Catalyst for synthesizing methyl isobutyl alcohol and isopropanol from acetone and its preparation method and application

A technology of methyl isobutyl alcohol and catalyst, which is applied in the field of catalysts and preparations for synthesizing methyl isobutyl alcohol and isopropanol from acetone, and can solve the problems of poor market flexibility, single product, and low conversion rate of acetone. Achieve the effects of not easy to deactivate, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

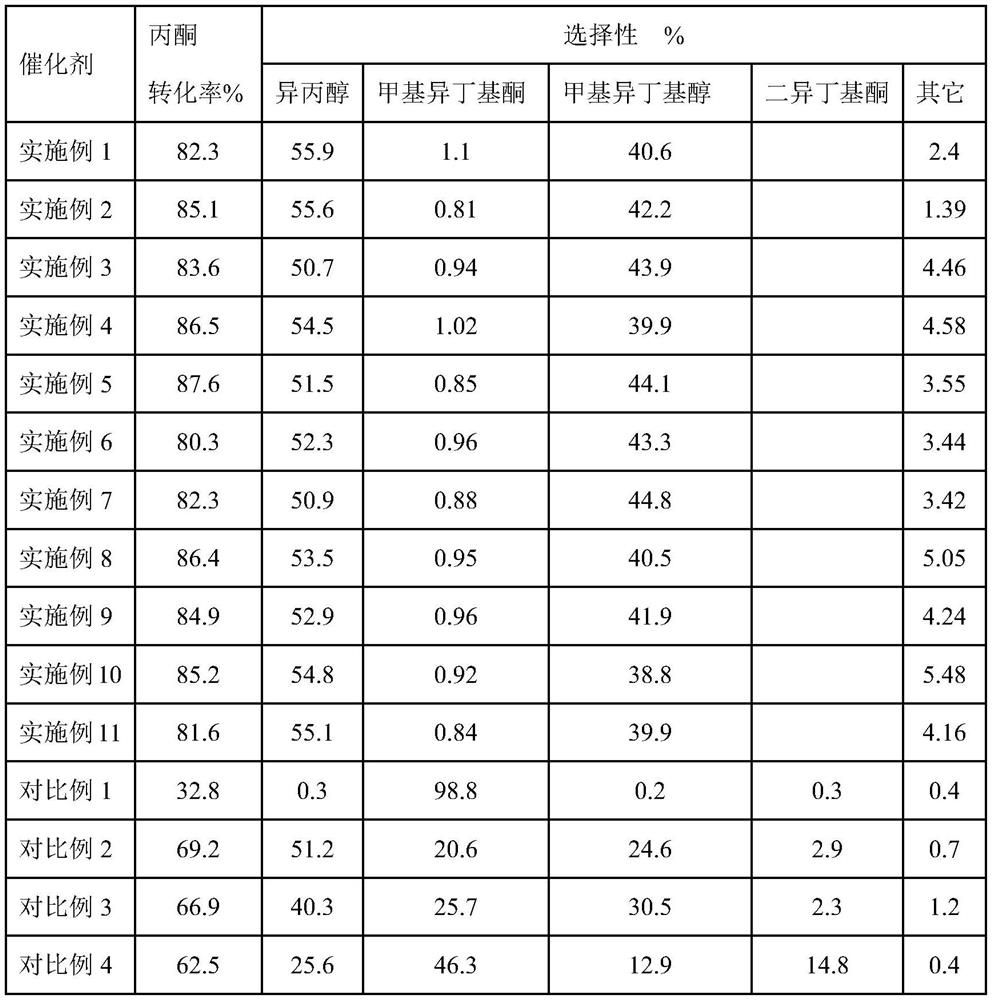

Examples

Embodiment 1

[0044] Dissolve 15g of nano-titanium dioxide in 10mL of ethanol to make mixture I, weigh 90g of silicon dioxide and 25g of alumina powder into mixture I and mix thoroughly to make mixture II, add 7.5mL of dilute nitric acid to mixture II Stir and mix with 55mL of water, then dry, and roast at 1050°C to obtain a titanium-modified carrier powder; weigh 14.88g of copper nitrate and 19.33g of cobalt nitrate and dissolve them in 50mL of water to make solution IV; choose 0.12mol / L of ammonium bicarbonate aqueous solution is used as a precipitating agent, which is slowly added dropwise to solution IV to control the pH value of the end point of the precipitation reaction to 7.5, add 90 g of the carrier powder prepared above before the end point, age at 60°C for 5 hours, and then Wash and filter, dry the filter cake at 120°C, roast and decompose at 400°C, pass in hydrogen at a space velocity of 1000m 3 / m 3 h -1 Under the conditions, the temperature was programmed to 420°C and kept ...

Embodiment 2

[0046] Dissolve 106.5g of butyl titanate in 50mL of isopropanol to make Mixture I, weigh 35g of silica and 70g of alumina powder and add them into Mixture I and mix well to make Mixture II. Add 6.6ml of dilute nitric acid and 72ml of water, stir, mix and react, dry, and roast at 1100°C to obtain titanium-modified carrier powder; weigh 13.02g of copper nitrate and 21.74g of cobalt oxalate and dissolve them in 50mL of water to make solution IV ;Choose 0.08mol / L ammonium bicarbonate aqueous solution as the precipitating agent, slowly add it dropwise to the solution IV, control the pH value of the end point of the precipitation reaction to be 7.8, add 90g of the carrier powder prepared above before the end point, at 80°C Aging for 3 hours, then washing and filtering, drying the filter cake at 120°C, roasting and decomposing at 440°C, passing through hydrogen at a space velocity of 1000m 3 / m 3 h -1 Under the conditions, the temperature was programmed to 420°C and kept for 5 hour...

Embodiment 3

[0048] Dissolve 20g of nano-titanium dioxide in 13.5mL of butanol to make Mixture I, weigh 110g of alumina powder and add it to Mixture I and mix thoroughly to make Mixture II, add 4.0ml of dilute sulfuric acid and 80ml of water to Mixture II Stir, mix and react, dry, and roast at 970°C to obtain titanium-modified carrier powder; weigh 11.16g copper nitrate and 24.16g cobalt nitrate and dissolve in 50ml water to make solution IV; choose 0.10mol / L ammonia The aqueous solution is used as a precipitating agent, which is slowly added dropwise to solution IV to control the pH value of the end point of the precipitation reaction to be 9.0. Before the end point, add 90 g of the carrier powder prepared above, age at 70°C for 4 hours, and then wash and filter. The cake is dried at 120°C, roasted and decomposed at 450°C, and hydrogen is introduced at a space velocity of 1000m 3 / m 3 h -1 Under the conditions, the temperature was programmed to 420°C and kept for 5 hours. After cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com