Liquid concentrating apparatus

A concentrating device and liquid technology, applied in the direction of spray evaporation, etc., can solve impossible problems and achieve the effect of increasing kinetic energy, large interface area, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

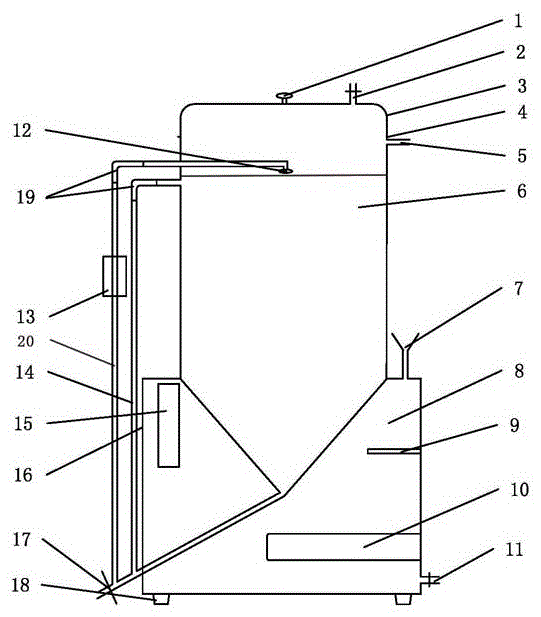

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] As shown in the figure, a liquid concentration device includes a temperature-controlled water bath system and a negative pressure tank 6; the temperature-controlled water bath system includes a water bath 8, and the water bath 8 is provided with a water injection hole 7, and the water injection hole 7 is kept unblocked, and the upper end A funnel is connected for water injection, and the funnel is conical. The inside of the water bath 8 is provided with a temperature measuring probe 9 and a heating device 10. Constant temperature control; the upper end of the negative pressure tank 6 is provided with a liquid inlet, and a tank cover 3 is provided on the liquid inlet. The negative pressure tank 6 can collect, store, and preheat the liquid before and after concentration. The bottom of the negative pressure tank 6 is conical. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com