dropwise to adjust the pH value to 10.0, and stirred at 70°C for 4h to obtain slurry III; weigh 19.6 Add 2 g nickel nitrate and 24.42 g cobalt nitrate to slurry III, and add 0.05 mol / L aqueous urea solution dropwise to adjust the pH value of the solution, control the pH value of the precipitation end point to 8.5, and age the prepared slurry IV at 100 ° C for 3 h , and then filtered and washed to obtain a wet filter cake; the filter cake was dried at 120°C for 2 hours, decomposed at 320°C, and hydrogen was introduced at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com